Leaderboard

Popular Content

Showing content with the highest reputation on 10/04/23 in Posts

-

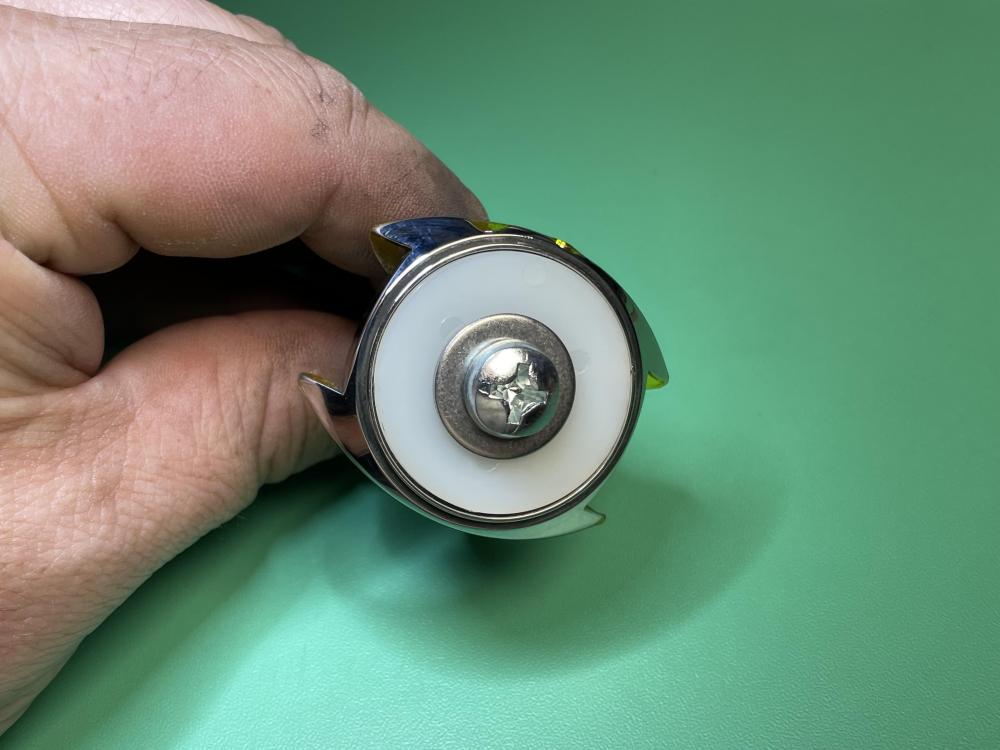

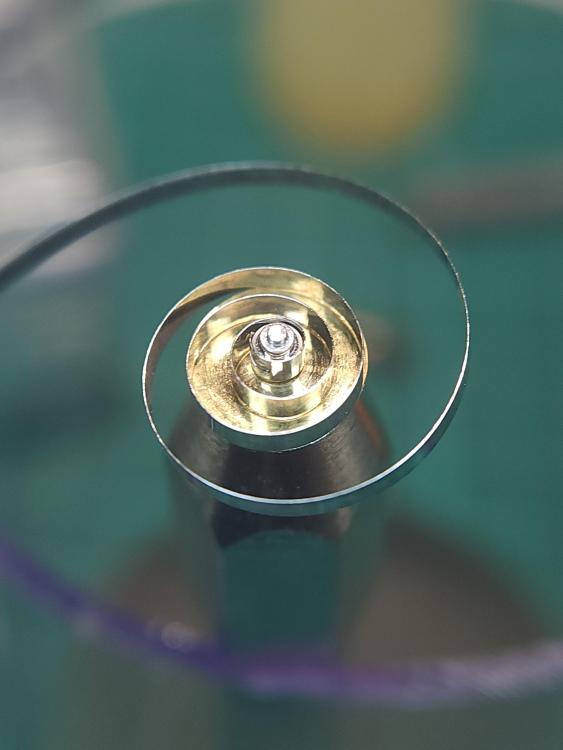

I’ve got a case that I’d like to do some radial brushing on. A lapping machine is far out of my budget, so I tried to improvise this evening. I secured the case between a nylon washer and one of my plastic crystal dies. I chucked it into a drill, and then used that to align it at the proper angle against a brushing wheel. It’s clearly not perfect, but I think the concept is sound. I’ll probably need something different other than a thick brushing wheel to get the desired effect, so I’ll play around with it a bit more. I am encouraged that this may be a workaround to a very expensive tool. Obviously a lapping machine can do many other things, but I’m just trying to accomplish this radial brushing for now. About two weeks ago I came up with a very crude way of holding a case back centered and allowing it to spin, so I can apply radial brushing to that part. It seemed to work pretty well. The first two pictures are before my brushing attempt on the case.7 points

