Leaderboard

Popular Content

Showing content with the highest reputation on 10/05/23 in all areas

-

2 points

-

2 points

-

2 points

-

You do know that "hugging your tool" could be taken the wrong way. Hehe.1 point

-

News from the front- It is with much sorrow I report that pump poussoir à pompe 105 is no longer with us- dead, deceased, run down the curtain and joined the bleedin’ choir invisible, an ex-pusher. It was fatally freed from the stake by a pair of Amazon 1-day nylon-jawed pliers. (link below) An autopsy reveals a pusher broken from the base- a victim of tight tolerances from the factory combined with a stake slightly out of round at the mouth. The body of the victim was quickly binned as protocol requires (since Thursday is trash day). In lieu flowers neighbors pump pushers 95 and 115 request donations be made to CousinsUK or that lot of 404s you’ve had your eye on in the EBay auction concluding Sunday… …on a brighter note during the commotion it was revealed the once stuck screw thingie what prevents the pusher from spinning has released its grip, likely due to a combination of stress from pliers and the Phosphoric acid applied yesterday. The remainder of the Seitz tool has been dismantled, inspected, cleaned, lubricated and reassembled. Only the North side indicator has failed to report, perhaps the result of a previous application of now sticky lubricant. The tool is now returned home and is resting comfortably in its dents in the bakelite tray… Best wishes to all- don’t forget to hug your tools tonite…1 point

-

1 point

-

That's exactly what my bride said. Get a peg, then you can use the pliers to squeeze the heck out of it without marking. DIY rules.1 point

-

You could try something like a clothes peg with some of the non slip lining you put in drawers.1 point

-

empathy or schadenfreude does not matter- that you think of me at all is everything ... ...so now that I'm accustomed to draining my savings I'm off to see if the pusher stake is a replaceable item...non non non but I see an enterprising someone and has invented the perfect tool to ease my sorrows... I have nylon pliers on the way to try to free up the retaining screw so I'll give those a try first, but has anyone ever found one of these in their kit? Does it work? For the price it should but some like to prey on the desperate...1 point

-

The other day at work I saw watch doing this exact thing. Then yes the second hand was really impressive with how fast it was spinning plus none of the buttons seem to do anything. Although in this particular case it was a chronograph movement and to chronograph movement skip to be more complicated with circuitry. I suggested a reset and I wasn't working on it but apparently the person did a reset and the problem went away Your watch is a lot simpler and normally it wouldn't have a reset. Found the service manual for you attached PDF and parts list the link below. Looks like the circuits available. And in your image it looks like a lot of corrosion around where the battery was. If that gets onto the circuit board that would be her problem you may be a look clean the circuit board perhaps but it depends on how much damage Has been done. Then for that level of corrosion servicing the watch would also be recommended. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=OME_1445 3493_Omega 1445.pdf1 point

-

Yes. I think you can see that I have filed the top of the stake so that it goes into the bottom of the plate hole. Hence why I have made the hole in the plastic container to make it more solid hold, no wobble. The holder is glued to the wood, therefore it makes the stake very stable. I have a number of stakes filed and ready for insertion when I need a specific stump. I based this system on the Marshal staking set. The Marshal set has stakes the same size top and bottom for the hole. My stake set has larger stakes into to brass fitment that fit up into the plate base.1 point

-

1 point

-

rehajm, please don't get me wrong but The English and French clocks from around 1910 and back are far superior to any American clock. I know Howard Miller clocks are famous in the states but they are very poor. Any thing you need to know about the photos such as the names of parts just ask me.1 point

