Leaderboard

Popular Content

Showing content with the highest reputation on 09/12/23 in all areas

-

3 points

-

Today I've been wearing my newly serviced "Services" with the Smiths Cal 627. I new nothing about the Smiths factory at Ystradgynlais making "cheap" watch movements until I got this. This is a rare(ish) 17J and runs better than I ever imagined it would. After running overnight, I've warn it all day, including a round of golf (a challenge for any watch) and after 24h it's +2s. Amazing for such a cheap watch. I wrote about it here3 points

-

2 points

-

2 points

-

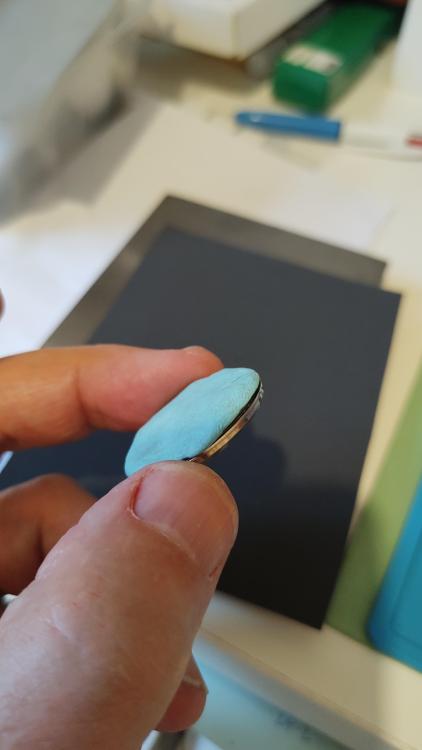

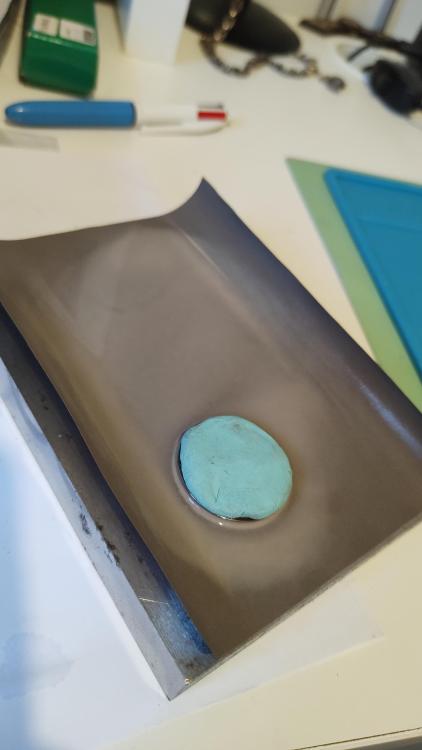

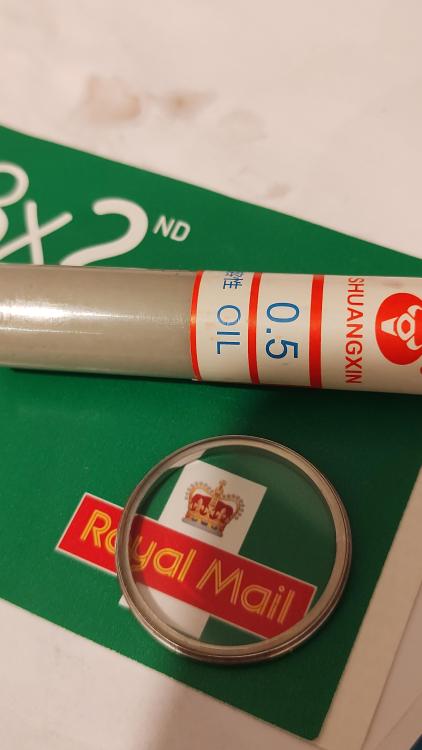

Hi, just wanted to share in case it helps anyone. I made my first attempt at glass polishing recently and was very impressed with what I achieved as a first attempt. Equipment used - Flat machined steel block approx 100 x 150mm. Consumables - Silicon carbide grit paper, grades 600, 1000, 1500, 2000, 2500, 3000, 5000, 7000. Also diamond based polishing compounds, 2.5, 1 and 0.5 micron. I started off with the 600 paper on the metal block slightly wetted. I used some used rodico on the inside of the glass to protect from any stray abrasives. I spent less than 2 minutes rubbing in a circular motion while periodically rotating the glass by 90 degrees at a time. A milkyness would appear on the paper and that was the abraded glass particles. Then I moved on to the next finer grade. Between grades I would wash the glass surface and also wash the new piece of abrasive paper to get rid of any stray abrasives particles. After each finer grade the translucence of the glass would be improved. After 7000 grade there was a certain kind of speckled textured when looking into the light through the glass. At this stage I used the 0.5 micron diamond paste on a small cotton Dremel wheel and ended up with a bit of a fine orange peel effect. Nicely polished but not what I wanted. I reverted back to the 2.5 micron paste and then used the 1 micron followed by the 0.5 micron and this gave the result I was after without any orange peel. Looking back I think that the 1 and 0.5 micron pastes didn't add much to what was achieved with the 2.5, maybe they made the glass just a bit more reflective. If I was to do it again I would try and find some finer grade papers than 7000 and try and use those instead of the diamond paste to keep everything optically perfectly flat. Also I would try to minimise the glass loss of thickness as much as possible by using the harsher grades as little as possible (I ended up at 1.38mm from 1.45mm that I started off with, just under 5% loss).TBH though I am very happy with the results that look pretty much perfect to me.1 point

-