-

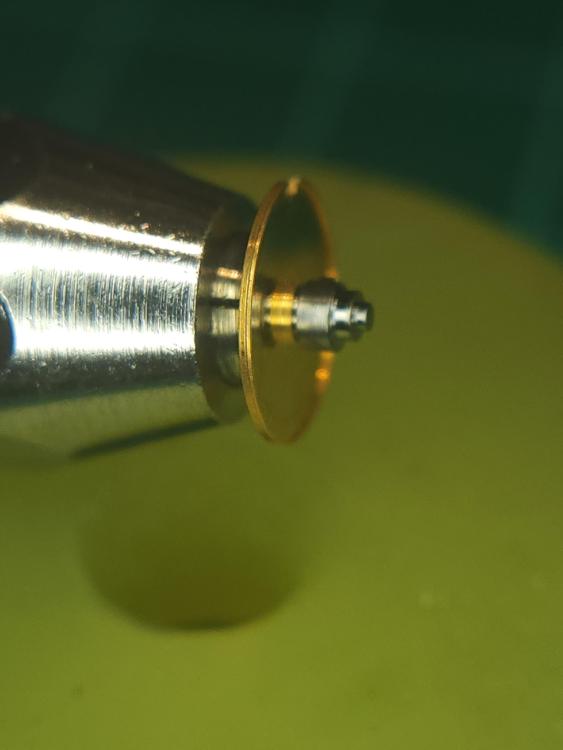

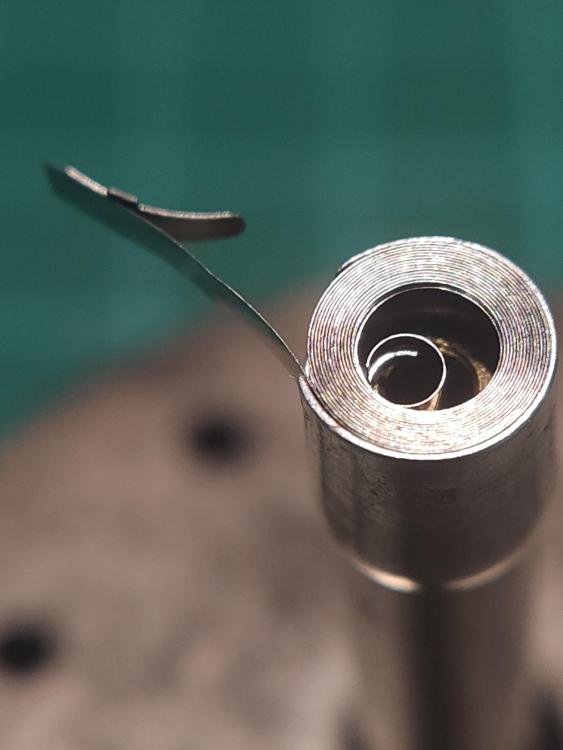

What do you do when the correct size mainspring winder you have has an arbor that looks like this? This is exactly the situation I encountered last night. I was servicing a Slava 2428, twin barrel movement. The barrel is so small that the only winder that could fit was a Watchcraft #2. But my arbor looks like it got chewed by a dog. I remembered a post a couple of months ago about a homemade mainspring winder using a plastic sheet and a pinvise to hold the actual watch barrel arbor. Then it hit me. I could mount the barrel arbor into a pinvise and wind it directly into my winder. Initially when I tried it, the mainspring kept twisting and buckling and wouldn't wind nicely into the winder. I had the idea of cutting a washer to cap the open end of the winder. When I finished doing that, I looked at the washer and thought it looked a lot like the barrel cap. I took the barrel cap and realized that the barrel cap fits perfectly. So I mounted the spring and wound it into the winder easily.5 points

