Leaderboard

Popular Content

Showing content with the highest reputation on 09/20/23 in all areas

-

Now that is an understatement! The above will get you 80% there with only 20% of the headache. Start off simple and then you can develop your own best practices and arsenal of exotic oils/greases/epilames/Lubeta..... and oilers to chase those elusive final few degrees of amplitude. Perfection is expensive to approach and impossible to achieve!4 points

-

With a lathe of that size you need to think safety, it doesn't look to have an NVR switch, it's not worth taking risks i would fit one of these before using it. https://www.axminstertools.com/kedu-nvr-switch-230v-1ph-e-stop-200093?utm_source=tag&utm_medium=affiliates&utm_content=2266&tagrid=59481565&glCountry=GB When using it wear a t-shirt no long sleeved clothing, don't wear gloves, wear eye protection, clean the swarf away with a brush not you fingers, i don't want to sound too preachy with a lathe of that size it can do a lot of damage, think SAFETY first. Just think of all the tools you can make enjoy using it, i'm drooling, you got a really good buy that was a blumming bargain, you need to buy a lottery ticket with luck like that.3 points

-

Hey all watch peeps, are we all well. So i went and did something silly, but we do silly things when we are in love. And I fell in love with this and now i dont know what to with her but she's gorgeous. She's an A3 Boley and Leinen production lathe from the 40's. Yes i know too big for watchmaking maybe unless i can get hold of some 15mm collets for her to munch on. But just think of all the other things i can make ? Ideas anyone ?2 points

-

I like Alex a lot. I learned a couple things from this- on this old stuff the grease on glass for the wolf teeth and liberal use of 9504 instead of hp or 9104… He doesn’t live far from me and I think I owe him a pint…2 points

-

I think that is exactly the problem. The sharper the knife the easier it is the create a sharp point. With these sharper blades I can create a fine point in a fraction of the time it used to take me with standard blades - I'd often get fed up and give up after a while' True, but we are (hopefully) gaining new ones2 points

-

2 points

-

how about a bonus document the lubrication guide. Yes technical documentation for watch repair is quite interesting. A lot of this isn't obvious unless you know what it actually is supposed to look like. so much of the documentation we have was scan to PDFs for the purpose of parts identification only. It's why a lot of times that's all you see is the parts list you don't see if there ever was anything resembling servicing. like for instance Longines I noticed this a while back when somebody need of the technical guide. The online version 5 pages the actual technical guide 19 pages. All of the service information a course is missing from the online version. Is not just this but there's lots of technical stuff like this somebody last week was doing an Omega watch the parts list is just a picture of the parts on the discussion now there is a PDF of the service guide and the only reason that exists is I scanned it I believe six pages. I really do not like scanning technical documentation it's incredibly tedious to remember which page I was on and I get annoyed if I miss a page or have well duplicate would be fine but missing a page is an annoyance. Seiko is another interesting one as you noticed nice and pretty and in color. Then a lot of the early ones were like that where they had the smaller images of these of the parts that go in and this step versus the drawings. But even the parts lists we typically don't see them as their really supposed to look because they are color-coded. Somebody didn't bother with the color and a lot of times they don't bother with the detail so unfortunately yes there's a whole bunch of technical documentation out there in the world that still hasn't been converted to PDF. Seiko-4006A_TECH_Oil.pdf2 points

-

2 points

-

Ok, Im not sure if this is appropriate for this forum so, mods, please remove it if it should not be here. But, I made a strap! I recently bought a "nice" watch from Japan and wanted to put a decent quality strap on it. My only problem is that Im not sure what constitutes "decent quality" for any given price point. So I figured how hard could it be to make my own?! A few YouTube videos and a peruse of ebay and I had the equipment and (hopefully) the knowhow to give it a go. Now, don't get me wrong, it is rough, and I have no idea if it will hold up but it is my first attempt so I still consider it an achievement!2 points

-

2 points

-

No, it just becomes less convenient to make smaller things. I have a Schaublin 102, comparable to your Leinen there, and have made many parts for customers on it with tolerances of +- 3 microns. But if the part can be made more coveniently on my little Leinen (50mm center height, "standard" watchmaker lathe), I do it there. When the part diameter gets above what I can hold in a collet on the little Leinen (around 6mm), it goes to the Schaublin usually. There are larger (10-11" swing) lathes that can easily hold the precision or better than the best watchmaker lathes, for example the Monarch 10ee or Hardinge HLV-H. In many ways the extra stability and mass of the larger machines makes higher precision easier.2 points

