Leaderboard

Popular Content

Showing content with the highest reputation on 09/14/23 in all areas

-

Yes I noticed that invisible hairspring? It's an American pocket watch it's there it just isn't like a Swiss watch. Yes the rust looks extensive ill be interesting to see what it looks like under the dial. Maybe you should start with reading exercise like a book you can download it in a variety of formats https://archive.org/details/TM9-1575 Providing I got the serial number right this should Be your movement looks like it's a 16 size for some reason the picture looks smaller? Oh and regarding the picture you want to remove the dust ring because when the dust ring is in place you cannot get to the dial screws. https://pocketwatchdatabase.com/search/result/elgin/14501378 Then be careful with the crown wheel screw it's probably Left-hand thread. Typically are but not always.4 points

-

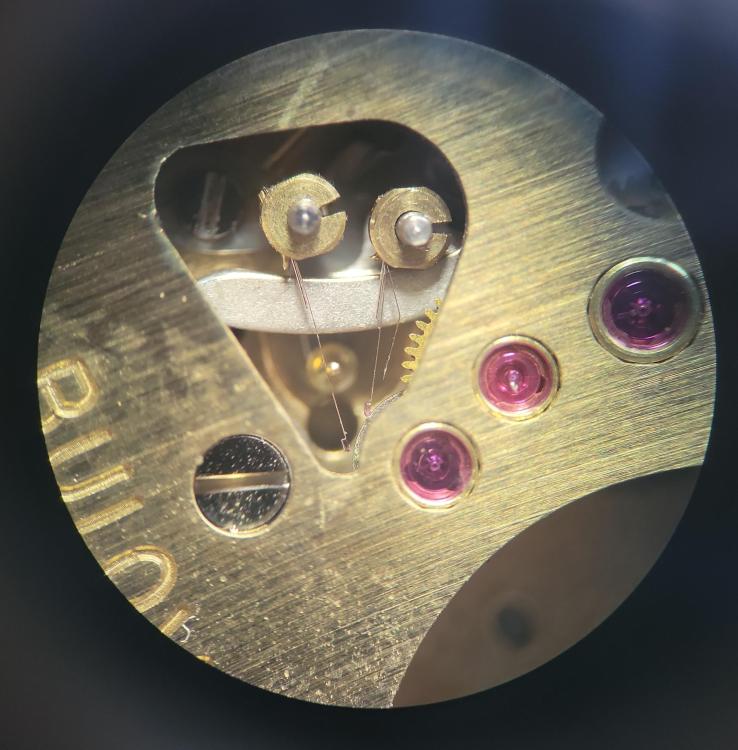

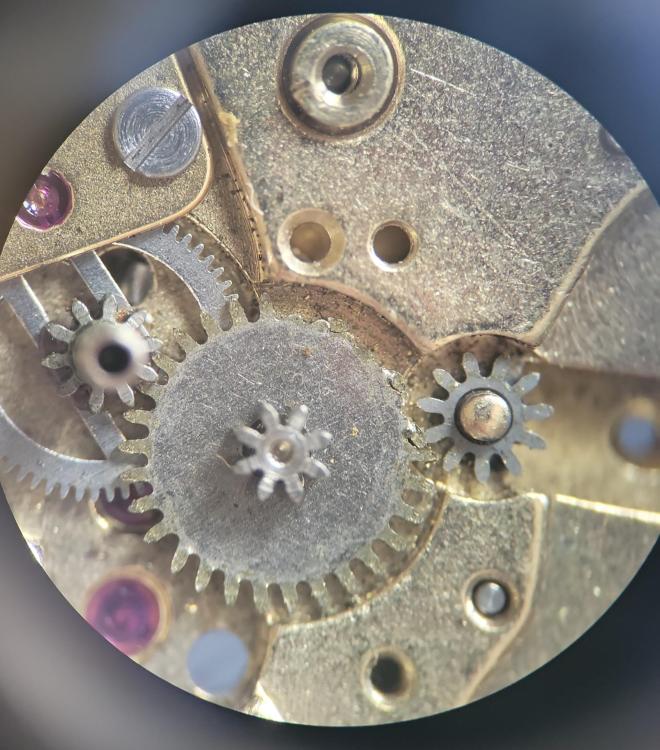

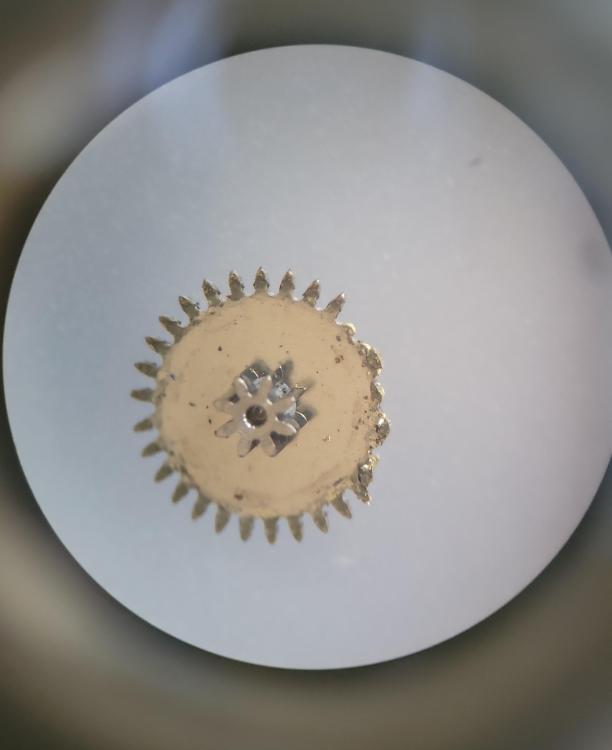

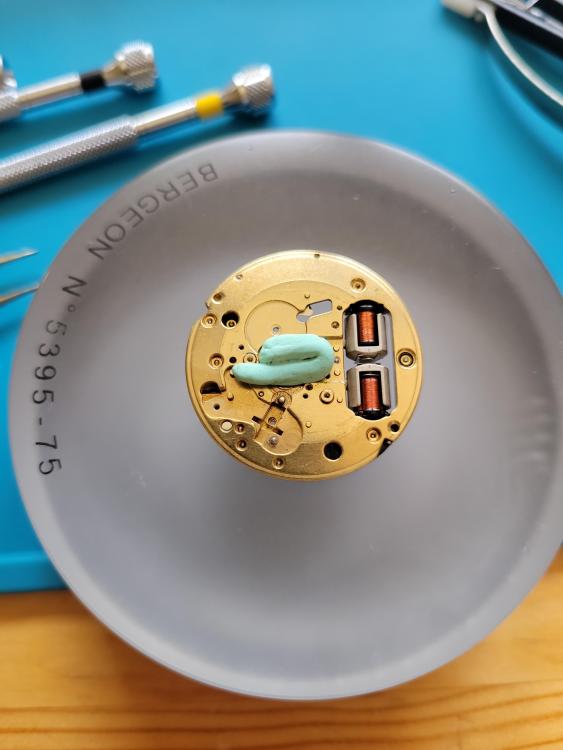

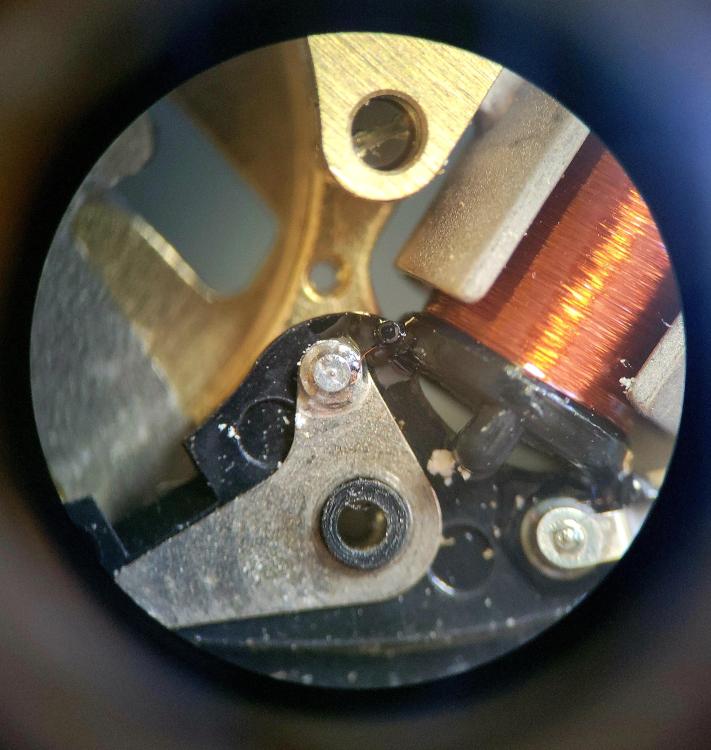

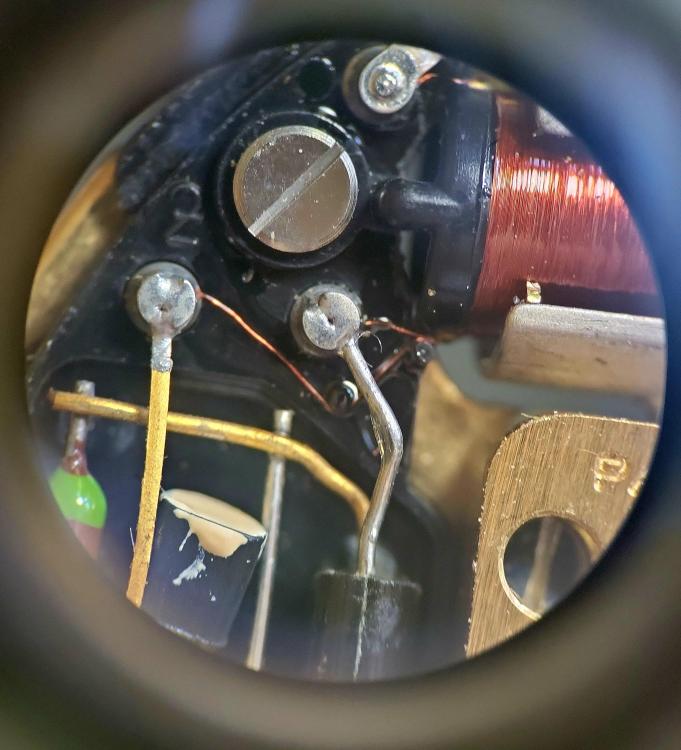

Hi All, I thought I would share where I am up to with my latest project. While doom-scrolling Ebay I came across a soon-to-end auction for tidy looking Bulova Accutron 2181 and chanced a bid. The seller was upfront that the seconds hand turned but the minute and hour hands did not move. I had already read elsewhere that this was a common problem and figured I should be able repair or at least replace the seized parts. This is my first Accutron... The project is a simple stainless steel dress watch with a silver face and simple baton hour markers. Should look nice on a black leather strap. On first inspection after opening the case it is obvious there has been a battery leak. It looks mostly contained to one area and Im hoping it will clean up. I checked the "fingers" and while dirty, they look ok. So far so good! I started