Leaderboard

Popular Content

Showing content with the highest reputation on 09/29/23 in all areas

-

No. Was set at £175. I got it for 64%. I'm happy with that. I know it's early, but It was (is) my Christmas and New year present. Can't buy anything now until February 2024. But think of the fun I can have till then. Oh gosh, I'm a tool Saddo.4 points

-

I've got a couple watches lined up in addition to the one I posted about in the Newbie repairer category -- waiting for my confidence to arrive. Not a huge investment, but I'd like to give them the attention they deserve, and hopefully once I get inside, they deserve the attention I give them! Something about having a small queue makes me feel a bit more urgency in getting stuck in.4 points

-

3 points

-

2 points

-

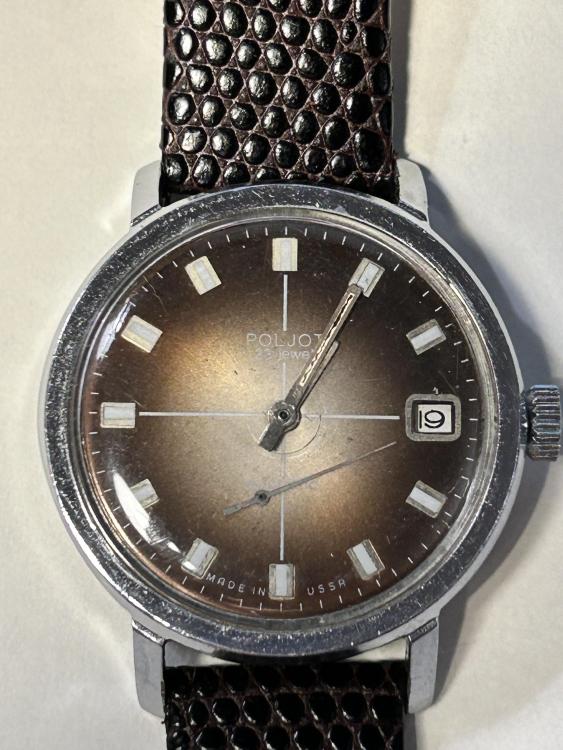

The Poljot looks pretty good. Its probably a Poljot 2614.2H, and parts are relatively easy to come by. Quite a few USSR era Sekondas share this mechanism. I'm looking forward to seeing the Gruen too. I presume the button on the Ricoh is a date quick set. I'm not that familiar with Ricohs, so it will be interesting to see how that one is put together too. Watch out for flying springs on the Poljot date mechanism. Don't ask me how I know.2 points

-

2 points

-

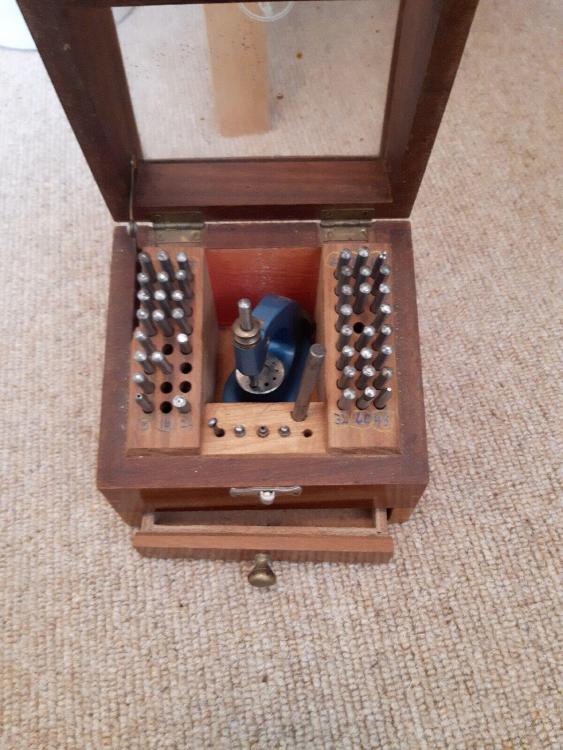

Well. I've done it. It's on its way. A staking set Made a silly offer on ebay and the seller accepted. I'm over the moon. Will keep you posted on its arrival. Will do a full clean, as did 'watch with mike' YouTube video. Wohoo! Thank you for the like Richard. Can you feel how excited I am? Saddo or what?1 point