-

Took a bit of thinking. But I've done it. The base is a wooden block from a local Supermarket I cut the base and shaped it so that the Staking set would sit on top. The cut out allowed the stake to be set on the podium to be used a s stump for the set. I placed a piece of metal at the bottom of the stake to allow hammering, and to keep the stake in a set position I have secured a plastic container with holes for the stake. No movement now. Heath Robison, but it does work well. All done. Back to watches now.3 points

-

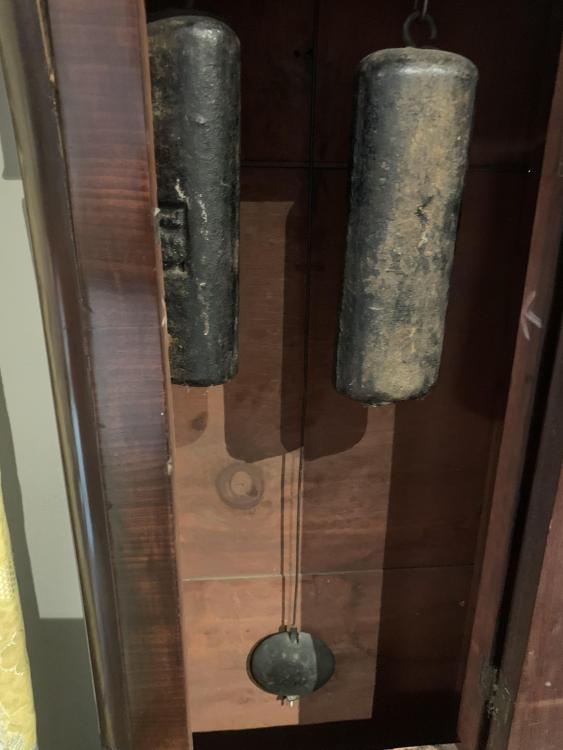

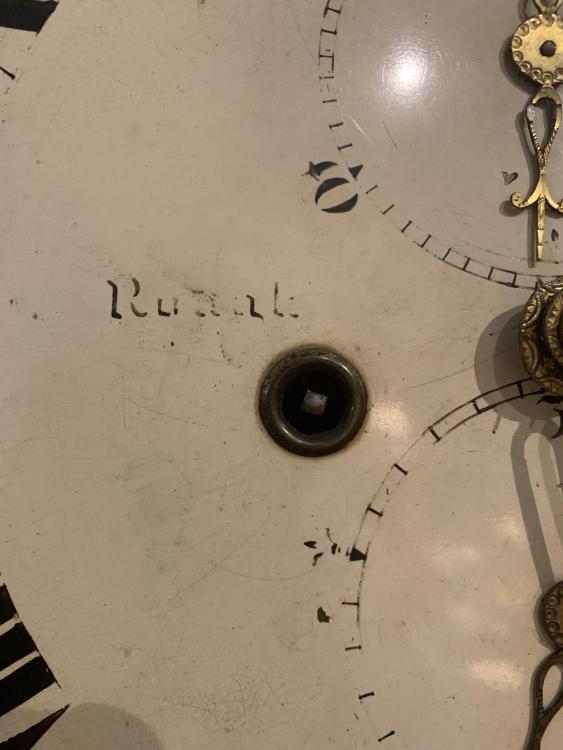

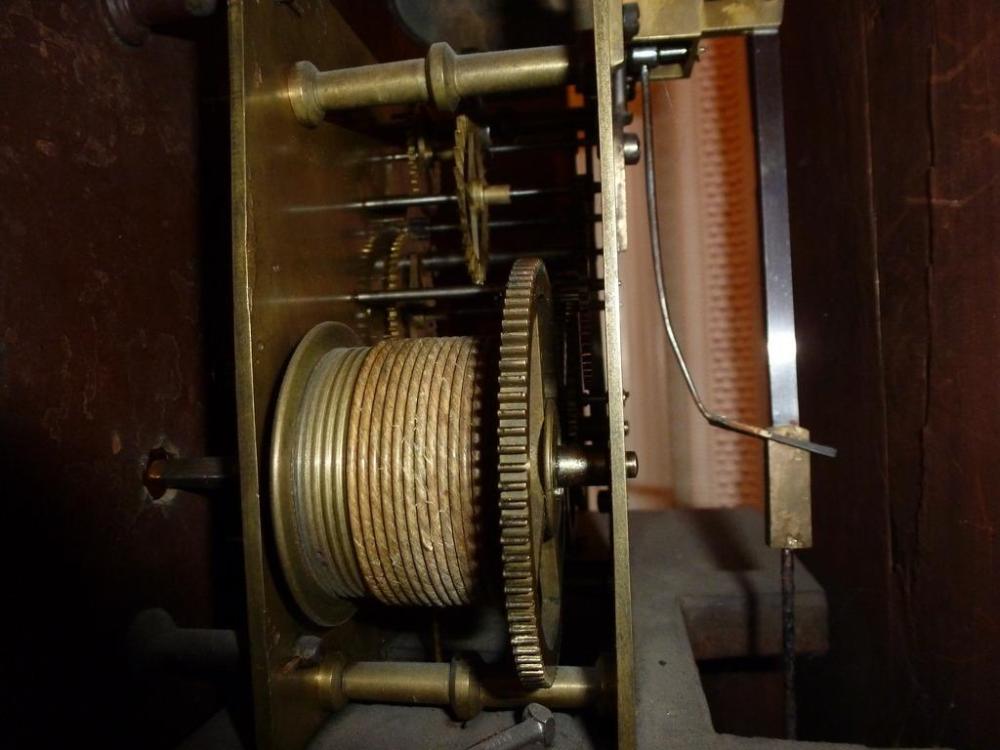

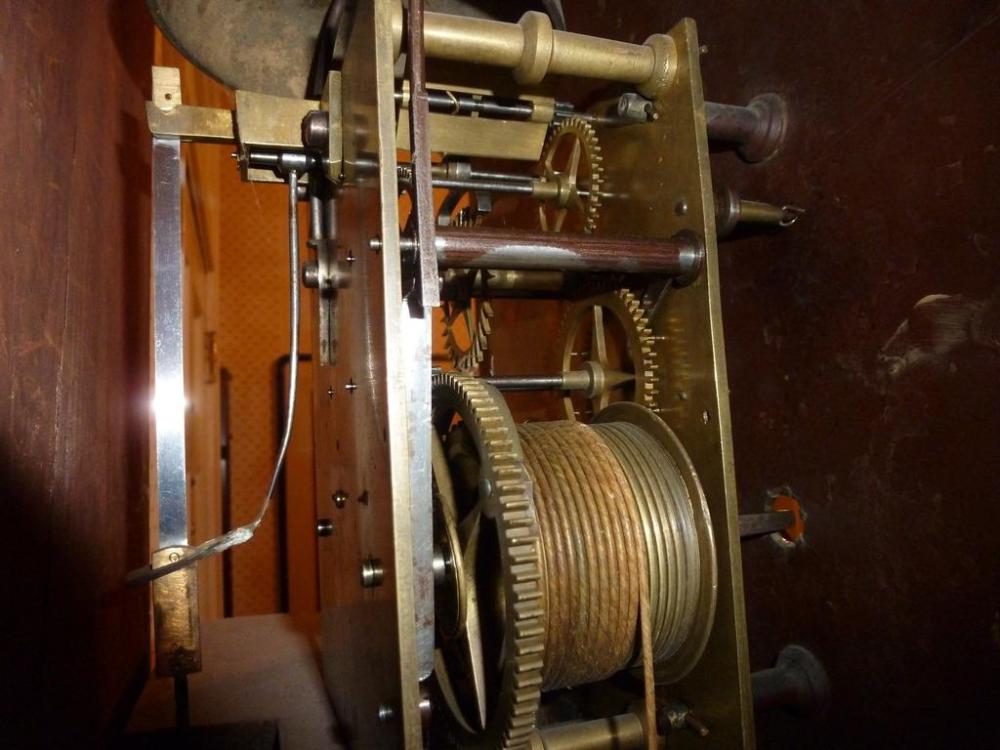