-

1 point

-

"The Most Accurate American Watch Ever Made(*)" https://www.youtube.com/watch?v=pDv8KDzfWlo (*) 80 plus years ago.1 point

-

From what I've seen they are refurbishing mostly vintage quartz and digital Timex watches, and selling those. Who knows if they'll expand into the old mechanical ones. The ones which are deemed scrap are recycled. Maybe someone in Timex is trying to make amends for those millions of watches that ended up in landfill over the decades.1 point

-

Tell me about it mate, 25 years on and 3 stone heavier has really ballsed up my flamenco1 point

-

I know very late to the party. I've restored a dozen 5206 and 5215(bc they are one of my favorite seiko movements) and I believe that this is a common issue with this series in particular but other seiko autos as well but to a lesser degree. First off the part is the same for the 5206 and 5216 imo, the main difference being that its cosmetic. I typically do the 99:1 namtha/9010 dip and it seems to do the job most of the time. The second thing to consider is whether the previous owner was a habitual hand winder(tisk tisk). That might mean worn down pivots or even a broken jewel. I would suspect worn or scored pivots since the replacement works. I've never tried it but polishing the pivot and adjust the endshake could fist a worn differential as well. all in all were in this together. I can tell you how many times this has been the culprit and I suspect this is why may seikos have a seperate plate just for the differential.1 point

-

You should never straighten out springs. Clean them in petrol with a good strong brush with long bristles, then wipe in a clean cloth. A simple way of judging the correct length of spring for the barrel is 1 third for spring, 1 third for arbor and one third of distance between arbor and spring.1 point

-

Shouldn't be that expensive but it is Rolex. Remove the bezel, replace the spring and refit the bezel.1 point

-

@Neverenoughwatches Rich, take a look at the professional sewing machine motors and controllers, They should have the power to drive Helga and give you a lot of control. Tom1 point

-

I think thats how the A3 was originally set up,driven from underneath and built onto a purpose made stand. Mine has the headstock top cover missing to set up the belt and side motor. It may well have been poached from a factory or a small engineering workshop. Thanks for the link Tom, its given me ideas of what to look for.1 point

-

@Neverenoughwatches Rich, with your skills you can add a lot of value to the new lathe, seen this and thought of you. https://www.ebay.co.uk/itm/335036033511?mkevt=1&mkpid=0&emsid=e11021.m43.l3160&mkcid=7&ch=osgood&euid=a128a8a8a7424b5eb50fe1640373c227&bu=45234913067&ut=RU&osub=-1~1&crd=20230920052019&segname=11021 Tom1 point

-

Seems that that contraption is a watch timing machine. https://www.ebay.com/itm/134415570816 I take it that the one part on the left is for the paper and the part on the right holds the watch and can be rotated through different positions. I have a saved search, so I'll be notified if anything new pops up. I'll probably have better luck by trying to meet local watchmakers and get a line on a staking set that way. I found a local chapter of the NAWCC that I'll drop in on.1 point

-

I've tried all sorts of craft blades to try and find the sharpest. I eventually found these on Amazon (about £9 for 15 blades). As it says on the pack, they are Double Honed, and easily the sharpest blades I've found. They seem to last quite well too. I sharpen the pegwood with the tip flat against a block of wood. With these blades I can easily get a very fine point - I've even pegged balance hole jewels.1 point

-

I use these cheap as chips craft blades, they slice up pegwood nicely straight out of their packet, a little better with a few strokes across a fine Washita stone. I particularly like the short flat blades that come in handy for popping up a caseback or bezel but quickly lose their edge with this use. More expensive blades would be a thinner more durable steel with more effort put into sharpening them.1 point

-

So, I picked up this set from my local hardware store for £1.50 (!) so I'm not sure they can be called "good quality blades". To compare the sharpness to my Japanese blades I placed a new small blade in my Japanese blade holder and it did a decent job. My Japanese blades are noticeably sharper but it's certainly not a night and day difference. On the contrary, the difference is quite small and the inexpensive blades can certainly be used to sharpen peg wood. However, it could be that the Japanese blades last longer, but taking the price difference into consideration that wouldn't make much of a difference. As a general rule of thumb, I tell myself to get the best tools that I can reasonably afford, but in this case, especially if you're on a budget I'd say the cheap blades are good enough. That said, I will keep using my Japanese blades and probably order new ones when I run out if I can afford them by then.1 point

