Leaderboard

Popular Content

Showing content with the highest reputation on 09/28/23 in all areas

-

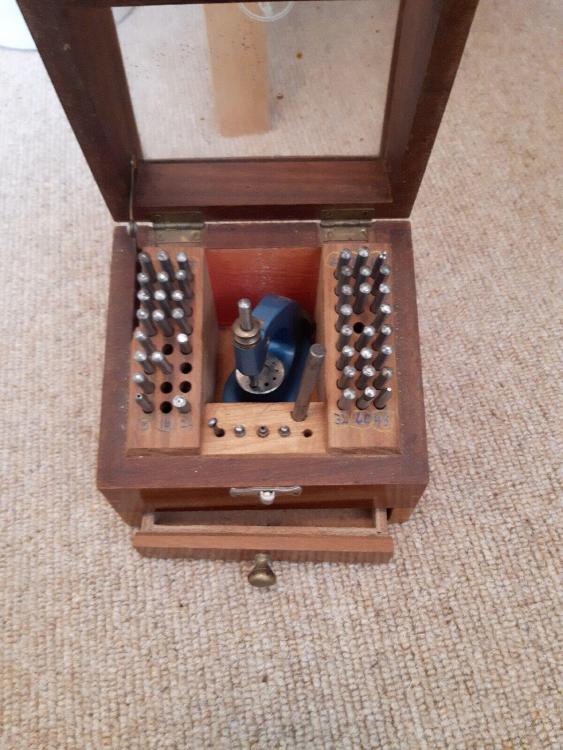

Well. I've done it. It's on its way. A staking set Made a silly offer on ebay and the seller accepted. I'm over the moon. Will keep you posted on its arrival. Will do a full clean, as did 'watch with mike' YouTube video. Wohoo! Thank you for the like Richard. Can you feel how excited I am? Saddo or what?7 points

-

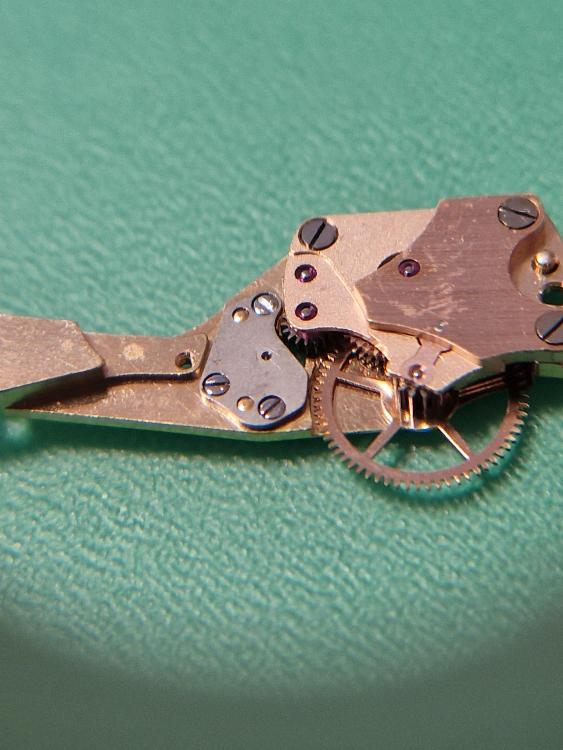

Final update on this piece! I'm done. Finally. While the replacement of the lower auto bridge solved the issue of the reduced amplitude, there were some other things that I fixed. 1. I replaced the reversing wheel with a NOS part (cleaned as per usual process with L&R cleaner and rinse in U/S; then lubricated with Lubeta V105 without disassembly) 2. The rotor was a bit loose. Didn't yet touch the rest of the movement, but certainly would have go there soon. So I ordered a new axle with already fitting rotor pinion. Note: if you buy a new pinion, it needs to be reamed to fit the axle (to 0.701 or 0.702mm). Here's the process: a. I pushed out the old pinion from the rotor with my Seitz press. I used a pump pusher to keep it centered; if I recall correctly it was the .105 size (but not sure). b. I pushed in the new pinion with a small flat anvil. I though I was done... c. ...but after installing the new axle, I was shocked that A. the rotor was way too tight (it wouldn't move by gravity alone) and B. , even worse, it was not straight - the rotor was touching the movement on one side and quite high on the other side. Oh dear!!! I decided to tackle issue B. first and put it in my staking set between two flat stakes and hammered it very gently. Back and forth between movement and staking set (with slightly increasing force). No change. It stayed uneven. SHIT! d. Before taking any more drastic measures, I decided to try out the old axle (after all, it is steel and should not wear much). And what relief!!! It was straight! But still very tight. e. So I took a smoothing broach (not cutting!) and moved it around VERY gently. Remember, the tolerance is in the 0.001mm = microns. And yes, fortunately, that did the trick already! I was relieved that I didn't start with a cutting broach... that would certainly have done too much. [sorry, no picture here, but you can imagine] I'm wearing the watch today to see if it winds well over the course of a normal day. The rotor is still on the tighter side, so will see if it winds efficiently enough. Hopefully, by this weekend (after testing power reserve) I can declare this job done-and-done!3 points

