Leaderboard

Popular Content

Showing content with the highest reputation on 10/13/23 in Posts

-

Yes, it is ok as far as I can tell. I ended up flattening the wheel by placing it on a staking block such that only the rim of the wheel was supported and lightly pushing on the spokes immediately surrounding the pinion with a suitable stake. I can't discern any bow to the wheel, and it no longer touches the barrel. Thanks for all your tips guys!3 points

-

I made a copy of that tool with 2 sewing needles welded together at other end so that they don't separate and stuck them into the end of a bamboo chopstick. It does work quite well but it can leave marks on the surface of the plates.2 points

-

Yes, I noticed that too. I'm thinking of making a saw cut down the middle of the brass rod, so that it straddles the spoke of the wheel and keep the leverage closer to the midline of the wheel.2 points

-

Hi guys. I’ve watched Marshall and Mike on YouTube way too much and I thought I would give this a try. I don’t have the steadiest hands so worried about that but I love Seiko watches and excited to rebuild a few2 points

-

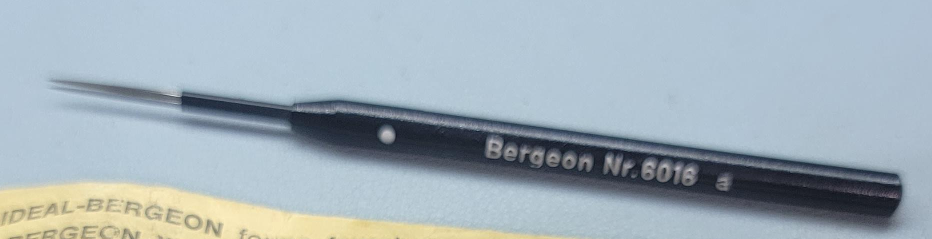

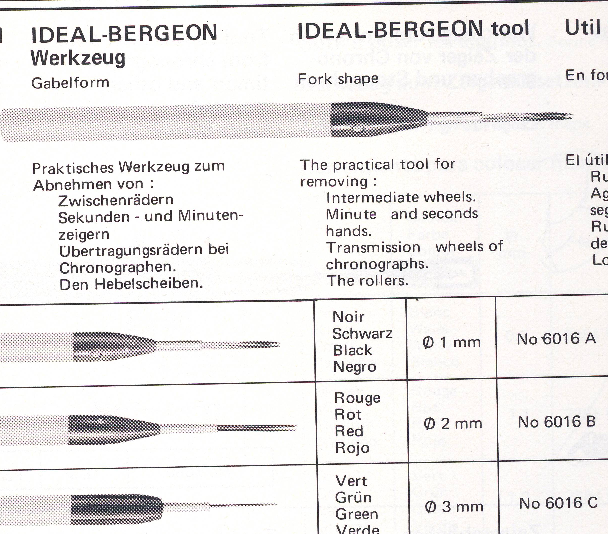

WIth the Bergeon 6016, you slide it under the wheel, then twist the handle, and the two blades tilt, effectively rising in height, bringing the wheel with it. I have one, and never seem to find a wheel the blades actually fit under. I use the Presto tool. Those work great, only gripe is it would be nice to have a stop, as on a tight wheel, when it lets go, sometimes it comes up quite violently occasionally bending the wheel. Always been able to straighten them though.2 points

-

Hi it looks like it's a minlature clock called a torsion clock or better known as an anniversary clock. Plate 1406H you would need a spring unit 5C, 5D, or 5E which is recommended. Don't know where you would buy one in Spin in UK Counsin's sell them Year c1970 good luck.2 points