by disengaging the fingers from the index wheel - apparently any rough handling during hand removal can cause these to break. Once I had stripped the dial side down I came across the reason why the hands were not moving. Indeed the canon pinion had seized - and properly so! The minute wheel teeth had been striped! After wrestling the centre wheel away from the movement it was clear it had rusted solid and the previous owner had attempted to free it up using force applied to the crown. I used a bit of Rodico to clean up the rust and teeth before proceeding as the forks are magnetised and will attract any ferrous material. Also of note virtually all the components were magnetised to some degree or other so will need to deal with that. A couple of shots showing just how thin the coil wires actually are! I finally made it down to the tuning fork and got stuck trying to remove one of the two screws holing it to the plate. I was putting significantly more force in to turning that screw head than I was comfortable with so decided to place a drop of penetrating oil around the screw in the hopes it will have loosened up by the morning. Now I need to start looking for some replacement parts...... I will update this thread as I progress!3 points

-

So much of anything we do related to a balance staff is dependent upon the equipment you have and your skill set. As I said I've heard stories of people who can re-pivot faster than you could replace a staff. I've also heard stories of people can make new balance staffs very very quickly. Then for others it's just replacing the balance staff it just depends on what you have your skill set etc.3 points

-

That wasn't what I was hinting at. I heard stories of people in the shops who can repair the staff faster than most people can replace one. But that wasn't what I was annoyed with it mainly had to do with the entire YouTube channel I'm just not a fan of his.3 points

-

