Leaderboard

Popular Content

Showing content with the highest reputation on 09/13/23 in all areas

-

Cyanoacrylate does react with acrylic crystal, makes them fog up, reacts with anything plastic in close proximity easily. Sometimes after it has set.3 points

-

I was advised on this forum not to use super glue. It gives off gasses wich fog the crystal and probably won't do the movement any good either.3 points

-

In case anyone is wondering. I found a great article on Dave's Watch Parts that describes how to replace the pusher in a hunter pocket watch with diagrams and an example. Just look on his page at the bottom or use this direct link to get the PDF. It does require a lathe to do this. While I have one I don't have a motor for it yet.3 points

-

3 points

-

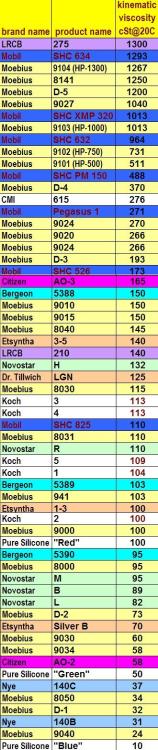

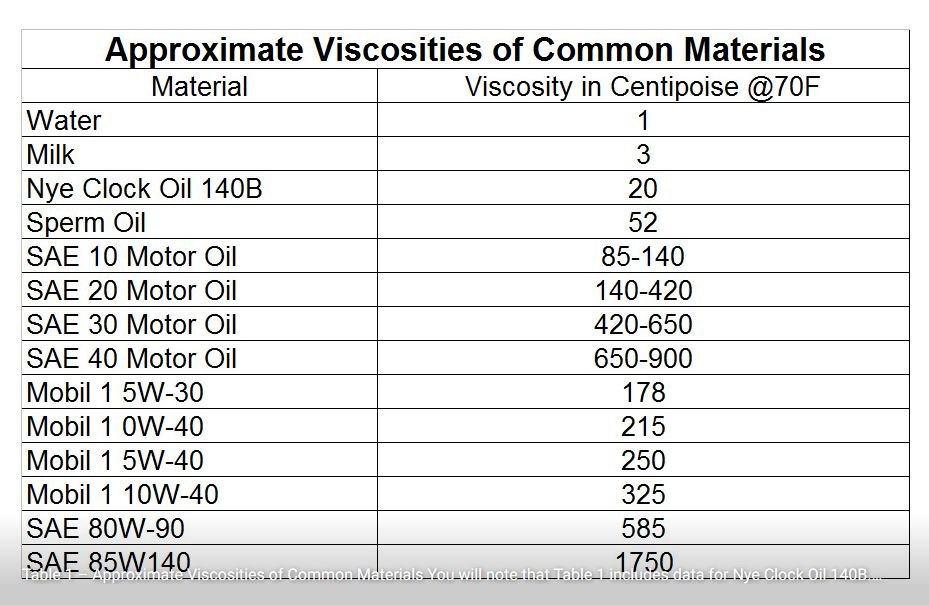

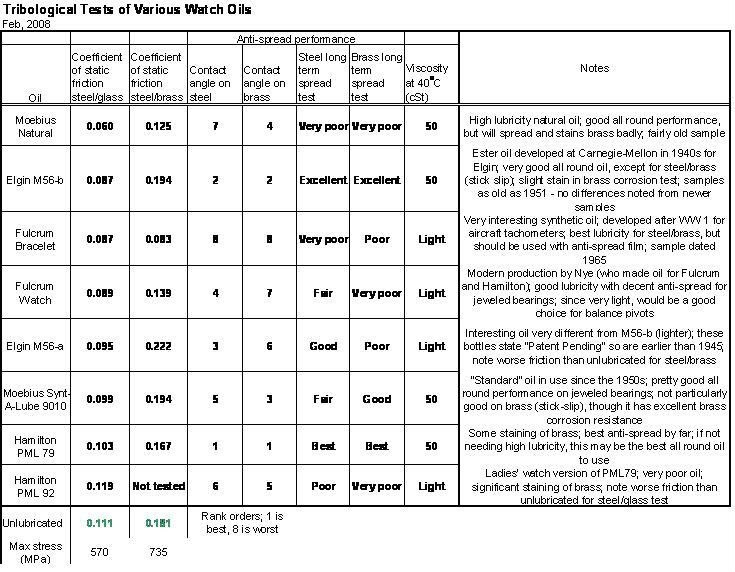

Yes the problem with specifications. We really don't get all the specifications we need like contact angle is interesting and we don't get that. So at some point in time typically all we get is viscosities like here's a chart I once found. Here's another viscosity chart I found. This one is interesting because he does clocks and he's using automobile oil. I even have a link where he talks about the oil uses and why https://www.snclocks.com/TechnicalInformation/Tid-Bits/Tid-Bit-22-Oil-Oilers-Sinks/ Actually the fact that we can even have a discussion about lubrication is outstanding. There are other groups where people are very very can't say that an tough opinionated and that would mean trying to have a discussion about lubrication would result in people running for cover and basically the suggestion was never discuss it ever again. It's only been a relatively recently that maybe the opinionated people of going away so typically you cannot discuss horological lubrication in a discussion group For instance the obsession with how expensive it is. Or the speculation that it is really automotive oil packaged in tiny bottles to rip us off by the Swiss who like to rip us off. But typically for people obsessed with the cost of lubrication I recommend anchor oil is available for a variety of sources like Amazon and its cheap why pay the greedy Swiss when you can get a cheap oil. Oh here's another interesting chart in addition to viscosities we get something else Notice there's a reference to contact angle which as I said typically we almost never see. Which unfortunately is important because it tells you whether your oils going to spread with time. Then that assumes that you properly cleaned your watch and you weren't using compromise cleaning fluids like lighter fluid that has bonus additives that might leave a thin film of oil behind perhaps. This is where just because that looks clean doesn't mean that it's clean and anything left behind like a super thin film of oil will dramatically change whatever you're using because it's much more likely to spread away much faster than it normally would half. This is actually something that everybody on the group should be doing anyway. Actually we should be doing is establishing a proper timing and evaluation of your watches. But in the absence of that check your watch dial down and crown down. Record the rate in most important the amplitude. Wait 