Leaderboard

Popular Content

Showing content with the highest reputation on 09/15/23 in Posts

-

I have been keeping my eyes open for a decent looking jacot for a long time but was reluctant to spend what good Steiner go for. This arrived today, German I believe, the makers mark on the box is GJL so a bit of research is in order. The box ends need a liberal application of PVA but apart from that it is all in very good condition, really pleased. Tom4 points

-

3 points

-

I once asked my mentor when do we straighten and when do we repivot? His answer was to try straightening first and if it breaks, then repivot.3 points

-

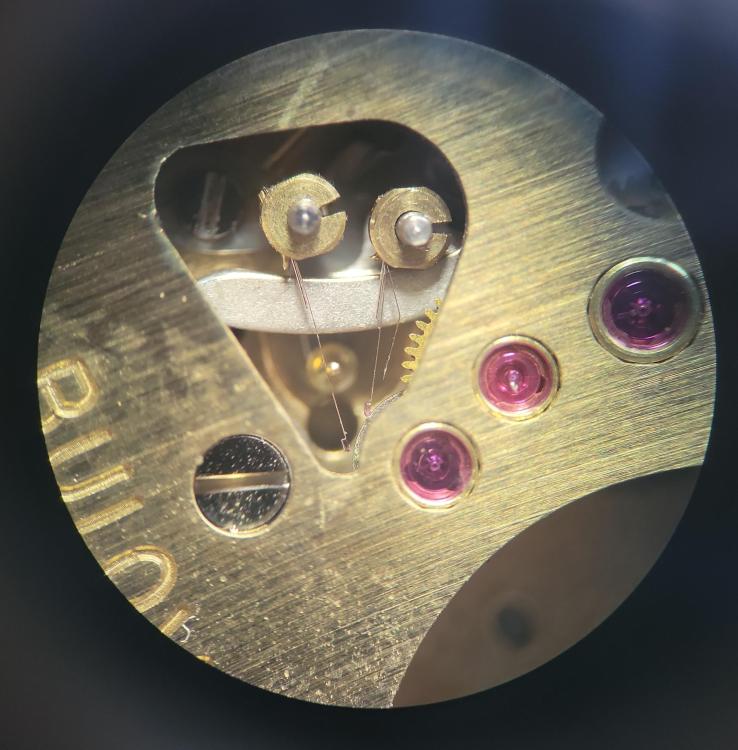

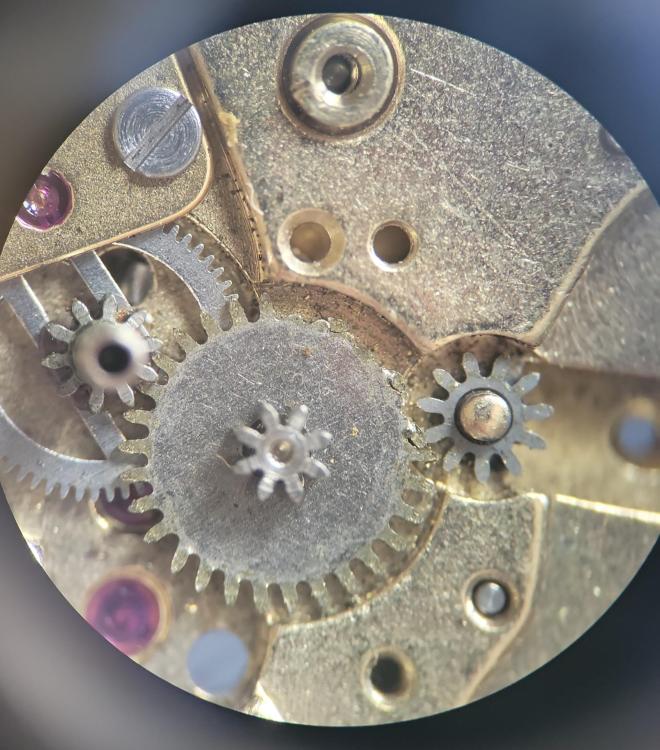

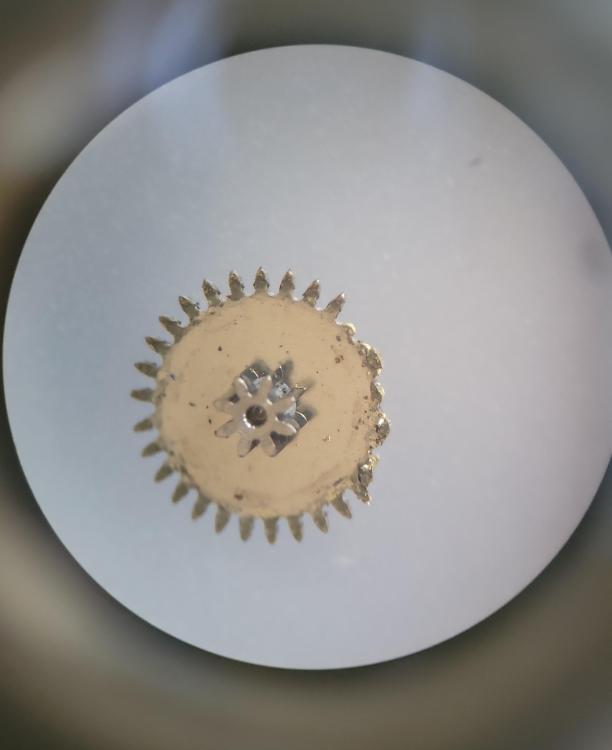

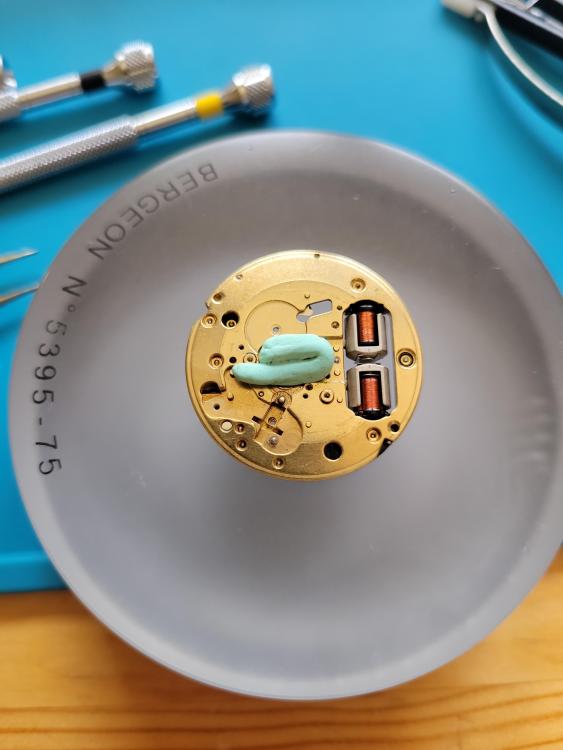

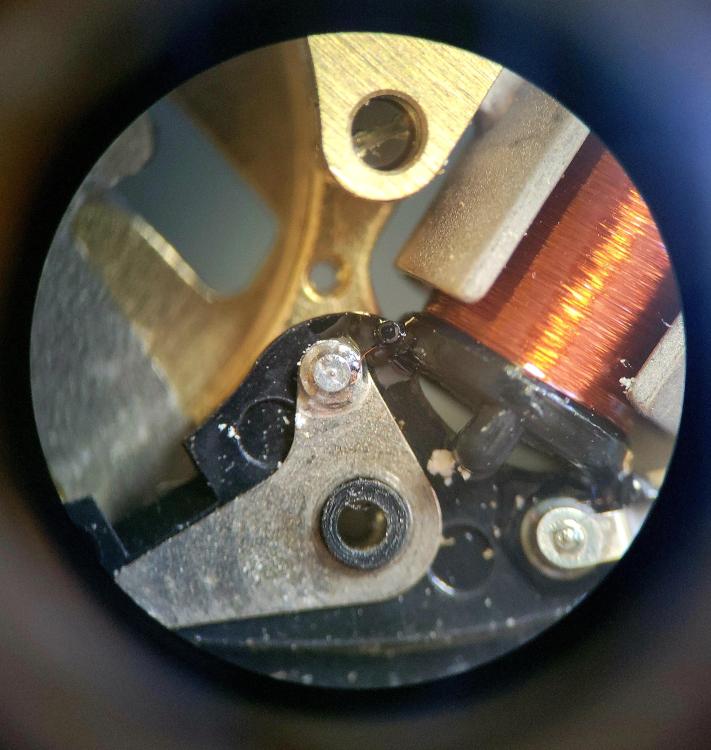

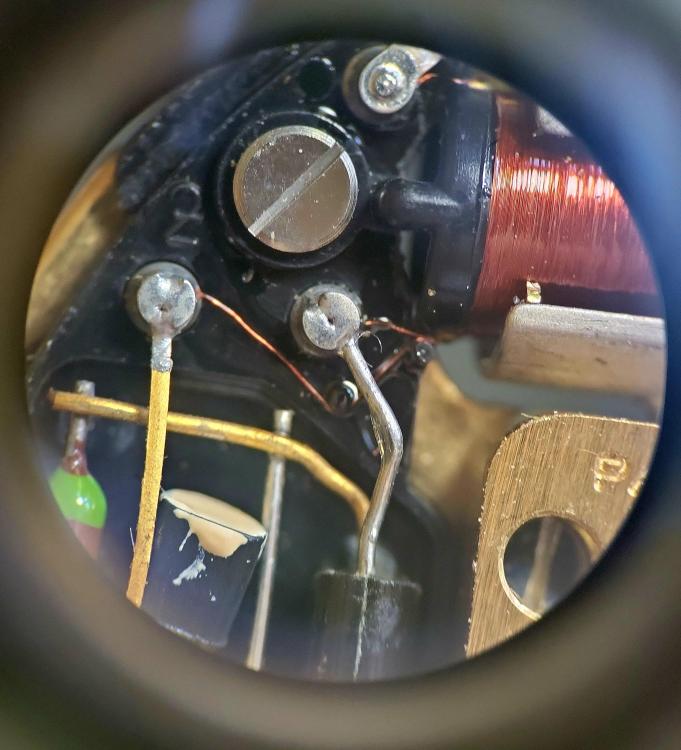