Gents - purchased a tall case clock some 50 years ago and it has certainly been reliable. Have always wondered how old it might be and who might be the maker. The face looks to say something for the maker's name like Rouak Kirkalan but very hard to read. I had a part repaired about ten years ago - maybe the snail tail?? - but other than that it has been no problem. Does anyone have an idea about the identity/age of this old clock? Pictures attached. Thx.2 points

-

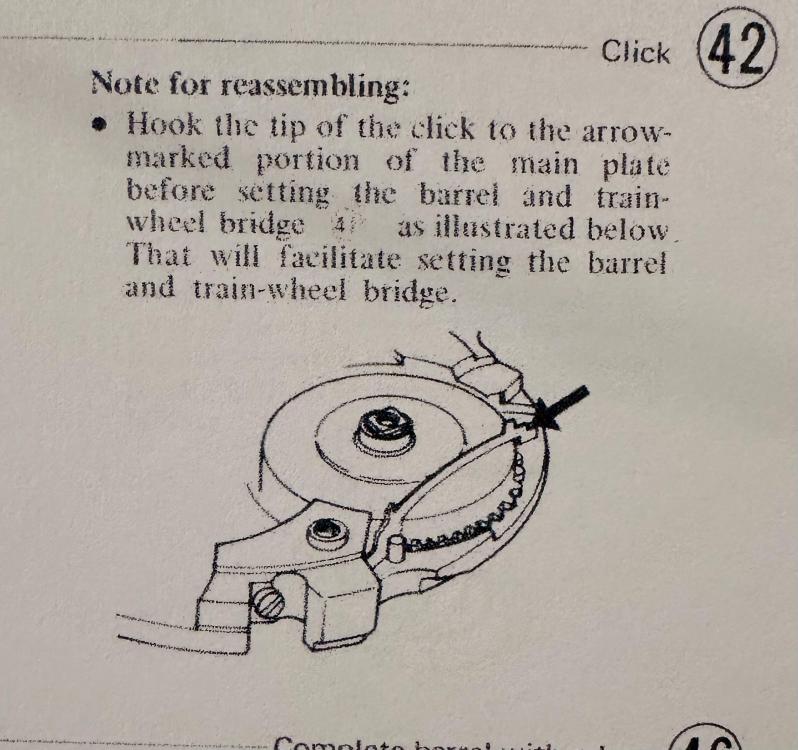

Hard to tell but from the angle in the photo the click looks misaligned. There is very little clearance for this type of seiko click… …not that you didn’t use care. I’d second the idea of just doing a refit…the good news is there’s room to adjust the position. Bad news is there’s room to adjust the position…2 points

-

1 point

-

1 point

-

I don't know, I just know that @Nucejoe recommends it, maybe it's just easier to get as everywhere sells it.1 point

-

WD 40 isn't a penetrating oil, so you could try some proper penetrating oil. One of our members, @Nucejoe, I think swears by Coca-Cola due to the phosphoric acid.1 point

-

1 point

-

1 point

-

Thank you all for your kind messages of support helping me heading in the right direction. I'm out of town some days and won't be able to disassemble the pieces and assemble only the escape and pallet as suggest, but I'll do that soon and get back with photos. Thank you all for your wonderful advices.1 point

-

I see lots of white particles on the mainspring!? Are these shavings from the 3D printed winder?1 point

