Leaderboard

Popular Content

Showing content with the highest reputation on 09/18/23 in Posts

-

3 points

-

I do the same as you @VWatchie with the balance installed and chatons and cap jewels separate. I was always surprised in Marks videos on WRC that he didn't remove the jewels, and only after the cleaning machine did he remove, clean, and oil the cap jewels. It's not the cleaning of the cap jewels I'd be worried about (as I always do a final check and clean by hand if necessary), but I'd be worried that the balance pivots would not get a full clean.3 points

-

Hi that’s the crucial factor. It was designed to tell you the time with reasonabl accuracy, amplitude is a side issue, If it works and is accurate. It’s good.3 points

-

3 points

-

Hey all watch peeps. I thought a great idea for a new regular thread that would help the tool collectors among us ( which is pretty much all of us ). I've had a few wins just lately and I'd love to see the rest of us take something back from the Bay as well. I spend some time looking for bargains and often see stuff that i already have that would be put to good use by other members that i know dont have them or are saving up for something in particular. After a fair bit of practice I've started to get a feel for a sale outcome, often putting in last hour offers below starting prices that sometimes get accepted or cheeky offers on relisted items that initially get overlooked. Its just about drawing members attention to a potential bargain and can even be aimed directly at a member whom you know is searching for a staking set or a jewelling tool or whatever. Members could post up what they are searching for, regular ebay scanners can shout out a sighting or something else that might be of interest.2 points

-

2 points

-

2 points

-

Actually the Lathe is big enough to make a watch. It should be big enough to turn the watch plates which sometimes would be hard to do with a smaller Lathe. Then the link below might have some useful information somewhere http://www.lathes.co.uk/boley/2 points

-

I know H the starting price was 200, i knew someone would at least bid that plus a bit more. I made my max 302 and was quite surprised at it finishing up at 209. They are compared at least in size to the Myford ML7 and these are knocking out at 12 -15 hundred. So i can only guess its worth roughly a grand. I will need some help sourcing some generic 15mm collets and a draw bar, i expect the originals are like rocking horseshit, so if anyone has ideas, much appreciated you guys.2 points

-

2 points

-

A good cleaning machine would be one that you do not have to disassemble some jewels like American pocket watch Jewels you can keep them together. Which is rather nice because usually the screws are all stripped and that would be a pain to deal with. On the other hand if you're dealing with something modern that has Incabloc even with a nice cleaning machine I would still take them out. Then you can put the balance wheel with its bridge back on the main plate without the jewels and the balance pivots are protected Even without the jewels. Especially good with etachron systems Where it's inconvenient to remove the balance from the bridge anyway. So you want an outstanding state-of-the-art modern cleaning machine. With unfortunately a undesirable price. Uses vacuum to move the fluids around and it keeps the chamber under a vacuum during the cleaning process. This means all the little bubbles of air that's trapped like between and stones is pulled away. Two separate ultrasonic frequencies very very nice. Just really expensive fortunately I didn't have to buy it as it's where I work we have one and yes it does do an outstanding job of cleaning. https://youtu.be/Wcc_Bk7DO4k?si=nX65yriRuLFPxqdR But that wasn't really the answer you are seeking was it? The real question would be able with an ultrasonic watch cleaning machine how far will fluids penetrate if you have and stones? Some of those are actually designed for cleaning but most are not. If the lubrication is organic then they basically still have to come apart. Or even with the fancy machine up above if you end up with a metal fragment no I don't know how it got in their but there was a metal fragment once on a balance jewel assembly I had to disassemble it is no way a cleaning machine can get that out.2 points

-

I've mentioned it before but I'll mention it again. When I was new, timing machines almost killed my interest in servicing and repairing. Firstly they are not always as accurate as we may think, and secondly, a movement may perform excellently even if it does not reach the desired amplitudes. For example, Japanese movements typically do not reach the amplitude levels of Swiss movements but can still perform just as well. One of my very finest timekeepers is an Enicar cal. 161 (Swiss ) but it has never reached an amplitude of more than about 250-260 degrees DU/DN being meticulously serviced and fully would. I've had situations where a TM has indicated low amplitude when in reality the amplitude was more than acceptable. I've also had situations where the TM indicated errors in the escapement where there were none. Most of the time this is due to an incorrect set gain level on the TM. In my opinion, TMs can not be used to determine if a watch is capable of keeping good time, they can only indicate it, but there's no guarantee.2 points