24 hours do it again see how your watches doing. Then repeat this every six months and see if you see anything. But there'll be a problem with the experiment. The experiment will only show up on the timing machine if the lubrication goes bad in a undesirable way such as getting sticky. But lubrication can do other things like what if it's no longer where it's supposed to be for the most part one of its spread. One of the unfortunate problems of synthetic oils that typically do not go bad is they may no longer be functioning as a lubricant. This is a common problem with early automatic watches with a lot of metal on metal bearings where the lubrication is no longer functioning but it doesn't show up on the timing machine and eventually the automatic mechanism is ground to dust especially if you do get a little bit of moisture into the watches the gaskets disintegrates. Oh and if you want to have fun with your lubrication experiment? Try servicing a watch lubricating the key less so that the watch can be wound but don't lubricate anything else at all. Now you don't have to worry about your lubrication going bad but see what results you get. Then start lubricating and see if things get better or do they get worse? Yes I've done the experiment it's quite amusing at least until you get the escapement as that usually always has a spectacular improvement.2 points

-

Bit harsh there Richy old boy, ohhh bin the strap2 points

-

2 points

-

My latest project. Was a runner but not in great shape cosmetically. Opened the case and the gasket was tar. Got it out of the case but tar got on the dial near the 3 hour marker. This movement dates to 1972 and has the plastic dial ring and plastic bushings for the dial feet. Long story short broke both dial feet...was able to get the kit to cut the base for the new feet, but it was a Chinese version and the blade center tip broke during practice runs on a cheap dial. Source a replacement blade from Cousins UK and continued on. Ended up with a temp fix using dial dots to hold the replacement feet to the dial. You can see in the final shot a very slight rotation (maybe 1 degree) and the day ring is off slightly as well. Will need to adjust before using JB weld or super glue for the dial feet. Will also add a dial washer to put some tension on the day wheel to tighten that up. Has very poor amplitude so will need a complete disassembly and cleaning and oiling. I also sourced a new mainspring. This should be a fun project with a beautiful movement. before pics Then after cleaning and adding a new crystal and adjusting the flexible bracelet.2 points

-

Hi Jules, have a look here for collet dimensions, not all 8mm lathe collets are the same. Measure yours up to check them against the star entries. There should be a couple of matches in the list which will give you a few options when buying. http://www.lathes.co.uk/collets/ Tom2 points

-

2 points

-

Those are also called split chucks Jules. They fit direct to the headstock and pull tight with the drawbar in the same way the jawed chucks do. Notice the keyway in the side of the collet that coincides with a mating section inside the headstock. Be sure to locate this before drawing them in. I thought the lathe came with a full set of these ? a full set comprises of in the region of 40 +.2 points