-

These Longcase clocks are known as White Dial Clocks. According to the dial features it dates about 1825. With late white dials the painting is crude and not fine. This ties in with the case as the later the clock case the shorter the door. One way of finding the makers name is to shine an ultra violet light on the dial it normally helps. The hood has what is called swan neck Movement is standard 8 day duration with rack striking on a bell. It has had a repair to the rack are which in not good it needs to be remade. There are parts missing to operate the calendar. Parts can be made to have it fully operational. The crutch is wrong with a bad repair the suspension spring is the wrong length for the crutch, this makes me think the weights are not the original; also the pendulum might not be the original, because if everything was as it should be the clock would gain a lot. It needs a good service as it is very dirty and one of the lines is starting to fray. RichardHarris123 A lot of experience I have about 30 years in horology mainly with high grade clocks. I also worked as an adviser on clocks for one of the main antique shops. I also valued clocks as well. There are many good books about clocks and the different types. Look up Brian Loomes he has a vast range of books many on Longcase clocks.1 point

-

Its the phosphoric acid in the coke that breaks down any rust thats seizing up the screw. Nucejoe has a contract with Coke-cola to promote their products. I'm curious as to why the pusher spindle is prevented from turning. Does the spindle have a keyway ? I'm curious as to why the pusher spindle is prevented from turning. Does the spindle have a keyway ? Your next major purchase Ross. A friction jewelling tool.1 point

-

1 point

-

1 point

-

PS I'm as guilty as most people for not following up on posts. I broke a stem, removing a stubborn back. Just enough stem to grip but couldn't move the crown. Soaked in coke for 22 hours?, unscrewed easily.1 point