-

Tissot calibre 781 Disassembly (Please sort the images by name in ascending order) Tissot calibre 781 Assembly (Please sort the images by name in ascending order) Tissot calibre 781 ranfft facts Some time ago my brother handed me this Tissot dress watch from the mid-1960s housing a Tissot calibre 781. My brother collects watches but doesn’t tinker with them (yet). Anyway, I thought it would be interesting to give this Tissot 781 an overhaul (you always learn something). It did seem to run and being a 17-jewel manual wind watch I thought a service shouldn’t take too long or pose any challenges in particular. Anyway, when I removed the case back, I noticed to my surprise that the balance had stopped. I thought “that’s funny”, as it was fully wound and had been ticking along fine while I was looking at the dial. Going deeper I realized that the one of the balance staff pivots was broken off. So, I called my brother and told him the bad news and that I had no experience replacing balance staffs. Well, my brother didn’t become too upset about this but simply told me to keep the watch and possibly repair it in the future if and when I would learn how to replace a balance staff. I wasn’t sure I was ready for it, but life is unpredictable so I thought that it was now or never that I would learn how to replace a balance staff and get the necessary tools to do it. Long story short, I did learn how to replace a balance staff and the watch is now ticking along just fine. In the process I got first class help and illustrations from my fellow Swede @HSL, and if you are in the process of learning how to replace a balance staff, I do recommend reading the following thread where you’ll find HSL’s (and other helpful) posts about this “Staff replacement, balance wheel wobble”. To call this post of mine a “Service Walkthrough” is perhaps a bit of a stretch as the pictures don’t include any oiling suggestions and/or tips/instructions. Nevertheless, I’m thinking that the pictures still might be useful to anyone servicing this calibre and perhaps pondering in what direction the main spring should go and/or what screws to use where, and so on.1 point

-

Perhaps Phenix Vibrochoc? Shock Springs.pdf1 point

-

Are you questioning somebody on a YouTube channel how dare you. YouTube personalities are God's we must never ever questioned them. There is quite a few of the watch repair channels that even though as I said these people are gods and I must worship the ground they walk on I think there false gods with an attitude and even though they have a YouTube channel with a whole bunch of followers maybe you should usable common sense like Uber observing here and maybe they really aren't God's maybe there false gods. Oh and timing machine results? One of my amusements was people selling watches on eBay and they will happily show you the timing machine results and claim the watch was serviced but well I guess their learning and you're going to buy watch and the learning phase because a lot of times the timing machine results suck and I wonder why you're proudly showing your handiwork? On the other hand the probably making money selling these watches on eBay. Although I have seen some legitimate people selling watches where if the watches running to put her on timing machine the show you this is the state of the watch are buying we haven't service did yes it's running but it runs like this. In other words it's running really poorly and there showing you as opposed to look at my handiwork. Which of course brings up the problems you buy something on eBay that was serviced and looks like crap on the timing machine now you'll have to deal with it Oh I wouldn't worry about this this is a minor issue. If you want to do something bad go against the narrative of a tool blessed by every God in the known universe like I did then you get your story squashed and embarrassed but don't worry it was done for the greater good of the group. The reality is we can't pay attention to everything is why like group discussions where one person will see something that you don't see and you'll see something different and together as a group we will hopefully see the big picture hopefully.1 point

