Leaderboard

Popular Content

Showing content with the highest reputation on 09/16/23 in all areas

-

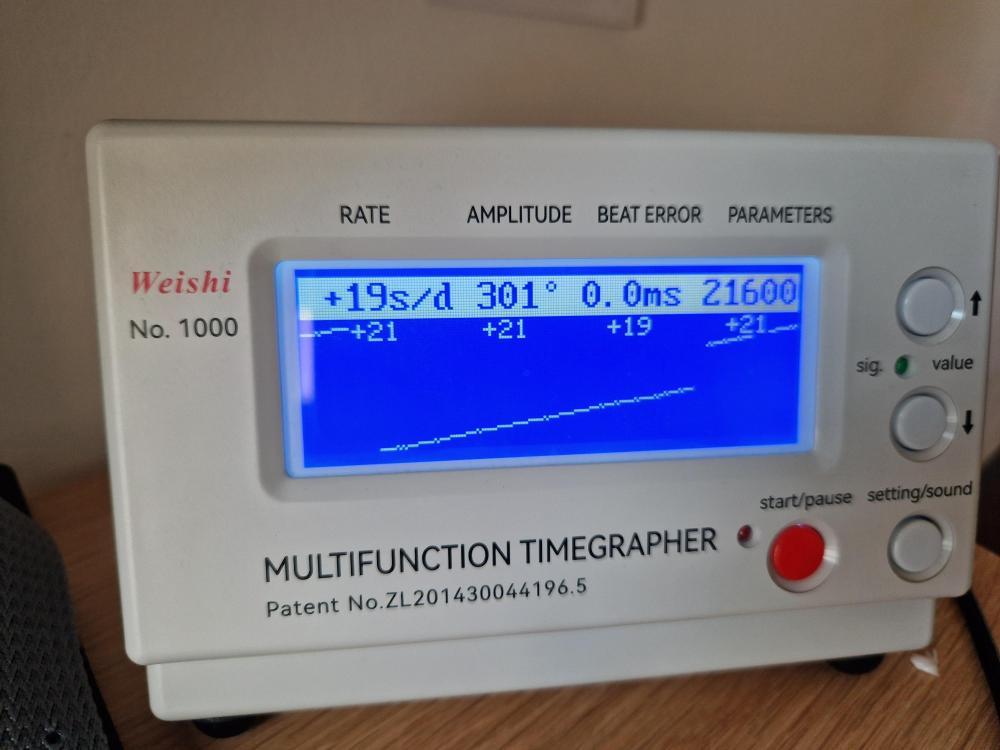

Well, getting the original Seiko mainspring made things easy. It just fits with the right inner coil for the arbor. Seiko part 401.113. I have to boast a bit on this occasion... I achieved oiling perfection on the pallet stone lubrication. Note that this movement is 13x15mm small and that the parts are absolutely tiny. I oiled it last night by pure feel (I don't have a microscope). Checked today and I'd say that the oil contact area is spot on. No? The timegrapher trace is also spotless. Before: After:2 points

-

2 points

-

I always advise those just starting out to practice on pocket watch movements because they are the same as a bog standard watch movement only bigger. But this movement is really pushing the boat out. Our friend could learn a lot more with a better movement, this thing doesn't have a hairspring so he has no chance of removing it from the balance cock and putting it back, which is a very important thing in watch making.2 points

