Leaderboard

Popular Content

Showing content with the highest reputation on 10/14/23 in all areas

-

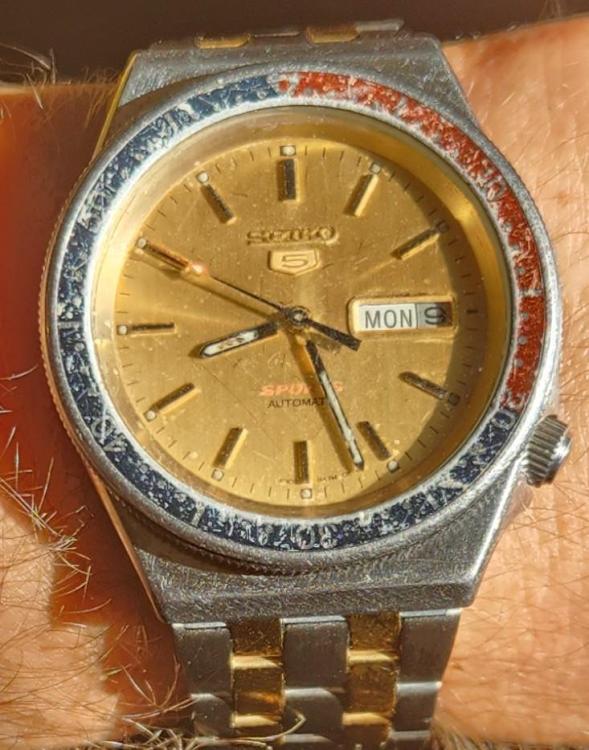

My work in progress 1983 serial numbered Seiko 6309-836b or Seiko 5 sports diver with Pepsi bezel. With the original bezel insert and a "NOS". Slightly different size numbers on the new insert. Aftermarket bracelet goes very well with the case, I think. Hands are in good shape except for the lume. Slightly scratched glass. Re-lumed, new glass, and polished case this would pop quite a bit more but is quite nice as it is as well.6 points

