Leaderboard

Popular Content

Showing content with the highest reputation on 09/24/23 in all areas

-

3 points

-

2 points

-

1 point

-

You need a new spiral ( hairspring ). We can go by the diameter of the movement to get an idea of the springs strength.1 point

-

You say it's a 2846 but on the plate it shows 28?8. There's plenty of new parts available for these movements. Where have you looked? For instance, Cousins have a lot of parts for 2846, as do Jules Borel Are the top balance jewel and spring sitting properly? It's hard to see as the pic is out of focus.1 point

-

1 point

-

I think that's it! I thought I had it bookmarked, but turns out it was the PC Timing machine software. I'll check it when I'm home, ty.1 point

-

Sorry but I do recall a video and/or post what had software that showed ‘pin pallet detected’ or some sort on the screen. Since you have watch o scope and the other- isn’t there open source Tg Timegrapher for PC? I’m in mac world so haven’t bothered…01 point

-

Looks like a Lemania cal 1281 @Nucejoe , have a read of this : https://thewatchspotblog.com/tissot-chronograph-lemania-cal-1281/1 point

-

Hi what you have got is a Swiss/French five bar cylinder movement. The likelihood of getting a balance spring is remote. On the other hand you could get a spring and have it vibrated to match the movement ( expensive if you don’t have the tools) even getting a donor won’t be easy. ThT leaves us with repairing what we have got, again not easy without the tools. The word Geneve would lead me to think Swiss.1 point

-

The regulator arm is missing. What is the diameter of the movement ? Also a top and side close up of the spiral is a good start. Rgds1 point

-

this is the unfortunate problem of vintage watches where somebody before you made a repair for them with zero thought of what will happen in the future. In other words it was convenient for them to change the jewel and not worry about you at all.1 point

-

1 point

-

Hey matey, at least she took an interest and asked a question. Thats some kind of win, unless you went on and on and on and on about it and she was just trying to shut you the hell up1 point

-

1 point

-

Well done waggy, you straightened out that little blighter . Bless you Ross , tooth pain , the closest pain a man can get compared to the fairer of our kind popping out a small human Someone has to , are you crazy ?1 point

-

1 point

-

Good man you are. I'm now at my skill level where I am going to try to repair mangled balance springs. Microscope at the ready. Well actually in a few days. Can't concentrate to well after a tooth extraction and infection . Hence watching Youtube and reading 'Talk' posts.1 point