-

Yes. This machine can function in 2 modes, soldering and spot welding. The spot welding mode can be used for broken screw removal as well as repairing broken mainspring bridles. If your DIY one works fine, then there is no need to buy another machine. But if you are thinking of buying a new machine, I suggest you wait awhile because I heard that there is a new machine under development that in addition to the above 2 functions, has a 3rd mode that can be used to fill pits in corroded metal surfaces.1 point

-

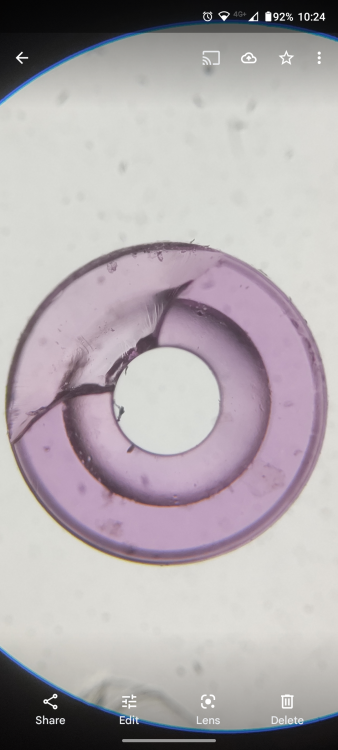

It definitely needs re-bushing and with those punch marks around someone has tried to tighten the bush that was used, I would say the hole was broached to big for the bush. So it was a complete bodge up. The old worn bush needs tapping out and a new one fitted. In this case the hole might need to be plugged first before re-bushing. The pivot needs to be checked for wear and will certainly need to be burnished.1 point