-

What would be "a good cleaning machine"? The only argument I previously heard for not taking the shock systems apart when cleaning in a cleaning machine was to protect the hairspring and staff pivots from damage/wear and then clean the chatons and cap jewels separately. However, I was later told by or read a post by @nickelsilver that there were no risks in removing the chatons and cap jewels before putting them into the cleaning machine. And, that's exactly what I have been doing since and never had a single problem with damage/wear. Quite the contrary, it seems to be an efficient method for getting them really clean. I find it hard to believe that cleaning shock systems in situ in a cleaning machine will be as efficient as taking them apart before going into the cleaning machine, but I'm open and interested in hearing more about this!2 points

-

2 points

-

Thinking about contact angle and other lubrication properties there is a book. Book seems expensive but you have a preview here you get see if first about 111 pages with all sorts of lubrication details. We also get the contact angle of some popular oils. Plus all sorts of other interesting specifications. https://books.google.com/books?id=1awuxJ5v2ucC&pg=PA40&dq=Contact+angle+9010+Moebius&hl=en&sa=X&ved=2ahUKEwiu3rD-3LGBAxUkIDQIHXIGBQkQ6AF6BAgFEAE#v=onepage&q=Contact angle 9010 Moebius&f=false2 points

-

This is why 99% of the time i make the balance staff. From a professional perspective, not counting American stuff, for average AS stuff for example, there might be between 2 and 6 possible staffs. By the time you determine the exact one you need, then find a supplier who has it,buy it and ship it, to find out they sent the wrong one or the righr one but it's rusted etc. dang I make it for less effort. But I've made them regularly for a quarter century; seems to be a rare thing. As John has mentioned there are often different pivot sizes, which means different jewel sizes. Jewels and staffs were easy to get even for less common American stuff 30 years ago. Not uncommon to see staffs altered because someone had a 0.09 jewel on hand but the staff they replaced with had 0.10 pivots. These things often were serviced yearly or close to it. Bottom line was get it ticking and get it out. You could easily have wrong sized or different sized jewels, as a start.2 points

-

Hey all watch peeps, are we all well. So i went and did something silly, but we do silly things when we are in love. And I fell in love with this and now i dont know what to with her but she's gorgeous. She's an A3 Boley and Leinen production lathe from the 40's. Yes i know too big for watchmaking maybe unless i can get hold of some 15mm collets for her to munch on. But just think of all the other things i can make ? Ideas anyone ?1 point

-

I may be wrong here but I think confirming voltage is adequate for a battery. Test the voltage, if it's correct then the fault lies in the watch or it needs resetting which we don't know how to do.1 point

-

I have one of these but a different design, instead of the revolving cartridge with various sized holes to support the balance whilst its being drilled, mine has different sized spindles to pass the drill holders through. Generally go for 50 - 100 quid. Oh its for Repivoting1 point

-

Fantastic post @JohnR725! I especially enjoyed and could relate to the last sentence1 point

-

Absolutely Tom , i have eyes and ears open at the ready. I was going to name her Big Bertha, she weighs nearly as much as me, plenty to hold on to1 point

-

1 point

-

1 point

-

What's interesting when I see the name and a quick look at the watch I think of the pocket watch movements they make as it sort of looks like that until I realized it's not sized like a pocket watches it? Then as a parts list and no indication that things have been discontinued yet which is typically what happened when I look for watches on the website. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=UT_6565 Then looks like stem is still available cousins should have one though http://www.julesborel.com/s.nl/it.A/id.25267/.f1 point

-

1 point

-

Same as all of the trade patterns buddy. The smallest case is 30mm. But you have a movement with good history and possibly some value.1 point

-

How can a jewel under cap stone be checked? where there is a cap stone, it must be removed to see the hole jewel. A 48hrs soak in CocaCola wont cost anything and you'd be amazed with how easy screws unscrew its specially helpful with little screws.1 point