-

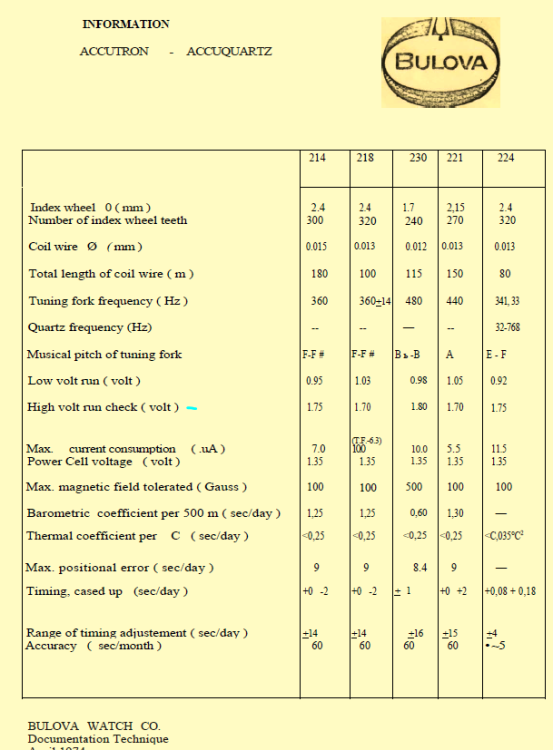

The classic problem of the center wheel assembly has rusted itself to the post. Then a minute and hour hand no longer turn the secondhand churns the friction part of the center wheel assembly is totally destroyed. Occasionally can flip the wheel over and buy yourself a little time but typically you'll have to replace the wheel. Then if you have really enthusiastic user you'll end up with a minute wheel stripped also. I would recommend not following the lubrication specification of whatever they say for the center wheel to avoid this ever happening again. I really wouldn't worry about the magnetized components unless you get rid of the magnets on the tuning fork. Basically magnets on the fork everything else is going to have a problem with magnetism typically is not going to bother anything at all unless of course you have steel tweezers. Oh and when you finally get the screws off and remove the fork be very careful because typically underneath our spacing washers. The color-coded to refer to their thickness. But I find it's usually best to just put the screws back in once you've lifted the fork out of the way that way you don't have to worry about which washer is where and basically is random whatever you going to find. The purpose is to tilt the fork so it agrees with the circuit. In watch repair yes you're supposed to pay attention but this is example of where you really have to pay attention otherwise well at least the fingers can be replaced. So they have to be at least one of them rotated out of the way to get the fork out. Then typically I rotated back and after the wheels are out I put the bridge back on to protect the finger when it's in the cleaning machine. Then when you're putting it all back together of course you remember to rotated out of the way and put it back etc. oh and remember to rotate it back before you put the screws in for the tuning fork because typically it sticks up too high and he can't get it past the screw head. So basically there's a lot of rotating that finger around to do things and it has to be in the right place or else, did I mention they can be replaced? Phasing on silver cells is interesting. Then yes you really should have a variable voltage power supply but there is something amusing about all of this. For instance is a technical specification for their watches and notice I marked something? As we know running on a silver cell has too much voltage out of the package brand-new without a load you can get almost 1.6 V and they are originally designed for Mercury batteries so obviously that is way out of specifications but if that is true why on the technical sheet is there the high-voltage run check? Which by the way is not mentioned in the service manual because normal service manual relies on using the normal meter and your source of power would've been the Mercury battery which cannot get to the voltages listed here One of the amusements and watch repair is service manual versus the factory? Or sometimes service manual versus other technical documentation that you typically don't have. In one of the other discussion groups is somebody who worked at the factory and she had pointed out that they use a variable voltage power supply and they did test the watch at a higher voltage. Then I'm attaching a PDF an interesting article about the problems of silver cells. 1996-08-web horological times Accutron silver cells phasing.pdf2 points

-

But is there a residue? Watch cleaning is all about being clean. No residue. Because whatever residue remains could react with the microscope amount of lubricant and cause it to spread or other bad stuff. Old high performance watch cleaning machines used 2 rinses to get the cleaning solution off; then 3 became the norm. Now, new gen machines have 4. I remember watching my mom or dad wipe down the counter with a soapy sponge, and be happy it was clean. My little brain was saying "but, there's still soap there!". Maybe that set me on the path of watchmaking. Rinse rinse rinse (and if you want a watch parts account rinse again.... in isopropyl alcohol!!)1 point

-

Would you like to elaborate? In other words service them for money service them for fun give them to you? The reason I ask is the outcome varies because we can't See in the case as others have indicated. So for instance if they're being given to you don't worry about it. If you're servicing them for the fun of its where I'll that's problematic and if you're doing this as a moneymaking venture well that becomes even worse because there a black box we can't see what's inside there and they can very very very dramatically from something that can be serviced to absolute positively never be serviced. But if there a gift by all means take them watchmakers always take stuff it's how we accumulate all the stuff we have. Well at least is one of the ways to accumulate stuff.1 point

-

Thats damned impressive. I'm still struggling with more "normal" sized pallet stones!1 point

-

The Ebel has something extra about it with the Merc hour hand. Rarity is always nice the Reconvilier, but most are quite small and i have stupidly large hands for a 5' 9" bloke the Rotary is the largest.1 point