-

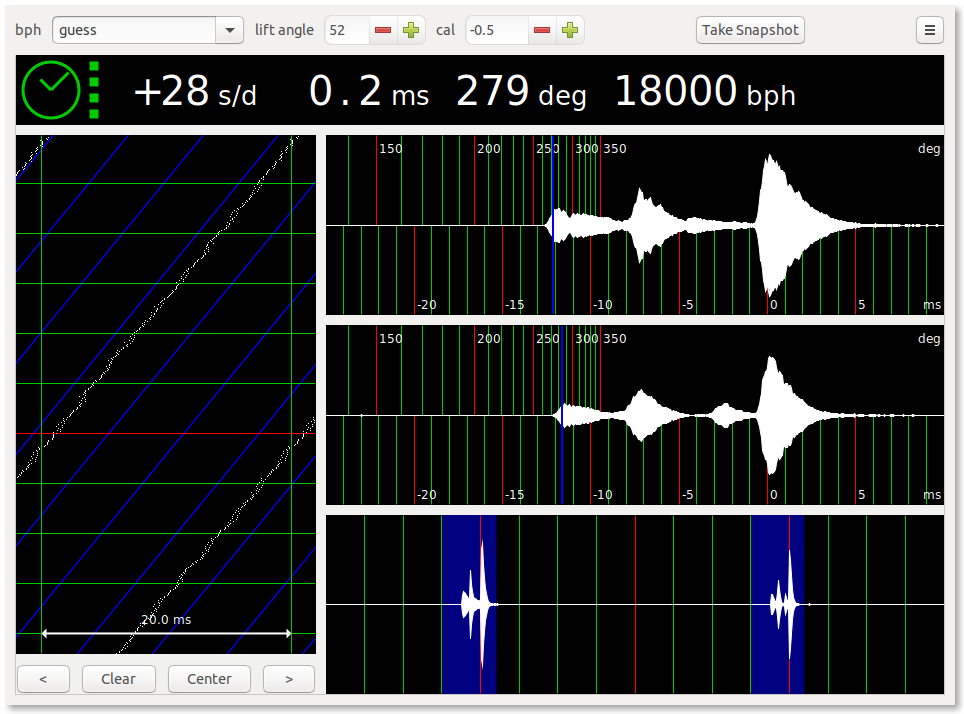

This is indeed a useful additional information! I had actually assumed that this would be appropriate depth, also because the previous pinion was at that depth. So the wobble of the old pinion was not due to this -- it was actually wear. As the final-final update, I can now report a successful conclusion to the service I wore the watch for a pretty lazy working day at the office and it was fully wound at the end of the day. Great! Actual real-life timekeeping (12h worn, 12h dial up resting) was -0.5sec/day. Timegrapher readings at full wind: Dup: +2@259°; Ddown:+11@266°; Cdown: +5@239°; Cleft: 0@234; Cup;+3@233°; Cright: -2@228°. AVERAGE +2. Timegrapher readings after 24h: Dup: +1@214°; Ddown: 0@212°; Cdown: -1@192°; Cleft: +1@190; Cup;-14@189°; Cright: +6@191°. AVERAGE -1. Traces are consistently clean+straight and beat error between 0.0 and 0.2ms. Amplitude isn't super high, but fine in comparison with the Omega specifications that @JohnR725 had posted (amplitude should be above 160 after 24h in all positions. My lowest is 189°). According to Omega, the Delta should be below 25 at full wind (I have 13), and below 35 after 24h (I have 20). My power reserve is 41h (Omega target 38h). So, all in all, especially after all these challenges, I'm very happy.1 point

-

`Don't think of this as a hand holder only. Is used any time you need to hold anything flat and open up the hole in it. Then pictures might help complements of the Internet. But let me read the description first Yes this is a really interesting description isn't it. So you unscrew part of it then you squeeze like shown in the image and it opens up. It is a spraying keeping it together. Once you get your item where you'd like it to be then you can tighten it back up and be careful when you're holding it not to break off the hand that sticking out typically1 point

-

I posted up a few other types a couple of hours ago, have a look and give me your thoughts. So unscrew the long handle fully which it isn't in the pic press the button at the bottom which opens up the clamp. Insert a dial hand into the appropriate hole that fits the hand then screw the handle back down to tighten the clamp. Once the hand is secure in the clamp and is centered within a clamp hole you can broach through the clamp to increase the hand hole diameter .1 point

-

The 6349 was already disassembled to begin with. I have the PDF of both 6309 and 6349 specs and identified the differences. I installed the 3rd and escape wheel of the 6349 on the 6349 plates. If I said otherwise, I'm sorry, it was a mistake. The train looks to be working well, it has power. It's just something between the escape and the pallet fork. Yes, I have 2 pallet forks and 2 pallet bridges. I already installed both, but no luck. Thanks for your reply.1 point

-

A new mainspring, a strong amplitude, good service with proper lubrication, and a perfect cannon pinion tightness, then there would be no need for any explanation, as there wouldn't be any movement of the second hand in this manner.... lol1 point

-

The Ricoh is interesting, plenty going on with that dial, i like it. The Gruen much more reserved but should be a good watch. Grunen for a time shared movements with Rolex, also dial names as seen here. Its not a Rolex but it is a Gruen nice watches matey1 point

-

Jobbers would have hard time convincing the watch owner to accept this.1 point

-

I didn't put it quite as detailed or as eloquently as you Jon , but i did kinda say its quite common. Did anyone listen ?1 point

-

...you're good at finding the funky ones. I like the idea of 'vintage quartz' that shows... My vote is the Poljot. Under that crystal I bet that dial is great. I'd relume instead of keeping the original...the Gruen is a nice classic. Work on the Ricoh first ....1 point