-

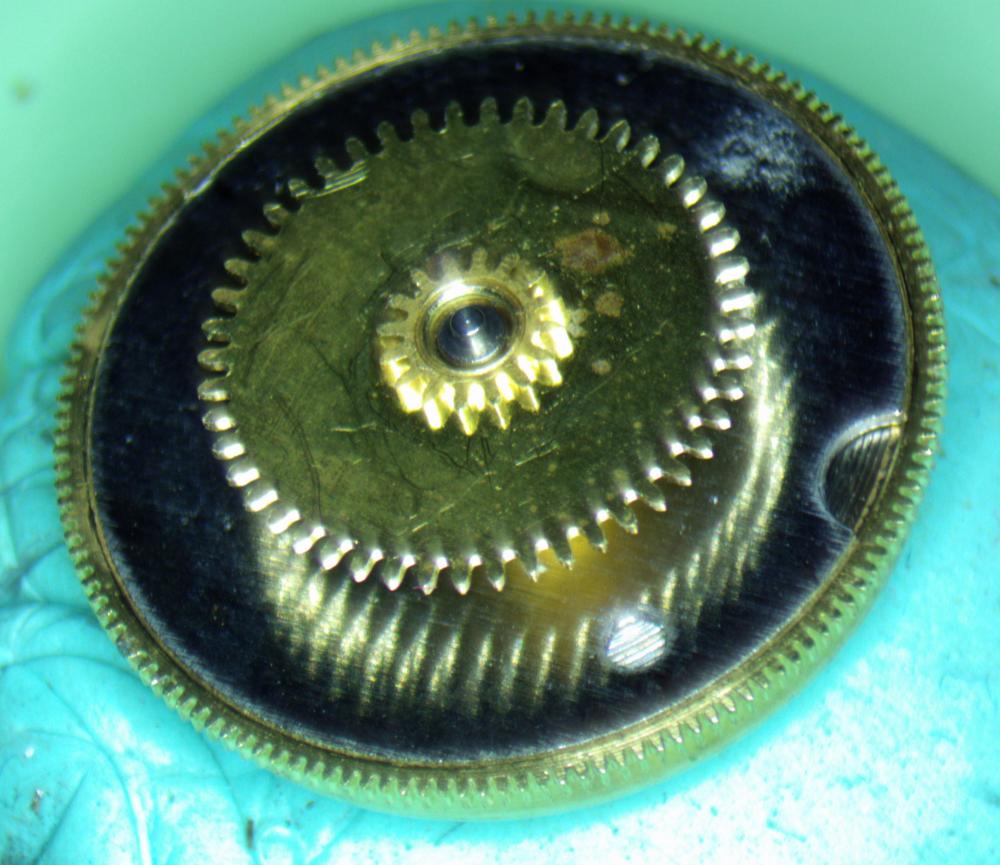

Working on a Rocar (Ebauches Bettlach Cal. 8135) which is really putting my Padawan skills to the test - "I am no Jedi yet". However I think I may have spotted 2 issues, the first being a mangled hairspring: Usually I would have walked away from this, but decided to 'give it a go' and it ended up like this: Quite proud of myself Here is issue number 2.... can you spot it: Replaced the jewel using my jewelling tool (another first!) Lets hope those were the last of the surprises!1 point

-

MJD. Made the same decision on my first match disassembly. A BTC fob watch from about 1900. Since then I have been lucky enough to obtain two movements, supposedly the same, but slightly different. I'm pretty sure I am now capable of doing a full movement repair. Only have to learn how to repair a case now. Take your time and do a watchmaking course. Well worth it. It's a wonderful hobby.1 point

-

When you initially checked the hand setting before anything got disassembled and you thought it was 'Goldilocks'... Not too tight and not too loose when setting the hands, well when you get to the friction-fitted minute wheel, you would turn the minute wheel above the barrel which is friction-fitted in place and 'feel' how tight it is. That is the tightness you want to 'feel' when replacing the minute wheel and using a domed punch in your staking set of the correct size to slightly splay the collar that passes through the minute wheel. That's why it is important to check that tightness on each hit of the punch because if you go too far the hand setting will be really tight, but also you'll need to remove the minute wheel and start again. Knowing that it can be hard to remove the minute wheel, if you have over-tightened it, it will be incredibly hard to remove, hence making those hammer blows light and keep checking the tightness. After you have had the experience of what feels correct a few times, it'll be child's play afterward. remember to check the minute wheel and barrel cover after removing, so that it is absolutely flat before replacing. You can see why the minute wheel needs removing by the amount of old grease in there, by your pic. Most of what I've explained is in the presentations. The slide I show using razor blades to rest the hand levers on is pretty important, as too much pressure will be put on the barrel cover and bend it. In fact, if you have a washer, cut it in half and that makes a better support, as it will rest on most of the barrel cover.1 point

