Leaderboard

Popular Content

Showing content with the highest reputation on 09/17/23 in all areas

-

The two jewel ISA 1198 based " Montine of Switzerland" "Swiss Quartz" arrived, and It looks completely unworn. However the original battery had destroyed the lower battery contact. Bizarrely it hadn't corroded, in a conventional manner, but rather it had split into a number of thin strips. I fabricated a replacement (from a 10K ohm resistor leg, flattened in the vice), and now it is running perfectly.5 points

-

2 points

-

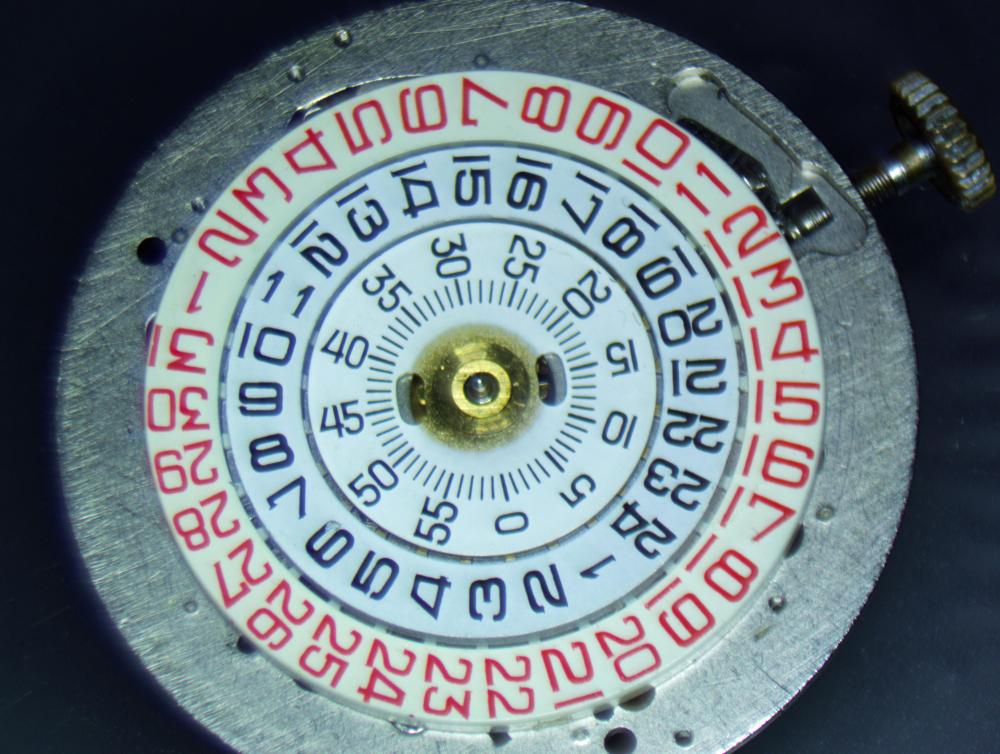

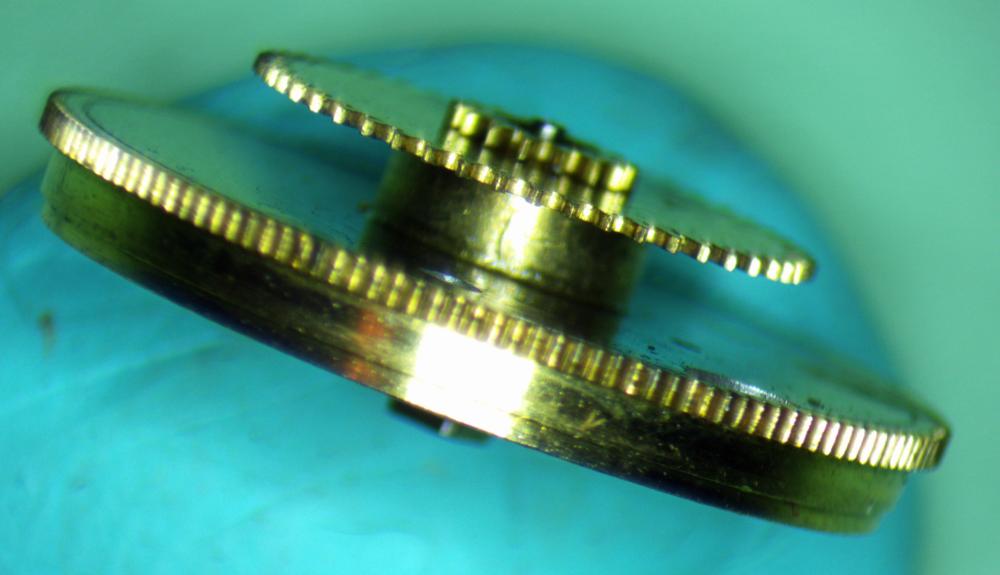

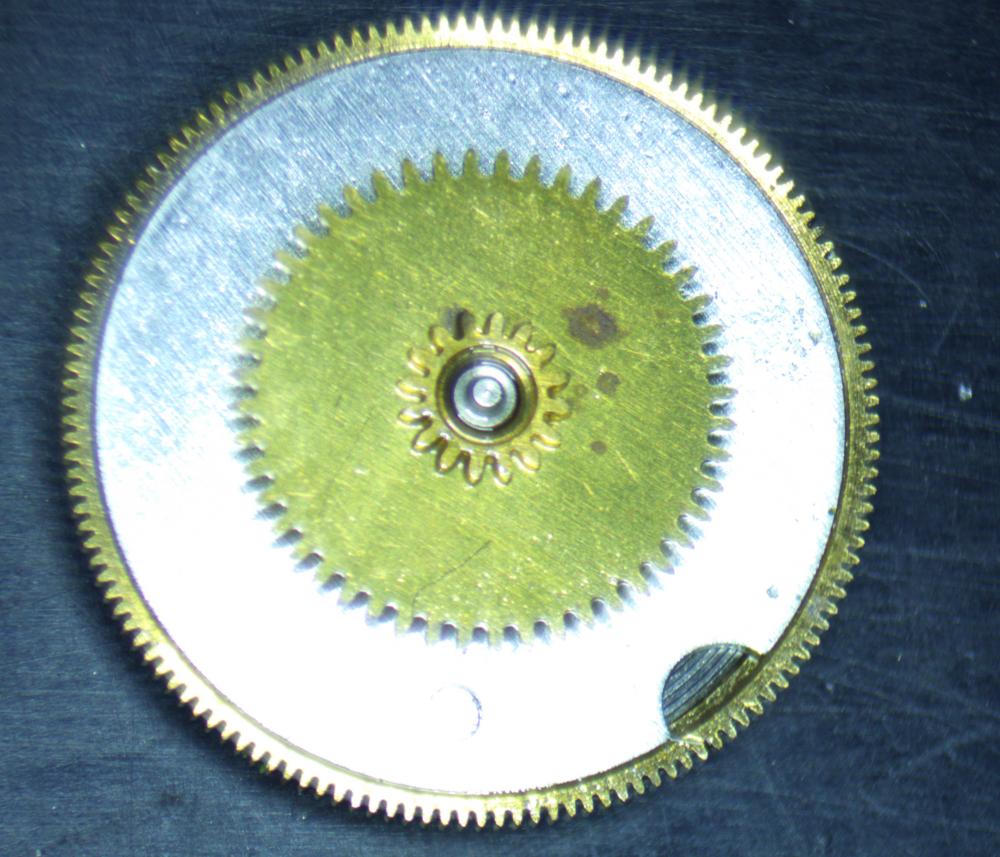

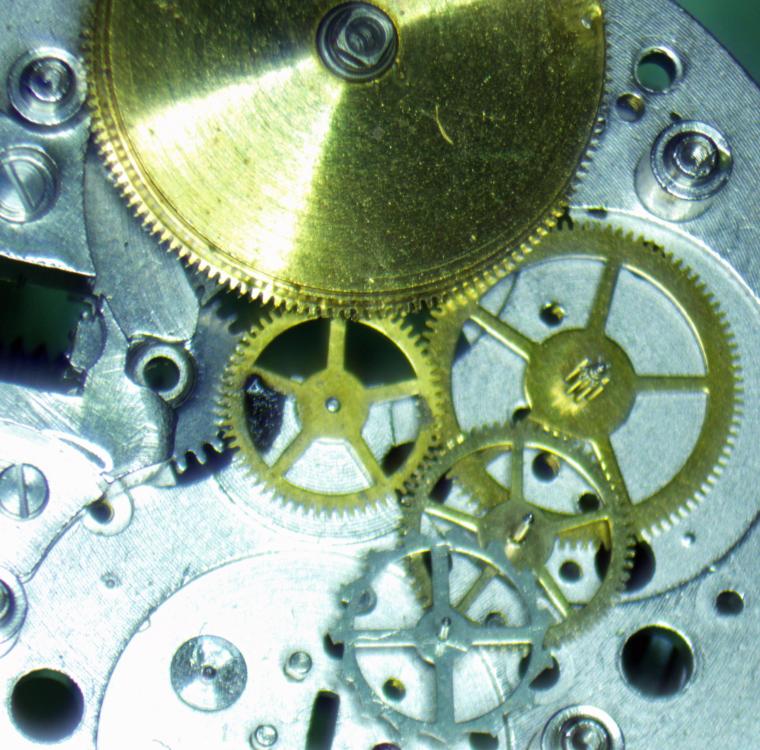