-

I know you said you cleaned your watch, but I'm not going to make the assumption that you have serviced and properly lubricated it. If you look at the third wheel on this Rolex 1215 (in the giff I posted) which drives the sweep second pinion (which isn't in situ), you'll find this moves quite a bit when setting the hands anti-clockwise, which in turn will always move the sweep second pinion regardless of how much tension you put on the brake spring. This is because the gear train is being moved when setting the hands anti-clockwise which strongly infers that the centre wheel is being turned via the cannon pinion and the whole gear train as well, thus a drop in amplitude and sometimes brings the movement to a complete stop. This is either the centre wheel not being lubricated properly, or/and the cannon pinion being slightly too tight on the centre wheel. Some like to have the movement come to a complete standstill as this is a type of 'hack'. I call it a 'poor man's hack'. The hand moving backward isn't such a big problem and you'll find that happens with other movements. I'm guessing you didn't replace the mainspring, as a good amount of power/torque from the mainspring through the gear train will massively help overcome this, also, as I've already said, a well-lubricated centre wheel before the cannon pinion goes on and the correct tightness of the cannon pinion will also alleviate this. If you have a low amplitude, it suggests the mainspring needs replacing. If you haven't got at least 270 to 280 degrees amplitude, there is very little that you can do to solve this, as broaching the cannon pinion will only make the hand-setting sloppy. That's why I initially asked about servicing and lubricating properly and this is why I bang on about changing the mainspring as standard because you are trying to diagnose and solve a problem when it was screaming at you all along. Not enough power from the mainspring!1 point

-

As my partner says "it's all about the undertones". with the silver case I'd go for a yellow-ish tan strap that avoided red tones -- so cooler. or a teal-ish blue strap if you didn't want a brown strap. I'd also do a slightly padded strap to balance the thickness of the case.1 point

-

1 point

-

You will find both a staking and a jewelling tool invaluable. As long as you continue with watch repair you will never stop spending money. Its like being married but without the nagging1 point

-

Ah yeah true.. want to be able to replace balance staves if required so I'll need to do my research into what's the most versatile tool. Or, just buy two tools! Why stop spending money now1 point

-

Ah man, great purchase other Ross. I've been looking at replacing some mainplate jewels on a couple projects and have been eyeballing some staking sets. Keen to see how you get on with it!!1 point

-

You will find this totally different from the 218. Take your time with this. Read all you can on servicing a 214. Goodluck.1 point

-

Matey, i think you just need to take a close picture of each of the pallet fork pivots for everyone to have a look. We all just guessing here, lets rule something out and then move on.1 point

-

Did you use 6309 escape/3rd wheel with 6349 mainplate and train bridge? You shouldn't because they are different, the pivots are different shape and length. Just checking.1 point

-

Haha i can feel it Ross, my hands are tingling . Saddo ? you are among some of the finest Ross . Mate it keeps the dust off the business end when the lid is off. . Major issue though if you don't have any fngers to turn them the other way up. Thinking about it thats a major issue altogether if you are trying to repair a watch. It will be fine Ross Be positive. As my old mum said to me just before she passed away from an incorrect blood transfusion, " B positive Richard B positive.1 point

-

Good idea for a new thread. The choice of leather strap is almost unlimited with colours, pattern, texture , detail as with stitching, piercing, buckle, loop, clasp, a cuff design for a watch you love but just looks too small on your wrist. Rubber, nato cloth, canvas military bands, metal can get you out of a dilema . Initially i used to think silver case black strap, gold case tan strap, but that only seems to work for white dials. The dial colour dictates way past that so that classic look doesn't always work and the reverse can look better if the strap colour ties in with the dial or details from the dial as in Richard's watch. A black strap wouldn't work here even though the case is silver and the dial face is pale. In general i think the choice of leather strap as far as colour goes must pull something from the dial. Great idea for a thread as Richard has said some folk dont have an eye for it, but there are some pretty basic rules that you must to follow.1 point

-

Coins be hands fouling, also check the leaf spring correctly sitting on the back of the seconds pinion if it has one. This spring is there to stop the seconds hand 'stuttering'. Just need to pop the back off and look.1 point

-

Grey sounds like it should work, or how about a dark navy blue? My lunchtime fix for today. Not much to say, new crystal obviously, new battery, full fumigation and case clean and polish. The original Rotary strap was almost unworn, so it also got a fumigation and was re-used. .. and here is the Montine I did the other day for comparison. I'm spoilt for choice.1 point

-

After my defeat at the hands of the Rocar I decided to try another, an Orient. After battling with the pallet fork, balance, date finger wheels (the horrible plastics ones), putting on new dial feet, crystal, crown, winding stem and second hand (ship of Theseus??) I finally managed to get it up and running. Wearing it into work today after a first pass at the regulation after assembly, I'll tweak it tonight, but seems to be running well.... So far. Black strap is just temporary, thinking of getting a grey one as permanent one... Any thoughts?1 point