I am kind of expecting a few "Oh my god what are you doing type comments.... but here we go....) I have been following advice I have found here and there for cleaning watch parts - with very limited access to chemicals and without the expense of a cleaning machine. My process has been to put the small parts into little mesh baskets and then put those baskets and the bridges and plates into a sequence of jars which I put in a cheap ultrasonic bath full of warm (50º C) water. I then separately take balance and pallet forks and just soak them for 20mins or so in lighter fluid before giving them a fast rinse in IPA before putting them in my food drying thing. Jar 1. 8mins or 16 mins... deionised water with a few drips of washing up liquid (Zalo) Jar 2. 5 mins 99.9% Isopropyl Alcohol Jar 3. 3 mins 99.9% Isopropyl Alcohol To be honest my results are not great! So I decided to try adding a prewash to the above list. Jar 0. 8mins deionised water with a few drops of "Muc Off - Drivechain Degreaser" (This is a water soluble degreaser that I have been using in a 1:9 mix in the same ultrasonic cleaner to clean bicycle chains) The difference has been night and day - tray of clean parts! I also had a balance from another movement that was sticking together and had black gunk on the hair spring - lighter fuel had not done the trick so I thought... why not! I put it alone in one of the mesh baskets and put it through Jar 0. and then Jar 1. on my cleaning process before taking out the wet hairspring and gave it a quick dip in IPA and then into the food dryer. Once dry it looked nice and clean - the shellac on the roller jewel looked intact and the watch that I had taken it from that was all over the show on the timegrapher started to produce steady results. Planning to find a junk pallet fork and put it pure degreaser to see if survives...1 point

-

Hi folks, I've talked to some of you over the last days about the fact that I was going to buy a lathe - well here it is just out of the couriers van and quickly assembled to make sure that everything that I was supposed to get - I got and it seems I did, nice start. Now I am going to take it apart and lubricate it and then test out the motor. The wife says I have to get it off the dinning table before I lubricate it and fire it up... OK so the motor works! Now I have to figure out the oiling and using part! Any comments on things to look out for welcome. Once I figured out how to do something useful I'll send you some photos! All the best...Jules It seems from a bit of video watching that I have some collets in my set but not a collet chuck. If anybody can take a look at the photo and correct me or explain what it is I would use that's be great. All there best...Jules1 point

-

Despite the other day having an overwhelming desire to purchase women's underwear on eBay or at least look at it that has not translated into something apparently I need to purchase on this discussion group how sad. EBay must be feeling really desperate if all were seeing is eBay stuff and not even seeing necessarily the stuff I look at like for instance it looks like I'm in the need of a motorcycle at least if I believe what eBay thinks Other than the motorcycle let's what I've been seeing on the top of the page all this week with no change at all. Oh and I notice the color scheme that you have quite stylish except I don't like it at all. This happened a while back with one of the software updates and snipping out an image for you if you go to the bottom of the page where it says theme you can hit the arrow and changed the light theme I find it much nicer to have a white background for the words. unfortunately there doesn't seem to be in a way to pick our advertising choices.1 point