-

When asking questions always helpful to give more information like who made this watch and maybe a picture of the gold parts. So I googled and looks like it's a citizen and I'm attaching the service manual not seeing anything that looks like cold Springs though? So hopefully I guessed correctly for who made the watch. Also the citizen manual isn't as nice as a Seiko because Seiko usually is a parts list citizen we don't owe parts lists I can't see if there's anything that looks like gold springs but there are some technical drawings. citizen_e001_e011_e031_e101_e111.pdf1 point

-

The screwdriver set only appears to have 2 handles. I'd give this a miss.1 point

-

I cant see what they are. I thought I could see one with a small wheel, so I thought of bur removing.1 point

-

Rubbing is due to unlevelness of the turning parts, if you see no damaged teeth/part, the sound must come from a broken part or mainspring slippage. Does it run if you rewind after each stop?1 point

-

1 point

-

If all fails, you could perhaps try this Italian seller ..... seemingly a new movement for €99: https://www.ebay.de/itm/225761270458?hash=item34906b9aba:g:1wQAAOSwBUNkiyV7&amdata=enc%3AAQAIAAAAwH09%2Ba8VM7883Q5OhWmiVw%2BpDawwulT9404BJUumVi5YYw%2FwVM95c%2BoSWJf%2F%2Bdrhy%2F5wCon9CbV2hJUWBCo4NcHhEs%2BZP9%2FJxESpBUvs%2F1FJia9B0BhjFkVSq50ZxK1dEIIjAXUS0y32efvtm5t9Da1N6t9vCxHi8i8mUB5pd1Qu0Ozzl4wQPnlx80OefgyKKV1eMSXoFoIsHY%2BFrnHMsQHlFqLHuUYYJNkz7s1NmYo92%2FSOQCceO5wrAMxynBM97Q%3D%3D|tkp%3ABk9SR_Cxk5vfYg1 point

-

Usually most quartz coils are damaged by external influences. In other words that's really tiny wire and you don't want anything touching the coil. Typically when batteries are being changed people's lap and scratch the coil. Or when checking for coil resistance you want to keep away from where the wires touch the circuit board in fact you want to stay a far away as you can because if you touch in the wrong place that is a bad external influence a you probably break the coil. So no typically coils do not fail at a super high rate not without help. Usually the downfall of quartz watches is the lubrication goes bad with time and or External influence again of dirt and debris getting in the watchmen somebody changes the battery. Gaskets that fail moisture gets in the battery leaks that can get all over the place. Depending upon the age and if it's ever been serviced poor lubrication practices were oil can get sticky very sticky. I was doing a Seiko's ladies watch once and lifted up the plate and all the gears were stuck to the plate that would be an example of poor lubrication practices.1 point

-

Watch mainspring winder. Looks like a bur remover. Bergeon broken watch screwdrivers with tubes for spare blades. More watch winders. Various bits in the round pots. Blue box various watch buttons. Value depends if you want it. £10 max. Pictures are poor to be more precise close ups of the items and take the lids off the pots.1 point

-

I wonder is something shorting them out, your tester maybe ? I am surprised how many have failed, something faulty with the design of the module. Out of the few hundred or so quartz movements that i have stripped down very few had a broken coil.1 point

