Leaderboard

Popular Content

Showing content with the highest reputation on 09/09/23 in Posts

-

Oh what have you done @whathaveidone , your confidence to reshape it back to the overcoil it was, is admirable. There are videos and lessons showing how to shape an overcoil, but doing it technically right is kinda advanced. Good thing is, you get all the help you need here on WRT forum. Good luck pal2 points

-

Just a wee reminder to everyone. Please do not make any posts that either directly or indirectly constitute a sales advert, as it contravenes the long established forum rules and it will be removed. Thank you.1 point

-

You can also contact an individual privately and discuss business good for all!1 point

-

Just got myself a seitz tool with a pusher and reamer spindle, the star pushers fit the seitz and the 4mm chinese horia clone stumps and pump pushers also fit. The Marshall C &E set i have is totally non compatible with pushers or reamers.1 point

-

I have always used watch staking tools, with a small hammer, the bush should be a third way in the hole so it doesn't take much to hammer home. Pivots should be looked at for signs of wear and roughness, tidy up by removing marks this is done by using needle files, a small Arkansas stone, emery sticks then finally burnish them all.1 point

-

This one was a fiver inc. a half decent electric power drill. It won't have quite the same application as the purpose made pillar drill as there is no stop , but it gives you an idea what you can pick up for very little. I talk to the regular sellers when i go and they all say how hard it is to sell at the moment, its definitely a carboot buyers market. But folk having old parent's garage clearouts nearly give stuff away, just to dispose of stuff without actually disposing of it. If you pick something up its always nice and interesting how well you've done.1 point

-

You have options ? Lovely to see you back Suomaf matey. hows the family ? that missus of yours still giving you a hard time ? If you are worried about losing the spring, a popular trick to try is to place the watch a clear plastic bag and work from inside that. Its fiddly until you develop a technique but greatly reduces the chances of spring loss.1 point

-

1 point

-

That sounds like a great idea the drill press without plugging it in, like a large jewelling tool with the addition of a revolving sprindle. I have just the thing. Any car boots near you ? I often see drill presses for around 20 -30 quid, they dont even need to work electrically if you are just using it as a press, they usually have a depth stop.1 point

-

yes I think you are right. I found this I think I do not have enough hands the dexterity to do it. I cannot imagine the spring behaving itself and not flying into space.1 point

-

I think I said I use a bench drill as a press. It’s a tool which if you have is usefull for the job, it is an option only if you have one to hand, just as you don’t need Bergeron broaches or Bergeron tools to do the job there are many watch tool makers do Broaches. I got mine from Melvyn Passmore when he was in business and they are good as were his other tools .1 point

-

Did 2 404s over the course of the week after my previous disastrous weekend (getting back on that horse), first was a SWISSAM 1215-21 and the second was a KIENZLE 058/01 both were part of the same job lot so cost me £2.00 each. Before and after pictures below: SWISSAM before: Unfortunately to date ring was plastic and so old it had become brittle, when I put the watch together the tips or the teeth on the date ring crumbled when the date finger tried to move the ring so it's stuck on 23rd... at least it will be correct one day of every month! Here is the finished watch: Dial is not the greatest, but shows its age honestly.... and groundhog day!! its the 23rd (again). New strap, but everything else (including the crystal is original. Here is the KIENZLE before and after pictures: Watch was a non-runner and the crystal is cracked at 8-9 O'clock position and feather cracks at 1 O'clock so had to be replaced Some small tweaks on the hairspring required The final finished watch with it's new crystal and strap1 point

-

Im getting myself this - https://www.amazon.co.uk/gp/product/B003OJOGA4/ref=ox_sc_act_title_1?smid=A3P5ROKL5A1OLE&th=11 point