-

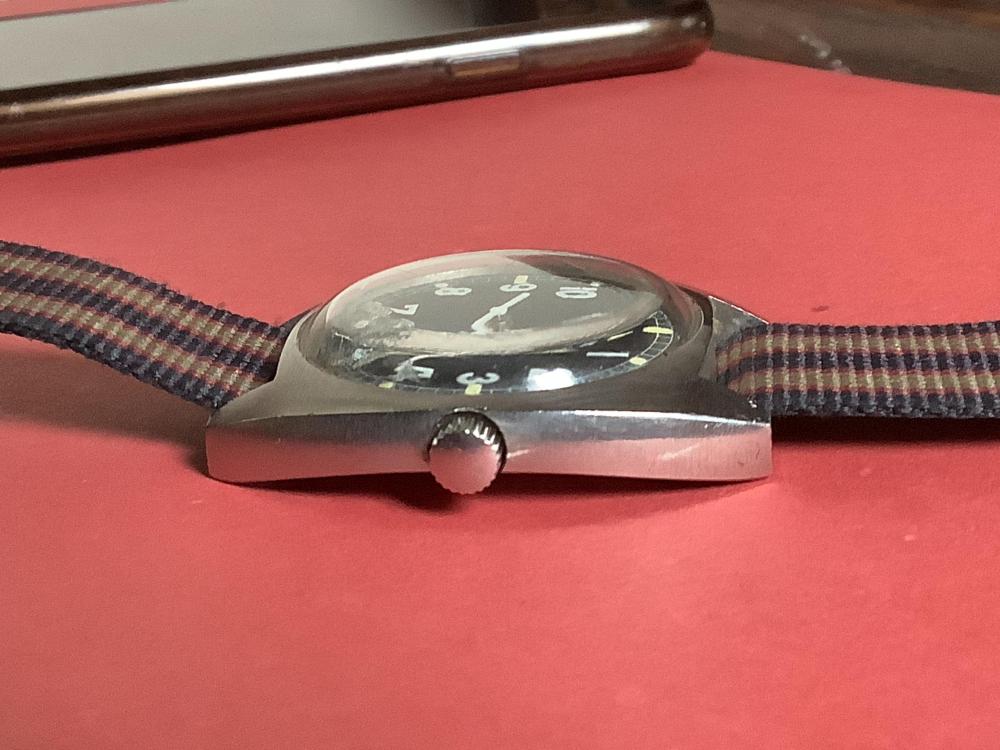

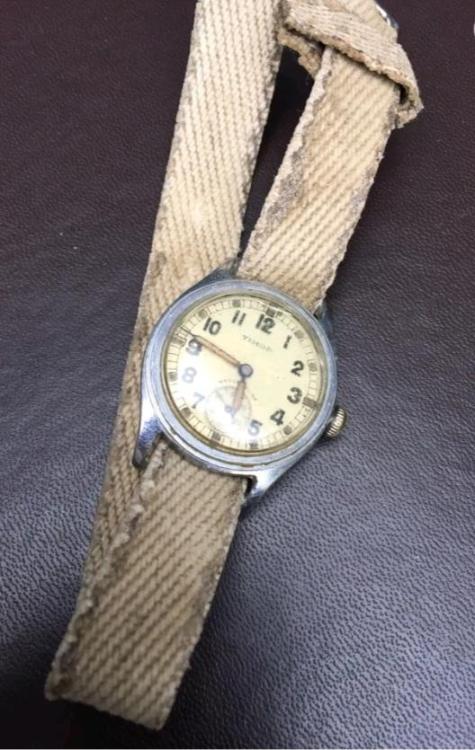

The Timor arrived this morn. Richard you are right the strap is tenacious mank and needs a good clean if its staying on. It looks old but i dont think its the original. Dial looks good and everything seems correct for what the watch is, it runs and seems to be keeping time ok . I was a bit worried as the seller said the lug pins had been repaired, not the best job possibly lead soldered in, not sure until it goes under the scope. But its good for the price, ive seen these at three and four times what i paid for it.2 points