I asked that same question 30 years ago. The bodgers of old were highly skilled chair makers. The story goes that a group entered the woods with the view of spending days there making their furniture from the trees. Each man had his own skill and made a seperate part of the chair, a seat, spindles for the back and legs, a spindle bender, an assembler, maybe a carver. No one man completed the chair, hence a bodger doesn't complete the work .2 points

-

2 points

-

2 points

-

2 points

-

Oh i see, thanks for clarifying , i have to say i was a bit disappointed when I thought you were not a fan of the technique, i hoped it was a fair idea and more within my scope than making a staff . Somethings you just have to try for yourself and see how they work out.2 points

-

I still don't like the sound of that. I think it would be better to start a new discussion with how to replace a balance staff and you can get off in the right direction versus well to be honest I really don't want to know what he's doing I try not watches videos. Apparently Repivoting the staff John, there are a few good videos on the technique. I have a couple of the purpose designed gadgets to do it, ive never tried them, i guess a diy way get out for folk that cant aquire or make a staff themselves, sounds like you are not an advocate of the idea John ? You're about bob on with those prices Tom, i was very lucky with my wolf, i had 1 missing out of a set of 40 from 0.1 to 4. A seller showed up on ebay shortly after i bought it with the 0.6 selling for 12 quid.2 points

-

@Juleswatch £10 a collet seems to be a rough median buying second hand collets. The Chinese ones as far as I can find out are WW pattern and not the same as Lorch/wolf Jahn/Star. The prices can vary though from if you’re lucky £6 upto £18 depending on the size, larger collets like 60(6mm) or the in between sizes like 29(2.9mm) tend towards the more expensive as there are a lot fewer of them around. I think a full and complete set is around ~70 collets. Tom2 points