-

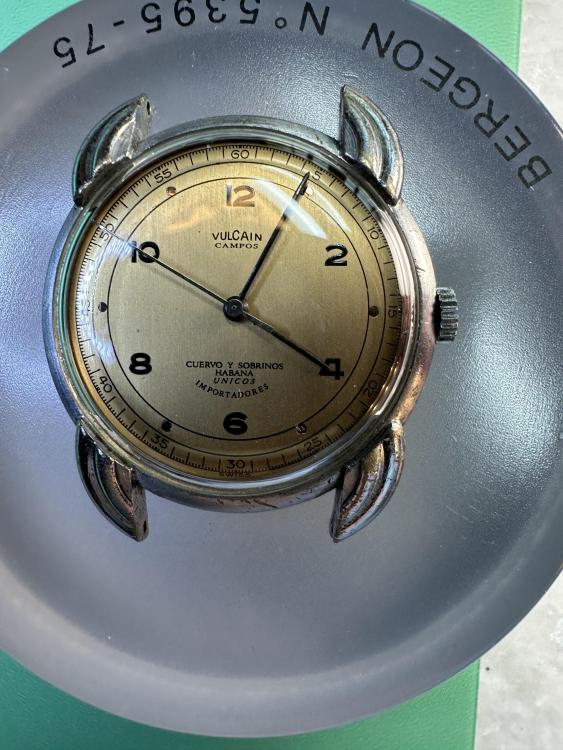

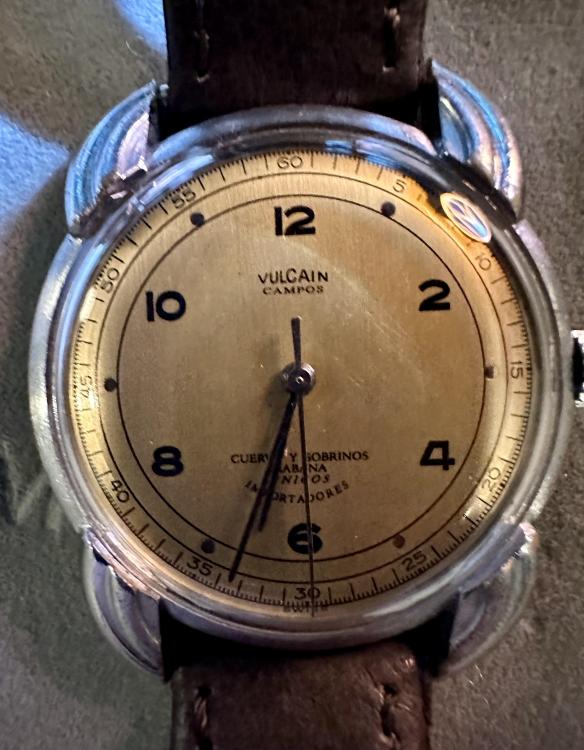

So this is what I finished today. Cuervo Y Sobrinos is a famous jeweler what emigrated from Europe to Cuba in…the early 20th century? Maybe 19th…uh, here… …so like the story probably said they imported swiss movements and watches to Cuba and like Cartier or Tiffany branded them with their store…this is one of them. I always appreciate a Vulcain and this simple watch was no exception. I’ll post more photos and important stats later but highlights include - Cousins didn’t have the appropriate mainspring- discontinued. So I guessed and it was a bit strong so there was some rebanking as it built a head a steam. I let it run a few days and it settled in so amplitude doesn’t drift above 300 degrees for long periods. Also the lower balance pivot was bent…and I used the useless Seitz tool to straighten it. I don’t care what consensus is, sometimes it works! …Hello Polly! and diamond paste on the crystal what came with- looks great. I’ll add some good images later…peace.3 points

-

2 points

-

Mikepilk. Thank you for the download. I have a Breitling Top Time, using a Valjoux 7730 movement. Another 2 years of self imposed apprenticeship before I tackle it. I could probably do it now, but I want to do it properly.2 points

-

I don't see any problem with small amounts going in to ground fill in the UK. There are parts of the UK with significantly higher background radiation (3x) than the average e.g. Cornwall, Scotland. Even granite buildings have increased background. We are just making it more even by spreading it around2 points

-

Thanks for this write up! I've got a 781 in pieces and cleaned, waiting on a new cannon pinion so I can get it back together. These pics are invaluable.2 points

-

2 points

-

Hmmm... are you worried that your blood sugar levels are normally high but because you fasted overnight, your sugar levels drop to normal and don't show it? Well, you can ask your doctor to do a Hba1c test which will show the average glucose level over the past 3 months. This test will show up the blood glucose levels when you are not fasting. It is a good test for catching diabetic patients who fast and watch their diet a few days before their blood test but at other times binge on sugar like there is no tomorrow. Many of us think that diabetes is genetic, ie. if your parents and siblings are diabetic, you are likely to be diabetic. Well, many years ago a professor told us at a lecture that is not true. He said that if you are diabetic, don't blame your parents. It's entirely your fault. But honestly, there is so much that doctors don't know about so many things. Like why some people who don't exercise and eat all the sugar and all the junk food they like, yet have a healthy glucose and cholesterol level. While another who lives a seemingly healthy lifestyle has diabetes and a heart condition. I ask that question everyday and just thank God for everything.2 points

-

Haha, ok ok. Thanks for the reality check. I actually appreciate it -- and I must admit that I've wondered about this too. You are probably right.. I'm just very enthusiastic and the tool-addiction (more, more, more!) has hit me hard.2 points

-

Pivot size is 0.65mm. I have an 0.5mm bushing (too small) and an 0.7mm bushing (a little big). I have read up on this topic and it seems like I a bore size about halfway between these two, but they are not made. Maybe use the 0.6 and ream/smooth it to the desired size?1 point

-

1 point

-

I can't judge the size of the movement but its the same as those 2 inch 30 hour movements you could get back in the 70's & 80's, pin pallet conical balance staff.1 point

-

Moebiud clock oil will do no problem I have some and still use it You can re bush the hole. Or close it, on a cheap movement. Better bushed.1 point