-

Today I've been wearing my newly serviced "Services" with the Smiths Cal 627. I new nothing about the Smiths factory at Ystradgynlais making "cheap" watch movements until I got this. This is a rare(ish) 17J and runs better than I ever imagined it would. After running overnight, I've warn it all day, including a round of golf (a challenge for any watch) and after 24h it's +2s. Amazing for such a cheap watch. I wrote about it here2 points

-

So I was just looking in another post about a recipe for making Lubeta V105, which uses 97% IPA and 3% moebius 9010. Using 9010 to make this seemed like an expensive proposition which is when I remembered I have a bottle of Dr. Tillwich 1-3. So I decided to compare the two to see if I could substitute the 9010 with Dr. T 1-3. Long story short it is difficult to compare the two using the published data and make a fair comparison. Only Dr T quotes lubricity data in the form of friction factor coefficients, hence one must use viscosity as an imperfect analogue for lubricity. So at the data show that over 3 different temperature ranges the two oils are very different: 9010 @ 0°C = 625 cSt 9010 @ 20°C = 150 cSt 9010 @ 40°C = 52 cSt T 1-3 @ 0°C = 340 cSt T 1-3 @ 20°C = 100 cSt T 1-3 @ 40°C = 40 cSt My curiosity peaked and I began to look at other oils. So here is Mobil 1 5W-20 (data only available for 40°C), which is 49.6 cSt. So we can see that Mobil engine oil is a closer match to 9010 than Dr. T 1-3, at least at 40°C. So assuming that I use a quality brand to ensure it is clean (debris and impurity free) and consistent formula, why should I not use a 5W-20 engine oil to make my V105 or even...shock horror... lubricate my watch movement. Note, for reference the cSt for water at 20°C is about 1, and 1 cSt = 1mm2/second.1 point