-

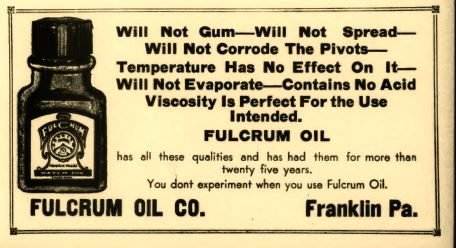

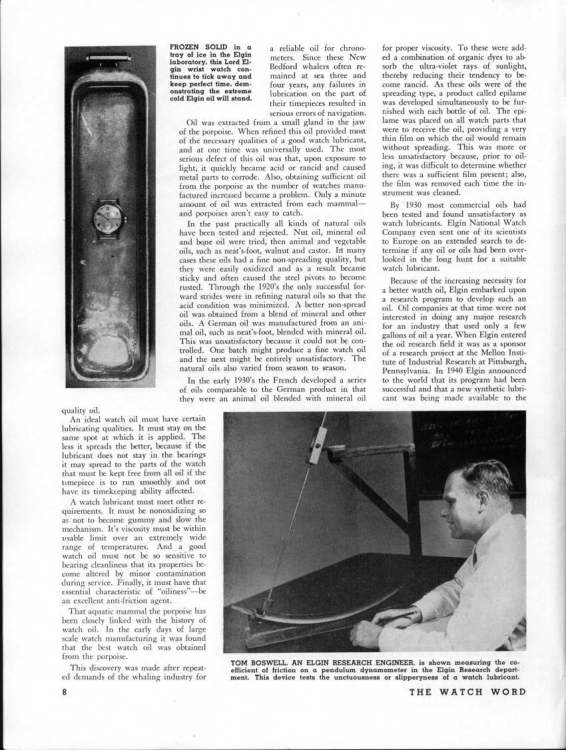

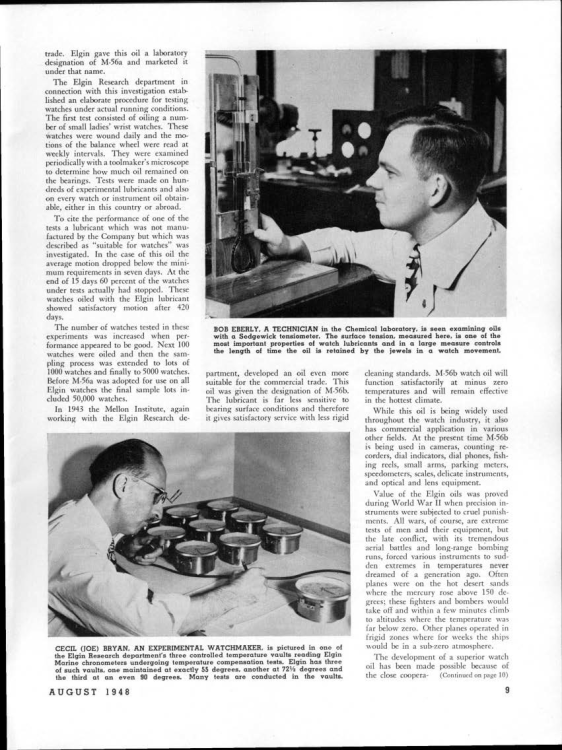

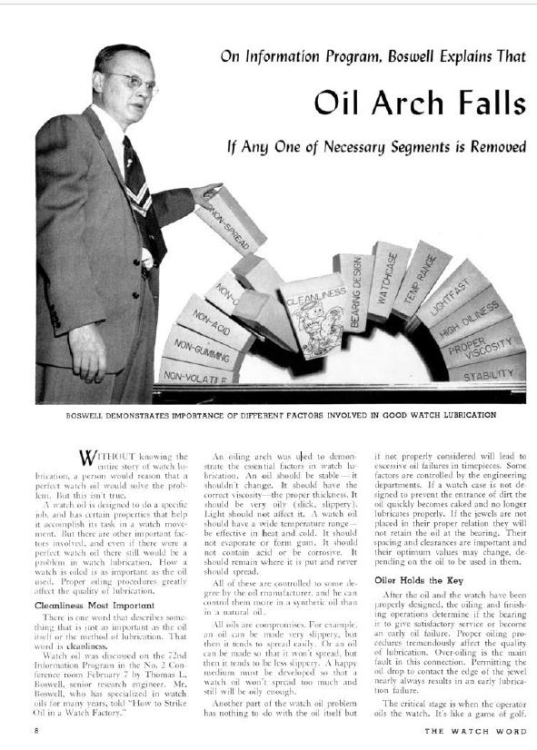

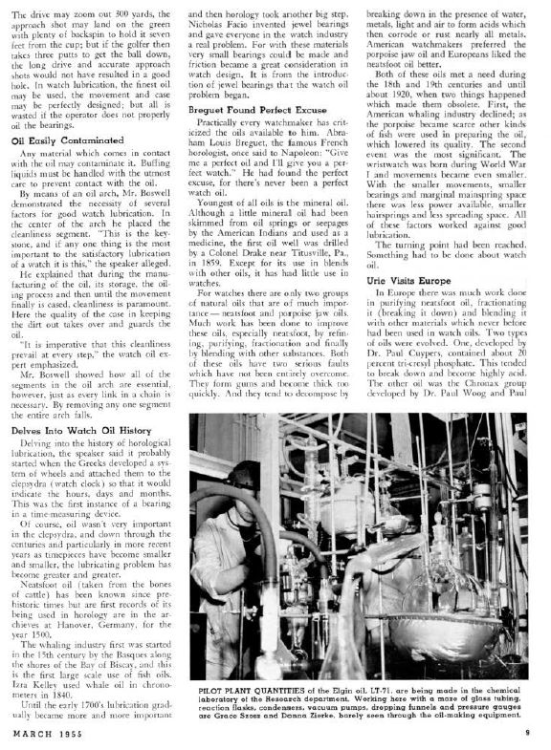

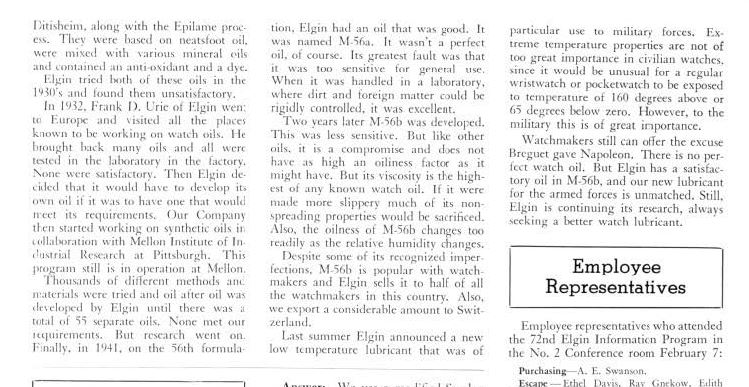

The annoying thing with contact angle is it's not really the angle lets the problem. In the old days the Swiss used to put a technical sheet in their little tiny can that has their little tiny bottle of oil so somewhere I have a tech sheet on 9010 and another one on 9020 and in that literature it had the contact angle. For which I find fascinating because 9010 has a habit of spreading without epilam so every single reference we have the 9010 basically says use epilam or it will spread. But the 90 20th from my own experience does not spread seems the last forever it is absolute perfect and that wasn't a big difference in contact angle but there was a difference but who knows where I put the technical sheets because for one thing in order to fold up into something that tiny is printed on really thin paper so I put it someplace safe and in a house safe things go Fortunately it looks like the title were discussing horological oil and I believe somebody asked her made a reference to what is horological oil so I have some images. For instance here's one it looks promising unfortunately it doesn't have a date now thanks to the Swiss we have to be concerned about the data the oil This one looks promising although I prefer the second version at least it's priced right Other advertisements Now the next one is interesting because people have questions like what makes a good lubrication for horology. Tells us a little about the different types of oils of why some were good some more bad. Although the definition a good is interesting in that organic oils tend to lubricate better than synthetic except that in life is not there. Then we get a nice list of all the properties were supposed to have minus other stuff that would be interesting. The Elgin watch company produced a magazine for their employees. In the old days companies might have a newspaper for the employees the day whatever it is would be all online but Elgin had a magazine with Elgin related stories in all sorts of other interesting stuff. Here's one on lubrication 1948 1955 article A little hard to read unfortunately but still interesting and it makes a reference to another Elgin oil that you've never seen something for the military.2 points

-