-

1 point

-

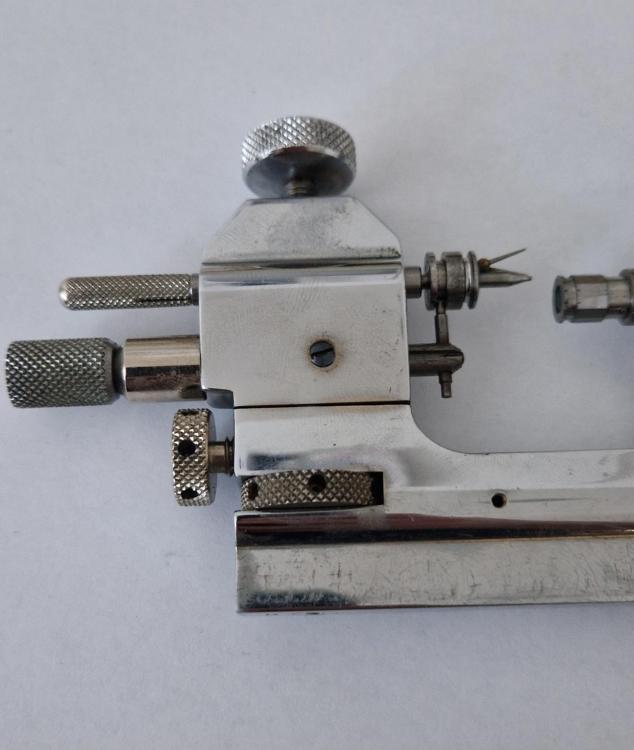

If you look at the headstock end with the pulley and runner removed, you see a sort of V block in there. There are jack screws at each end, with holes around their head permitting a rod to be used to turn them. Tightening them pushes the block upwards, loosening (and then inserting the runner and firmly tightening its lock screw) pushes it down. The V block is slit along its length allowing it to flex, thus being able to move up or down in the round bore. This is for the vertical alignment. Then, a simple tool can be inserted to rotate that block in the bore, which gives the lateral adjustment. Some tools have a more obvious vertical adjustment (see pic), those dispose of the jack screws but the lateral alignment can still be done. To check the alignment I just use a wheel with the shortest possible pivot to pivot length, and put it in the tool (check that the wheel is true!), and see how it looks compared to the tailstock runner face. The short arbor magnifies any error, and if it "looks" good in the tool, that's good enough. One thing I have seen on many of these is the simple headstock runner is bent. To check that I put it in collet in the lathe, and check. I use a dial test indicator, but again, if it looks like it turns true just visually checking against the T rest or something, that's probably good enough. Truing it is simply a matter of bending it the right direction. I haven't broken one yet. As to why Steiner moved to this design- I imagine it makes it easier to produce, as things are less dependent on getting the hole for the headstock runner absolutely perfectly placed. And it just nice to be able to adjust things if and when needed.1 point

-

Hi. NEW, One look at its construction and you can tell it’s fron the lower end, a movement see in many travel clocks some with an alarm. Never consistent but did the job. Pin lever cleaned up a nd a drop of windles oil and it’s a runner.1 point

-

I'm afraid not! Oh, and I do agree! Power tools should be used with great care in watch repair. I now have an excellent Proxxon rotary tool (fantastic!) but I limit its use to polishing watch cases. Power tools can make things go very wrong very fast.1 point

-

1 point

-

BTW, I am not really setting up a service center. I bought another house about 100 miles away to be close to my son's family (being a grandpa!). We plan to spend about half and half between the two homes. I agonized about my time away from my watch shop and did not want to replicate it. Sooooo, I decided to focus on accutrons at the remote location because I only need a small subset of tools to work on them. Aaaaand...I have about 50 accutrons in a box waiting for service. I have yet to work on the first one, so I am starting at ground zero!! But...I have many smart friends on this forum who will nudge me along.1 point