-

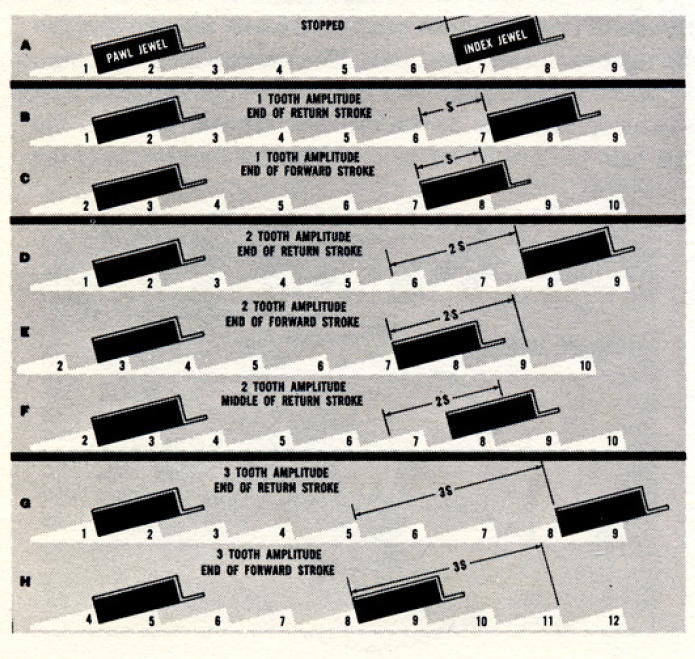

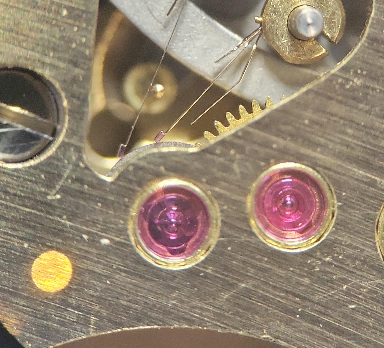

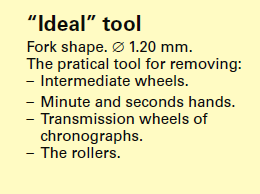

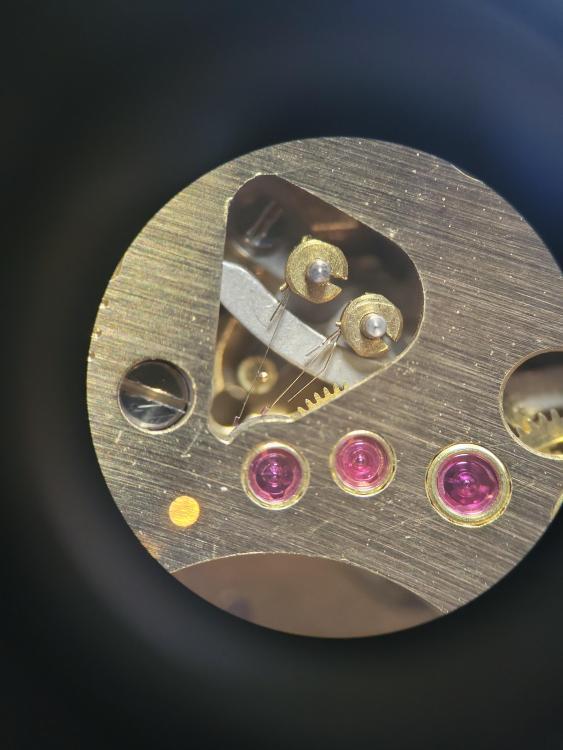

I snipped out something from one ear images I assume you're using a microscope to do the phasing? Now let's look at something else a design improvement I wonder what that improvement was? One of my complaints about people who obsess about using their microscope to see better is you don't. Well you argue with me you do but here's a problem if you look at the two images on the 219 they improved something is even though were looking at it with probably a microscope we can see the index wheel. In your image were looking straight down and you can't see the index wheel which now presents a problem a big problem You can see the wheel next to it that will help but ideally you need to see the index wheel so if you really have to use your microscope which is preventing you from seeing the big picture then tipped the movement holder a little so you can look in because ideally you need to see the index wheel because you have to see what it is doing not the results of what it's doing if it's having a problem now for party your question you didn't ask here's a different image of what phasing is. At work for instance my bosses decided phasing is speed control and he's even asked if I can move the regulator to make up for the speed difference in the answer is no. Phasing can be such a pain in the ass by the way you have to have everything where it's supposed to be an ideally a nice shiny clean index wheel. So what is the purpose of phasing? Phasing achieves something almost magical and you'll have to study the image the magical aspect is as the tuning fork amplitude varies between One and two Teeth as it shows below the result of that amplitude difference is only one tooth is picked up and the wheel spins at its normal rate. This is why in one of the documents I had where it talked about factory specifications they would even run the voltage up to 1.7 V to check to make sure the watch would work with the differing voltages a bad race.Because like in the case of a silver cell battery when it's brand-new and this watch represents such a tiny load initially it's almost 1.6 V. Now what happens if things are not right then if you can see your index wheel it will go up in speed very fast it's not just a variable throttle control of slowly ramping up its speed it will go normal speed double speed and yes it's noticeable but you have to see the index wheel.1 point

