Leaderboard

Popular Content

Showing content with the highest reputation on 09/10/23 in Posts

-

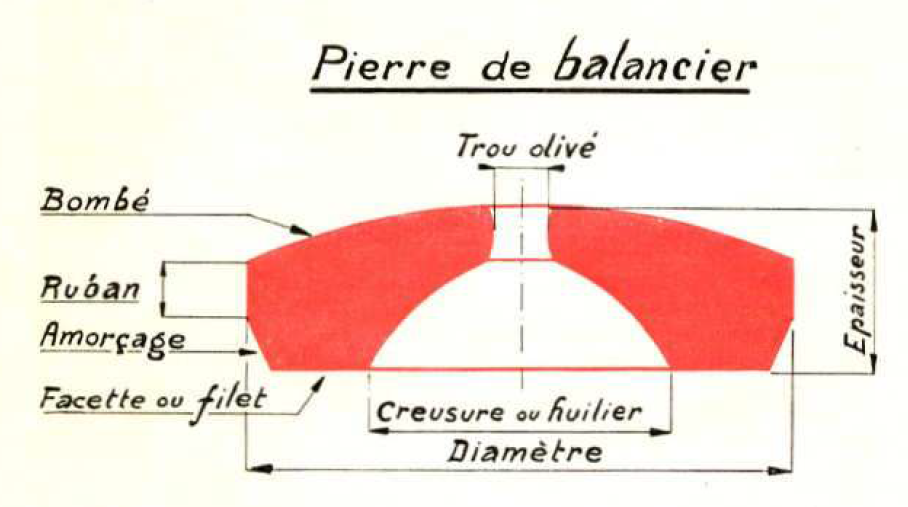

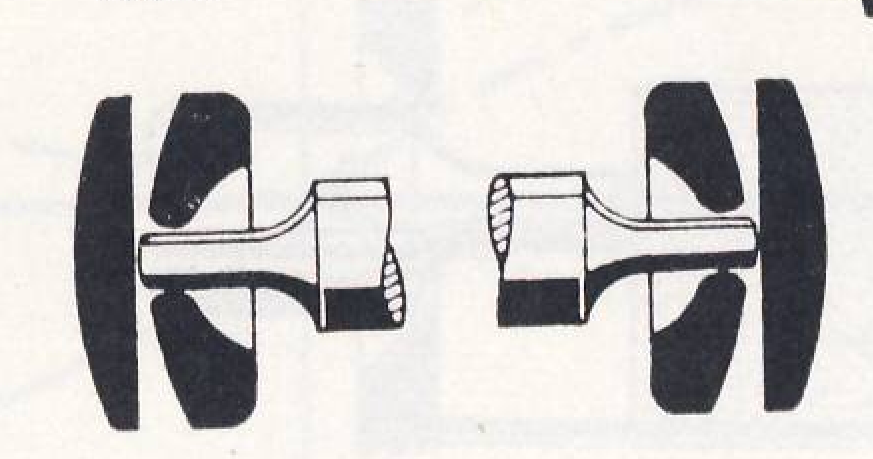

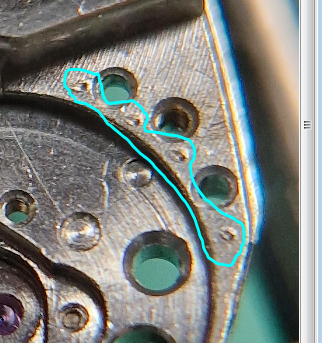

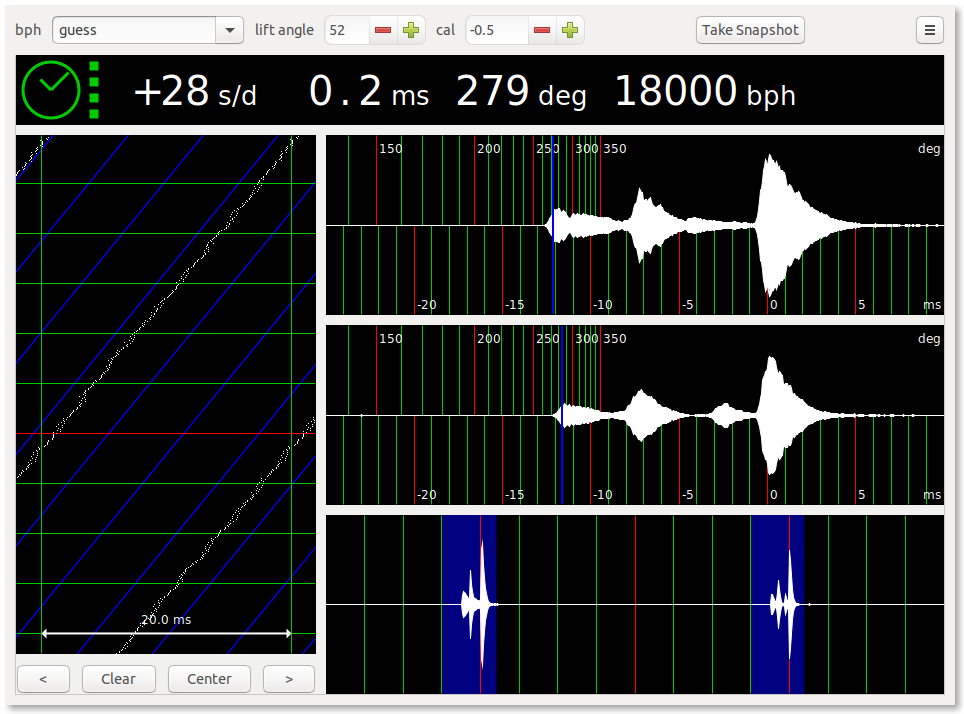

The normal classic rule in watch repair is not to modify the watch to fit the part. Because someday somebody might replace a balance staff and wonder why they're having an issue because somebody modified the watch to fit their situation as opposed to just fixing the problem in the first place. Of course you do have to identify what the problem actually is.. Then just a reminder what does the balance jewel look like and why your shoulder will never ever touch the jewel if it does your having a serious problem. Now that you see with the jewel looks like let's see what your pivots are supposed to look like in the jewels As you can see normally it should be impossible for anything other than the pivot itself to touch the jewels if the cone shaped Part of pivot is touching the pivot is way too short and the balance staff should be replaced. Oh and when you're looking at the pivots notice how the ends are only slightly rounded. If your balance staff pivot has ends that somebody polished nice and round to reduce the friction you end up with too much amplitude on the ends in the pivot versus the sides and it leads to goofy timing because you have huge amplitude differences. The typically the balance pivot is just slightly rounded. Usually when you're seeing dial up and down amplitude issues in addition to the jewels in the usual thing you look at the pivots are they shaped identical. Or in the case of pocket watches if you look in you see a winking affect. Often times of the watches been dropped the pivot will have a flat spot and when you look in the flat spot catches the light it winks at you not a good thing at all. Oh and remember the golden rule of not modifying the watch? Here's an example somebody has modified your watch notice the items I circled if you look carefully somebody has pushed on the metal to raise it up just a little bit because they probably change the balance staff and that was a hair too long.Which as I said modifying the watch leads to confusion for future watch repair3 points

-

@JohnR725, your imput is invaluable and of course you were invited into the thread. @Neverenoughwatches was just confirming that the tools weren't for the shock spring, please do not take offence, texting is inferior to speech, so much is lost.2 points

-

2 points

-

Folks, I can now confirm that the issue was the lower automatic bridge (part 1033). It must have been ever so slightly bent. I got a replacement and installed it this evening. No change in amplitude between with or without automatic bridge. What a relief! Thanks to you all, especially @Nucejoe@Nucejoe and @JohnR725, for pushing me towards further assessments of potential contact points between base movement and automatic bridge (and less into the reversing wheel).2 points