-

I'm over in India at the moment, and this chat brings to mind the "Delhi Alps" also known as the "Great Delhi Garbage pile", a 65m - 220ft high garbage dump which is actually quite impressive in its sheer scale when you see it in person. It is obviously a hazard, and it obviously pollutes the water table, and the air, due to the regular uncontrolled spontaneous fires it suffers from. Uncontrolled dumping has resulted in some alarming levels of all sorts of interesting toxins, including, according to various reports, radioactive medical waste, heavy metals (lead acid batteries I would imagine accounting for a fair amount of that), chromates, mercury, dioxins (caused by partial incineration in various fires over the years) and all the usual toxic suspects. I suspect that a lot of the waste disposal sites in the UK from the 1950s through to the 1990s would have similar levels of these toxins per ton. All told, I think a few watch and clock hand are not gong to make a huge difference to the amount of crap we are pumping into the environment, but none the less, we should be trying to make some effort to dispose of them carefully.1 point

-

You probably could do it now Ross, but you are doing the right thing by waiting. Especially for such a nice watch. I started on pocket watches, then manual wind wrist watches, automatic movements, and finally alarm watches (Seiko Bell matic are good practice) before finally a Chronograph, many years later.1 point

-

I´m seeing/reading that the complicated issue in these clocks is setting time. The easy task for now is cleaning the machine...Now I understand Willow's good luck . I have already ordered the suspension spring on eBay. I will take advantage of the time to continue learning things about this type of clocks. There are quite a few threads in this forum. Best regards Miguel1 point

-

When I wrote, I did mean to add - "I don't see any problem..." : as long as it doesn't get disturbed by someone building a housing estate in a few years time.1 point

-

"...and at the bottom of the cliff there was another pile of garbage. And we decided that one big pile is better than two little piles, and rather than bring that one up we decided to throw our's down."1 point

-

Sure! I was going to wait until I can report on it's quality, but here you go already: https://www.fishersci.com/shop/products/micromini-20x-led-pocket-microscope/S811421 point

-

Absolutely. What I will say is that while technically the amounts involved are very small, and the risks are low, if everyone follows this advice, then there will be elevated levels of radium at every landfill and incineration site, since any "securely sealed" container will stay "securely sealed" for about 5 seconds once it enters the back of a trash compactor (aka bin lorry). Having said that, this is small beer compared with for example the beaches on the Fife coast near a former WWII era scrap merchant which disposed of large amounts of luminous instrument dials by burning in barrels and discharging the resultant mildly radioactive slurry down the Fife coast. https://www.bbc.co.uk/news/uk-scotland-edinburgh-east-fife-63515856 Not to mention the disposal by Timex Dundee of barrels of lumed dials from fishing trawlers into the North sea. Out of site and out of mind seems to be the British disposal policy. That didn't end well at Dounray. https://www.bbc.com/news/uk-scotland-highlands-islands-54085592 Low risk, throw it in the trash, don't tell anyone, and let the council burn it. What could possibly go wrong that is worse than what has already gone wrong?1 point

-

I have a Poljot Blue Angels 3133. I assume you know it's a copy of the Valjoux 7734 (I believe they bought the old tools from the Swiss). Endeavour does a nice walkthrough here And the Valjoux technical guide is useful Valjoux-7733-7734-7736-technical-communication-service-manual-EBAUCHES-SA.pdf1 point

-

1 point

-

Thank you very much watchweasol. While confirming this data I have been cleaning the mechanical machinery, the base, etc. I am entertained while I continue reading information about these types of watches. Best regards1 point

-

Haha yep John is on one today, so you better listen up. Yesterday he was talking about using high explosives to blow up watches. I'm just glad i aren't in Seattle tonight,1 point

-

I haven't used up before but that does explain why you are able to find the watch because using the reference number was worthless. But at least they gave us a picture typically people won't even give pictures and then that becomes extremely worthless waste of time. Usually had a bewilderment to the person asking the question where it seems very straightforward to them.1 point

-

Hi from the top of the top block to the bottom of the bottom block 95mm according to Twilligers book. the thickness of the spring is the important factor, length no so much. As its a torsion pendulum it is the rotational speed that controls the rate.1 point