Hi All, I thought I would share where I am up to with my latest project. While doom-scrolling Ebay I came across a soon-to-end auction for tidy looking Bulova Accutron 2181 and chanced a bid. The seller was upfront that the seconds hand turned but the minute and hour hands did not move. I had already read elsewhere that this was a common problem and figured I should be able repair or at least replace the seized parts. This is my first Accutron... The project is a simple stainless steel dress watch with a silver face and simple baton hour markers. Should look nice on a black leather strap. On first inspection after opening the case it is obvious there has been a battery leak. It looks mostly contained to one area and Im hoping it will clean up. I checked the "fingers" and while dirty, they look ok. So far so good! I started by disengaging the fingers from the index wheel - apparently any rough handling during hand removal can cause these to break. Once I had stripped the dial side down I came across the reason why the hands were not moving. Indeed the canon pinion had seized - and properly so! The minute wheel teeth had been striped! After wrestling the centre wheel away from the movement it was clear it had rusted solid and the previous owner had attempted to free it up using force applied to the crown. I used a bit of Rodico to clean up the rust and teeth before proceeding as the forks are magnetised and will attract any ferrous material. Also of note virtually all the components were magnetised to some degree or other so will need to deal with that. A couple of shots showing just how thin the coil wires actually are! I finally made it down to the tuning fork and got stuck trying to remove one of the two screws holing it to the plate. I was putting significantly more force in to turning that screw head than I was comfortable with so decided to place a drop of penetrating oil around the screw in the hopes it will have loosened up by the morning. Now I need to start looking for some replacement parts...... I will update this thread as I progress!2 points