-

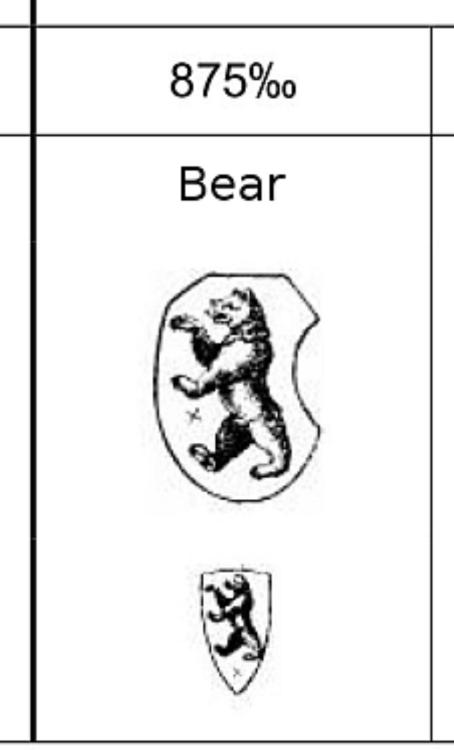

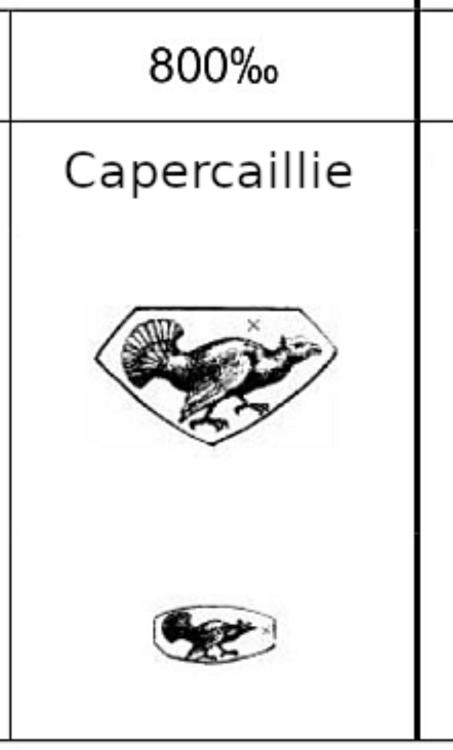

Looks more like a big cat to me.1 point

-

1 point

-

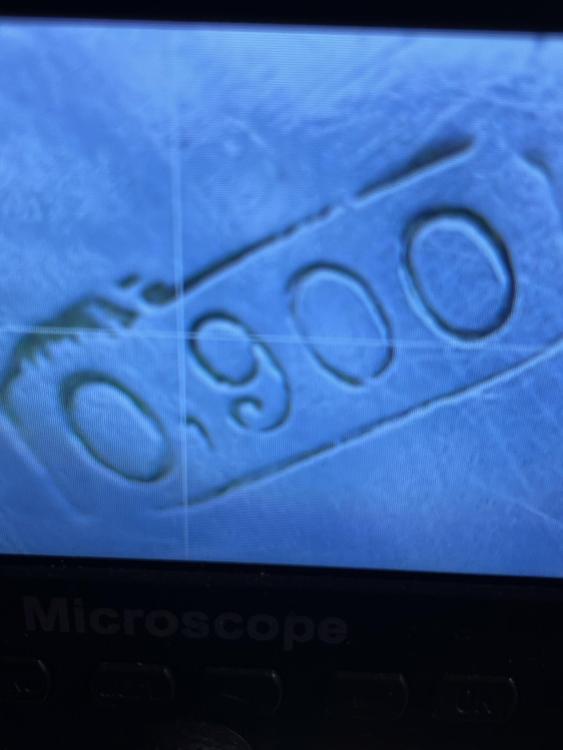

Lol, i bow to rehajm, my eyesight ain't what it used to be. The bear was the Swiss hallmark for above 80 % silver. Tbh i didn't know there was 90 % i thought the finer grade was above 0.900 hence my mistake for 0.800. The bear was later changed for a duck, go figure that one lol.1 point

-

Another 404 club watch. Looks like maybe a paper dial, and almost certainly a low grade movement, but at 0.99p it should provide a little low cost fun. If you look closely at the second hand, it is actually snagged on the minute hand. I doubt if that is the only issue with it, but you never know. The two have been like that for a long time judging by the corrosion. I'm intrigued to know exactly what is inside it and where it was made.1 point