-

I would just go for it, take lots of pictures on your phone (photons and memory on your phone is free!) and try to segregate the groups of components. nothing worse than trying to figure out what screw went with what. Assemble in the reverse sequence to which you disassembled. I don't see any problems hand winding the mainspring if you don't have a set of winders - My Retro Watches has a good YouTube on how to do this. As for lubrication the service manual (if it exists) is the best way to go, but it's also OK to follow standard practices.... here are my rules of thumb: If its a jewel = 9010 If its a metal post with something rotating on it at high RPM = 9010 If its a metal post with something rotating on it at low RPM = D5 or HP1300 If its metal rubbing/grinding on metal = grease (Moly XD or similar) If in doubt D5 or HP1300 is your friend (it's halfway [ish] between 9010 and grease, so even if you get it wrong you won't be too far off) For mainsprings with auto works you will need breaking grease on the wall of the barrel so the spring can slip, and you will need different grease on the spring itself (I use 8200) regardless if it's an automatic or manual winding watch. Nothing on the pallet fork jewels, leave them dry. Of course there are exceptions to the above, but I think if you follow this you can't go far wrong.1 point

-

For me this movement is derived from the ETA 2770 family. Ranfft Service Video1 point

-

Benrus didn't have its own calibers, relied on Swiss movements, thought might have changed designs of some parts of complications and stamped them with some designations of Benrus, which obviously is on this auto-rotor, it would lead us to its ETA base caliber, therefrom we can look for datasheets for it. Take lots picture as you disassemble, most anyone here has worked on ETA movements so no worries as we'd work with you to reassemble it. Rgds1 point

-

Welcome. I can recommend Marks course. Gave me the basics of the engrossing hobby. Alex Hamilton 'watch repair tutorials' also has a distance course. Chronoglide has a self teach course without guidance. Mark's course was really informative and gave progression tutorials that made it easy to understand and move to the next level. I purchased levels 1, 2 and 3. I have completed levels 1 and 2. Levels 1 and 2 give basic foundation and advocate practice, practice and more practice. You have no idea how correct he is. I am still using level 3 as my go to when I come across a Youtube video that causes me problems. I have not purchased Alex's course as it only started a month ago. His YouTube videos start as basics and them move to Marks level 3 for information. They are very good. His distance course appears also exceptional. The members here are the additional additive to me keeping a level head and not progressing beyond my skill level. Good advisers with excellent knowledge. Hope this information helps. Ross1 point

-

Hey Daz! I'm new to this as well; but I've been shopping on ebay for a long time. When I started searching for something to work on that was less likely to be a disappointment I made use of the boolean search features that ebay has. I started with the basic search "Automatic Watch". Clearly that's very broad, and returns thousands of useless results. I then use the left side bar to set my budget -- say just a max of $60CAD & Buy It Now only. Finally I start trimming: "Automatic watch -quartz" -> "Automatic watch -quartz -timex" -> "Automatic watch -quartz -timex -seiko -citizen" ... That cleared out a good portion of the mixed heritage specials that typically ship from India or Pakistan and the engineered to cost, jellybean timex family. I'm sure that there are some fantastic "Mumbai Specials" to be had, with quality parts that haven't been completely worn out prior to installation, but that's not what I was looking for ... so then continue cutting and refining until I have a few candidates and press play!1 point

-

Haha no problem watchie, i blew that out of the watch not long after i posted it. 3 more jewelling tools, another jacot, another staking set, a hairspring vibrator, a 6 x4 shed load of hand tools and now another lathe later. at least double maybe even triple that figure1 point