-

1 point

-

Even if a replacement is available it's still a nice feeling to say I did that myself. Well done1 point

-

I use about 100 ml in each jar and change after 5 watches. So 2.5L will clean about 125 watches Me too. Water and watches are best kept apart.1 point

-

1 point

-

1 point

-

Not sure about shellac, but I am sure that the Elma solutions don't dissolve it, as they are watch cleaning solutions. If you are cleaning watches, why not go for the solutions especially designed for that job? Then you know they won't cause any damage or leave nasty residues. I was surprised how much better they clean than naphtha, and how shiny it leaves the parts.1 point

-

So in the Netherlands as it would be serviced locally would it be serviced at the same cost as a newer Rolex in other words it's not considered vintage? What I find amusing on eBay is not so much the screws but people selling balance wheels with interesting hairspring conditions. For instance a quick look for 1570 gives us this balance wheel At the bargain price of $250 because something with a better hairspring cost a couple hundred more as you can see it has interesting hairspring problems and almost looks like perhaps a little discoloration like maybe a little rust? Actually the first step to doing anything with the hairspring is to figure out what is actually wrong with it. As the original pictures were very misleading. It's one of the problems I have with people using microscopes and looking straight down and not looking in like they should be because for the most part the hairspring is probably just fine but we don't get a report back the original posting person. We only get that straight down picture of oh dear it looks bad.1 point

-

1 point

-

Yes. People have died from excessive ingestion of the stuff.1 point

-

I feel you, getting access to the proper chemicals in Oslo is not trivial and shipping is expensive! I also started out with jars of White Spirit (the Norwegian kind which, as far as I can tell, is pure naphtha) in the ultrasonic followed by a rinse in IPA. I was also getting poor results, but that might have been due to my weak ultrasonic (from Clas Ohlson, the local equivalent of Harbor Freight). I have since gone over to the old-school approach using a set of stiff paint brushes and small jars of White Spirit and IPA. You can approach perfection using this method, it all comes down to patience... An added benefit is that you are forced to really scrutinize each part, so spotting bent/broken pivots, damaged wheel teeth etc. becomes that much easier. The ultrasonic is only used for cleaning cases and bracelets these days.1 point

-

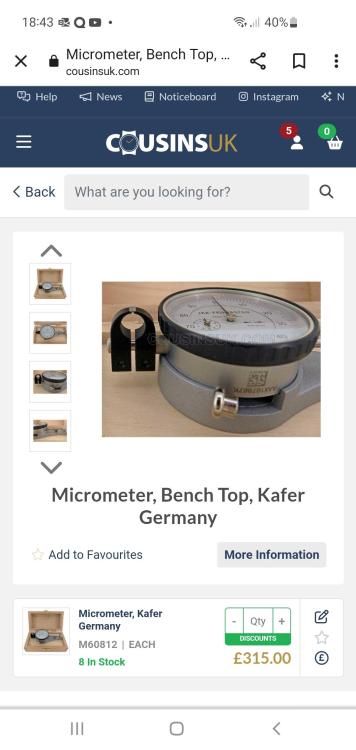

Ross, being in the UK, surely Cousins must be the first place you look for all things watch related ? I use Elma WF Pro cleaner, and Elma Suprol Rinse. I use Elma rather than the L&R cleaners as you can buy them in 2.5L containers = cheaper. They are both about £28+VAT but will probably last you a couple of years. I fill jam jars about a third full, and clean 5 or 6 watches before changing the solutions. Keep the tops on and the smell is minimal. Follow the advice of @JohnR725 above. They clean much better than naphtha. I still do a final 30s rinse in IPA.1 point

-

Thanks for all your advise. I've disassembled the balance and reclean the upper cap jewels and the the staff pivots and no more error working fine Thanks a lot1 point

-

Hello and welcome. I think you are talking about the keyless works, please post photos.1 point

-

Did you know that you could purchase cleaning fluids in United Kingdom? For instance if you're looking for L&R versus Elma cleaning fluids that will get you really close in the link below. No idea what shipping charges in the UK are. https://www.cousinsuk.com/search?searchTerm=L%26R Ultrasonic - Watch1 point