-

Finally found a time window to sort out the low amplitude issue on my lovely non-Mumbia Favre Leuba. The only job left to sort was the replacement of the twin mainsprings - pure cowardice. I'm delighted to say it has transformed to amplitude from 215 to 275 degrees so worth doing but not a beginners job. Here's what was learnt from the struggle which should help fellow watch menders. Forget about getting the exact spring from Favre - the new company is another resurrected imitation. According to Dr Ranfft you are looking for 1.55 x 6.5 x 0.065 x 210. Another site suggests a 270 mm length. The old springs were tired but 270 mm long so looking at the fill in the 6.77 mm internal barrel diameter using the longer length looked the way to go. The nearest Cousins UK had in stock was GR4052 which is 7.5 mm diameter so they will need to be unwound and rewound into a 6.5 mm winder barrel. At over £20 each inc VaT this was expensive - Gleaves & Sons had 1.5 x 0.7 x 285 x 7 mm dia for £6 each so they got the order. It still meant rewinding so make sure you have the small winding tools this requires. The barrel design is probably unique. To save height there is no barrel top - instead the winding wheel sits on top of the open barrel and covers the spring. It has a hollow stem which forms the arbor and has the spring hook on this sleeve. The barrel has a hollow stem and one fits over the other - very neat. It's a pig to get apart. Use your sprung hand puller hooked under the geared cover as shown in the pictures. Next problem is that the new spring will have the inner circle in too large a diameter so that the arbor hook will not engage with the attachment slot. I tried a few tricks but the one that worked was to go ahead and install the spring in the open barrel. Then using flat ended strong tweezers squeeze the spring end to tighten that last curve until the wheel/arbor grabs. Patience and trial and error will be required.... It can be done before inserting the spring but make sure you put a drill through the middle to squeeze against thus preventing the brittle metal from snapping. 1.2 mm proved to be the best size. However I would suggest you do it after the spring is in the barrel since it makes it easier to thread in your winding tools. The hollow spigot in the barrel works as a handy former to shape the spring against. Don't forget to put a drop of HP 1300 or something similar on the outside and inside of the barrel spigot. Note that the spring should be CLOCKWISE in the barrel - ie starting from the centre it curves clockwise. Helpfully the neat design means that both barrels run the same way so are identical. Also admire the large ruby bush pivots on the barrel bridge - a feature that very few factory produced watches offered in this era - and still don't. Also look how well the balance is supported. Be careful when screwing down the bridge - the small winding wheel has to be guided into the barrel cover gear. This is a delightful slim movement and a great shame that so many ended up in tropical climates. She now runs like a champ 275 degrees amplitude DU and a two position delta of 6 seconds.1 point

-

1 point

-

Notice what you just said? Does not reach the desired amplitude? That's the amusement with this group amplitude is the most important thing the desired amplitude is the most important thing and you must please the timing machine or else nothing is more important than pleasing your timing machine. But yet when you look at timing specifications from the watch company except at 24 hours they could care less about amplitude unless it's too much. Then even Omega with some of their watches will be still acceptable At 160° as long as it's keeping time. This is another amusement timing machine versus chronometer certification for instance. Chronometer certification relies on visual observation of what the hands are doing over a span of time typically in various positions with some temperature changes. They do not care what a timing machine says it's basically a test to see what the watch would do on somebody's wrist. Timing machines only show you what the watches doing at the exact instant you have it on the machine. Yes that's a clue of what will probably happen but ideally you should have a better timing procedure. Most people I put the watch on the machine fully wound up in one position and think that's it. Ideally should look at the watch and more than one position because on your wrist is going to be in more than one position And then you should check it 24 hours later to see how it's doing. Plus you still need to run the watch for several days and make sure it actually does whenever you perceive it's doing. When I was in school instructor George had all sorts of interesting sayings about things. This was a day where the timing machine spit out paper tape with two lines no digital numbers no amplitude just two lines possibly one line if it was in beat. But even then George had a saying don't please the timing machine they would probably be good for a lot of people on this group to remember that. The most important thing is does the watch keep time on your wrist or in your pocket or wherever you carry it. Timing machine is only a diagnostic tool that you do need to understand which are doing with that otherwise looks like your career and watch repair will be short-lived as you have a heart attack stressing over those numbers that don't really matter anyway as long as the watch keeps time.1 point

-

Ive had a few examples of watches with low amplitude before and after service that keep pretty good time. I think the isochronism more or less takes care of the timing. But what i have noticed because of the amount of friction causing the low amplitude that the power reserve is lower than specified, often only 24 hours. Not really an issue if you wind your watch morning and night, but what damage is that extra friction causing ?1 point

-

1 point

-

I'm the same watchie. I think the more surfaces that are exposed the better the cleaning method is. If the shock assembly is intact there are edges and joints that cant be reached and flushed out throughly I suppose it all depends how good your cleaning machine is, it cant take anything apart though1 point