-

I'll put it under the microscope and put this to bed! Thanks for all your input, my lathe skills and tools are going to be pushed to the limit, may have to fabricate the bezel - all good fun... So the microscope shows the pictures below. Looks like rehajm wins the salt and vinegar crisps for the day it seems to be the bear he showed above and it is 0,900 silver. So rehajm who used this bear mark that you cleverly identified for me? More goodies for more info Under the microscope it is maybe a horse and a dragon If I still had my bigger lathe I could probably do it, maybe I can borrow a couple of hours of use somewhere - keep you posted After further review I think it's a horse and dragon, some spears and then some roses underneath, you might be right a mythical design, maybe George and the Dragon, who knows. Anyway we have the bear symbol and I'll try to get some lathe time on a larger lathe to make a bezel then once that's all done I can source a glass - quite the project, looking forward to it1 point

-

1 point

-

If it was english there would be assay marks usually 4 or 5. Swiss or swiss imported maybe, 0.800 purity swiss silver has a walking grouse, could the small stamp be that ?1 point

-

I think it's a horse, I've not seen it before, might be a bull! I'll put it under my microscope and resend a photo. I've plenty with the Moon and Crown which I believe was for exportation to Germany, but this is a first for me. It'll be fun trying to get poach or make a bezel, sourcing the glass after might be the easy part!! As a child of the 60's and rock festival goer of the 70's I have to agree! Seen plenty of great bands live back then and some later; Led Zeppelin, Deep Purple, Alice Cooper, Kiss, Motorhead, Aerosmith all the way through to Status Quo to name a few, and even went to one of the early Sex Pistols shows in Gt. Yarmouth in the late 70's. Sorry I digress from watches yet again...1 point

-

Yes the treasure hunt all the interesting things that can sometimes be found in miscellaneous stuff. This is why for those lucky enough to have Watch and/or clock shows where they sell stuff or car boot sales or whatever. Always important to go through all the boxes look at everything a lot of times interesting stuff could be basically found in the miscellaneous nobody cares category you just have to take the time to look and be lucky.1 point

-

This is absolutely true John, i have never had so much fun sorting through balance staffs and watch stems ( yes very sad i know but we all have our strange ways ) i think of it like treasure hunting, ohhh a Longines, ohh wow an Omega , yey an Elgin, woohoo a Blancpain !!1 point

-

Not necessarily. Too many variables really. Plus it depends upon how much money was spent versus buying something else. For instance if you don't have a watchmaker's lathe then Then they become less valuable. We really need a better assessments in the meantime it has value for entertainment purposes as to us pondering why it exists at all and I would say that has to be the most balance staffs I've ever seen in one place.1 point

-

If you want to see worthless Rich , I'll send you a picture of a balance staff next time i try to repivot one1 point

-

1 point

-

The verbiage is referring to the number of jewels and the straight line configuration of the lever escapement, which was likely notable new tech when it was made… That crest is amazing- sorry, it looks like a 70s euro metal band album cover or something.1 point

-

Measure the inside lip of the bezel and we will tell you what size to order. PS. It's a pin set movement.1 point

-

1 point

-

It looks like those are all broken which would mean there was a watchmaker that was a hoarder It is most definitely not normal…1 point

-

They've updated the tool and of course it's price that is if you're purchasing it new which I would not recommend. There are so many other tools that would be more essential that have. I'm attaching the PDF of how the tool is supposed to function. 7135 7136 tool for straightening bent pivots.pdf1 point

-

Try this link instead. I've only done the 219 phasing so far, which is a little simpler, but it's fairly straightforward if you have a variable power supply. There's no way to disassemble the movement without rotating the pawl finger out of the way. In fact, I usually rotate the fingers so they're more protected by the parts they're attached to, so I'm slightly less likely to bend the crap out of them. I put the index finger in line with the fork arm, and the pawl finger turned in over the bridge.1 point

-

What condition is the dial in? If beyond hope, drop the whole thing in CocaCoal, in 48hrs you find all screws can be removed with ease. Your likely to break some screws, if you were to start without a good soak. Hairsprings should not be soaked in CocaCola.1 point