-

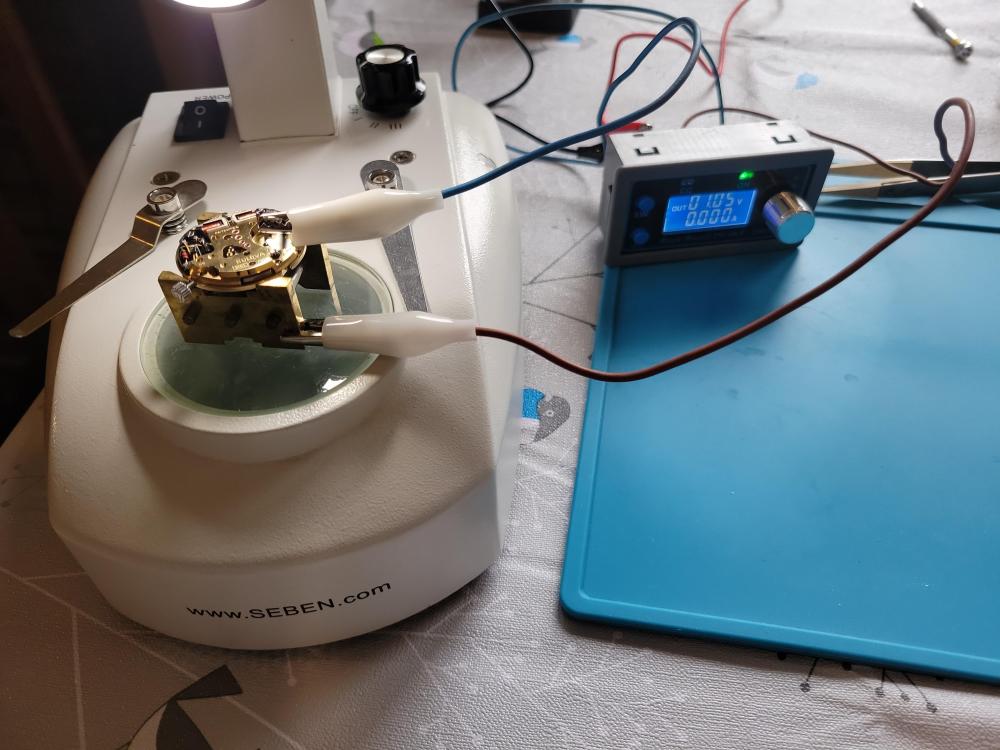

Thanks!! Hmmm.... one possibility is that the variable power supply I was using was very slow to change voltage. I probably would not have noticed any gradual change in speed. I left it for an hour next to a watch I trusted and it seemed to be keeping time. Its close enough for the moment.1 point

-

1 point

-

Personally I find you need both tools because there are situations where one may not work. Then there is the other problem which I did point out that apparently no one was paying attention to. One of the classic problems with any tool is if you don't know what it is you will break things. Look how much destruction occurs every day with newbies and tweezers and screwdrivers a perfect example of destruction of watches because They don't know what they're doing but we will blame the tools not the individual because that's what we do. So basically the tool is bad the use of it is not especially when the use of the tool may not be obvious to some people oh and there is the other little problem what exactly does your father have? Oh yes the picture let's look at the picture Nobody was paying attention to the fine prints because I did point out something let's look at my tool because as I pointed out the quantity of tools that we can purchase seems to have decreased? I wonder what that means when let's look at mine and technically I had the third one but one of the problems With working in A shop with other individuals is if they like your tool it may go missing. So when I left the shop I was unaware of a missing tool or two or three. This is actually a current problem where I work now I can't Lock my bench that I never know if I'll even have my tweezers when I get to work. There appear to be two of them? Now we need the physical catalog because it has stuff that used to exist that no longer does When the problems today of course is you only get one tool and as an added bonus you get a really poor description because it gives you a size that I have no idea what it means because their size references do not compare above you get what is probably the tip size or maybe it's the thickness size on twisted I'd have to measure it and now you get this size that means I have no idea what.1 point

-

Titanium rods are available from AliExpress. Titanium is not some super material as one might think. It cuts like aluminium. I used quite a bit of titanium in dentistry. The problem with titanium is that it fatigues easily and cracks. Anyone who has used titanium tweezers will understand.1 point

-

Really not perfect for 5-spoke wheels. You can see clearly the pivot bending. He tries to conceal that by changing positions of the tool. Frank1 point

-

As the Begeon 6016 is a tapered, it does have to push up at a slight angle as you slide it in. But I do it gently, and rotate it round, so I'm levering in all directions. I also wonder about the possibility of damage from a Presto type puller. They are quite large and ungainly for such a delicate wheel. I think Alex's solution of two bits of brass tube is a winner. It's cheap, easy to make, will not mark the movement, and easy to get a vertical lift on the wheel. Although I have the 6016, the next time I need to remove a wheel, I'm going to make some brass tools.1 point