-

Haha i can feel it Ross, my hands are tingling . Saddo ? you are among some of the finest Ross . Mate it keeps the dust off the business end when the lid is off. . Major issue though if you don't have any fngers to turn them the other way up. Thinking about it thats a major issue altogether if you are trying to repair a watch. It will be fine Ross Be positive. As my old mum said to me just before she passed away from an incorrect blood transfusion, " B positive Richard B positive.2 points

-

There is a beautiful old marble mantel clock at a indoor carboot sale not far from me, its been there for sale for well over a year. One sunday i decided to chance my luck and ask how much he wanted, the guy kind of knew me as I go often, he said you dont want it. I said i might do, expecting him to throw a crazy expensive price at me. 'Take a look inside it, its the local carboot joke ' he told me. Yep a 2 quid AA battery alarm clock turning the hands , ' er no thanks buddy I'll pass on this one '2 points

-

That's a very interesting watch! But there's zero chance of finding a commercial stem to fit it, it will need to be made by a watchmaker.2 points

-

In fig 2 you can see the washer which is press fitted, press it back with .01 mm tolorance to the balls of the bearing, obviously theres a risk of damaging the balls in the bearing or deform the washer if you punch. Support the other side of the bearing on a anvil.2 points

-

1 point

-

Compare amplitudes before and after instaltion of canon pinion and min train, I consider 5 degrees drop acceptable. The oscilator should not stop or slow down much when you move the hands anticlock, neither should the seconds ( otherwise called min hand ) stop. Not too much not to little resistance when you turn the crown in order to set the time. a-In case seconds hand can be moved backward ( anticlock), check the locks on pallets as well and side shake on fork and escape wheel . b-When teeth of a gear in the min train jumps over teeth of the adjacent gear, I want to check canon pinion for overtightness.1 point

-

As far as I know there isn't an actual test as we don't have a micro torque wrench and even if we did all the watches are different. Basically unacceptably tight is when you start breaking things. But unfortunately this is a subjective thing somebody once had me service a watch and I eagerly like the look at the watch movement and don't always pay attention to details like can the watch be set for instance. It wasn't was reassembling and I went to set the watch that are practically break something in the keyless because the Cannon pinion was on so tight. On the other hand I have a Waltham watch small ladies pocket watch and I thought it was too loose so I tightened it up but now having issues with part of the mechanism doesn't want to stay engaged because it thinks it's pushing something with too much force. There has looking at another wall from the see how tight it wasn't decided that may be there supposed to be much more loose and regular Cannon pinion or the sliding parts and the keyless are very Unhappy. As one of my tasks today is open the Cannon pinion back up to see if that solves the problem. Or in other words put it back to the way it was before why thought it was too loose but I was only judging that by how it felt not by how it functions.1 point

-

Do you have any projects lined up Ross to put her straight to work, cousins have spare bergeon 4.7mm punches if you need to fill the gaps, there doesn't seem to be that many missing. What's the large tool stuck up where the anvils are?.1 point