-

Sorry, just couldn't help myself!1 point

-

I picked this out of the scrap pile this evening, as the internet had gone down, and it was pissing down with rain outside, so I was in need of a little watch therapy. I didn't hold out much hope for it as the balance appeared to be glued in place, so I thought the pivots were probably bent. However with a little stripping, cleaning and a little oiling, (the watch you understand, not me), off it went. No fusee chains were injured in the process, which was a bit of a relief. Its a shame I don't have a suitable case for it, as that intricate engine turned dial, blued hands and fusee movement could do with a new home. I'm not sure if the jewel is a diamond, or the balance is gold, but whatever they are, its quite spectacular. Dial is 35.75mm and the movement is 33.80mm, depth/thickness is around 10.00mm so its also relatively small for the time. You could almost squeeze it into a large wrist watch case. Shame the dial has been bashed about a bit and the original case melted down, probably to make sovereign rings for chavs. The internet is now limping along, so I barely have the bandwidth to post a couple of still pictures. No moving movement videos tonight I'm afraid.1 point

-

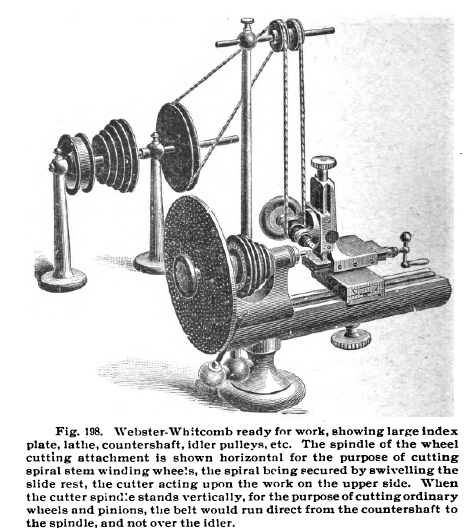

the precision is more of a quality factor of the particular lathe not necessarily its size. It's commonly thought of by people that if you want to make something small you need a small tool. But small tools have disadvantages they don't have necessarily the strength or mass in other words they tend to flex and not be stable versus something big. but a lot of it depends upon what you're doing with the lathe general turning small lathe would be fine what about some other task like gear cutting on the watchmaker's life is at a good thing or not? I swiped an image out of the book that's your standard gear cutting set up for the watchmaker's lathe. Fits all the requirements tiny gears tiny lathe but what's the problem? the basic layout of the gear cutting here whether it is a watchmaker's lathe or something much much bigger more or less looks identical or at least can look identical. The difference is the bigger lathe having way more mass the holder for the spinning gear cutting just tends to be way way more stable than something like this which can flex depending upon how much pull the belts put on it. so a lot of it just depends upon what you're doing big tends to be more stable.1 point

-

Hello, sorry I didn't see your introduction, so a belated welcome. I agree with @Neverenoughwatches1 point

-

A tg obviously can't take account of all the variables of a wrist worn watch for different people's lifestyles. Apart from the diagnostic side , its just a quick convenient device to get you in the ballpark. After all these were originally just used by professional watchmakers to get the watch back on the customers wrist and the wmaker paid up quickly with a fair chance of returning an accurately running watch. Its only in fairly recent times that they've become cheap enough and available to everyone and their dog. Your time and effort to set up an individual's watch should yield much better averaging accuracy. So besides the fault finding which should help with preventing wear and tear much like the plug in diagnostic machine of a car to pinpoint arising issues, the tg is a quick convenient way to regulate time. I still would need mine to be prised from my cold dead fingers1 point

-

As far as I can tell this is the only tech guide from Seiko that actually tells you the amplitude. Seiko-4006A_TECH.pdf1 point

-

1 point

-

Actually the Lathe is big enough to make a watch. It should be big enough to turn the watch plates which sometimes would be hard to do with a smaller Lathe. Then the link below might have some useful information somewhere http://www.lathes.co.uk/boley/1 point