-

I know my advice sounded a bit harsh but for a beginner who hasn't developed the fine motor skills required for working on pivots as fine as 0.12mm yet, I think my advice is justified. For the same reason, I don't advise beginners to do hairspring adjustments. The motor skills required for such jobs have to be developed over time. The cost for a decent Steiner Jacot tool is around $600 at the moment. I think the money could be better spent elsewhere, like better lighting and a microscope. I would say that the microscope is the biggest game changer in watchmaking. It takes time adjusting to working with a microscope but I think the learning curve is not too steep and the gains far outweigh the inconvenience. And I think a microscope actually helps to develop fine motor skills. I think the reason why I don't use my Jacot tool much is because I find it difficult to work the Jacot under a microscope. And the tool addict in me is telling me to get a Jacot drum for my lathe and get another microscope with a swing arm.1 point

-

Have you ever thought of explosives? Occasionally at work I ask if I can get some C-4 or perhaps primer cord and as of yet none of that has materialized. Although I wasn't actually thinking of using it for disassembly purposes well kind of I was more thinking of making a problem go away permanently. But that might be considered inappropriate and probably some custard be unhappy. Although conceivably I might be very happy of some of the watches were to disintegrate permanently but we do not take watchmakers happiness into consideration in things The end up with interesting situations. Perhaps the original person found the Presto tool Not working. As you'll notice there are actually two separate tools so conceivably they had the wrong one. But as I also conveyed their other tools and finding the other tools are challenging if you don't know they exist. Then a creative souls might work out other ways to do the task. This then of course brings up the problem of? We end up with a interesting problem of if somebody has a bad experience with a Tool does that make the tool bad for ever for everyone in the universe? So yes we do get interesting problems and watch repair we seem to have lots and lots and lots of different ways lots of different opinions lots of just everything. With the unfortunate reality of anything in life is there is no 100% this is the way to do it or else. Although that can conflict with some of the views on this group Who do seem to believe in Absolutes.1 point

-

I make a lot of staffs and do a lot of pivot work and there's no way I would be without a Jacot tool (as mentioned, I have a number of them). It's how pivots are finished at the factory, and by far the best and easiest way to get an excellent finish on a small diameter. While the old style are perfectly good, I would stick with the new style. The ability to tweek the alignment if needed is well worth it.1 point

-

1 point

-

1 point

-

Another productive weekend, I fixed my Orient which suddenly stopped, on inspection I found a blue fibre wrapped around the escape wheel... no idea how it got there. I then decided to do a Seiko 7009 from 1985 that I purchased recently from speedtimerkollektion. On reassembly I noticed that the centerwheel was cracked around the inner diameter where the pinion is fitted... very strange (sorry forgot to take a picture). The crystal broke when I took it out (of course!) so I had to replace, hence the missing 24 hour numbers which were painted onto the original crystal. Everything else is original including the bracelet. Before and after pictures: Here is the movement: Our old friend Mr Glue! - no dial feet: I replaced the dial feet using my new mini soldering gas gun and low temperature solder paste, worked a treat, and here is the finished watch, complete with fingerprints (Doh!): Let me know what you think I gave it a rough calibration, but will wait 24-48 hours to do the final calibration.1 point

-

I think some tasks are more suited for the sensitive touche of hand work. Power tools often help us make bad parts more efficiently. I can't see how polishing doesn't remove at least some material, Even as VWatchie says, it may be down in the microns. These look very interesting. Thanks for the heads up, I will definitely be ordering some. I have just one question; Will these help in correcting mistakes within my correspondence? Shane1 point