-

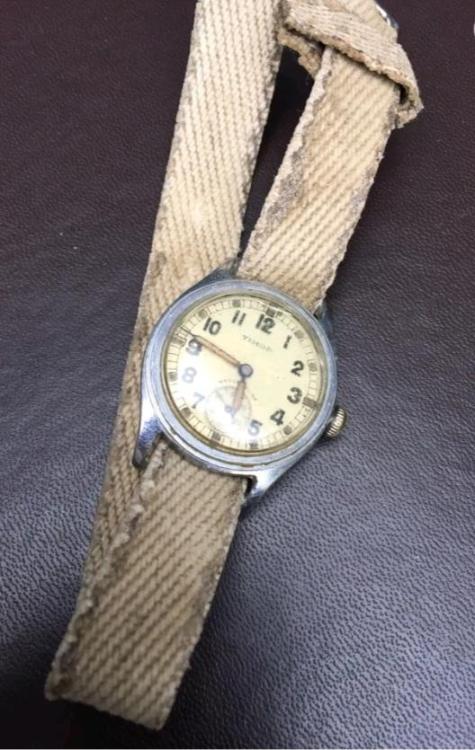

Another 404 club watch. Looks like maybe a paper dial, and almost certainly a low grade movement, but at 0.99p it should provide a little low cost fun. If you look closely at the second hand, it is actually snagged on the minute hand. I doubt if that is the only issue with it, but you never know. The two have been like that for a long time judging by the corrosion. I'm intrigued to know exactly what is inside it and where it was made.1 point

-

1 point

-

I cannot recall if I have posted this one before: I was in the mood to wear black today. And I've always liked the color combination of black and gold with a black dial. This is an uncommon one these days; an Avalon "Rivera", from sometime in the 1960s, with the usual 17 jewels, incabloc, & water *resistant*. I do not remember off the top of my head which Swiss ébauche is in here, but it is Swiss and looked pretty sweet. Fairly accurate as well. And makes for decent eye-candy also.1 point