I love jump hour watches, and I couldn't resist this black and white Oberon. Overpaid for it a few months ago as "needs repair," I'm finally tearing into it now. It looks like the previous owner did the old "soak it in oil to make it run" trick, but it was definitely not running. Came to me fully wound. The balance seemed free, but wouldn't oscillate, so I set about disassembly. Everything, including the dial, date, minute, and second rings are completely soaked in oil. The main plate is marked BF 866, which looks like Baumgartner's mark. Now I just have to figure out how to get the barrel open. Well, there's your problem. I don't know what that black crud is, but it was definitely gumming up the works.1 point

-

1 point

-

1 point

-

1 point

-

Hello everyone, I'm sharing my latest project, the servicing of an OISA watch by Domenico Morezzi, a watchmaker active from the 1930s to the late 1960s. I hope you enjoy it.1 point

-

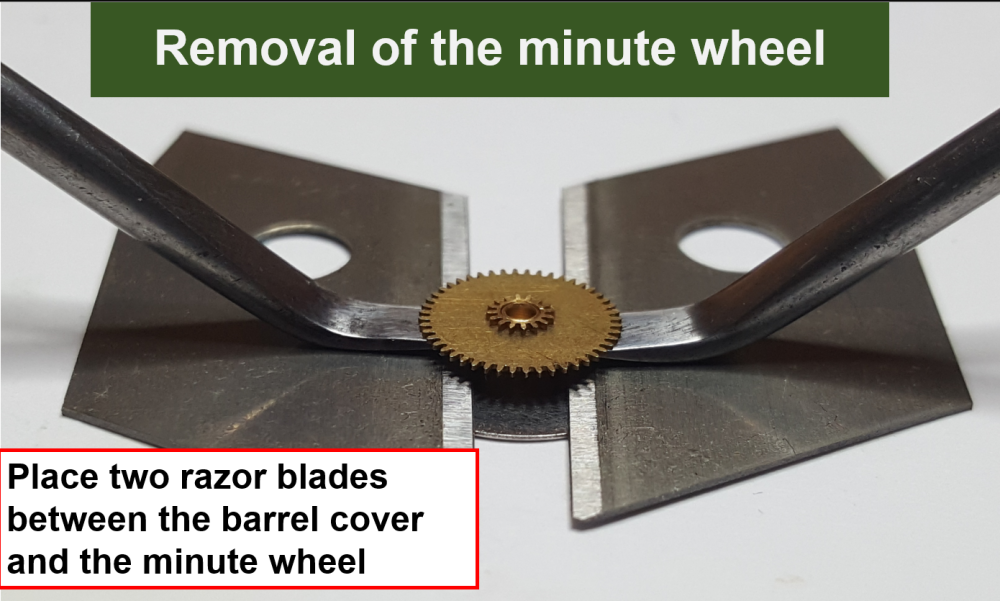

Thanks for these. I was able to get the center seconds wheel off with the Presto tool I bought for Bulova sweep seconds hand wheels. Finally came in handy again! But for the life of me I can't get the minute wheel off the lid of the barrel. Even with my largest hand levers and carefully prying only at the center, I can see the wheel flexing as I apply leverage. Any other techniques besides the one shown here?1 point