-

I haven't worn this for a few months, so I figured it was time to give it an airing. A Felsa 790 series "Orfilux" 25 Rubis Automatic from around 1955, in a "Hermetica Garantie" case. RWAG is most likely the case maker Rodi & Wienenberger AG, Pforzheim Germany. (Translated link). Sadly RWAG appears to have ceased trading around 2019. I can find nothing on line regarding the "Orfilux" brand, but I suspect it may have been a German company, using Swiss movements. If anyone else knows anything about "Orfilux" I would be keen to hear. I cleaned and serviced this on November 30th 2019 and it is still going strong, though I suspect that is more a testament to the quality of the caliber than it is to my amateur servicing efforts. It also probably helps that this is not a "daily driver", and that thus far I have resisted the urge to pull it all apart again and "fix" the hands, a process that might be fraught with possible pitfalls. The "patina" (some might call it rust) on the hands, isn't obvious unless you shoot a macro shot of it and post it on line, so when I'm wearing it, I can live with it. I should really sort it out by polishing and reluming the hands, but I'm happy enough to leave well alone for the time being. Maybe next time it needs a service, the I will be unable to resist the urge.1 point

-

How was it when you did the initial inspection before disassembly? Can we see how it behaved on the timing machine / timegrapher or whatever you have before you disassembled it?1 point

-

No not at all john. I mean my reply was a part answer just agreeing with richard that the tool didnt look like it could be used to remove a spring and why would you need anyting besides a pair of tweezers. I didn't address the use of the tool to remove a setting. Maybe it lifts the cap jewel or pivot jewel or chaton.1 point

-

Yes that is very impressive hairspring work were seeing isn't it. But if it really was in over coil and he puts it back the way he found it, it still is the wrong balance wheel and hairspring for the watch because this watch needs a balance wheel with no screws and a flat hairspring.1 point

-

1 point

-

I bought the Weishi stand alone from China and made this converter box to be able to use the stand with both my PC/laptop and smartphone. It worked exceptionally well! I couldn't be happier for had gone all out for this mod. Definitely recommend this mod if you already have a PC and can effort just the stand alone on Aliexpress. I made a little video showing my result Weishi 1000/1900 Stand plugs into PC1 point

-

I'm getting quite good with my Sekonda's, although I only work on the Slava 2428 and 2427, as you can see from the 'what's in my wrist' postings. Yours Poljot looks interesting.1 point