-

I think you'll find that between the laundry list of names (and the prices associated with them) and the potential for fraud, you might be barking up the wrong tree... Name brands only really mean anything for the fashion conscious, and this (mostly) ain't that crowd. If you're new to the hobby, the first thing to do is throw out the fashion hat, and put on your engineer's hat. The name on the machine doesn't matter, it's a machine. What does one look for in one of these machines? Condition is obvious, and has been touched on. The "mumbai special" is slang for a severely polished severe turd, but the same concept applies to watches from anywhere (and they can absolutely come from anywhere). Beyond that, look for fully jeweled movements; that means there are jewel bearings on the escapement and all of the wheels. Often the barrel is excluded from this, but bonus if it's jeweled as well. Decoration is a nice thing to find, and often (but certainly not always) indicates a nicer movement. If it's something you want to wear or resell, or something beyond just learning to dis/assemble a movement, pay attention to the case. All stainless cases tend to hold up, look better with wear, and be recovered from wear better than any flavor of plating. They also tend to get at least mid-grade movements. Budget is your last thing. There's a whole long thread called "404 club" that's nothing but watches found for dirt cheap (under £4.04/$5 + nominal shipping). You don't have to spend a fortune on "victims" to the altar of learning this stuff. Seriously, that's about it. Condition and appointments. Name on the dial is pretty much meaningless, and name on the movement is often difficult to impossible to divine from your typical auction (especially now that Ranfft is down). Bonus: Beyond that, I personally like to focus on a particular "school". Russian watches are robust, but simple and not very precise. They're cheap and hard to kill. Japanese watches are like more precise Russians. Accordingly, they're almost as cheap, and almost as hard to kill. European watches tend to be better quality with some finishing. As the most common point of origin, they tend to run the gamut, and you can end up with anything from gold to garbage; kinda have to have a bit of a clue for what you're looking at, but not much more than the pre-bonus outlay. American watches are like European watches, but with gold lettering and harder to find. The US was where the good watches came from until the Swiss picked up the mantle (there was a brief period of Swiss watches being faked up to look like they were American), so the nice American watches tend to be of the pocket watch era, and get more and more rare as time goes on.1 point

-

Fair point, I haven't compared. My comment was that other countries produce steel to the same standard and thus should be able be sharpened to the same degree. There's a lot of mythology about samurai blades, they weren't superior but the Japanese blacksmiths took low quality steel and forged it into good quality steel.1 point

-

Sorry to have failed to reply on how this turned-out. Turns out it was just a broken alarm spring and it was indeed possible to remove and replace the alarm barrel without a full teardown. The center bridge did have to come-off, but that was the only significant effort. The alarm bridge was a since after that.1 point

-

Rant incoming: I can certainly understand Plato's frustration. I myself am questioning my own future with this hobby. Don't get me wrong, I love doing it, but there's just always something that stops me in my tracks. Buying a watch on eBay is always a risk. If a buyer sells something as "not working," or even if it is running, albeit poorly, that can mean 100 different things. And those 100 different things could potentially each require a new tool. And the niche nature of these tools means that they cost a lot. There's always the possibility that the tools are missing parts or have worn out parts. Best case scenario you can buy new production ones, or you might have to invest in another entire tool (such as a lathe) to make replacement parts. Sometimes they're so specialized that you're S.O.L. unless you can find antique ones on eBay that are usually hotly contested. And then, it takes time to become familiar with these tools. Sometimes you need to buy scrap movements to practice on, couple that with the time it takes to become proficient, and you're spending 90% of your time/money acquiring and learning the tools rather than using them in a job. I understand that this is the nature of the beast, but neither my time nor money are unlimited. I just offloaded a lot of spare watches that I was planning to get to some day, but after realizing the amount of time it's taking to do just a single watch, I decided it was pointless to hang onto them. I read the books, I watch the videos, I ask questions here, I upgrade my equipment, and try to be as careful and systematic about it as possible, and even if nothing seems immediately concerning, only about 50% of the time, the watch will spring to life after a service (I am watching the fault-finding course by Mark, but with regards to solving these faults, see first two paragraphs). Of that 50%, only about 1/3rd of the time is the amplitude healthy. It's demoralizing to put so much effort into something and get so little out of it. Don't get me wrong, I understand that I am by no means an expert and my results are solely my own fault. Point is, I understand Plato.1 point

-

I can understand Plato’s attitude, But it’s a shame he is n disenchanted as his input was always good and informative. the watch repair game is not cheap. If it was not for the Chinese tools being available at reasonable cost it would be hard work. I myself have a limited amount of tools some home made but effective in carrying out the required task but limit myself on un regulated spending. It all depends on how deep you want to go and the skill levels you have. We have said on WRT may times the best tools in the hands of an idiot are just scrap. NEW, Ihave three lathes and poke about on them when required but used to make bits on a Myford 7 for accounting machines, rivet posts and shafts. Used HSS cutting bits though tungsten bits were not available then1 point