-

Haha yep OH its what i call future Endeavor buying, just thinking ahead with my eyesight. I wanted something bigger ,Its above what i really was after but at such a good buy only a touch over 200 as its a collection only and 40miles from me, i though an absolute bargain.1 point

-

1 point

-

Over coil hairsprings have to have the regulator pins as tight as possible but still allow the hairspring to slide. Then ideally they hairspring should build the slide in for reassembly. Otherwise if they're far apart that would be a reason for running slow especially as the amplitude drops. Just keep the original balance wheel with the watch and don't worry about it.. It only really become an issue if the replacement balance wheel wasn't working properly at least as soon as you deal with your timing issue.1 point

-

The back is a snap on, look for somewhere to fit a blade between the case and the back. Once the back is removed, you need to remove the stem. Take a photo once the back is removed and we'll tell you how to remove the stem.1 point

-

Hi arron, the capstone jewels in the endpieces should not be removed. Without a jewelling tool would not be easy besides. I clean them separately and reinstall them during reassembly. Well spotted watchie, i seem to think rehajm also had it. You can split the winnings of a balance staff of your choosing .1 point

-

1 point

-

Well, patience or no patience, I’ve learned SO MUCH working on this watch. I really hope to get it going correctly, but if not I’ll move on to the next one and do my best to apply what I’ve learned with this one, and get the next one done right. I’ll keep ya all posted as to the final results, it’ll be another week as I’m waiting for the new staff to be delivered. thanks for all the help guys!1 point

-

Yes, the jewel in the removable plate is the cap jewel. Do not remove the jewel, clean both together. You can clean it by hand using your solution and a paint brush. If you are working on more than one watch, keep the parts separated.1 point

-

1 point

-

1 point

-

Several problems would occur. Special lubrication methods may be used special tools.Timing for instance it really should have probably a very very nice timing machine that gets calibrated on a regular basis if you really want to offer super precise timing. But there is the biggest problem of all liability of breaking something and zero availability of ever getting spare parts.1 point

-

The two jewel ISA 1198 based " Montine of Switzerland" "Swiss Quartz" arrived, and It looks completely unworn. However the original battery had destroyed the lower battery contact. Bizarrely it hadn't corroded, in a conventional manner, but rather it had split into a number of thin strips. I fabricated a replacement (from a 10K ohm resistor leg, flattened in the vice), and now it is running perfectly.1 point

-

Hi and welcome to the forum….. I in its present state (cased up) you will not be able to see anything so do not go cranking the hands round as it will lead to breakages. First remove the hands and then the movement and have a look at the complete thing. Check that nothing has dropped causing a jam. A wheel / lever might be out of place by not being clipped or pinned properly.. also post pictures of the front/rear and from the sides they help a lot in diagnosis.1 point

-

Bless ya Joe not stupidity mate, you do what you do because it feels right at the time. I've got two kids and wouldn't be without em or change em for the world. Haha yar I'm 56 and mine still works perfectly as well just ask my missus, just adapted so as not to produce any more rugrats1 point