-

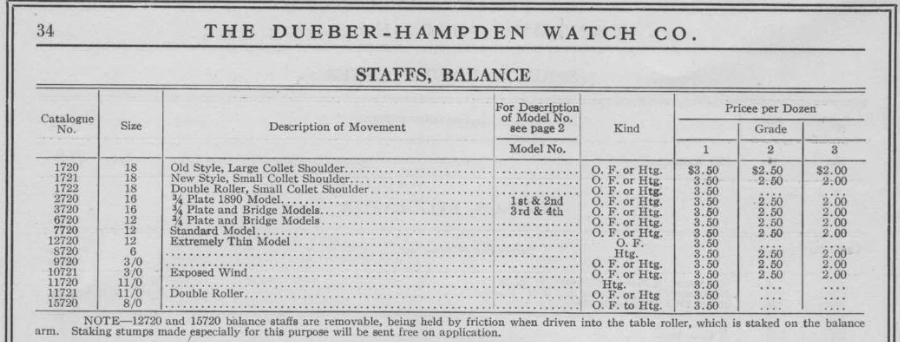

I was doing a search in another discussion group to see if I can get any staff information I found this The 2720 (old number 159) is 5.60 mm long. The balance seat is 1.27, hairspring seat 0.76 and the roller seat is 0.68-0.71 in diameter near the hub. The hub is 0.65 mm long The 3720 (old number 627) came in two styles. Style 1 is 5.13-5.15 mm long. The balance seat is 1.27, hairspring seat 0.75 and the roller seat is 0.71 in diameter. The hub is 0.52 mm long The 3720 style 2 is 5.51 mm long. The hub is 0.55 mm long. The other measurements are the same. There was yet another 16 size staff, the old number 158. It is 5.75 mm long. The balance seat is 1.30, hairspring seat 0.82 and roller seat 0.72 mm. The hub is 0.75 mm long. This by the way is the classic problem of American pocket watches variations in parts. Plus variation with the same part numbers. Oh and once I realize there was a material book found one of the pocket watch database. The problem with a lot of reference books like we can see here is they're basically worthless for details. Some companies did a much much better job like Elgin describes all of their variations here not very helpful at all1 point

-

You get to the mainspring just the way it looks- silver lid and wheel up, push down on the edge of the barrel. The big thing here is there will be dried up lubrication in the lid. The link to Jon’s lessons below has what you need to know. I’ve done a bunch of these and if the pivot holes are good (or you get them there) they can run quite well. I followed all of Jon’s Roskopf series.. There’s one more tip that made a bjg difference for me - Ranfft once recommended to use Dr Tillwich blue oil for the pins. A couple drops on the top of the pins and let it run down. Don’t oil the escape wheel teeth. It was good for at least an extra 20 degrees of amplitude vs the recommendation of 9010 or whatever you use on pallet jewels applied directly to the escape wheel teeth…1 point

-

When it come to replacing clock springs measure in side the barrel for height up to where you see the line for the barrel cap and the inside circumference of the barrel, that is all you need, don't bother about the strength. With no id on the movement it will be English or German I always tend to think German.1 point

-

I thought it might be helpfull and answer your question at least partially.1 point

-

After re-reading your post again JohnR, I looked at the available balance staffs and found an older style, Part# 2720 that is 5.6mm long, the part # 3720 is 5.13mm long. So it all kind of adds up, the staff I have is too short. There's no pivot size number, but I'm betting they are smaller, so I ordered two and well see,1 point

-

Turn isn't exactly the right term. In other words you're not going to use a graver and reduce the size. I have a link below scroll down to the section titled Joseph School of Watch Making. You can either do the sections or the bottom of the list the entire book would be preferred. Then there is a section on making a balance staff but you really need the next number four as act covers reducing the pivots size to what you need. Then I'm still truly amazed that you were able to tighten the balance bridge down when the pivots are not in the holes because it would make me wonder if your balance staff is too short when you ordered your balance staff Did it have a part number? https://www.mybulova.com/vintage-bulova-catalogs1 point