-

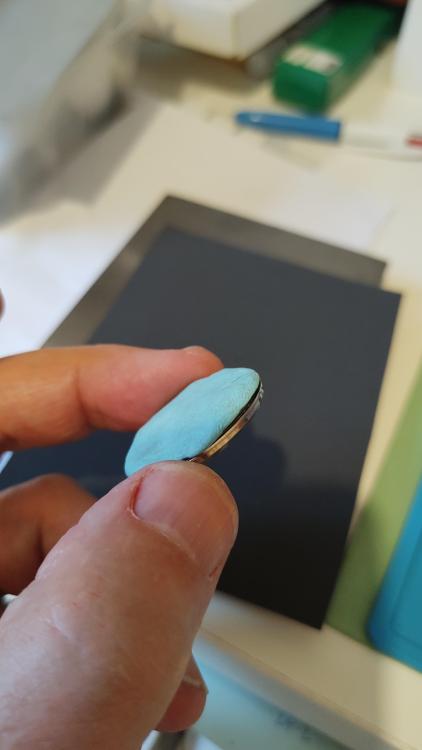

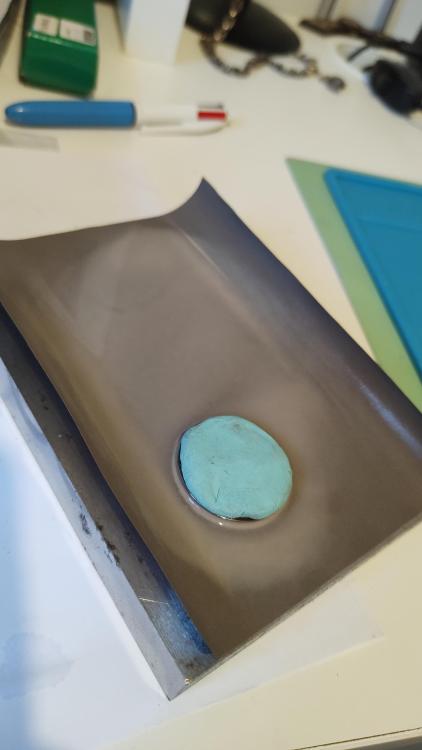

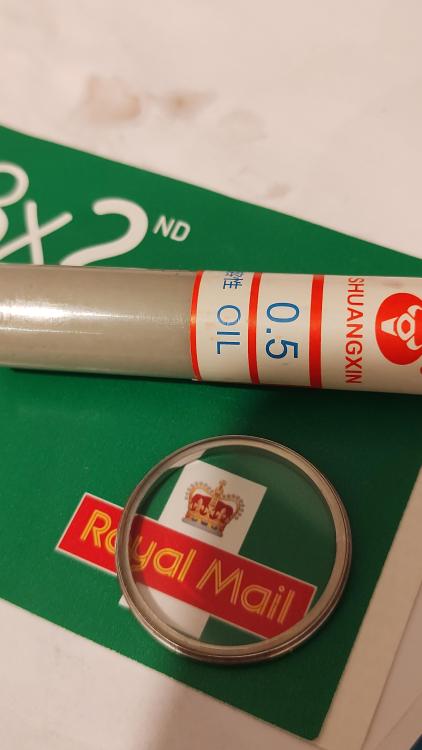

Hi, just wanted to share in case it helps anyone. I made my first attempt at glass polishing recently and was very impressed with what I achieved as a first attempt. Equipment used - Flat machined steel block approx 100 x 150mm. Consumables - Silicon carbide grit paper, grades 600, 1000, 1500, 2000, 2500, 3000, 5000, 7000. Also diamond based polishing compounds, 2.5, 1 and 0.5 micron. I started off with the 600 paper on the metal block slightly wetted. I used some used rodico on the inside of the glass to protect from any stray abrasives. I spent less than 2 minutes rubbing in a circular motion while periodically rotating the glass by 90 degrees at a time. A milkyness would appear on the paper and that was the abraded glass particles. Then I moved on to the next finer grade. Between grades I would wash the glass surface and also wash the new piece of abrasive paper to get rid of any stray abrasives particles. After each finer grade the translucence of the glass would be improved. After 7000 grade there was a certain kind of speckled textured when looking into the light through the glass. At this stage I used the 0.5 micron diamond paste on a small cotton Dremel wheel and ended up with a bit of a fine orange peel effect. Nicely polished but not what I wanted. I reverted back to the 2.5 micron paste and then used the 1 micron followed by the 0.5 micron and this gave the result I was after without any orange peel. Looking back I think that the 1 and 0.5 micron pastes didn't add much to what was achieved with the 2.5, maybe they made the glass just a bit more reflective. If I was to do it again I would try and find some finer grade papers than 7000 and try and use those instead of the diamond paste to keep everything optically perfectly flat. Also I would try to minimise the glass loss of thickness as much as possible by using the harsher grades as little as possible (I ended up at 1.38mm from 1.45mm that I started off with, just under 5% loss).TBH though I am very happy with the results that look pretty much perfect to me.1 point

-

Tissot calibre 781 Disassembly (Please sort the images by name in ascending order) Tissot calibre 781 Assembly (Please sort the images by name in ascending order) Tissot calibre 781 ranfft facts Some time ago my brother handed me this Tissot dress watch from the mid-1960s housing a Tissot calibre 781. My brother collects watches but doesn’t tinker with them (yet). Anyway, I thought it would be interesting to give this Tissot 781 an overhaul (you always learn something). It did seem to run and being a 17-jewel manual wind watch I thought a service shouldn’t take too long or pose any challenges in particular. Anyway, when I removed the case back, I noticed to my surprise that the balance had stopped. I thought “that’s funny”, as it was fully wound and had been ticking along fine while I was looking at the dial. Going deeper I realized that the one of the balance staff pivots was broken off. So, I called my brother and told him the bad news and that I had no experience replacing balance staffs. Well, my brother didn’t become too upset about this but simply told me to keep the watch and possibly repair it in the future if and when I would learn how to replace a balance staff. I wasn’t sure I was ready for it, but life is unpredictable so I thought that it was now or never that I would learn how to replace a balance staff and get the necessary tools to do it. Long story short, I did learn how to replace a balance staff and the watch is now ticking along just fine. In the process I got first class help and illustrations from my fellow Swede @HSL, and if you are in the process of learning how to replace a balance staff, I do recommend reading the following thread where you’ll find HSL’s (and other helpful) posts about this “Staff replacement, balance wheel wobble”. To call this post of mine a “Service Walkthrough” is perhaps a bit of a stretch as the pictures don’t include any oiling suggestions and/or tips/instructions. Nevertheless, I’m thinking that the pictures still might be useful to anyone servicing this calibre and perhaps pondering in what direction the main spring should go and/or what screws to use where, and so on.1 point

-

I've long used balancestaffs.com as a reference when making staffs, and have bought from them as well. As of 3-4 days the site is totally down, anyone know anything? It was a great resource and easy to use site- and easy to order (and good pricing!). I hope it's not gone forever- yet another supplier! I actually ordered a staff maybe 2 weeks ago (got it in just a few days), no issue whatsoever. balancestaffs.com1 point