-

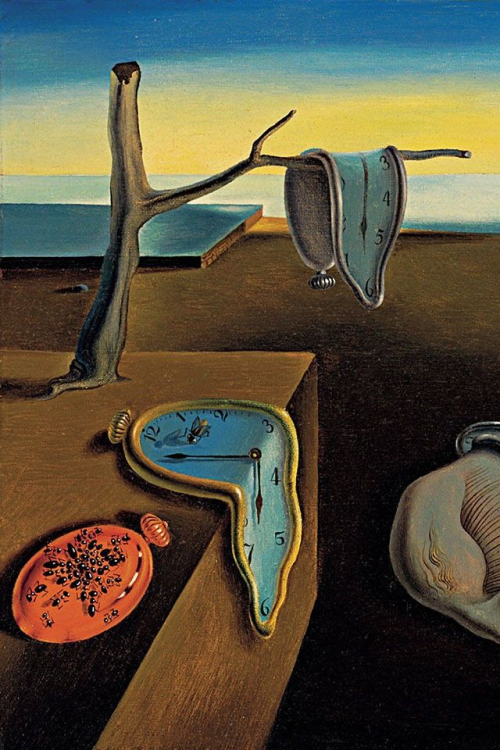

Hopefully it is silver soldered, but if not, remove as much of the lead as possible mechanically (file and emery paper), as leaded solder can screw up attempts to use silver solder and/or braze things. I've not done any brazing or silvers soldering on watch cases (yet), but I have used these techniques in the past to fix stuff. The internet is awash with how to techniques for silvers soldering and brazing. I',m not sure welding is practical with small brass objects, unless you have access to some pretty specialist micro-welding kit. I suspect silver soldering shouldn't present too many problems, and is probably much more likely to produce a good result than attempting to weld stuff at home. "Easy" silver solders melt at a considerably lower temperature than brass, so you should be reasonably safe using them. Brazing might be more hazardous as the brazing rod may melt at a similar temperature to the case, and you really don't want to turn the whole thing into a Salvador Dali art work. Your mileage may vary of course, and for all I know I may be speaking to an expert micro tig/mig welder. Once soldered, and re shaped, filed and polished, you will then need to re-plate the case too, to hide the repair, and probably re-drill the lugs if necessary. Keep us posted if you go down this road.1 point

-

Many thanks. I did ask Silvermans who were most polite but they don’t support these older watches now. They pointed me in the direction of a certain watch repairer but I’m confident I can do it myself. It’s keeping good time but with an amplitude below 200 degrees so a clean, new mainspring and fresh oil should help. Here’s a photo of the watch with the incorrect crystal. With the aid of air pressure delivered via syringe, I’ve just popped it off to have a look. There’s no tension ring and my vernier caliper reads 30.5mm, so I’ve ordered a Sternkreuz ATC 305. The chrome ring might stand out but will be a reassuring reminder that the glass and movement won’t fall out any time soon!1 point

-

I don' think so. You could probably tighten it a little bit on one side (with the Seitz tool) -- maybe even both sides (the other side with a staking set). BUT the pinion is a long shaft/tube that should be equally tight everywhere. I should make contact with the rotor axle along its whole length. So if top and bottom are tight to hold the axle, it may seem fine at first. But it will wear quickly on those two ends. And then you have a loose rotor rather soon. PS: also have a look at the post by "AI J" in this thread: https://mb.nawcc.org/threads/omega-seamaster-deville-rotor.187235/1 point

-

Recntly I was quite amused by one of the YouTuber watch women who makes a living hunting the world for your favourite watch. One of her favourites- she had acquired her grandmother's Cartier only to discover grandma had changed out the mechanical movement for quartz with the local jeweler back in the '70s. Yes, it was indeed a thing... Last Christmas my wife gifted me a quartz movement for a stocking stuffer. It is patiently awaiting a mission for some amazing unsalvageable I acquire...1 point

-

I hate the idea, the choice where they can be used is very limited, any watch with complications is a really struggle. Besides you are introducing something into the movement that just shouldn't be there. I have seen a few what i did consider reasonable youtubers use them as a last resort though. Nah not for me either, perish the thought.1 point

-

Just thinking that dial-dots aren't looking like such a bad option anymore...... just kidding1 point

-

Hi. Intermittent stopping is indicative of the clock requiring a service ( dismantle clean and oil). Possible causes are many the common one being dirt, congealed oil, worn pivots an bearings , also a broken main spring etc. All of which requires the clock to be dismantled and inspected. A picture of the clock and movement would be useful.1 point

-

You know, I never even considered these could be adjusted. I just replaced the rotor assembly on my 6139B. This is why I browse this forum1 point

-

So the next test would be to remove the hr, min and seconds hands and repeat the test you did before; If didn't slow down the oscilator, its the hand tubes that rub. if did , the fault is with the canon pinion and/ or minute gear, tight canon pinion ....etc. You already have the canon pinion mounted on center arbour, so it needs not to be broached, just add a bit of oil on center arbour and turn the crown, this will reduce friction there and if you remove/ clean the oil/ grease the center arbour your done. Stuttering seconds hand can be moved anti clock, but something must move it back, which takes us to faults said above.1 point

-

1 point

-

From the looks of it should be adjustable. Press on the washer thats underside of the bearing ( fig 2 ) to move it until you feel it ( the washer) doesn't want to move any deeper. It can be done in situ Press carefully: DO NOT PUNCH Good luck1 point

-

1 point

-

As watch porn goes the pictures are wanting- all the punches are upside down! Well done, anyways! I hope you enjoy...0 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)