-

1 point

-

This is a great discussion, thinking about it, there are so many variables in what makes a 'good' oil it's almost impossible to make an informed judgement just looking at the technical data (of which we are starved). In the absence of such data I suppose all we can do is experiment. However, in my years of working in the oil industry (drilling for it not refining it) I have seen soooo many flawed experiments where the 'results' do not answer the question. So I purpose the following (and invite suggestions/improvements) for my experiment: 1) I purchase 6 new Seiko NH35 movements at the same time from the same supplier and, therefore, (hopefully) the same manufacturing batch - new movements will remove any doubts about previous wear and tare on the movements skewing the results. Using 3 in each batch will reduce the chances of a fluke result from a random bad movement. Using 2 you wouldn't know which is real and which is the fluke, but with 3 you can spot the fluke. 2) Strip all 6 down 3) Clean all 6 movements using the same method/process 4) Lubricate 3 of the 6 movements using 9010 and HP1300 and reassemble 5) Lubricate the remaining 3 movements using fully synthetic 5W-20 (see below) and HP1300 and reassemble Note, any errors in reassembly will be systematic errors and therefore should not change the results. 6) Take TG readings of all 6 movements in all positions 7) place all 6 movements on a auto winder and run 24 x 7 repeat step 6 every month for a period of 1 year - looks like I'll need a new winder too for my other watch work ha ha 8 ) Rrview the results to see if there is any significant difference in each type of oil. One caveat, if I get a failure in the first week after reassembly I would like the opportunity to strip, lube and rebuild the movement, as this is almost certainly an error in the reassembly(er) and not the lubricant and therefore shouldn't unduly influence the results. My weapon of choice: Let me know what you think of my proposed experiment method, and/or you want to join in and pool data/results.1 point