-

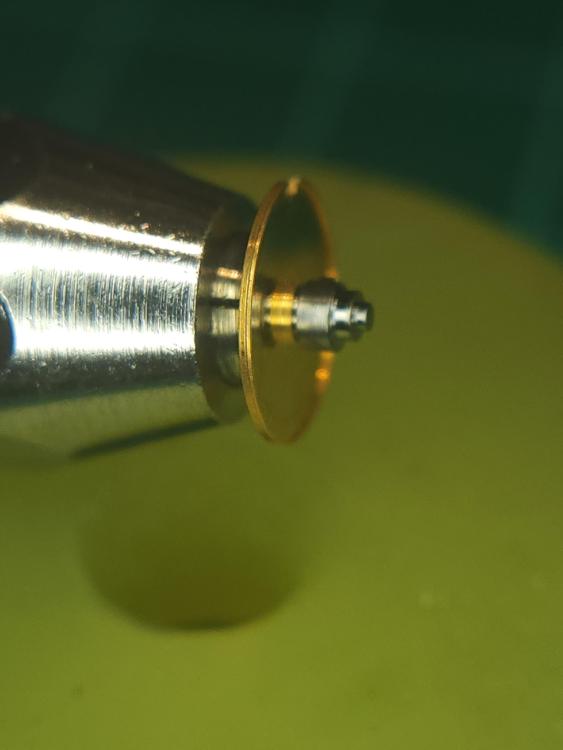

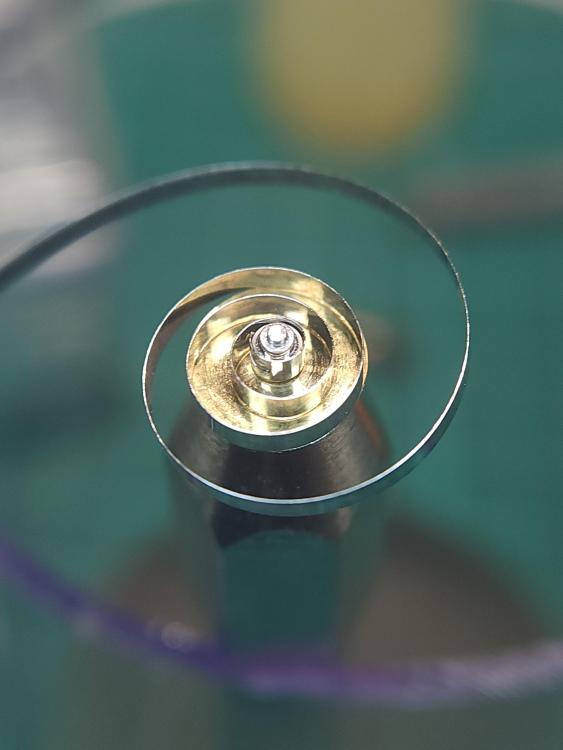

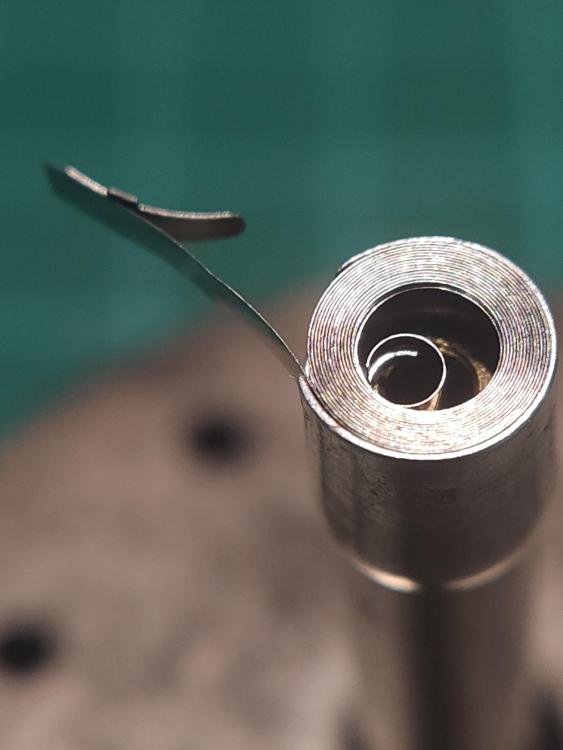

What do you do when the correct size mainspring winder you have has an arbor that looks like this? This is exactly the situation I encountered last night. I was servicing a Slava 2428, twin barrel movement. The barrel is so small that the only winder that could fit was a Watchcraft #2. But my arbor looks like it got chewed by a dog. I remembered a post a couple of months ago about a homemade mainspring winder using a plastic sheet and a pinvise to hold the actual watch barrel arbor. Then it hit me. I could mount the barrel arbor into a pinvise and wind it directly into my winder. Initially when I tried it, the mainspring kept twisting and buckling and wouldn't wind nicely into the winder. I had the idea of cutting a washer to cap the open end of the winder. When I finished doing that, I looked at the washer and thought it looked a lot like the barrel cap. I took the barrel cap and realized that the barrel cap fits perfectly. So I mounted the spring and wound it into the winder easily.1 point

-

1 point

-

I've got a couple watches lined up in addition to the one I posted about in the Newbie repairer category -- waiting for my confidence to arrive. Not a huge investment, but I'd like to give them the attention they deserve, and hopefully once I get inside, they deserve the attention I give them! Something about having a small queue makes me feel a bit more urgency in getting stuck in.1 point

-

No worries Anilv! Thanks again for posting your pictures as it was enough to get me in the right direction. The rebuild went well and I am so happy with the result. I will eventually post the rebuild either here or in a new thread and post the link here so others can find both. I really learned a lot about this family of calibers and picked up another 2591 and had a 781 to use as a donor for some parts until NOS came in. Particularly the pallet and its Bridge. Also had the source a minute wheel (broken teeth) and the day and date rings. Have a new mainspring but you can see rhat the center coil is much too large for the arbor. I was able to service the old one so did not need one to get it running but got one anyway because the amplitude is low. Also needed a minute train bridge screw. I still need to put the finishing touches and asjustments but this one really wears nice on the wrist and runs well!1 point

-

I took apart my AS 1914 and examined the friction pinion - it actually seemed like it had sufficient tension already. I could turn it with tweezers, but felt a good amount of resistance. So I set about adding lubrication to the day jumper and reducing its tension slightly, wherein I broke the tip off the spring. So my original problem is solved; the day changeover no longer impedes the motion works but now the day ring is a little loose and not centered in the window. So off to replace that part. On the bright side, it was a pleasant surprise that this movement didn't require me to disassemble the calendar works and motion works to remove the train of wheels. I guess that's a benefit of putting the friction into that wheel instead of the cannon pinion. I only had to take off the ratchet wheel and train bridge.1 point