-

Hi folks, I've talked to some of you over the last days about the fact that I was going to buy a lathe - well here it is just out of the couriers van and quickly assembled to make sure that everything that I was supposed to get - I got and it seems I did, nice start. Now I am going to take it apart and lubricate it and then test out the motor. The wife says I have to get it off the dinning table before I lubricate it and fire it up... OK so the motor works! Now I have to figure out the oiling and using part! Any comments on things to look out for welcome. Once I figured out how to do something useful I'll send you some photos! All the best...Jules It seems from a bit of video watching that I have some collets in my set but not a collet chuck. If anybody can take a look at the photo and correct me or explain what it is I would use that's be great. All there best...Jules1 point

-

One of the ways to remove a balance staff from its wheel is to cut away the rivet that holds it in place. This is performed on a lathe using a hand graver. I wonder what jd was drilling ? It can gather dust just as easily in my house1 point

-

Thanks for the heads up folks, actually a couple of the split collets I have are Lorch I checked them today and they work fine. Not that I knew that there were different dimensions at that point just good beginners luck, or the guy that sold me the lathe was being nice. I was able to speak to the seller today and he told me that he had bought a whole retired watchmakers shop contents some years ago and that's where the Star came from. Unfortunately he didn't have any more collets or tools. Wow that's a heavy price for one unit - I've seen some much cheaper ones here in my quick check today, although I will check the dimensions against the ones I have and the Lathe before I splash out. On the good news side after getting dragged back to my normal work this morning even though I claim to be semi-retired I was able to set up the Star in my workshop (not the dinning table like yesterday so zero wrath from the missus) and it seems to be working fine. I stripped it down cleaned it up, lubricated it, checked the motor, set it up and had a quick play, nothing elaborated really just to see if I got any tremble or noises I thought I shouldn't see. All seems to be well. Also wired it through the variable speed pedal I use for my cleaning tool and it seems to work great, it didn't come with it's own pedal. Also my two A. Schild 8 day balance shafts arrived from France this afternoon, so I shall get to have a play over the next days, trying to get the old ones out of the balance wheels and the new ones in without damaging too much. My easier option full balance wheel assemblies made it from Virginia to Miami so far and apparently they are on their way to Brazil and should be delivered at the end of October - so I guess in at the deep end it is for me. I was watching J.D Richards on youtube drill out a balance staff on his lathe last night but I don't have drills like that yet, or the attachment he had bought. I do have a staking set arriving on Friday, so let's see where we go over the weekend. As always any pointers are welcome! All the best...Jules1 point

-

I still need a cross slide for the wolf, i hear that yours is gathering dust1 point

-

Hey Rich, I only looked the once at the bergeon lathe, £38,000 for a lathe was not an option . I think the only manufacturers of watchmakers lathes left are Sherline, Bergeon, Star and the 2 Chinese ones. I do have a bunch of Lorch collet’s which do look like they are identical to Star collets, I don’t think I would get more than a 40th of that bergeon price for one iirc they are the less common larger sizes but not over 5mm, or size 50 if you prefer. Tom1 point