-

1 point

-

Working on a Rocar (Ebauches Bettlach Cal. 8135) which is really putting my Padawan skills to the test - "I am no Jedi yet". However I think I may have spotted 2 issues, the first being a mangled hairspring: Usually I would have walked away from this, but decided to 'give it a go' and it ended up like this: Quite proud of myself Here is issue number 2.... can you spot it: Replaced the jewel using my jewelling tool (another first!) Lets hope those were the last of the surprises!1 point

-

You won’t find an original willard or a decent dd in the US for under $1k. I think the willard repros are scarce now, too. A good A-11 can still be had for $300 a good A-17 for 500- get one of those yourself and make sure the company treats you! One of the hard shell militaries, Benrus et al will be a good choice, too… …and sorry to continue to veer ot but since the pics have been light here this week and if we’re talking tomorrow’s watch of today and something a bit more military, some visuals for one I hoped to have been posting by now… …got it to here yesterday, still much to be done…I’ll write it up in the more appropriate place…but what do y’all make of that dial?1 point

-

Personally i like to collect old iconic watches, so many made famous by films etc. Or unusual designs.That doesn't especially make them a great watch just a theme of collecting. You've mentioned the Willard, how about a genuine A 11 military watch. Another iconic Seiko would be the Pogue space watch. A Citizen bullhead ?. A grand might even get you a Dirty Dozen, i dont know the availability of these in the US though, an A 11 is more appropriate for your country. Pre Swatch Omega Tissot or Longines , like Richard I'm not a fan of Swatch.1 point

-

1 point

-

The two jewel ISA 1198 based " Montine of Switzerland" "Swiss Quartz" arrived, and It looks completely unworn. However the original battery had destroyed the lower battery contact. Bizarrely it hadn't corroded, in a conventional manner, but rather it had split into a number of thin strips. I fabricated a replacement (from a 10K ohm resistor leg, flattened in the vice), and now it is running perfectly.1 point

-

1 point

-

Today I've been wearing my newly serviced "Services" with the Smiths Cal 627. I new nothing about the Smiths factory at Ystradgynlais making "cheap" watch movements until I got this. This is a rare(ish) 17J and runs better than I ever imagined it would. After running overnight, I've warn it all day, including a round of golf (a challenge for any watch) and after 24h it's +2s. Amazing for such a cheap watch. I wrote about it here1 point

-

I haven't worn this for a few months, so I figured it was time to give it an airing. A Felsa 790 series "Orfilux" 25 Rubis Automatic from around 1955, in a "Hermetica Garantie" case. RWAG is most likely the case maker Rodi & Wienenberger AG, Pforzheim Germany. (Translated link). Sadly RWAG appears to have ceased trading around 2019. I can find nothing on line regarding the "Orfilux" brand, but I suspect it may have been a German company, using Swiss movements. If anyone else knows anything about "Orfilux" I would be keen to hear. I cleaned and serviced this on November 30th 2019 and it is still going strong, though I suspect that is more a testament to the quality of the caliber than it is to my amateur servicing efforts. It also probably helps that this is not a "daily driver", and that thus far I have resisted the urge to pull it all apart again and "fix" the hands, a process that might be fraught with possible pitfalls. The "patina" (some might call it rust) on the hands, isn't obvious unless you shoot a macro shot of it and post it on line, so when I'm wearing it, I can live with it. I should really sort it out by polishing and reluming the hands, but I'm happy enough to leave well alone for the time being. Maybe next time it needs a service, the I will be unable to resist the urge.1 point

-

1 point

-

Tressa Automatic 1970s ETA 2788 Running at 0 to +0.5 SPD in wear. Replaced crystal, crown (original crown worn and too small to wind effectively) and day wheel (plastic had gone very crumbly on the underside). Also badly chipped jewel on train wheel bridge (replaced entire bridge as easier than changing the jewel). Very good movement running at over 300 degrees DU/DD. All positions 0 SPD except PR, PU +2 SPD.1 point

-

0 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)