I am kind of expecting a few "Oh my god what are you doing type comments.... but here we go....) I have been following advice I have found here and there for cleaning watch parts - with very limited access to chemicals and without the expense of a cleaning machine. My process has been to put the small parts into little mesh baskets and then put those baskets and the bridges and plates into a sequence of jars which I put in a cheap ultrasonic bath full of warm (50º C) water. I then separately take balance and pallet forks and just soak them for 20mins or so in lighter fluid before giving them a fast rinse in IPA before putting them in my food drying thing. Jar 1. 8mins or 16 mins... deionised water with a few drips of washing up liquid (Zalo) Jar 2. 5 mins 99.9% Isopropyl Alcohol Jar 3. 3 mins 99.9% Isopropyl Alcohol To be honest my results are not great! So I decided to try adding a prewash to the above list. Jar 0. 8mins deionised water with a few drops of "Muc Off - Drivechain Degreaser" (This is a water soluble degreaser that I have been using in a 1:9 mix in the same ultrasonic cleaner to clean bicycle chains) The difference has been night and day - tray of clean parts! I also had a balance from another movement that was sticking together and had black gunk on the hair spring - lighter fuel had not done the trick so I thought... why not! I put it alone in one of the mesh baskets and put it through Jar 0. and then Jar 1. on my cleaning process before taking out the wet hairspring and gave it a quick dip in IPA and then into the food dryer. Once dry it looked nice and clean - the shellac on the roller jewel looked intact and the watch that I had taken it from that was all over the show on the timegrapher started to produce steady results. Planning to find a junk pallet fork and put it pure degreaser to see if survives...1 point

-

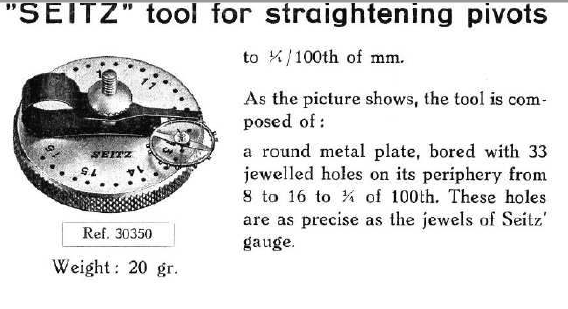

We really need the instructions for which that is not. As you can see it's a disk with a whole bunch a really precise holes and he starred in a really big hole and work your way to the smaller hole gradually straightening the balance pivot and. It's probably actually easier to do that is for me to try to describe it. Then the spring the thing is a gauge so we can see what you're doing but I found was doing my pocket watch pivot I just didn't worry about the gauge at all I just eyeballed it and it worked fine. They also make a really heavy tweezers that you can warm up in the warming up this critical and you can use that to bend the pivots. When I was in school the tweezers the instructor had had pieces of wood taped onto the handle C wouldn't burn yourself it's not heated up to red hot it's just heated up to be hot and then you can grab the pivots and gently bend it or use this tool when it's cold and it also seems to work or you can grab it with some other method and probably break the pivot off unless you're really lucky. Although by far the best to view just replace the balance staff.1 point