-

What you mean by it's not massive if you read some of the discussions on this group it sounds to me like this would be the first tool you would purchase before your tweezers everybody should have at least a dozen of these what you mean by it's not a massive club?2 points

-

Nice looking tool my friend . Welcome to the jacot club, or the club of jacoters. Its not a massive club but its a club, and you are now one of that club. I will send you a badge that reads ' i have a jacot and i know how to use it '. Wear it with pride, if you get into a fight with someone , flash your badge and use the loud verbal warning " I have a Jacot ", then watch them slowly back away turn and run.2 points

-

Measure the thickness of the mainspring, that's the strength.2 points

-

Wow thats some history Dick, your knowledge of watchmaking must be vast. You will have no brains left by the time we have finished picking them2 points

-

I can’t recall where I saw or the precise turn of phrase, something about the watchmaker must decide if they are the type to break their pivots efficiently and economically with tweezers or if they prefer the expense and precision of breaking them slowly with the Seitz tool…2 points

-

I thought i'd report back on my progress. The naptha did little to nothing to remove the polywatch or the haze. I spent over an hour wet sanding from 800 grit to 2k and then to 4k, as that is the finest paper i have. the results down to 2k are in the attached pic; the 4k made only a slight improvement. I have other liquid pastes and lotions to perhaps make some improvement, but given my experience with the poly i'm a bit hesitant to try them. When laid on the watch i can actually see the dial fairly well, not perfectly clear of course. The watch isn't worth much so i'm not sure i want to try and scrounge up another crystal, but we'll see. The lesson i learned is to not use polywatch on vintage crystals unless you are somehow positive that it's not celluloid. hopefully this helps someone. Arron.2 points

-

2 points

-

Oh man, those poor teeth! I just finished repairing two, 219s and am going to embark on a 218 next. The screws for the fork were surprisingly tight on both of mine as well. Expect the fork to be extremely tight on the studs once you get those screws off, as well. If you don't know, the docs say not to pry on the fork to lift it up, but to push it up from the bottom using the hole in the main plate. I put a bracelet pin tool in the hole and gently tap it to release the fork. Have you read about phasing the watch to run on silver oxide cells, or are you planning to use the Accucell?2 points

-

Crystal polished, glued in, and trying on new bands from Esslinger. I went with the first one, and not just because I put it on backwards in the second picture... It really is such a handsome watch, and I'm so proud of this one. If anyone has a favorite site or style I should know about, I'm open to suggestions!2 points