-

Just checked there Ross, if the list is correct waggy setting is about right.1 point

-

1 point

-

Note to Knebo. I've seen and done this myself on something cheap as a bit of an experiment. known as gouging done with a small pointed tool. Considered a bodge technique but can work to degree not that even i would condone it. Particularly done this way would angle the cock, that might impact the sideshake on that pivot. No it hasn't been mentioned watchie, another good point raised . That would increase endshake. The shims are a better idea that lift the balance cock evenly, cheap tin and foil finishes at around 0.01mm, but there are thicker better brands if needing for height. The gouging marks can compress over time.1 point

-

What if you filed off those bumps and " it didn't slove it " . Again, a test. Add shim ( aluminim foil is good ) to the outer circumference of the mainplate under the cock, to compensate for the bumps and see if it helps. Shimming can give down to .01 mm accuracy, you can fold the foil two folds or three , once you place the cock on top of the shims and tighten the cock screw and check the end shake, you can loosen the screw and slide the shims inward & outwards the center of mainplate, thats how you can adjust end shake on the balance to incredibly high degree of accuracy. You should fix the mess previous watch destroyer made. Would you gurantee a new staff will definately solve the problem, gurantee in writting please. We are dealing with collection of problems made by previous watch destroyers, faults are not totally diagnosed. Knebo, to check for insufficient end shake , just loosen the cock screw, insufficient end shake can put just enough pressure on pivots to let the oscilator run yet also limit its amplitude.1 point

-

Thanks for taking the time to respond! I checked them and they are ok.1 point

-

1 point

-

This is where a block comes in handy. Just google watch makers blocks. I had a steel block with out holes. Don't buy brass as you know brass is soft and it will soon dent.1 point

-

Hello and welcome, we usually introduce ourselves ourselves on here. Try a one sided razor blade and ease it around the bezel.1 point

-

Honing the top of the tool has improved cutting. The edge closer to the nose is cutting again, and the surface finish is better. If I could hold the tool well enough to hone the sides, I think it would be even better. However, holding everything by hand makes it too difficult to do the side. I need a better way if I'm going to do more of this, my fingers are sore1 point

-

See also https://adjustingvintagewatches.com/what-is-watch-adjusting/ Alos some nice remarks on this site on PU and PD issues and corrective actions.1 point

-

1 point

-

1 point

-

I've been using almost from my start a similar method. I didnt like the ipa clean at all and the risk of handling wet cap stones is too high. I started by rubbing the flat side on watchpaper but that crinkles up too much so i just rub the flat side dry on a sticky note pad. I also just use my finger on the stone to rub then pick the stone off my pinky with tweezers. With complete confidence in this method i never lose a stone and it cleans it perfectly.1 point

-

Hey, brand new to the site but I am a chemist by trade. Here's some the best summary I can make. Warning no TLDR. So The fixodrop is purfloroacyrlic polymer, and pretty nasty stuff. The short fluorinated chain or "tail" is what stands up of the surface of the part like a pillar causing the oil to stay in place. The fixodrop will work more effectively than steric acid. It will bind better to the metal parts and the the "tail" of steric acid is lipophilic, while the fluorinated tail of the fixodrop is omniphobic. The lipophilic steric acid will work mainly due to the physical spacing of the tails acting like pillars the oil would have to span, the difference is it wants to touch the stearic acid tails but not the fixodrop ones. I will tell you this right now. DO NOT ATTEMPT TO MAKE STEARIC ACID VAPOR you would need to heat it to over 300C. This is normally done by a process known as chemical vapor deposition and requires a ultrahigh vaccum chamber, a hot plate, and cold plate. The acid is heated in vacuum to make vapor and the cooler parts cause the vapor to deposit. This is the same method used to grow lab made diamonds. It is VERY expensive, and just heating strearic acid to 300c is a really bad idea (even in a lab if you don't have the correct setup.) The Fixodrop priced so high is because of the demanding chemistry, a fluorinated organic compound is massively expensive to make. Plus to get the thin monolayer it provided low concentration in a powerful solvent like tetrachlorethylene (onedip) which are expensive due to hazards. You are applying a nano layer of teflon like material to ensure oil retention/film integrity. Also the use of high grade fully synthetic oils should reduce the need as they have better film strength and more controlled shear viscosity that reduces unwanted flow. Some additional sources. https://www.awci.com/wp-content/uploads/2019/04/Seitz_StopOil_TECH.pdf https://patents.google.com/patent/EP1927648A1/en For those trying to experiment: Read the following and attempt at your own peril but for the love of god use a organic vapor respirator. Add 1g Steric acid/ 100g pure ethanol to a seal-able glass jar. Warm to 40C in hot water. Once solution is warm, place parts to be coated in parts basket suspended above the solution and re-seal. Place jar into a sonicator filled with hot water. (the prewarming was to prevent high pressure in sealed jar). Placing jar the in a sonicator basket improves vapor production. Let sit for 5-10 minutes. Remove jar from sonicator and remove parts basket in a well ventilated area. Blow dry. Placing a drop of oil on a non-critical area should show if its working. Let sit for 10-15 minutes and see if there is any spreading.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)