-

I know. This is an English speaking and typing site. That is why I have asked to type in English.1 point

-

I doesn't look as though anyone is going to guess. Richard was pretty close, but we know its for straightening out a bent pivot. The staff pivot is placed in a jewel hole that will accept it and turned. The spring held arm is just to stabilize the balance using it as a rest. The balance is then placed in progressively smaller holes until the pivot runs true. They also make use as good pivot gauge. Actually i did pay a little over 100, from a good seller i use frequently but they generally come up at around 300 My lathe was also a bargain at 180.1 point

-

Crystal polished, glued in, and trying on new bands from Esslinger. I went with the first one, and not just because I put it on backwards in the second picture... It really is such a handsome watch, and I'm so proud of this one. If anyone has a favorite site or style I should know about, I'm open to suggestions!1 point

-

I see 5 pivots under the plate, a lot of early Oris are like this. Its doable but frustrating first attemps. I found puttting one or two plate screws in lightly to hold the plate in position then work the pivots into place one at a time.1 point

-

I would have been running for the exit. I develop a rash if I consider anything with less than 15 jewels, so 1 jewel . From the pic the one jewel is a cap on the balance cock. The other end must just be a brass bush.1 point

-

Strange how we use bodge for poor workmanship but bodgers were skilled.1 point

-

1 point

-

I have always that same problem when i try . Its a good way to summon a member into the discussion @JohnR725 , ha i just did it. @ symbol then a space then you are give an option of members to choose from.1 point

-

1 point

-

I found if you don't actually follow the directions it worked just fine for me. In other words I wasn't concerned about the spring thing and just eyeball that. Which I did find interesting because I didn't think it was going to work. So yes it is a interesting tool. Yes I know no guessing from the pros maybe it's used to keep track of things? In other words maybe you insert or put things on the little circles and that allows you to keep track of things. Well maybe or maybe it has some other interesting use that I was rather surprised it did work.1 point

-

Make sure your driver is a really good fit on the screw. I've had a driver slip more than once on a fully tensioned movement, its not a good outcome. I make a point now of using the crown between my fingers or a crown winder to power down.1 point

-

Yes you mean the lazy watchmakers that don't embrace The traditional bow. Almost as bad as people using electric motors. Actually I think you'll find that there were several tools that used a bow I think the earlier version of a lathe whether turning between centers that can use a bow or be driven by other methods.1 point

-

O.K. I’m gonna bite it’s a thingamabob to hold an oumjythrumet so you can combobulate it accurately. Tom1 point

-

Don’t think it’s a spoof. If was the disarray among the Scots regiments caused by the sinking of Iron Bru tanker, HMS Sauchiehall, that led to Dunkirk.1 point

-

A jacot tool can be run this way. Clever watchmakers have upgraded the bow by pinning one of those retractable zip cord thingies for keys and fishing nippers to the bench...1 point

-

Unfortunately it does not come with the arrows which is very sad as they might be useful at some point in time. At one time yes but I think you'll find today like most watch companies they embrace technology. But more than likely they still hand finish.1 point

-

Yes, the story about a bow is correct. I watched someone polishing clock pivots with one.1 point

-

Anything that Archie Perkins Does is going to be outstanding. Then I have a copy and it is it very good book.1 point

-

The Perkins book is great. Another good one is The Watchmaker and his Lathe by Hans Jendritzki.1 point

-

Thanks for all the comments - a lot to learn, to drill or not to drill, to make or not to make, or to buy and replace - a book seems like a good plan! Thanks for the link I'll take a look today. I was also considering a book called "The watchmakers lathe and how to use it" by Archie Perkins - pricey so hopefully a nice book, has anybody seen it or have it, recommend it or not? Also thanks for the price ranges on collets, there seem to be some on eBay that are coming out of an estate sale that seem quite well priced, i shall measure mine today and ask some questions of the seller. I'll pick some up as needed and as they become available for a reasonable price. As you say my might was there for a reason, we just can't be too fussy!!1 point

-

You're in the stop position there, so the brake should be pressing against the side of the chrono runner wheel. Put it in the run position, make sure the rocking pinion is correctly in it's hole in the mainplate, and in its bridge (and right-side-up- little teeth to the chrono runner), and that the friction spring is correctly in position under the chrono runner. There, with the rocking pinion pulled away, the chrono runner should turn freely.1 point