-

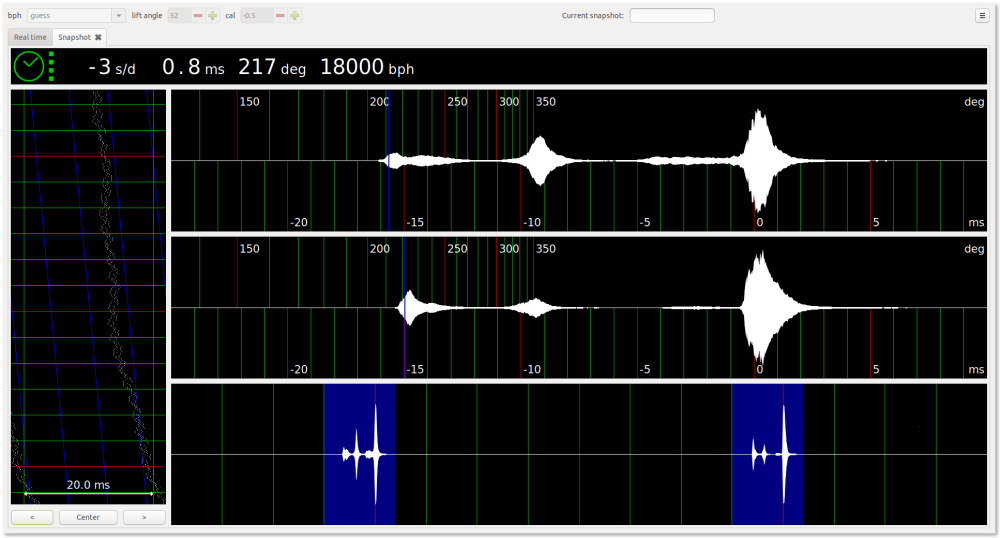

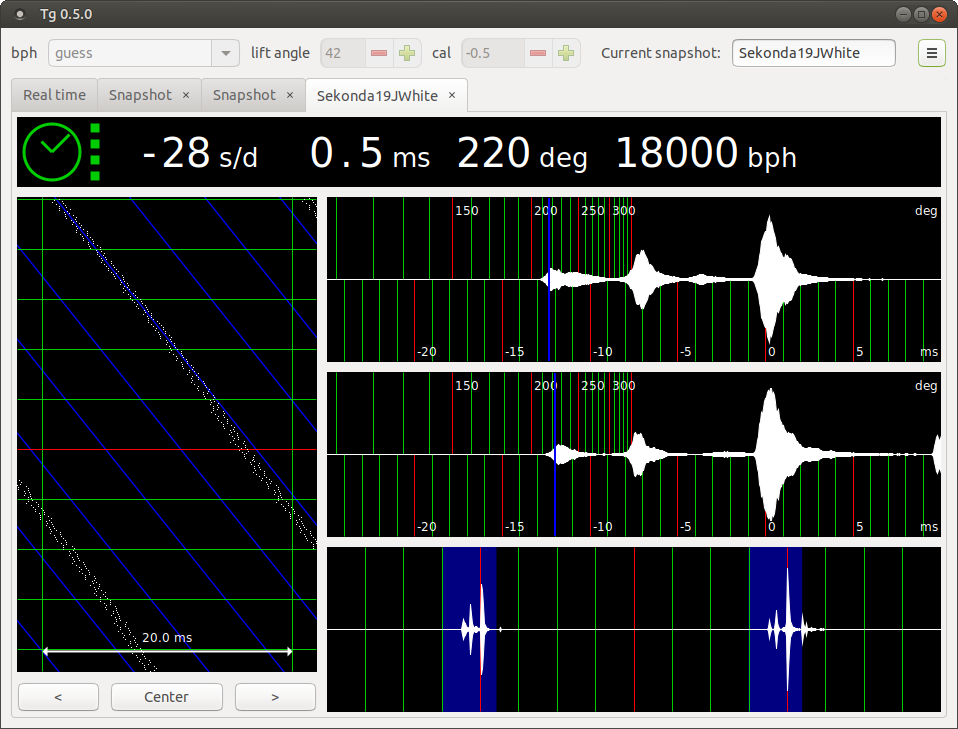

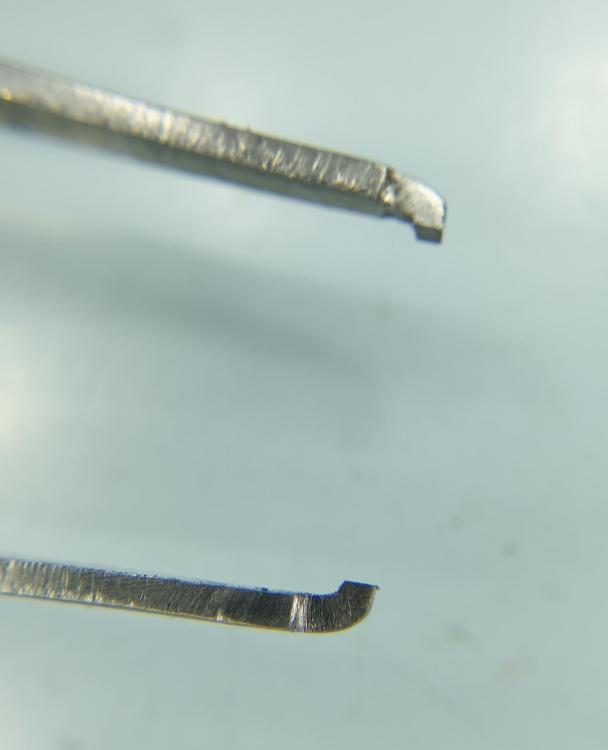

I have "serviced" an alarm clock at my wife's mother's house in India, with oil taken directly from the dipstick of a slightly ancient and battered Hyundia i10. I also posted about this sacrilegious act on this forum at the time. To the best of my knowledge, it is still going strong. Why engine oil? It was a choice between engine sump oil and sewing machine oil, as it was too hot, and I was too lazy to go in to town looking for anything more appropriate. However I also did some experiments with servicing a few of USSR era Sekonda (and a couple of other watches, some HMTs for example) with a rough analog of one of the formulas for watch oil that I found while digging through some articles about what might be in said oil. These watches are still going strong. In fact I think I might grab one and post its health status here soon. See below for an example. The formula I used contains a mix of neetsfoot oil, and unscented, hypoallergenic" baby oil at around 30% to 70%, rather than engine oil. It seems to work remarkably well. I do tend to use "the good stuff" (Bergeon oils) for anything that I feel might not take too kindly to such wild experiments, but USSR era Sekonda watches and HMT Indian ones seem to thrive on anything remotely oily that you throw at them. In fact they seem to survive on zero servicing for many years, often with no noticeable scars as a result. Having said all that, I would highly recommend that you do *not* conduct such experiments with any watch that is high value, or belongs to a paying customer. The manufacturer's oiling charts are a far better guide for longevity than the ramblings of a madman that you happened to read on line. One more thought on the matter. A lot of early watch oils contained fish oils of one variety or another. These do tend to dry out, and leave a sticky residue, so it will be interesting to see if the neetsfoot oil formulation suffers from similar issues. It may take much longer than I am prepared or able to wait, possibly a hundred years or more, before anyone can make any meaningful observations about this though. Why baby oil? "The ingredients in most commercial baby oil products are 98% mineral oil and 2% fragrance", so if you purchase the unscented stuff then it is basically 100% fine mineral oil, and since the formula called for neetsfoot oil and fine mineral oil, this seemed a perfect substitute. Here is one of the victims subjects of this experiment. I've attached the tg-timer trace from January 2020 when it was originally serviced, and a trace I just took a few minutes ago. There is not a huge difference between the two. As you can possibly see from the scratches on the crystal, this watch has been worn quite a lot since I polished the crystal in 2020. The clear, simple, easy to read dial and the gold plated case, coupled