-

It probably has some official term but push button would work. Then if you're missing one this is typically a lathe project. have to turn something out of brass typically. Then whatever the case is made out of could be soldered on the end so that matches the case material.1 point

-

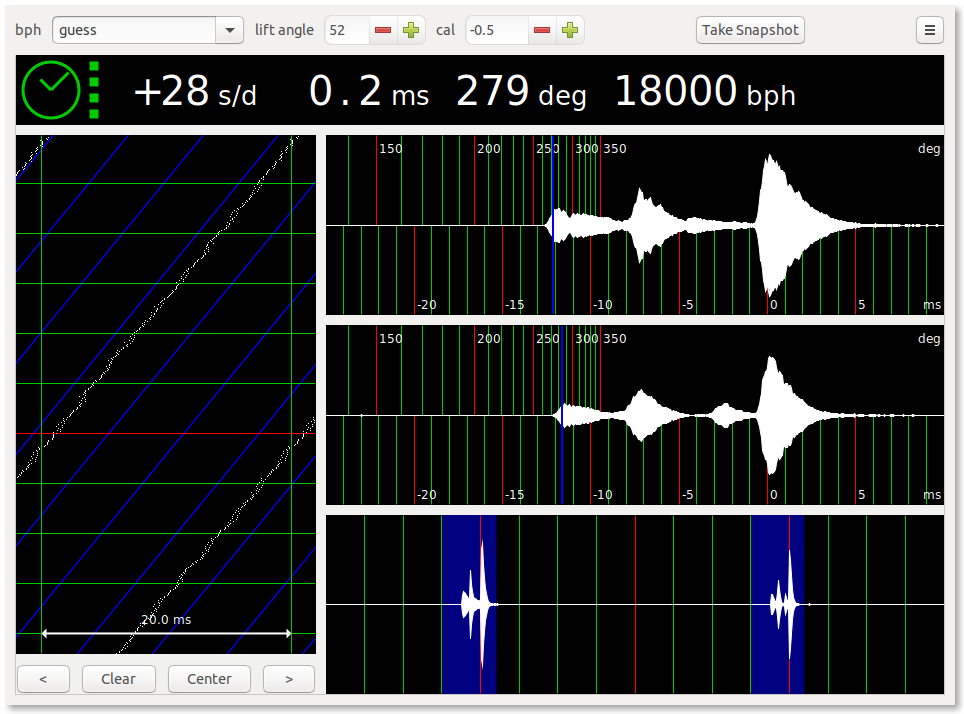

The claim that a rate is achievable to within 0.1 seconds per day is remarkable. Who would have thought a mechanical watch movement could be as accurate as a Quartz movement.1 point

-

1 point

-

1 point

-

The problem with vintage Omega is lots of variations. This is come up in the past when people are trying to figure out which one may have as their seem to be a lot of variations. Usually the best when looking for a balance staff is if we had the dimensions of the staff. If you're lucky because it's an Omega that there may be a base caliber that use the same staff and we can look in our staff reference books and whatever other references we have see if it matches the dimensions.1 point

-

This ninety nine pence, overlooked ebay item is on its way to potentially join the club. It is a two jewel ISA 1198 based "Montine of Switzerland" "Swiss Quartz", which I strongly suspect cost its original owner a whole lot more than I paid. It obviously needs a battery, clean, service and a suitable strap.1 point

-

Thanks for the welcome. I live in Leeds, but I'm originally from Brisbane (a long time ago). These are my soon to be patients. Sorry about the poor quality photo. They are all runners except for the Prescott. In fact I've been wearing the little Roamer at the top left a fair bit. I suspect it was probably fairly inexpensive even in its day. But it's a lovely little thing. It looks great on a tan leather strap, and it keeps perfect time. Of course, you buy one Roamer and the internet goes; "here's something else you might be interested in...". Next thing you know, you have two more... The one on the right is older. Late 50's early 60's I think. With the logo that got them in some bother with Rolex. I'll be sure to take better photos when I start working on them.1 point