-

1 point

-

1 point

-

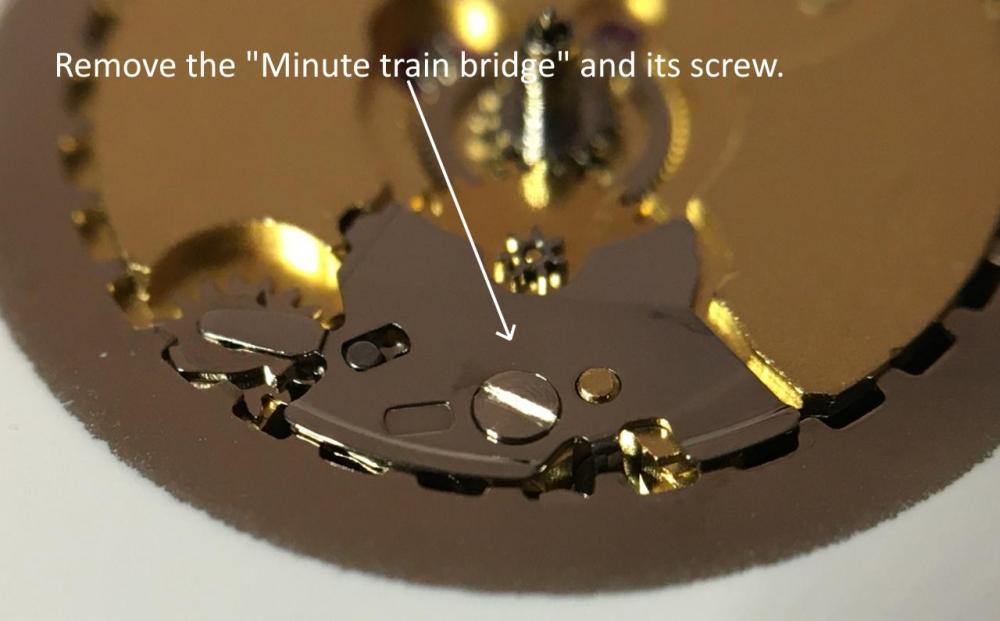

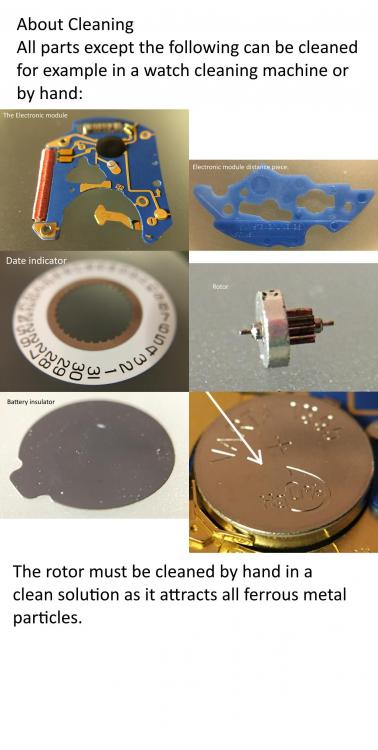

There’s no shortage of service walkthroughs for this and similar ETA quartz calibres on the Internet, and here on WRT. Nevertheless, I thought it would be good fun and educational to create my own walkthrough, and here it is now! Only having experience of servicing mechanical and automatic movements, I truly learnt that a quartz movement is not “just a time telling battery device”, but indeed a mechanical movement, except that the power source isn’t a mainspring but a battery and that the escapement is made up of electronics (no escape wheel, pallet, and balance). So, just like a mechanical movement, a quartz movement has a train of wheels, a setting mechanism, a dial train (motion works), and in this case calendar works. The watch belongs to my father who got it as a gift from my mother at his 40th birthday in 1979 (41 years ago!). He asked me if I could fix the crown which had come loose from the stem. So, I glued the crown back to the stem using Loctite 638. Perhaps not the ideal glue but at least the crown will never come loose again. Anyway, I thought to myself; why not try and give it a complete overhaul!? After all, it had never been serviced and I wanted to learn more about quartz watches and return a perfectly working and clean watch to my much-appreciated dad. One of the things that surprised me while taking this movement apart was that the parts are very small. Smaller than the parts in an averagely sized mechanical movement and that was a bit of an extra challenge. So, before servicing a quartz movement I think it’s a good idea to gain some experience servicing a few averagely sized mechanical movements first. Both the disassembly pictures and the assembly pictures basically mimic and complements @Mark's videos “How to service a quartz movement. ETA 955 412. Watch repair tutorials” and “How to service a quartz movement. Part 2. Assembly. ETA 955.412” which I used for guidance (Thank you!). However, my walkthrough includes lubrication suggestions according to ETA’s technical communication which are intentionally omitted in the videos to save time. For reference I also used the video “Quartz Service ETA 955.112”, @HSL's quartz movement walkthrough, and @Lawson's walkthrough (Thank you!). All part names I’ve taken from ETA’s technical communication. So, without further ado. ETA Calibre 955.112 Disassembly1 point