-

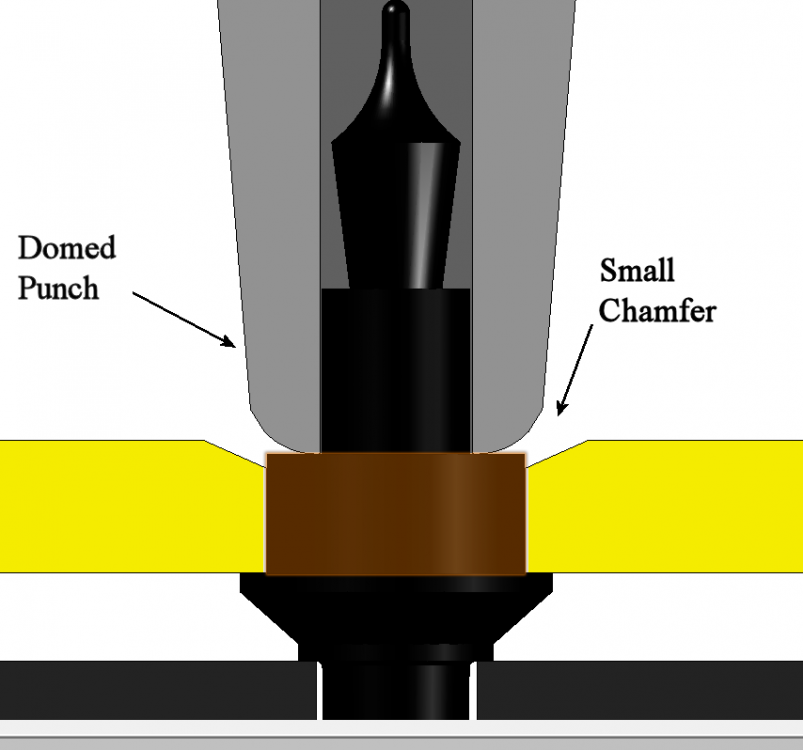

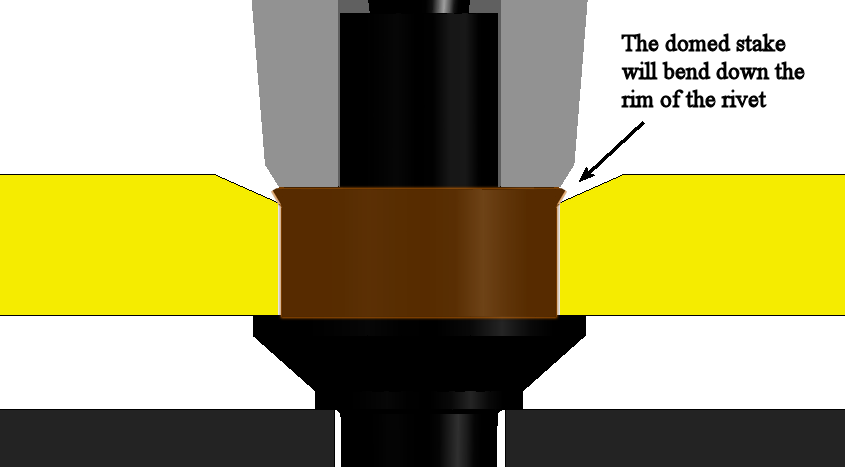

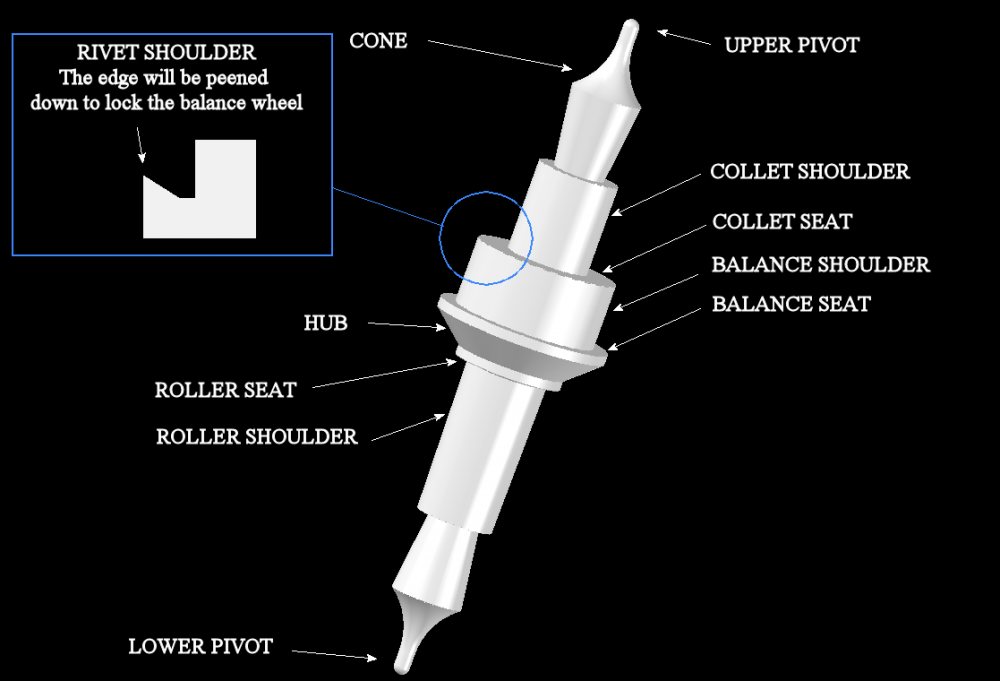

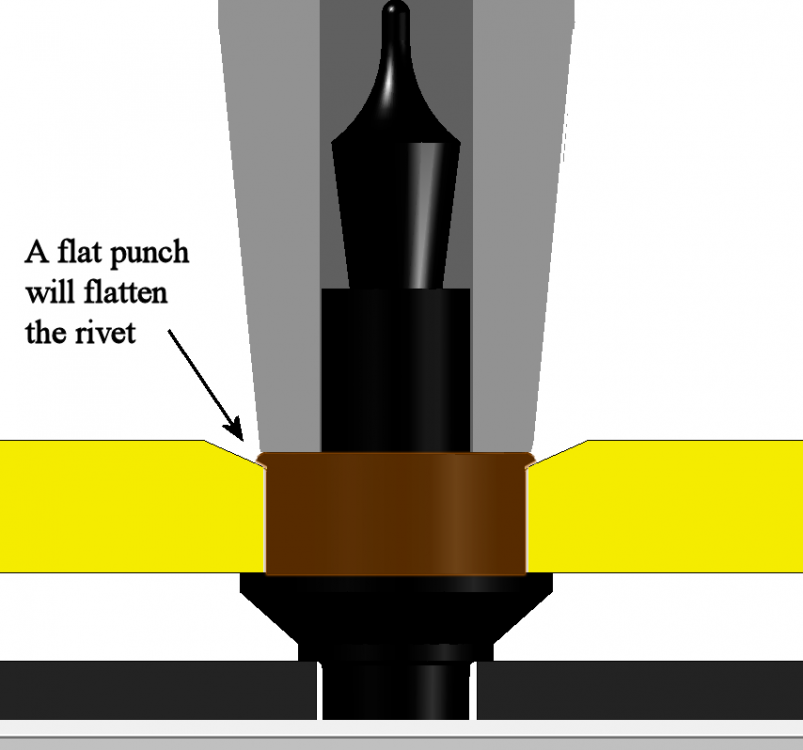

I think you are the only who can see if the rivet made a good and even spread. I mostly only use two stakes, I see you say narrow and wide. I guess the black art of this staking business is like taking your driver’s license, in the beginning you do all by the book but thirty years later you picked up some bad habits. With the risk of getting bombs sent to me by mail I try to show with some illustrations, which don’t need any focus set, and which shows approximately what should happen with the rivet. A too wide flat punch is not any good thing as you might end up hitting the balance instead.if the stake hits the spoke it might turn it slightly upwards. The tip of the stake should go inside the small chamfer on the hole. I intentionally have a different color on the balance shoulder so one know which part of the balance to concentrate on. After giving it a bunch of gentle but firm taps the doomed stake should have begun to spred the rivet shoulder. If not the stake is just a bit to small. But it should be a snugg fit. Rotate the balance to get a even spred and tension. Finish of with a nice and snugg flat stake. You still have to rotate it around. When done you will be able to see the rivet shoulder bent down with a close fit to the chamfer of the hole. I hope these illustrations gives you an idea what to look for. And just in case my vocabulary differs from your or someone’s else’s I attach a drawing of a generic balance with some definitions on here too. Now I think I go back to my 3D printer..... Lol well saw John answered at the same time too.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)