-

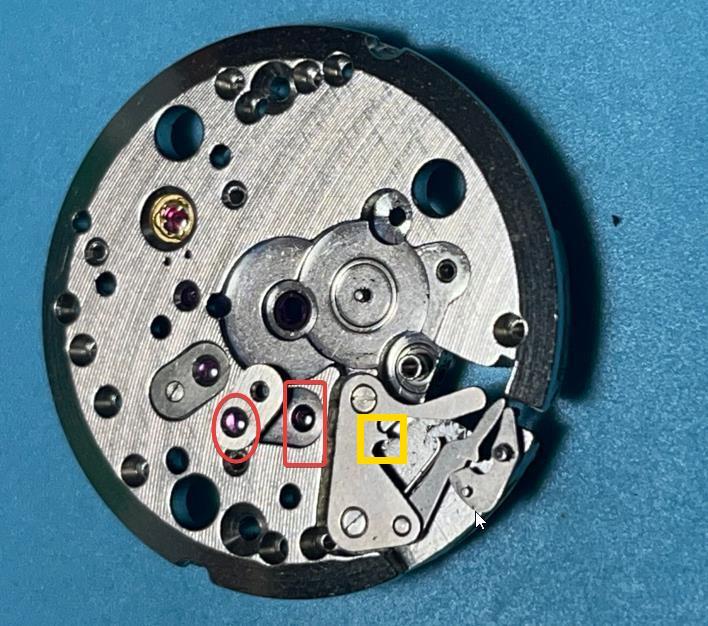

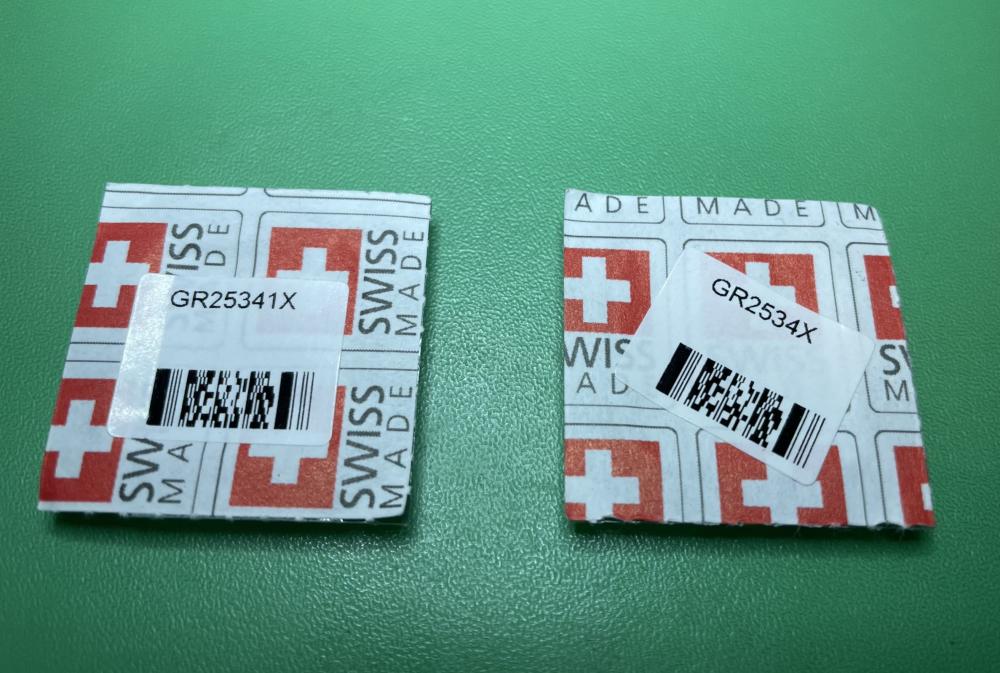

I know this thread is a bit dated, but I recently ran into some issues with 6138 and 6139 mainsprings from eBay being slightly undersized and underpowering the watch. I was finally able to find the exact correct replacement mainspring and thought I'd share it here for future reference. The correct dimensions for the spring are: 1.05 x 0.115 x 420 x 10.5 A search online references GR2534X, which can be found from Cousins. While the spring has the correct dimensions, the inner curve for the arbor is a bit wide and fits somewhat loose. This can be adjusted, but there is another (and cheaper) option. Cousins also has part # GR25341X, which has the exact same dimensions, but costs about 30% less. This part number is not referenced (anywhere that I could find) for the 6138, but the inner curve is smaller and fits the barrel arbor perfectly. If anyone is trying to source a mainspring for their Seiko 6138 chronograph, the GR25341X is what you'll want to get! I ordered a couple of them and just installed them in two of my watches. It brought the amplitude up from 190/200 (with the eBay spring) to 230/240. Here's a photo showing the difference in the inner curve between the two Cousins springs. The correct spring is on the left. FYI, the washers are the correct size and the spring drops right in. I hope this is helpful for someone in the future trying to find the correct aftermarket mainspring for their old Seiko.1 point

-

Are you sure the timegrapher is giving accurate results? The lift angle should be 56° for this movement - I believe the Seiko figure. You say that "I was getting approx 250 degrees dial up/down and 210 in pendant positions, and that is really too low". Really? 250° on most Seiko movements is very good. I would suggest 210-240 being the norm. I have just wound my 5606 and put it on the timegrapher set at 56°. I have about 240° DU/DD. It hasn't been run for a while, so may go up a bit, but I'm happy with 240° from a Seiko. Just checked a 5606 serviced by "The Watch Guy" - which shows 229° amplitude after service.1 point

-

Actually the most controversial subject is should you buy Chinese made tools from China or Chinese made tools packed into made in Switzerland boxes with the price hiked ten fold. I also would not be surprised if we found out Moebious etc do not actually make the oils they sell as watch oils but buy them from an existing oil maker in bulk for a lot less than they sell them for to us fools to pay exorbitant amounts for. Hat coat door bye.1 point