-

I think it be more fun not to worry about the details. In other words just categorize by shape and visual observation of size don't worry about the dimensions yet. Then any that have complete pivots on both ends separate them out. Then reference books I believe that's a Swiss book doesn't list American pocket watch staffs for instance? Then if you added an assortment from a factory making pin lever watches for instance conceivably there would be staffs that nobody makes replacements for this is what happens we get stuff left over from factory production.1 point

-

Would you like to elaborate? In other words service them for money service them for fun give them to you? The reason I ask is the outcome varies because we can't See in the case as others have indicated. So for instance if they're being given to you don't worry about it. If you're servicing them for the fun of its where I'll that's problematic and if you're doing this as a moneymaking venture well that becomes even worse because there a black box we can't see what's inside there and they can very very very dramatically from something that can be serviced to absolute positively never be serviced. But if there a gift by all means take them watchmakers always take stuff it's how we accumulate all the stuff we have. Well at least is one of the ways to accumulate stuff.1 point

-

Another 404 club watch. Looks like maybe a paper dial, and almost certainly a low grade movement, but at 0.99p it should provide a little low cost fun. If you look closely at the second hand, it is actually snagged on the minute hand. I doubt if that is the only issue with it, but you never know. The two have been like that for a long time judging by the corrosion. I'm intrigued to know exactly what is inside it and where it was made.1 point

-

They've updated the tool and of course it's price that is if you're purchasing it new which I would not recommend. There are so many other tools that would be more essential that have. I'm attaching the PDF of how the tool is supposed to function. 7135 7136 tool for straightening bent pivots.pdf1 point

-

1 point

-

That seems to be the same basket I have. My stirrer has an 8mm motor shaft and the hole in the Elma lid is 8mm. So there's a 8/8 shaft coupler and an 8mm shaft that I cut from a beaker holder that came with the stirrer. Those jars are just some kitchenware but the lids are metal and there's a rubber seal. Not the tightest one around so you can smell the 566 if you sniff the jar close. The shaft goes through a lid that slides up and down and acts as a splash guard while spinning the basket. It also keeps most of the flammable fumes and odours inside, which is nice. The jars are not very uniform, there's a little deviation in diameter and roundness so one jar fits the base better than the other but I just stick a piece of cardboard in if there's too much space. What or who is Mr. Kilner? First I was about to buy an Indian basket but I read and saw some bad things about the randomness in quality so I went with Elma. The machining is precise so the basket doesn't wobble in the shaft. The wobble I experienced is due to high RPM, jar not supported properly, long shaft and the shaft going through a tight hole. But no problem if I support the jar with hand. I have no idea about RPM, still experimenting myself. The Elma wavebreakers seem to work fine so I can go a little higher speed. I went with 10 min wash and 5 min rinse, and finally 30 sec rinse in IPA. I guess you can do a longer wash cycle when not using ammoniated cleaner? The results are very satisfying. I haven't tried using ultrasonic with L&R 566 but before I had hard time getting all the gunk off pinion leaves. Now they come up all clean and shiny with no precleaning.1 point

-

just as a reminder if you look at any watch company who give you any specifications on timing they all say the same thing more or less you do not time right after you fully wind up. you need to let it run down a little bit or stabilize or whatever they want to call it. Typically it's like 15 minutes up to about an hour is considered for wound up otherwise you get an artificially way too high of amplitude. out of curiosity does the watch keep time?1 point

-

Are you sure the timegrapher is giving accurate results? The lift angle should be 56° for this movement - I believe the Seiko figure. You say that "I was getting approx 250 degrees dial up/down and 210 in pendant positions, and that is really too low". Really? 250° on most Seiko movements is very good. I would suggest 210-240 being the norm. I have just wound my 5606 and put it on the timegrapher set at 56°. I have about 240° DU/DD. It hasn't been run for a while, so may go up a bit, but I'm happy with 240° from a Seiko. Just checked a 5606 serviced by "The Watch Guy" - which shows 229° amplitude after service.1 point