-

1 point

-

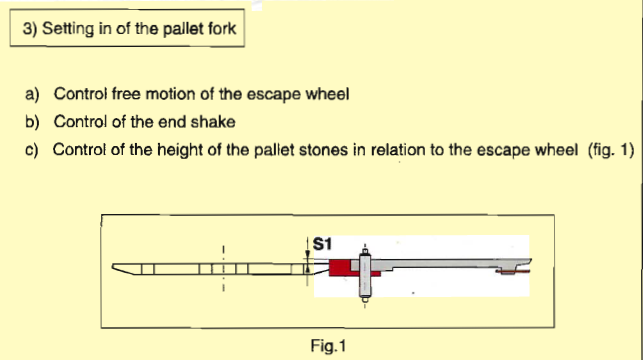

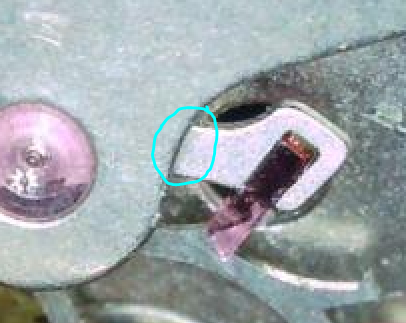

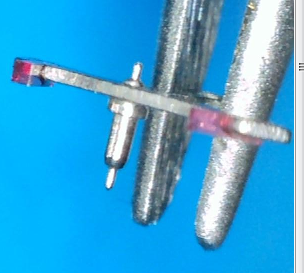

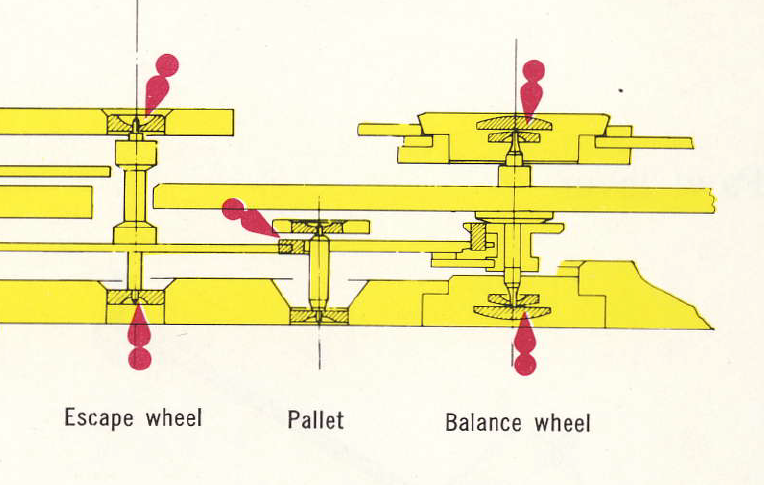

It could be an optical illusion? Probably just the camera reflection nothing to worry about here On American pocket watches I always frown on mixing and matching because when it came to the escapement the watches were adjusted with the components in the watch at the a mix-and-match it will be a nightmare. But this is a modern Seiko we can mix and match can't we? Now let's look at the basics that seem to be forgot pallet forks have to be in alignment like this image shows otherwise? Isn't this picture interesting yes the pallet stone appears to be out of alignment with the escape wheel but notice I circled something it appears to be that pallet fork might be a little high as it's touching the bridge? Let's look at the images the two separate pallet forks and who knows which one is in the watch but I'm guessing the second one. In the upper image you can see the pivot and a bit of the arbor sticking up. In the image down below we just have a pivot and well at least give a pivot it's not like we really need clearance here is it? Let's look at something Seiko has touted the lubrication guide for different watch. This is where it brings together all the concepts of escape wheel in the pallet fork have to be in alignment and you need to have some clearance between the fork and its bridge exactly like the image here shows versus the pictures were seeing in this discussion That's from a 7005 I believe they'll be a little different clearances but the concepts are all the same now let's go back to the first page and get a few things Tech sheets are nice parts list are nice and websites are nice reading cross reference components like this one http://cgi.julesborel.com/cgi-bin/matcgi2?ref=SEK_6349A So basically click on the components and see what it cross-references to. It's hard to tell with Seiko it almost looks like you're stuck with whatever you have because normally on modern Swiss watches the arbor is friction in and can be moved around. Oh and thinking about how this one doesn't appear to be in alignment it also has to align with the roller table on the balance wheel. Now let's swipe an image off eBay they claim it's the right pallet fork and see how it looks? Definitely looks better looks like more of the arbors sticking up like it's supposed to be definitely give you better clearance. Now before I leave the home page at least you gave us pictures. My favorite is for newbies to describe a situation and not give us a picture because we should instantaneously know what they're talking about. Which is why a lot of times I joke about I should get a crystal ball and learn how to diagnose watches on discussion groups. But here we got a picture right at the very beginning and? Interesting I'm sure it's an optical illusion again but it definitely looks like that fork is way too high and rubbing on the bridge which is only a secondary problem to everything else. And just think it was the very first picture?1 point