-

I haven't worn this for a few months, so I figured it was time to give it an airing. A Felsa 790 series "Orfilux" 25 Rubis Automatic from around 1955, in a "Hermetica Garantie" case. RWAG is most likely the case maker Rodi & Wienenberger AG, Pforzheim Germany. (Translated link). Sadly RWAG appears to have ceased trading around 2019. I can find nothing on line regarding the "Orfilux" brand, but I suspect it may have been a German company, using Swiss movements. If anyone else knows anything about "Orfilux" I would be keen to hear. I cleaned and serviced this on November 30th 2019 and it is still going strong, though I suspect that is more a testament to the quality of the caliber than it is to my amateur servicing efforts. It also probably helps that this is not a "daily driver", and that thus far I have resisted the urge to pull it all apart again and "fix" the hands, a process that might be fraught with possible pitfalls. The "patina" (some might call it rust) on the hands, isn't obvious unless you shoot a macro shot of it and post it on line, so when I'm wearing it, I can live with it. I should really sort it out by polishing and reluming the hands, but I'm happy enough to leave well alone for the time being. Maybe next time it needs a service, the I will be unable to resist the urge.1 point

-

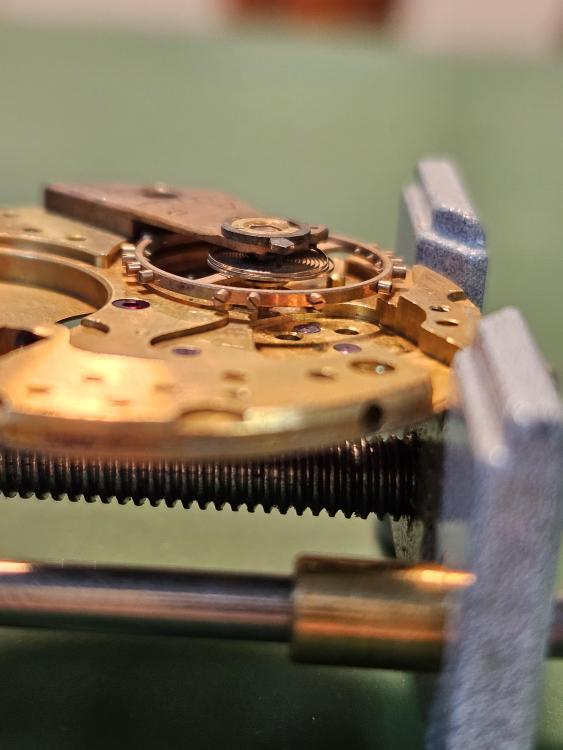

How was it when you did the initial inspection before disassembly? Can we see how it behaved on the timing machine / timegrapher or whatever you have before you disassembled it?1 point

