Leaderboard

Popular Content

Showing content with the highest reputation on 09/19/23 in Posts

-

Ok, Im not sure if this is appropriate for this forum so, mods, please remove it if it should not be here. But, I made a strap! I recently bought a "nice" watch from Japan and wanted to put a decent quality strap on it. My only problem is that Im not sure what constitutes "decent quality" for any given price point. So I figured how hard could it be to make my own?! A few YouTube videos and a peruse of ebay and I had the equipment and (hopefully) the knowhow to give it a go. Now, don't get me wrong, it is rough, and I have no idea if it will hold up but it is my first attempt so I still consider it an achievement!4 points

-

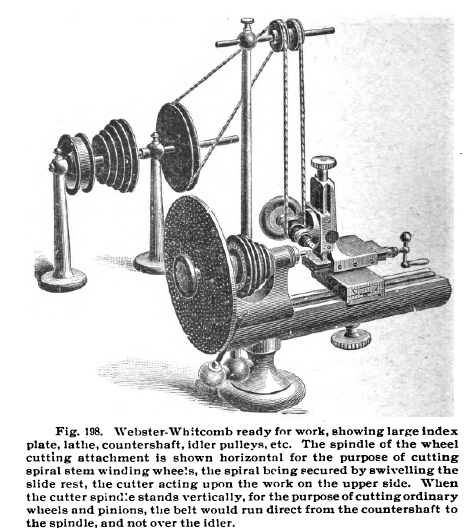

the precision is more of a quality factor of the particular lathe not necessarily its size. It's commonly thought of by people that if you want to make something small you need a small tool. But small tools have disadvantages they don't have necessarily the strength or mass in other words they tend to flex and not be stable versus something big. but a lot of it depends upon what you're doing with the lathe general turning small lathe would be fine what about some other task like gear cutting on the watchmaker's life is at a good thing or not? I swiped an image out of the book that's your standard gear cutting set up for the watchmaker's lathe. Fits all the requirements tiny gears tiny lathe but what's the problem? the basic layout of the gear cutting here whether it is a watchmaker's lathe or something much much bigger more or less looks identical or at least can look identical. The difference is the bigger lathe having way more mass the holder for the spinning gear cutting just tends to be way way more stable than something like this which can flex depending upon how much pull the belts put on it. so a lot of it just depends upon what you're doing big tends to be more stable.3 points

-

A tg obviously can't take account of all the variables of a wrist worn watch for different people's lifestyles. Apart from the diagnostic side , its just a quick convenient device to get you in the ballpark. After all these were originally just used by professional watchmakers to get the watch back on the customers wrist and the wmaker paid up quickly with a fair chance of returning an accurately running watch. Its only in fairly recent times that they've become cheap enough and available to everyone and their dog. Your time and effort to set up an individual's watch should yield much better averaging accuracy. So besides the fault finding which should help with preventing wear and tear much like the plug in diagnostic machine of a car to pinpoint arising issues, the tg is a quick convenient way to regulate time. I still would need mine to be prised from my cold dead fingers3 points

-

A "Craftsman", possibly in a Dennison case. I have no idea what is actually in it, but a number of similar watches online have a Cyma 990 15 jewel 3 adjustment calibre, so I may get lucky. As to its age, anywhere from the late 1930s to the early 1950s would be my guess. Obviously it needs a crystal and hands, but if the balance staff has survived, and if it is what I think it is, then it is 99 pence (plus postage) well spent.3 points

-

I'm curious about what you mean by condition? From a quick searching of the Internet apparently battery voltage is the key for this watch. Even though you may perceive your new battery is new or as others found their generic batteries renew if the voltage drops then it goes into the various power saving modes or it just doesn't run at all. So basically want to be as close to 3 V as you can be and since you have a voltmeter what voltage do you have? Then for checking battery voltage I found a service manual and they checked the battery out of the watch claiming it should be 3 V. But they also do tell you the other voltage is where the watch will go into the various power saving modes so that's not 3 V and it's less then that's why you're having a problem. http://www.chronomaddox.com/omega/manuals/service/1666/cal_1666_service_manual.html3 points

-

I picked this out of the scrap pile this evening, as the internet had gone down, and it was pissing down with rain outside, so I was in need of a little watch therapy. I didn't hold out much hope for it as the balance appeared to be glued in place, so I thought the pivots were probably bent. However with a little stripping, cleaning and a little oiling, (the watch you understand, not me), off it went. No fusee chains were injured in the process, which was a bit of a relief. Its a shame I don't have a suitable case for it, as that intricate engine turned dial, blued hands and fusee movement could do with a new home. I'm not sure if the jewel is a diamond, or the balance is gold, but whatever they are, its quite spectacular. Dial is 35.75mm and the movement is 33.80mm, depth/thickness is around 10.00mm so its also relatively small for the time. You could almost squeeze it into a large wrist watch case. Shame the dial has been bashed about a bit and the original case melted down, probably to make sovereign rings for chavs. The internet is now limping along, so I barely have the bandwidth to post a couple of still pictures. No moving movement videos tonight I'm afraid.2 points