-

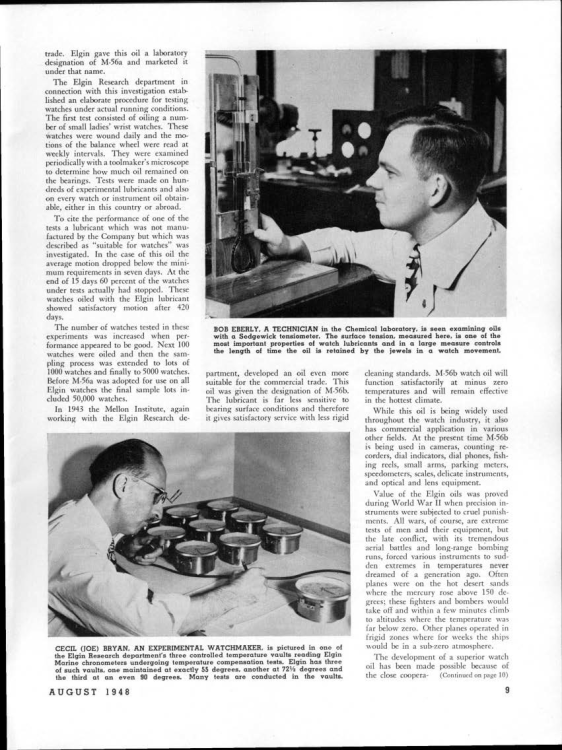

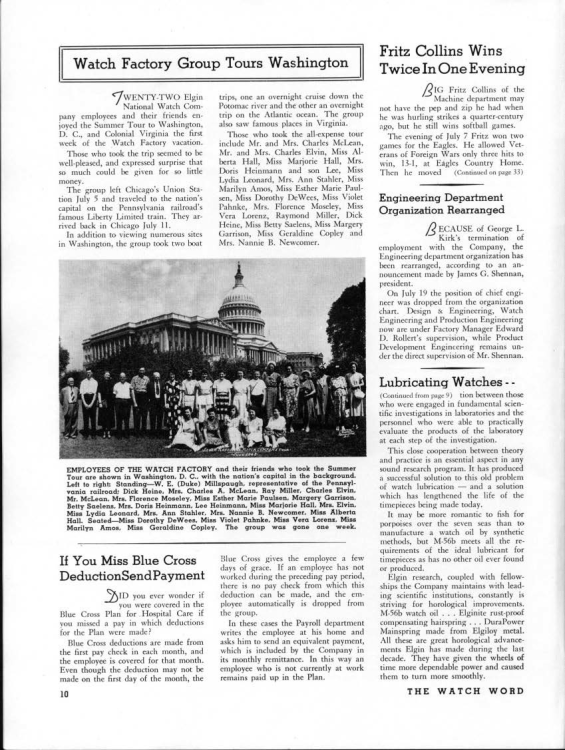

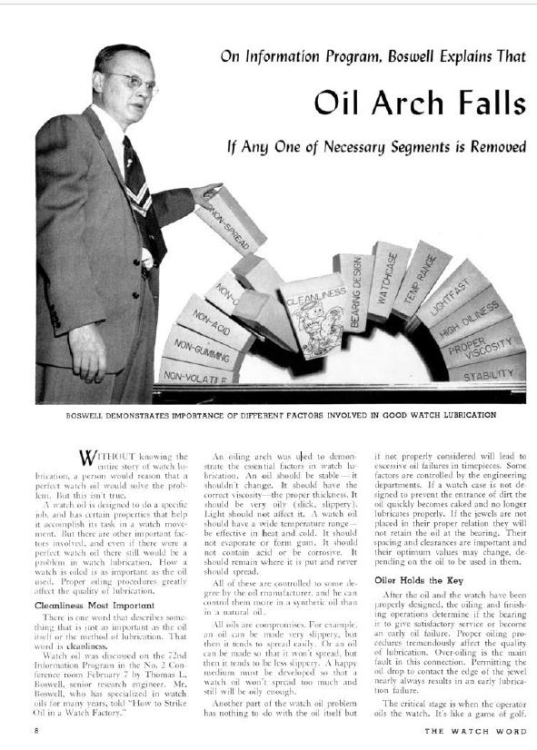

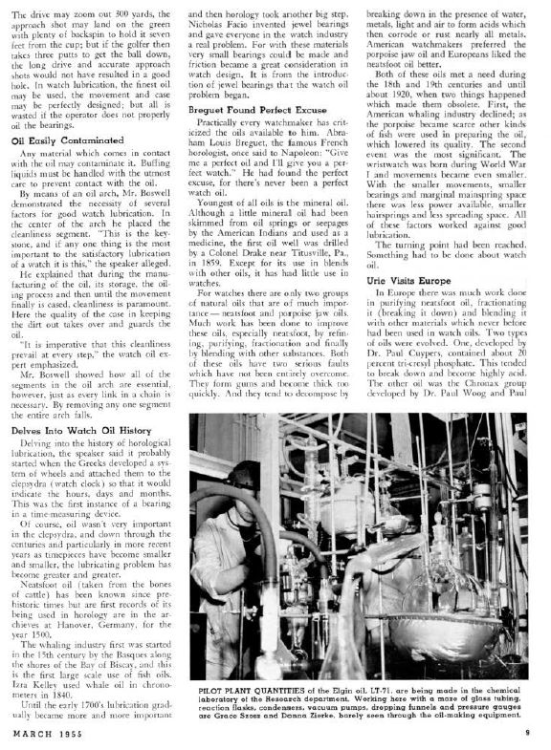

The annoying thing with contact angle is it's not really the angle lets the problem. In the old days the Swiss used to put a technical sheet in their little tiny can that has their little tiny bottle of oil so somewhere I have a tech sheet on 9010 and another one on 9020 and in that literature it had the contact angle. For which I find fascinating because 9010 has a habit of spreading without epilam so every single reference we have the 9010 basically says use epilam or it will spread. But the 90 20th from my own experience does not spread seems the last forever it is absolute perfect and that wasn't a big difference in contact angle but there was a difference but who knows where I put the technical sheets because for one thing in order to fold up into something that tiny is printed on really thin paper so I put it someplace safe and in a house safe things go Fortunately it looks like the title were discussing horological oil and I believe somebody asked her made a reference to what is horological oil so I have some images. For instance here's one it looks promising unfortunately it doesn't have a date now thanks to the Swiss we have to be concerned about the data the oil This one looks promising although I prefer the second version at least it's priced right Other advertisements Now the next one is interesting because people have questions like what makes a good lubrication for horology. Tells us a little about the different types of oils of why some were good some more bad. Although the definition a good is interesting in that organic oils tend to lubricate better than synthetic except that in life is not there. Then we get a nice list of all the properties were supposed to have minus other stuff that would be interesting. The Elgin watch company produced a magazine for their employees. In the old days companies might have a newspaper for the employees the day whatever it is would be all online but Elgin had a magazine with Elgin related stories in all sorts of other interesting stuff. Here's one on lubrication 1948 1955 article A little hard to read unfortunately but still interesting and it makes a reference to another Elgin oil that you've never seen something for the military.1 point

-

Without seeing the movements, I think it's impossible. The top one looks key wound and set. The middle one is pin set and the bottom is key wound but not sure about setting.1 point

-

Sometimes you need specialized tools to get the crystal off. Watch Front Cover Glass Opener Flat Glass /Arch Glass Remover Screw Tool Watch Part Repair Tool Accessory for Watchmaker https://a.aliexpress.com/_mrbeKIw This is a relatively new tool designed to pull the glass off from the front with double sided tape. I haven't used it personally but it was developed by my mentor's think tank group from China. He has been using it for a few years. Other times, you do this...1 point

-

I think you will have to put your lathe skills to the test and make a bezel.0 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)