-

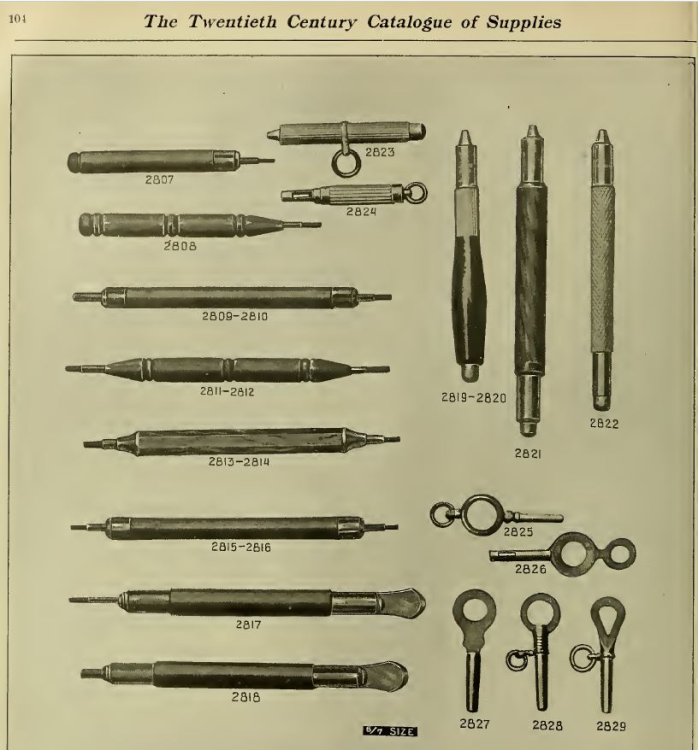

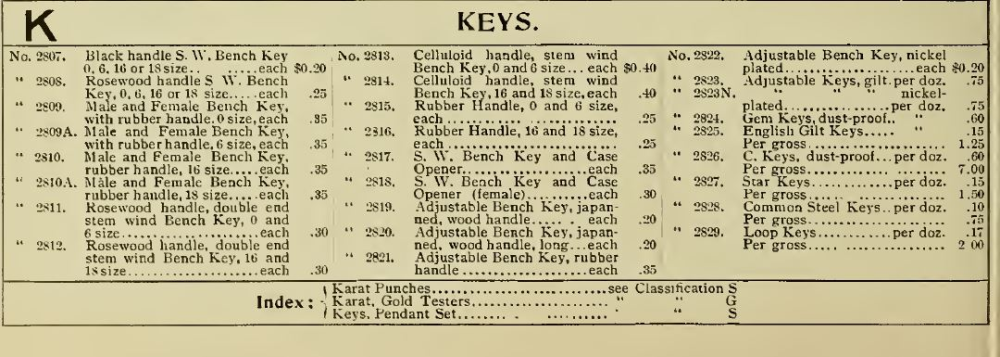

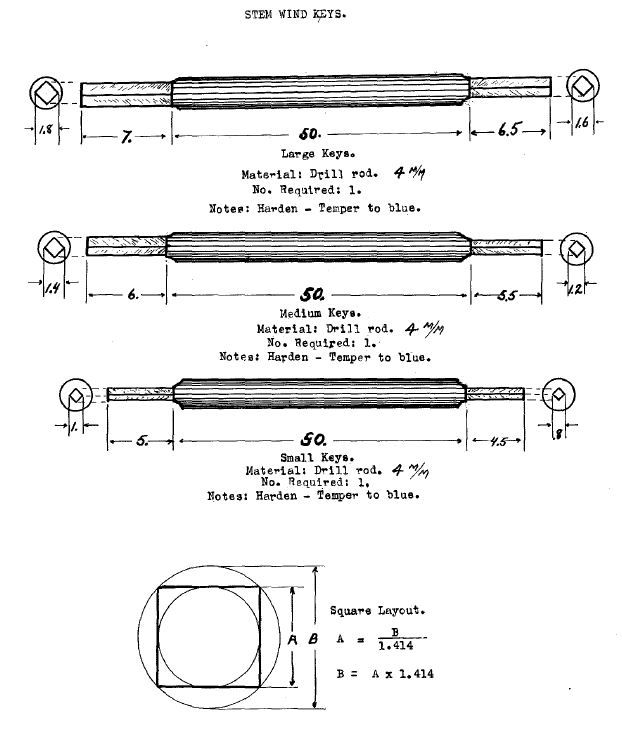

While the work on wristwatches it can become problematic on pocket watches as there's way more power on the mainspring. A better approach would be to use of bench key inserted into the side of the watch. American pocket watches out of the case typically require a set of bench keys rather expensive if you can find one on eBay or technically the set of three. In a case you insert your bench key wind just a tiny bit to release the quick and hold the click back and gently let the bench key spin in your hand. But yes it's definitely good to let the power off to avoid unpleasant things as you found it. Then the give you a clue what bench key is look like as they could easily appear in a box of miscellaneous tools as people might not know what they are. Typically of a set of three which would correspond all the sizes of an American pocket watch Here's a page of vintage catalog including the other universal keys for key wind watches where you can push the button on and an open up and go over a square Unfortunately the above prices are no longer in effect and if anyone knows what the bench keys are on eBay well if anyone knows what a the tools on eBay they tend up the price by quite a bit Then if you're going to Elgin watchmaking college they had a lathe project2 points