-

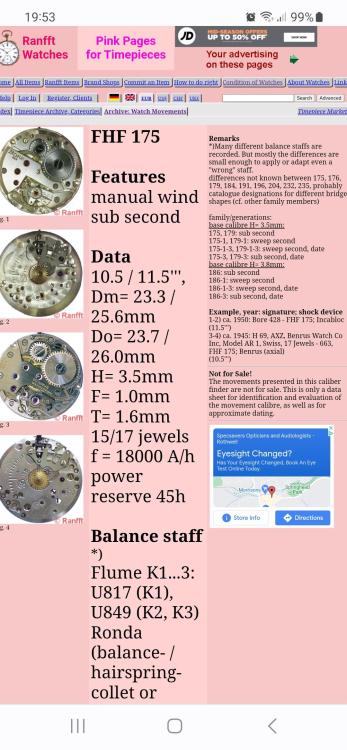

That configuration is commonly found on Benrus watches using the ETA 930 as the base movement, as seen in the Ranfft database for movements such as the BB4 and CE13: http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Benrus_BB4 http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&&2uswk&Benrus_CE13 If you can verify the specific base movement, a donor movement should be cheap. Or maybe you'll find a working spare movement and turn this one into a future donor!1 point

-

Kink or no kink, I'd call that a job well done. I thought this exact same thing when I read the procedure, but when I was phasing my 219, the change in speed was very obvious. I tried to capture it on video here, but I think I need a better frame rate to really get it.1 point

-

Final post. I had a go at phasing the movement using the link provided by @ManSkirtBrew tho I did struggle with step 4: I mean... how do you tell if it is turning normally or fast without putting the hands back on and running it??? But it appears to be running at a more normal speed compared to before I tried to phase it. OK, so here is a pic of the fingers after I had straightened them out. If you look closely at the root of the pawl finger you can see there is still a kink that I could not quite get to. The index finger has a scar from where I made contact with the screwdriver... Lessons learned... Random step-down power supply purchased off Amazon (verified the voltage using my multimeter just to be sure) And finally, after it is all beck together. Many thanks @JohnR725, @ManSkirtBrew for your help and advice!1 point

-

1 point

-

1 point

-

It looked like a wedge but appeaes to be two pins that flank the pivot. I suppose because the pins are so long you get even leverage on the wheel even though force is concentrated on the handle side…1 point

-

1 point

-

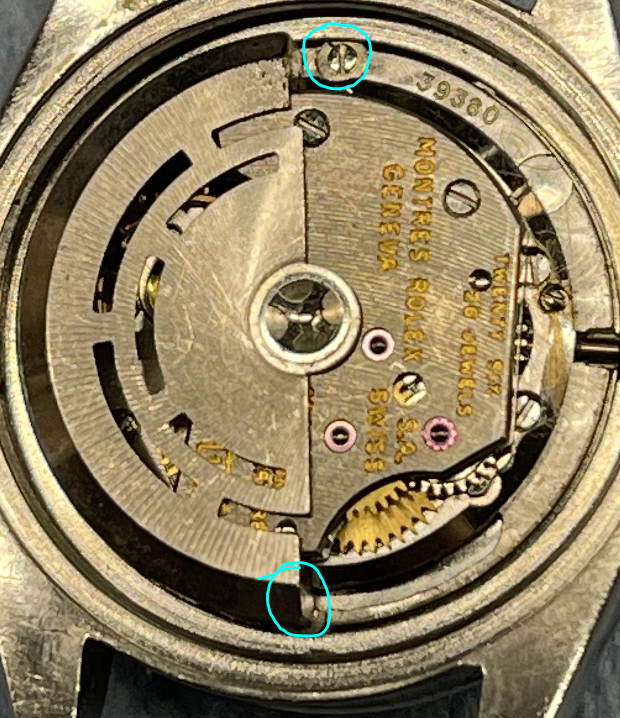

That number is a Rolex reference number. To help you with the watch we need the model number you will find that somewhere on the watch itself. The model number is probably a 2035 although I have seen references now it could be a 2135 that number should be visible somewhere in the movement. There is this little problem the movement does not look like in 2035. It is though an interesting looking movement much nicer than what you typically find in a counterfeit watch. Ignoring the movement itself to looking at the weight like below is a picture of a 2035/2135 notice the center and compare it to the allegedly Rolex and there definitely not the same. Then there is the other little problem of this Rolex should have the rather distinctive red color reverser wheels that you typically see on a Rolex watch. if you look really carefully in the picture you can see the other movement retaining screw or at least just the edge of it so I circled both of them1 point