with its experimental status make it a bit of a regular on my wrist. The winding is still buttery smooth too. Worth bearing in mind is that this is a 404 club watch, and if it does happen to die from some lubricant related cause, it wont be the end of the world. So far though, (with a sample size of one), the neetsfoot/baby oil experiment seems to be going quite well. Remember children, don't try this at home with daddy's favourite Rolex. EDIT: I think I'm going to have to polish those crystal scratches out now. What is seen, cannot be unseen. So long as you choose a low cost test victim, I can think of no reason not to give it a try. Let me know how the experiment goes. I may even try it myself.1 point

-

F--k me Tom have you seen how much some of the Bergeon collets (wolf jahn) are from cousins. Same list as from De Carle's lathe book. The 8mm Lorch takes the same collets as the 8mm star thats a big bonus when sourcing. Double check the 8mm Lorch collet sizes, much more of those are advertised Jules. There are a few others that match up as well. Am i reading this right ? For just one collet ?1 point

-

thanks for that reference. once i get the sweep wheel off, then the barrel bridge, hopefully that provision will make more sense to me. this is the first a11 i've worked on. i did order the removal tool on ebay, so just waiting for it to arrive to continue my progress. take care. arron.1 point

-

Yes, that is why we have the bright blue Moebius 9504 and the indigo blue Moebius 9501- so you will invest in Moebius 9501 then be told it will spread all around your movement, so you need to invest in the prettier Moebius 9504, composed of the basic Moebius 9501 grease and a metallic soap to get increased adhesion and consistency. A neutral additive gives it excellent high-pressure resistance and good attrition.1 point

-

sticky yet spreadable, i think i have a jar of peanut butter with those same properties in my fridge.1 point

-

Don't worry all the straps are going complete with the DNA I got for free with them. Not quite the most disgusting watches I've received. That prize goes to the fishy smelling Accurist I got a couple of months back.1 point

-

1 point

-

1 point

-

I have done a far amount of reading on radium dials etc and I have have a good base understanding of radioactive decay. I think that wearing gloves and a mask is adequate and your exposure time will be limited. However I know some people are wary of working with radium.1 point

-

There are two issues with radium dials. First the possible ingestion of radium. Secondly, when the radium atom emits an alpha particle it becomes a radon gas atom. https://www.northampton.ac.uk/news/wwii-military-watches-potentially-pose-serious-cancer-risk/ There are some internet experts who'll confidently assert that it's not a problem, but I'm going with the actual experts on this one and following something along the lines of Mike's regime.1 point