-

Yeah Rich, I lucked out and got a pair of the 4266 lifters cheap as a job lot, stripped, cleaned and lubed them whilst waiting for two new bases and grommets to come. Reminds me got to put one of those up for sale Tom2 points

-

There's the through-bore size and the reduced bore size. On a Schaublin w12 collet, 12mm body, max through is 8mm, but they're pushing it. On a standard Swiss 8mm collet it's 4mm, for most other 8mm it's 5mm. A w20 collet, 20mm body, it's 14mm. So 8mm through bore for a 15 mm collet is about right. On my little lathe (8mm collet), I can fit 6mm rod in a reduced bore collet 12-15mm deep. So in some cases, where maybe I want to make a part with an OD of 10mm, but work it in my Leinen, I'll turn a 6mm spigot on the stock on the 102, then hold it for final working in the Leinen.2 points

-

Looks like verdigris. In the coin collecting world a product called veridicare available fron Wizards coin supply. It is somewhat expensive but removes verdigris without a trace if it is not too far along. Very good on US cents and vintage copper pennies. In the coin collecting world condition is everything and any trace cleaning destroys a coin's collecting value so this is one product that could work more to watches that don't have to have untouched surfaces to remain valuable.2 points

-

2 points

-

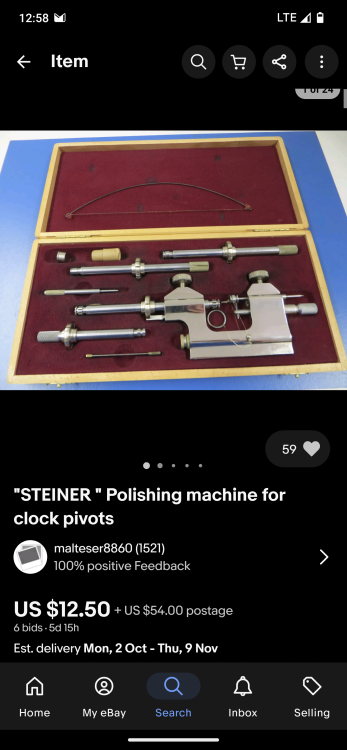

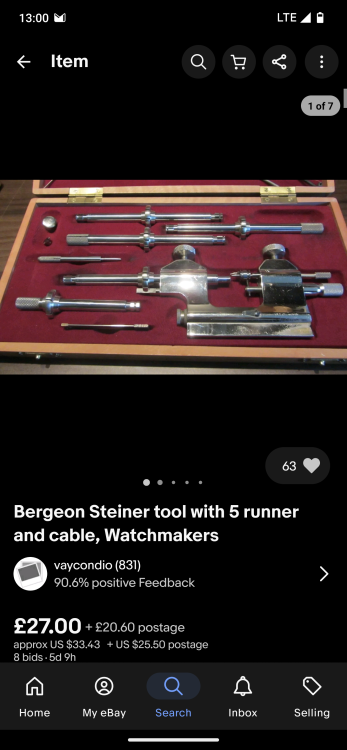

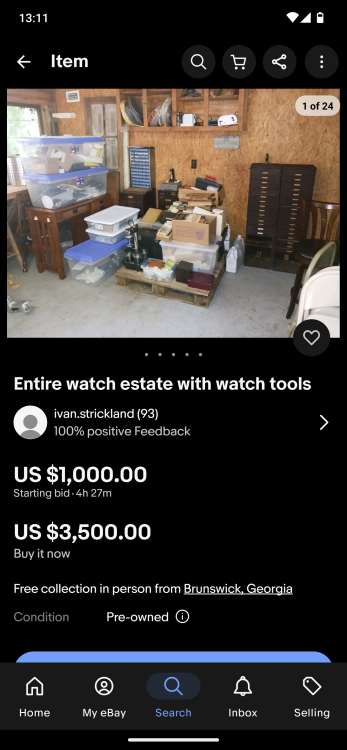

Still a long way to go, but look in great condition and could turn out to be a bargain! https://www.ebay.com/itm/166329068623?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=R53hS8XlR-m&sssrc=4429486&ssuid=WLDexrgWSNe&var=&widget_ver=artemis&media=COPY https://www.ebay.com/itm/266403540790?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=oURkpKIDSk-&sssrc=4429486&ssuid=WLDexrgWSNe&var=&widget_ver=artemis&media=COPY And if only I lived there!!! https://www.ebay.com/itm/175895318421?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=0w7DrVfQQlS&sssrc=4429486&ssuid=WLDexrgWSNe&var=&widget_ver=artemis&media=COPY Watch cleaning machine and staking set, press etc.... A steal!2 points