-

2 points

-

It looks like those are all broken which would mean there was a watchmaker that was a hoarder It is most definitely not normal…1 point

-

When I was in my first school learning watch repair the instructor at all sorts of interesting sayings and things he would say. Like is the glass half full or is the glass half empty. He would point out that students or in this case newbies on the message board always look at the watch as it can be repaired it can be restored. Or basically is this a watch that can be restored is this a full glass or is this half a glass of parts for a future project or for some other repair. The unfortunate reality especially with vintage like this is not everything can be repaired and restored. So if you accept that this is a fun project to learn techniques on and you don't care that it's never going to run and it is never to run probably then continue otherwise find a project that's going to be more rewarding. Yes all of us find it rewarding when the watch springs to life and preferably keeps running for more than a few minutes.1 point

-

Good morning: My name is Dick Hostetler, and I've been a watchmaker for 55 years. In the 60's I went to Bowman's Technical School, in Lancaster Pa and then worked with my father Jack (a certified master watchmaker) until his retirement. I then continued our store and have been working at the same bench for over 53 years.1 point

-

I'm not being rude here. Because it is in such a mess such as the hairspring missing its full of rust and the train is not jeweled so there is every chance some of the pivots could be rusted in the pivot holes. I would ditch it and look for something better.1 point

-

The hole end is the "H" type on the Cas Ker web page, and the other end is the regular Swiss tongue end.1 point

-

1 point

-

Watches? Hang on a minute, I thought this was the internet offshoot of tools anonymous! Tom1 point

-

Haha Jules. We are all very sorry, we should have warned you. The tools, the watches , more of the tools and more of the watches. No matter how old you are or how long you stick with it, we are all in this together to support each other,comfort each other when we buy poorly , hold each others hand when things get tough, advise and pat on the back when we do good. Oh and to help spend each others hard earned dosh , that is what we are actually here for, the rest of it was just complete bullshit1 point

-

Hi and welcome to the forum….. I in its present state (cased up) you will not be able to see anything so do not go cranking the hands round as it will lead to breakages. First remove the hands and then the movement and have a look at the complete thing. Check that nothing has dropped causing a jam. A wheel / lever might be out of place by not being clipped or pinned properly.. also post pictures of the front/rear and from the sides they help a lot in diagnosis.1 point

-

That's not a cheap book Jules, well done with the staking set, you are certainly on a roll with the tool collecting.1 point

-

1 point

-

1 point

-

I asked that same question 30 years ago. The bodgers of old were highly skilled chair makers. The story goes that a group entered the woods with the view of spending days there making their furniture from the trees. Each man had his own skill and made a seperate part of the chair, a seat, spindles for the back and legs, a spindle bender, an assembler, maybe a carver. No one man completed the chair, hence a bodger doesn't complete the work .1 point

-

1 point

-

Make sure your driver is a really good fit on the screw. I've had a driver slip more than once on a fully tensioned movement, its not a good outcome. I make a point now of using the crown between my fingers or a crown winder to power down.1 point

-

1 point

-

Easy peasie UFO section commander's, Earth Pivot Settlement attachment for robust insertion.1 point

-

Is anything in watchmaking ever easy? So, I need to add metallurgy to metrology, stereotactic brain surgery and an ability to cuss fluently in half a dozen languages. I'm truly doomed.1 point