-

It's hard to tell in the second photo but looks like the arms might be bent in just a hair? Not the reason why it's stopping low Then did you verify that the new staff looks exactly like the old staff preferably measuring with a micrometer. Often times there can be staff size variations even for the same part number Sudden stops are very bad. If you listen to the watch or this case the balance wheel when it makes a sudden stop can you hear anything? Also pay attention to the hairspring over coil hairsprings have to be while the little more tricky than flat hairsprings you want to make sure it's not touching the balance arms the over coil isn't touching of the upper bridge. I doubt a bad jewel would cause a stopping issue like you describe more like it's rubbing on something else perhaps1 point

-

Interesting I never questioned whether is valid or not. I did find it was rather interesting and I really did like the heater. Now I feel sad because I thought the heater was interesting idea.1 point

-

@JohnR725 he must have done that for April fools day! Having served in the British army there is no Scottish army, only Scottish divisions. I would have loved that ration pack whilst serving. Tom1 point

-

You would probably have needed sunglasses because the brightness Would blind you. You do realize the planet is a really big place. Then typical government military agencies the philosophy is out of sight out of mind don't worry about it ever again. So unfortunately for all of us these problems are ongoing for the entire planet. Oh give Scotland how about recycling is an example of a product that got recycled into something interesting.. Don't worry you'll figure out really fast he gets really excited about it. Yes something to keep you warm on a cold night perhaps carried in your pocket although it does get a little bit on the warm side. https://youtu.be/9Ry4QBQejFU?si=hgFjP2OGn3Jp8nus1 point

-

Best not to ask that question Maybe a book would be helpful for this like at the link below. This is a very good book on watchmakers lathes covers a whole variety of topics. https://archive.org/details/watchmakerslathe00good I still don't like the sound of that. I think it would be better to start a new discussion with how to replace a balance staff and you can get off in the right direction versus well to be honest I really don't want to know what he's doing I try not watches videos.1 point

-

Might be easier to stay on lingerie, but I'm trying to widen my horizons, perhaps I can fit in time for a new staff. Probably go with more old Swiss or German - heads up appreciated - not sure about Helga - might leave her to you1 point

-

Personally i would rather have old Swiss or German over fresh new Chinese, unless you are back to lingerie again Jules, then i'd be more swayed towards an Asian thong over a big old pair of Helga's bloomers ( only just swayed mind you ) Re. the repivot tricky procedure by all accounts, Nicklesilver has stated previously he would rather make a new staff.1 point

-

I might have the owners phone number, will look up list of my contacts, called him last year. I don't think he has shut down his business, likely to be back with new stuff.1 point

-

Me too Watchie it was a great resource for sizing staffs and stems. I was on the lookout a couple of months ago for some ronda and dcn catalogs just in case this happened.1 point