-

Hi. Do a recheck, remove everything and re fit the barrel and associated parts and check again it’s like Joe said bent , Brocken teeth, or even some hard grit in the teeth. They are usually quite straightforward.1 point

-

Hi NEW is on the right track, given the last picture where the pallet is riding over the escape wheel suggests that the pallets are not fitttet to the arbour correctly and need re seating on to the hub to bring them inline. But looking at the pictures of the pallets in the rweezers it looks to be ok. I wonder if the staff has been replaced and it was put on upside down. I would be inclined at this time just to fit the pallet and the escape wheel to the plate and check out the alignment between the pallets and the wheel, and a picture from the side so we can all see how it lies because somthing is definitely out of line.1 point

-

Sounds like broken/ missing barrel teeth, or mainspring slipping/ disengage.1 point

-

The pallet stones look to be riding ABOVE the escape wheel, the interaction between the two doesn't seem right. It's time we had a clear picture from the side, strip everything back leaving just the pallet fork and eacape wheel installed. My blind uncle told me dont believe anything until you see it with you own eyes. Hence he didn't trust anything1 point

-

1 point

-

Perhaps the shellac has loosened and allowed the pallet fork jewels to be pushed back into the setting?1 point

-

Fork horn and guard pin show the fork luckily installed right side up, installing it upside down is impossible Fork appear to be touching its bridge, bridge might pressing on the fork thus might have bent the pivot.1 point

-

No question or suggestion is dumb BW, a picture from the side which we haven't had yet would answer that.1 point

-

It was a public holiday here in the UAE on Friday, so I decided to put it to good use and work on a watch that has been on my to-do list for a while which is an automatic Zodiac square watch. The build went well, however I am still ironing out the bugs in my scope camera and ended up losing all the photos I took of the pre-build and build this also made the re-build a challenge as the calendar works side was a little unusual (bridge over the cannon pinion). So only have a picture to show of the before and finished watch, the dial was in great shape under a beaten up crystal which I replaced. I didn't do much with the case as the plating was already starting to wear, so just a quick polish with some Flitz. Here is the before: And here is the completed watch:1 point

-

I am very new to all of this watch making stuff however with the issues I'm seeing here... Is it as simple as you have the pallet fork install upside down in this movement? If the escape wheel is, as it appears to be, passing under the fork in the last pictures you provided and in the earlier ones it's looking like it's almost touching the pallet fork bridge. Since there is a short and a long pivot.... also if this is a dumb suggestion just ignore me. I'm only getting started.1 point

-

So yas, now that it appears you have two forks with two asymmetric but maybe correct pivots, back to this pic where it looks like the fork may not seated properly, hence the call for jewel inspection and an examination of the fork in place by itself, a check of end shake then division, then with the escape wheel back in place and do the pallet jewels and escape wheel play nice? …and then we’ve been focusing on the pallet fork but from this picture I can’t see a pivot for the escape wheel seated in the upper jewel, so even though you say the train has good power without the fork perhaps the escape wheel isn’t seated correctly or an issue with endshake or division or an issue with the escape wheel jewels and is there a cap jewel for the escape wheel shock setting upper and lower and does that raise/lower the escape wheel so it plays nice with the pallet fork? ...and yes I see from the photos you have cap jewels so without the cap jewels are the escape wheel pivots seated properly in their respective pivot holes and sitting neither too high or low?1 point

-

Building a watch isn't just putting the parts in place and tightening the screws. We should check the functioning of each part during disassembly & re-assembly. Bunch of forks are brought to the stage here, non work, there must be a reason why your fork delivers no power.1 point

-

Right having proved the pivots are as intended. One short one long and both intact, remove every thing from the plate and install only the pallet and the bridge and re check the fitting, both end shake and side shake, and if it still wobbles when fitted. Close ups of the fitted position from top bottom and side.1 point

.thumb.jpeg.5943fc3130d74bf2c7471fb8d6eef962.jpeg)