-

I may be wrong here but I think confirming voltage is adequate for a battery. Test the voltage, if it's correct then the fault lies in the watch or it needs resetting which we don't know how to do.2 points

-

Hey all watch peeps. I thought a great idea for a new regular thread that would help the tool collectors among us ( which is pretty much all of us ). I've had a few wins just lately and I'd love to see the rest of us take something back from the Bay as well. I spend some time looking for bargains and often see stuff that i already have that would be put to good use by other members that i know dont have them or are saving up for something in particular. After a fair bit of practice I've started to get a feel for a sale outcome, often putting in last hour offers below starting prices that sometimes get accepted or cheeky offers on relisted items that initially get overlooked. Its just about drawing members attention to a potential bargain and can even be aimed directly at a member whom you know is searching for a staking set or a jewelling tool or whatever. Members could post up what they are searching for, regular ebay scanners can shout out a sighting or something else that might be of interest.1 point

-

1 point

-

The crystal plate is not expensive Rich, neither is the proper Bergeon rubber grommet https://www.cousinsuk.com/product/gaskets-for-claw-type-fitting-tools-bergeon?code=G7346 https://www.cousinsuk.com/product/round-glasses-bergeon-4266 Tom1 point

-

Oops, that comment was about my mantel clock but I am happy with the carriage clock too. And it runs a bit fast. Not a problem. Two clocks working now.1 point

-

Makes perfect sense. Thanks for the help Nicklesilver and John. I can't wait to pick it up next Monday. Much learning needs to take place .1 point

-

I would be curious as your definition of a proper battery tester? typically the battery testers that watch shops have are pretty cheap things. Just an analog meter and a resistive load when it checks the battery voltage. versus using a DVM which basically places no load on the battery. Somewhere out there in the universe it probably tells you what the load resistance is to check a lithium battery if you're really concerned. Another thing you want to check for when you are purchasing your batteries is the expiring date on the package. Depending upon where there purchased from even though you are purchasing a brand-new battery it might not actually be a new battery depending upon the volume of these batteries they go through. yes typically anything that's complicated perpetual calendar whatever there is a reset procedure to put everything back where it's supposed to be. but if you're reading carefully up above you would've noticed this? this is telling me that somebody does not actually want to do a complete reset and start over with the setting. A lot of times with really complicated watches the setting can be really complicated. that I did take a quick look at the service manual and in the quick look I'm not seeing an actual reset procedure. It might be there but I'm not seeing it. A lot of times with the watches there will be a indication of a reset contact visible and usually chart that to the ground of the watch and that will do a full complete reset the other on this I don't even see that listed in the electrical tests or any reference to it at all? That might be there somewhere it should be there I just didn't see it.1 point

-

1 point

-

Just an update. Clock runs beautifully now, if a bit fast. I am at the bottom of the pendulum rod so unable to slow it down more. Will live with it. In any event, pretty happy and appreciate the forum help.1 point

-

I've seen the crystal spacing plate made from credit cards. The original plate is worth having and they do actually come up separately from time to time. Its still at 16.50 a couple of quid above might grab it. New from cousins they run at 70 quid. Tough call, another 40 notes gets you a new one. I would never ever go above half the new price for anything. So just an example of some input,the crystal lift has jumped to 22 quid plus 5.50 delivery it has the spacing plate missing . Its going beyond a bargain now.1 point

-

Thats will be a little cracker of a pocketwatch Andy especially if its a Cyma.1 point

-

1 point

-

1 point

-

No, it just becomes less convenient to make smaller things. I have a Schaublin 102, comparable to your Leinen there, and have made many parts for customers on it with tolerances of +- 3 microns. But if the part can be made more coveniently on my little Leinen (50mm center height, "standard" watchmaker lathe), I do it there. When the part diameter gets above what I can hold in a collet on the little Leinen (around 6mm), it goes to the Schaublin usually. There are larger (10-11" swing) lathes that can easily hold the precision or better than the best watchmaker lathes, for example the Monarch 10ee or Hardinge HLV-H. In many ways the extra stability and mass of the larger machines makes higher precision easier.1 point

-

Amazing what a fresh pair of eyes can see! Completely missed this, looks like I'm now in the market for a completely new case! Serves me right, only fools jump in where angels dare to tread!1 point