-

1 point

-

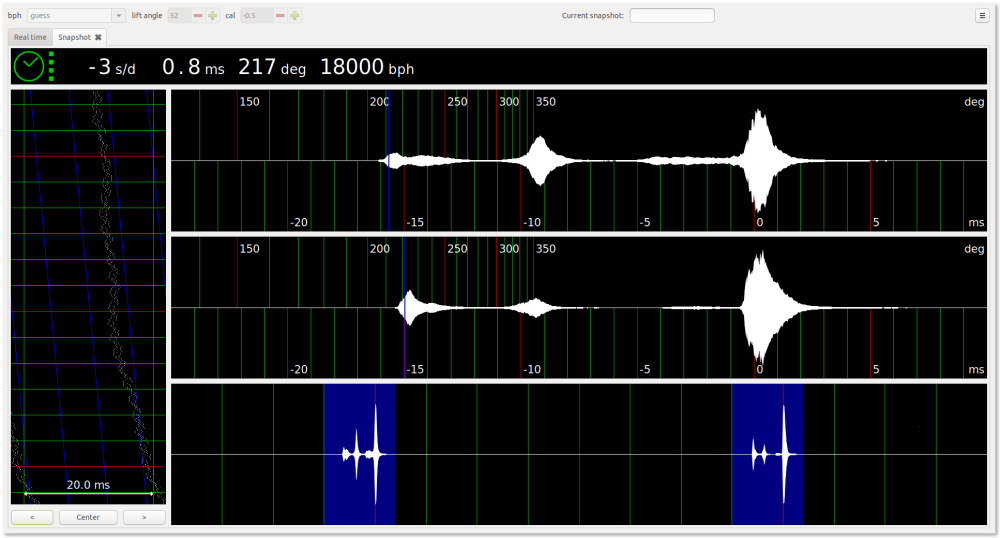

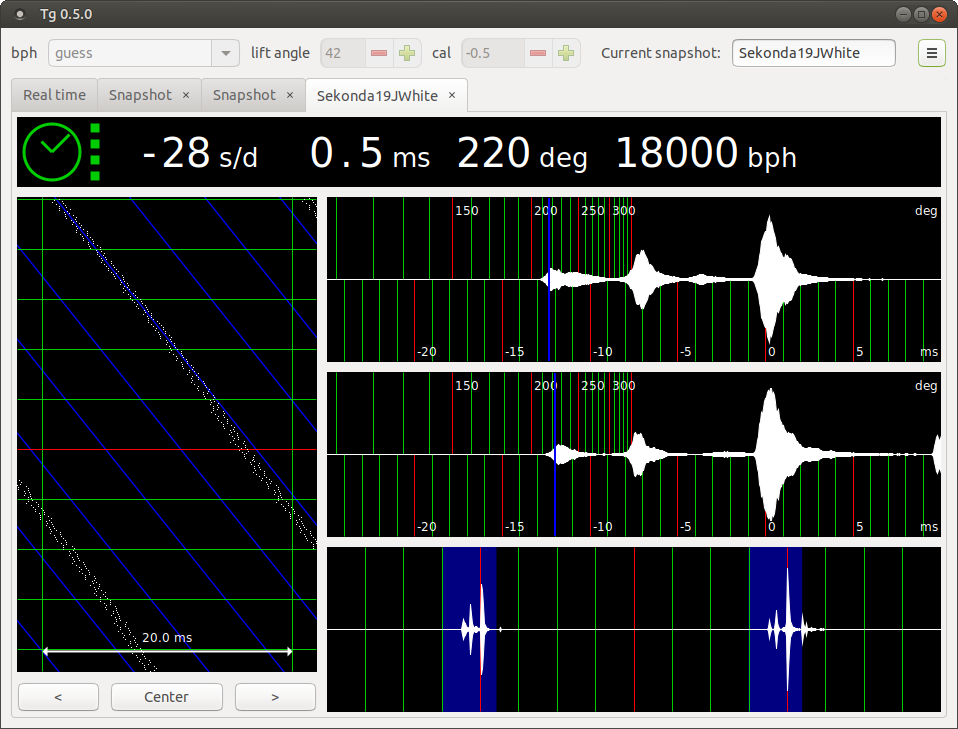

I have "serviced" an alarm clock at my wife's mother's house in India, with oil taken directly from the dipstick of a slightly ancient and battered Hyundia i10. I also posted about this sacrilegious act on this forum at the time. To the best of my knowledge, it is still going strong. Why engine oil? It was a choice between engine sump oil and sewing machine oil, as it was too hot, and I was too lazy to go in to town looking for anything more appropriate. However I also did some experiments with servicing a few of USSR era Sekonda (and a couple of other watches, some HMTs for example) with a rough analog of one of the formulas for watch oil that I found while digging through some articles about what might be in said oil. These watches are still going strong. In fact I think I might grab one and post its health status here soon. See below for an example. The formula I used contains a mix of neetsfoot oil, and unscented, hypoallergenic" baby oil at around 30% to 70%, rather than engine oil. It seems to work remarkably well. I do tend to use "the good stuff" (Bergeon oils) for anything that I feel might not take too kindly to such wild experiments, but USSR era Sekonda watches and HMT Indian ones seem to thrive on anything remotely oily that you throw at them. In fact they seem to survive on zero servicing for many years, often with no noticeable scars as a result. Having said all that, I would highly recommend that you do *not* conduct such experiments with any watch that is high value, or belongs to a paying customer. The manufacturer's oiling charts are a far better guide for longevity than the ramblings of a madman that you happened to read on line. One more thought on the matter. A lot of early watch oils contained fish oils of one variety or another. These do tend to dry out, and leave a sticky residue, so it will be interesting to see if the neetsfoot oil formulation suffers from similar issues. It may take much longer than I am prepared or able to wait, possibly a hundred years or more, before anyone can make any meaningful observations about this though. Why baby oil? "The ingredients in most commercial baby oil products are 98% mineral oil and 2% fragrance", so if you purchase the unscented stuff then it is basically 100% fine mineral oil, and since the formula called for neetsfoot oil and fine mineral oil, this seemed a perfect substitute. Here is one of the victims subjects of this experiment. I've attached the tg-timer trace from January 2020 when it was originally serviced, and a trace I just took a few minutes ago. There is not a huge difference between the two. As you can possibly see from the scratches on the crystal, this watch has been worn quite a lot since I polished the crystal in 2020. The clear, simple, easy to read dial and the gold plated case, coupled with its experimental status make it a bit of a regular on my wrist. The winding is still buttery smooth too. Worth bearing in mind is that this is a 404 club watch, and if it does happen to die from some lubricant related cause, it wont be the end of the world. So far though, (with a sample size of one), the neetsfoot/baby oil experiment seems to be going quite well. Remember children, don't try this at home with daddy's favourite Rolex. EDIT: I think I'm going to have to polish those crystal scratches out now. What is seen, cannot be unseen. So long as you choose a low cost test victim, I can think of no reason not to give it a try. Let me know how the experiment goes. I may even try it myself.1 point

-

I suggest that you watch a few videos on pocket watch repair. We will help you as much as possible though. To remove the dial, look for screws in the side of the movement. I can't see a hairspring, it may of corroded away. I'm not sure the movement can be rescued but you can still practise disassembly and reassembly.1 point

-

Even if a replacement is available it's still a nice feeling to say I did that myself. Well done1 point

-

Yawn, what? Did anybody get it yet? Is it a turret punch press tooling table saw stop? Could go by other names abroad.1 point