-

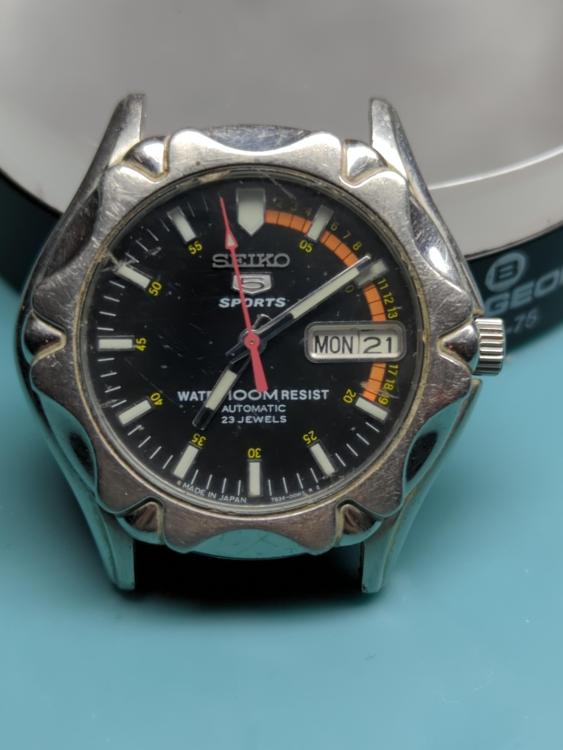

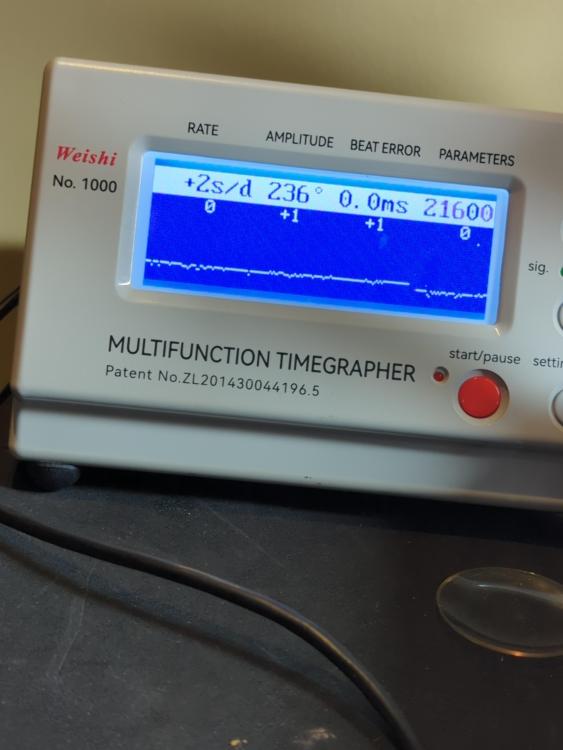

My son asked me to do a watch for him and his best friend to celebrate their exam results which are out in a week or two, so I let him loose on my 'to do' watches and he picked this one for his friend which is a Seiko 7S36 from November 2003. I was quite relieved that it wasn't a junker....but looks can be deceiving. I knew it was a non runner but there were a host of other hidden issues... Watch before: Gotta love that arm cheese When I came to remove the movement from the case it was very stuck... then I realised why... the dial feet were snapped off and the dial was glued in place with some kind of double sided tape which was sticking out and sticking the movement inside the case: Next I noticed that the crown wheel screw was sheared off, probably by someone not knowing it was a left handed thread... after a good clean I set about installing new dial feet: I then polished up the case restoring the correct finish, and here it is all back together and doing well on the timegrapher (no before numbers as this was a non-runner) - the amplitude isn't bad, and I expect it to improve in the next 24-36 hours... fingers crossed New crystal (broke 3 getting this one in - need to work on my technique) and new strap and here is the finished watch: And yes ... I contemplated keeping this for myself instead of handing it over to my son to give to his friend!1 point

-

1 point

-

Picked this little throwback piece up at a flea market, or boot fair is it called across the pond? $12US and was not running and missing the minute hand. Took it out of the case and the missing hand falls out on the bench! Put it back on, flipped it over and saw that the balance wanted to kick in. Gently pushed on the hair spring and then noticed the screws next to the balance were loose. Tighten them down, hit it with a puff of air and off trigger galloped! This seems original, the crystal is yellow but not noticeable at first. Edit: set this an hour ago and is running a bit fast but absolutely keeping time well.1 point

-

I have a couple variations for this Clinton watch with a bezel. I am not sure if it is supposed to be a diver or a world timer as it has a bidirectional bezel. Could use a new crystal. This is an FE3612 I beleive. I don't know why they didn't go full stainless case on these. This one has a bit of wear showing brass on just the underside edge by the crown. My other blue dial auto has the original band but is not a comfortable as this nato band. I ordered a black silicon band with red stitching and we will see how that wears later this week I am hoping.1 point

-

This Omega Genève, cal 625 from 1974 was a non-runner. I cleaned the dial a little bit too, but stopped before making it worse. Simple movement that went back to a strong beat after a good clean and oiling. BTW: pegging the jewels holes made a huge difference. I didn't do that at first and got around 270° amplitude (dial up, full wind) and lines were a bit choppy in the vertical positions. So I then disassembled again and polished the jewels with pegwood... and it went up to 290/300 with nice straight lines. I hope you like my "movement art"1 point

-

I am certain the pride will outweigh the disappointment the first time the repair happens the second time around … Well done with such a small movement- not a lot of lignes to work with. - and a very interesting watch and movement. That detail is like fish scales- very unique…1 point

-

Enjoyed bringing this one back to life for a (female) friend. Not my personal style, but it has a pretty mother-of-pearl dial. Very hard to photograph the shimmers. It was her early adulthood watch and it had stopped working decades ago. If fact, it was actually still running, but the crown was completely stuck due to water damage and rust. So it wasn't usable / couldn't set the time. Fortunately, the rust was only in the keyless works and relatively easy to clean off (after struggling for quite a while to get the crown/stem out ). The Cupillard cal 233 is running really well now. Now: Before:1 point

-

All worked out very smooth! Broaching was indeed very very light operation! I imagined to have done nothing instead it made an impressive difference just at the first fitting test! Actually I found out the rotor was very stable but still touching on the bottom tip, so I thought it was also bent, so I put it on an anvil and gently hammered it flat. Most likely the movement was damaged by a fall or something, and was bent both the stud and the rotor. Now problem fixed! The rotor is now very solid and not touching, no metal noise while revolving. I'm very happy and satisfied with the result. I could not find the pointed side document indicated by John searching online, it would be an interesting reading for me as I am try to focus on these lovely movements. Maybe is kind of a reserved document available only to Omega trained watchmakers? Again thanks for the very insightful suggestions, I learned a lot and I will make good use of this knowledge. Ascanio1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)