-

Just looking at the pictures, and I can see only 1 movement retaining screw (at 12:00 in the picture) maybe there is one obscured by the rotor at 6:00? Also, the screw at 12:00 looks domed. It would make more sense if this screw(s) were flat, but I'm not familiar with this movement - so don't take my word for it, this may be the reason for the rotor hanging up? Now to address the elephant in the room... are you sure this watch is what it says it is? Here is a reference picture of a 6917 movement, I saw several that look like this, but none that look like yours: However, like I said, I'm not that familiar with this movement so I may be speaking complete nonsense, but I think you should check it out and maybe some other members of this forum could chip in with their (more experienced) opinion.1 point

-

https://youtu.be/pDv8KDzfWlo?si=f3HCzwfYfvXyNfzT Alex shows how to to make your own pair of lifters for the freewheel.1 point

-

So I figured out what you were saying and pushed the bushing out. However the jewel is still on the other end? So I’m not very clear how this helps? I’ll be dammed—it seemed to work. Yay! Another win for Joe's Magic Rust Dissolving Solution. It's so safe that you can even drink it. You're wrong Joe. There's half a litre of Diet Coke in my fridge right now. Guess where the other half went. It was so hot yesterday that I had to get a bottle of Coke. Actually my preference is for Pepsi but the convenience store didn't have any. I have to be the worst example of a dentist. I've been a soft drink addict since secondary school. I still eat sweets, love M&Ms, Mars and Snickers. The "healthy stuff" like fruit juice, sports drinks and apple cider vinegar are far more damaging to the teeth than carbonated drinks.1 point

-

If the wheel wobbles there is at least one bow. Flattening the wheel isn't actually that difficult, I do it in situ with a pair of tweezers. Rgds1 point

-

How is hector to find this out, being a dentist his house is Cokeless zone. Levine, check bergeon tool 30209. Rgds1 point

-

Scott. Been looking on Chronoglide. He does two 'live' a week. I think it was two weeks ago. But I'm not sure of the movement he was working on. Maybe it is not posted yet. when I come across it I will let you know. Quite a few of the members watch 'live' as I do. Maybe one of them could remember? Ross1 point

-

Have you checked the sideshake/endshake of the barrel? This will happen again if the root cause is the barrel shake.1 point

-

Its been more than a couple of years since I posted anything I have been working on. But today I had an hour to spare in the lab. One of the students is a Glycine guy and he wanted to swap out movements on two different Glycine Airman GMT one with Sellita and the other with ETA. I told him they're practically identical, but he insisted so...here it goes. As you can see they both have 24 hour dials and some slight differences in details. The swap was straightforward and no problems with the dial. The case tubes prevented swapping the stem and crown, so those had to remain with the respective cases. Everything else was uneventful. By the way, one of these was converted to a GMT purist with a hands kit sold by glycine that includes a spacer to eliminate the red hand and make the hour indicate 24 hour like the original airman watch. That did NOT work out right because the washer didn't quite fit. The hour hand would indicate somewhere in between 12 hour and 24 hour time. The students watch has the metal bracelet, the other I might buy. It now had a Selitta 330-2 which I have not worked on. At 44mm, the watch itself is a little bigger than I'm used to, but its distinctive and has history.1 point

-

I picked this up on ebay quite awhile back. I think I paid $17. It was advertised as not working. Since I have already refurbished one, I had all the stuff to do the same to this one...except the capacitor which had to be ordered. Why do I need two? Well, I am setting a remote watch shop and plan to focus on learning to repair accutrons. Watching videos on their repair, I see that screwdrivers and tweezers get magnetized. I know not to demag the watch itself, but will have to demag my tools.1 point

-

A professional clock maker with experience will have no trouble at all in undertaking a complete service of such a movement. He will also have the means to obtain basic parts. The clock maker if he has a good equipped workshop should be able to to make parts or he will have contacts who can help him. Make sure he undertakes the basic work such as cleaning on his own premises and doesn't farm out his repairs, ask what type of guarantee he gives and for what for, it should be at least a complete guarantee for a minimum of 12 months. One last thing have the clock in a place away from artificial heat, away from pets and young children, heat can damage the movement and the case if it were made of wood which yours is not. Just ask if you need more help1 point

-

@Waggy somehow this popped into my YouTube feed, it’s not a tutorial but does show the end to end making of a strap. Tom1 point