-

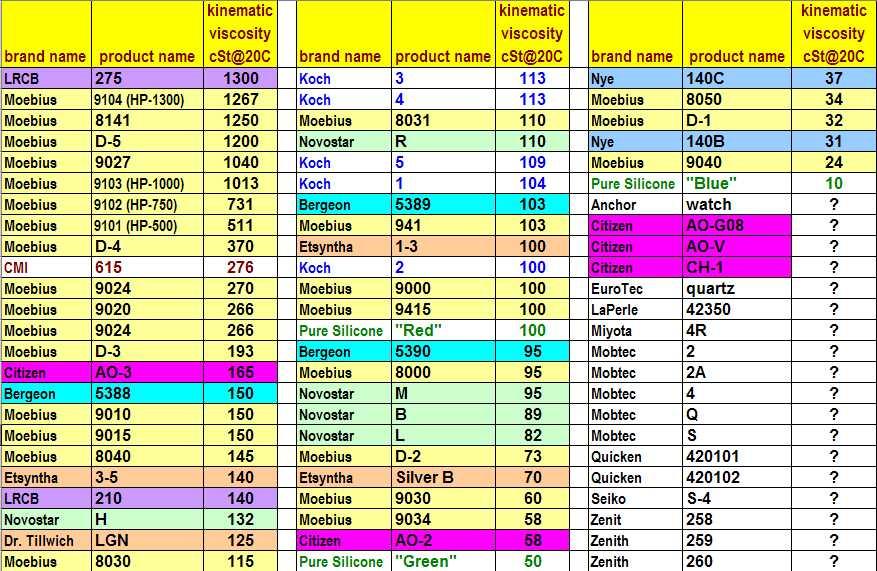

Nye did develop some horological lubricants for Hamilton back in the day, and they still make them. Moly-disulfide grease and lithium grease are probably fine on keyless works and manual-wind mainsprings. The moly might even work ok on automatic barrels, only experimentation will tell us. I vaguely recall someone recently reporting good results with a Chevron moly grease that is roughly the same consistency as Klueber grease for chrono parts. Nye clock oil is highly regarded in some circles. Nye 140C and 140B are (or were) marketed for wristwatches. There's also "Nye Fulcrum" oil which is apparently another product and the SDS sheet says it is about half derived from olive oil. My guess is that for practice it might be fine to use the nyoil you have, and if that doesn't work out and you still have budget restrictions, you could pick up a vial of Moebius 8000 for $10ish. Some of the Novostar oils are good and economical too, but they can be a little trickier to find, though there are sources in the US. Like this: https://www.watchmaterial.com/novastar-type-b-oil-ol-nov-b2/ Some years ago there was a project at another forum to compile a viscosity chart containing all of the currently available lubricants. It wasn't entirely successful but did produce some useful data. Note that the use of the silicone oils on this chart is very controversial, particularly as being "pure" silicone it is questionable whether or not they spread over time. There's no data available on them other than what is on the label, which isn't much. Only a couple supply houses carry them.1 point

-

1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)