-

1 point

-

Hmm interesting idea, would suggest 2 new movements, then past history/abuse would not be a factor. Then rebuild one in 9010 and one in engine oil and compare at regular intervals over a period of a year or so. Would be best to have 2 automatic movements on an automatic winder to make sure they are both ran around the clock for the same duration over that time period. Something like a seagul or other clone?1 point

-

An interesting experiment would be to take timegrapher results from a newly serviced movement, re-service using engine oil and compair results. Also you would want to see how the movement was working in six months time and beyond.1 point

-

Thanks to you both! Very good to know about the super glue and the potential for gases.1 point

-

Is it expensive? I only buy 2ml bottles of 9010, but made up a small bottle of Lubeta by using a syringe to measure about 0.1ml of 9010 to 3ml of IPA. That's plenty to dunk the reversers in. (or do it by drops if you don't have a syringe)1 point

-

Hey Scott, the thing about oils is they are designed for an intended purpose, some will just dry out over time, others will polymerise over time or with heat. As you said in your post viscosity is only one property of an oil with many other variables combining to produce the desired properties to meet the design criteria. lubrication is always a fun subject around here, (and any other place where watch fiddling is discussed) basically ask any two watchmakers about lubrication and you’ll get three different answers. I think Canthus did add a fair bit to one of the threadnoughts on lubrication and oils, I’ll see if I can dig it up. Tom edited to add this has a lot of discussion about oil, a place to start1 point

-

1 point

-

Oh silly me I should pay more attention. I have just gone through the post and I now see the movement which winds from the back and the hands set is the square on the front. What is missing is the bung that goes in the top. These days I have more senior moments every day.1 point

-

Thanks for the fast responses folks, much appreciated! I am in my seven day keep or return phase and I really like the lathe, but it's quite a bit different than those I used years ago which were much much larger - so I want to make sure I am getting what I need. I'm up early here in Brazil doing some of my regular work so I can get to stripping down the lathe and checking it all out, but it looks like a keeper. NE No I'm afraid it just came with five split chucks, so looks like I'll be on the look out for more. It did come with two chucks a three and four jaw one. OH you are right there is no tommy bar just two Allen keys to take it off. OH I was trying to figure out how I would close the three jaw chuck last night and there's the answer missing part! The other lathes I was able to source here in Brazil all seemed to have something missing, and to import one to Brazil would mean a 60% import tax, so I'm hoping I've got a good start I can add to? I will look for split chucks tonight and see how much they go for. If you have a photo of the three jaw chuck with a tommy bar do me a favour and post it and I'll make or buy one. I'll ask the guy who sold it to me if he has any other parts he forgot to give me or would sell me for a reasonable price, he says he has a collection of lathes. All the best...Jules Klassiker, thanks for that I just saw your message - things are starting to make sense now, loving all the comments and advice, so important when you're starting out!1 point

-

I can't see any tommy bars for the three jaw chuck that is fitted on the lathe. Easy to make or just buy.1 point

-

1 point

-

Remove the the chuck that is fitted. Hold it tight and unscrew the draw bar a couple of turns. Give it a tap with a mallet. Now unscrew the draw bar completely while supporting the chuck. Don't let it drop onto the bed! The back end of the chuck should have a profile like your collets; cylindrical then a tapered portion. The draw bar should have a thread which fits the collets. You should now see how the collets fit into the headstock.1 point

-

1 point

-

I think you'll find that the reality is you go through the solution so slowly that splitting would really be a good option. In other words if you have a whole gallon you're probably not going to ever use it up in your lifetime. Interesting choice to me it looks more like the cleaning fluid for watch cases not for cleaning watch movements. Plus it's water base which I know a lot of people use the water-based watch cleaning fluids but I just don't like water and watches together.1 point

-

1 point

-

Thanks for all your advise. I've disassembled the balance and reclean the upper cap jewels and the the staff pivots and no more error working fine Thanks a lot1 point

-

Grip the stem square with smooth pliers, and unscrew the crown. The stem should now pull out from the inside of the case.1 point

-

I’ve noticed that I’m beginning to enjoy some of my tools as much as my watches. Maybe I’ll die from starvation, but at least I’ll die happy holding my cannon pinion remover tool in my hands.1 point

.thumb.jpg.9b6e20bb9647a6b29ab13038e122cdba.jpg)