-

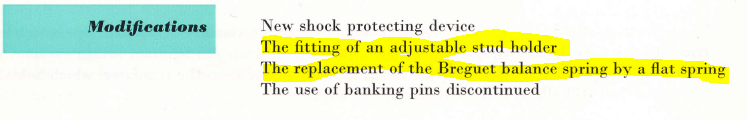

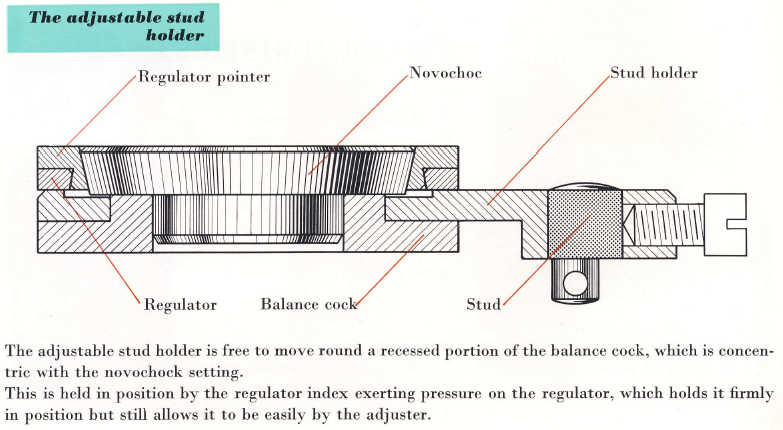

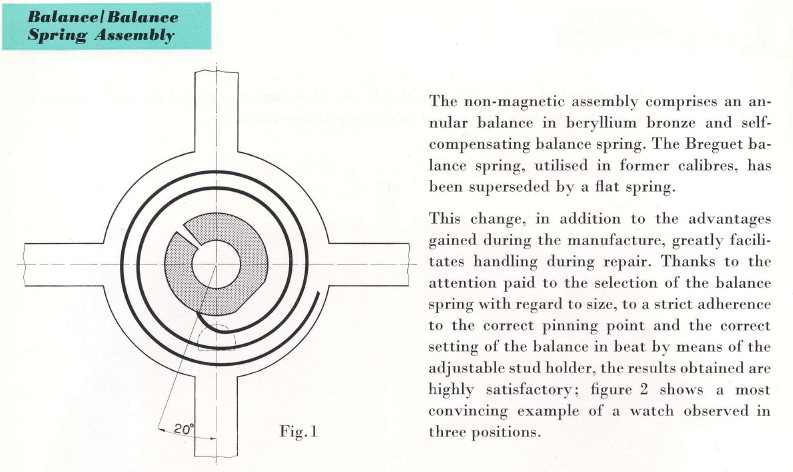

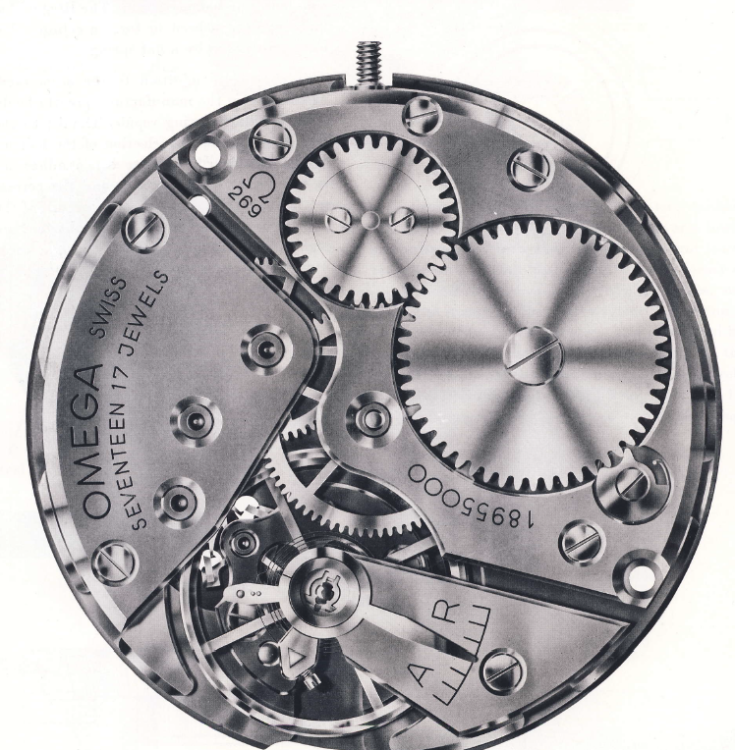

If you're asking a theoretical question I'm attaching a PDF of what Omega thinks about this. Omega-have-adopted-the-screwless-balance.pdf Thinking about that I guess it might help if we had the technical guide. And typically don't find technical guides because most of technical documentation was scanned for the purposes of the parts list. So for instance if we had the technical guide like the one that's attached what can we learn? There's a reference to these are improved versions of prior watches as in the first paragraph. Then we get a list of the modifications and because typically people don't like to read PDFs I will snip out the important stuff I've highlighted the interesting modifications and the technical guide talks a little more about those highlighted items like the adjustable stud holder I do find sometimes with Omega because of how well they manufacture things that may be the adjustable stutter holder goes unnoticed. But it is definitely adjustable then we have the balance wheel and hairspring A rather nice image of 269 and I suppose you could squeeze the balance wheel in there with screws of course it would defeat the whole purpose of the improvements to the watch but I think you'd have a challenge doing it and I don't think on watches when improvements are made I don't think you can Downgrade to a earlier non-improved version and mixing and matching parts. That usually doesn't happen Omega technical guide calibers 269 and 286.pdf1 point

-

I have to say, if that spring started as an overcoil, you did quite a fine job straightening it out! I'm very curious to see how you make out reshaping it.1 point