-

For 99p you can't go wrong. The dial looks in great condition and the case should clean up nicely.1 point

-

1 point

-

Funnier though is all the WJ cross slides I have seen since go for considerably more than I paid so buyer’s remorse has eased somewhat Tom1 point

-

As far as I can tell this is the only tech guide from Seiko that actually tells you the amplitude. Seiko-4006A_TECH.pdf1 point

-

No not wrong Rich voltage under the specified is an indiction of low power. I would test all the batteries you have, a fully loaded battery can be a little above what it says on the tin.1 point

-

The best oil to use is Windles clock oil. It is that good it is the only one you need for movements such as this. If you need any more help just ask. Thank you for using English.1 point

-

Notice what you just said? Does not reach the desired amplitude? That's the amusement with this group amplitude is the most important thing the desired amplitude is the most important thing and you must please the timing machine or else nothing is more important than pleasing your timing machine. But yet when you look at timing specifications from the watch company except at 24 hours they could care less about amplitude unless it's too much. Then even Omega with some of their watches will be still acceptable At 160° as long as it's keeping time. This is another amusement timing machine versus chronometer certification for instance. Chronometer certification relies on visual observation of what the hands are doing over a span of time typically in various positions with some temperature changes. They do not care what a timing machine says it's basically a test to see what the watch would do on somebody's wrist. Timing machines only show you what the watches doing at the exact instant you have it on the machine. Yes that's a clue of what will probably happen but ideally you should have a better timing procedure. Most people I put the watch on the machine fully wound up in one position and think that's it. Ideally should look at the watch and more than one position because on your wrist is going to be in more than one position And then you should check it 24 hours later to see how it's doing. Plus you still need to run the watch for several days and make sure it actually does whenever you perceive it's doing. When I was in school instructor George had all sorts of interesting sayings about things. This was a day where the timing machine spit out paper tape with two lines no digital numbers no amplitude just two lines possibly one line if it was in beat. But even then George had a saying don't please the timing machine they would probably be good for a lot of people on this group to remember that. The most important thing is does the watch keep time on your wrist or in your pocket or wherever you carry it. Timing machine is only a diagnostic tool that you do need to understand which are doing with that otherwise looks like your career and watch repair will be short-lived as you have a heart attack stressing over those numbers that don't really matter anyway as long as the watch keeps time.1 point

-

I don't suppose you have a specific watch? That's because we can end up with lots and lots and lots and even a few more different systems. But there is a book there's probably more than one https://www.amazon.com/modern-calendar-watchers-b-humbert/dp/297005731x1 point

-

Well, if it can wind a 7009, then it can wind all 70xx (7005, 7006, etc) and also the 7S26 and 7S36 at least. For the Seiko 66 and 6602 I use the same Bergeon winder that for the 70xx, but it is almost too big, so if the chinese 8200 is exactly or smaller than the Bergeon #6 then it will probably work, if it's a bit bigger then it won't.1 point

-

I thought it might be helpfull and answer your question at least partially.1 point

-

We end up with a certain unknown here that style of wheel with friction is common a lot of watches but it's a classic in this watch if it freezes up it's because it's now stuck to the post with what looks like rust. So the best guess is that the lubrication they recommended went bad. My current favorite lubrication is 9504 but basically a grease should work fine just not the one that they recommended. Basically you just have to be really mindful of what you're doing which sometimes I have not been. So it needs to be rotated out of the way to get the fork out. But you probably want to rotated back when you put the bridge on because I have this vague memory of putting the bridge on and breaking it off or bending the heck out of it. So unfortunately a nasty more or less in a specific place when the bridge goes back on then at least you can clean it without damaging it Then yes this is a definite problem sometimes we take them out they will practically literally spin with a puff of air because they are so incredibly worn out . But because you have nothing to lose you can try to tighten it. I think I've seen people use concave punches in the staking set in an attempt to squeeze and bring the metal in word not quite sure how you want to do this but you try something is worth a try1 point

-

1 point

-

I have a couple YouTube videos that make it look simpler than what you're describing. Plus we've already discussed this in the group somewhere before. https://youtu.be/-Xgcck692js https://youtu.be/1ozEEAkYX0M But to some degree it's a waste of time unless you're really obsessed or you're having some sort of problem like the amplitude is low on the timing machine but visually it looks great in the watch. Or the timing machine says the amplitude is way too high and you know it's not. Or for some reason you just really obsessed with having the perfect lift angle like for a pocket watch which could be just about anything versus a wristwatch that typically fall within a relatively narrow range. Which is why the timing machine defaults to 52°. Then I have a different reference that what's referenced above and it says 49°. https://calibercorner.com/miyota-caliber-8215/1 point