Leaderboard

Popular Content

Showing content with the highest reputation on 10/15/23 in all areas

-

2 points

-

You have the movement number and part number. Search Ebay - FEF 190 part 440. The is an Italian seller that has one for EUR 4.90 plus shipping.2 points

-

Hi Martin , glad you got there. You will likley Need a press to get the bezel back on. There are plenty on eBay.1 point

-

Hello and welcome to the forum, I take it you have an interest in the repair/ collection of watches. Would you care to expand your details a little.1 point

-

Hi welcome to the forum, not sure how ? Nice to have a woman's perspective what is your interest in watches please ?1 point

-

Different countries use different names for parts hence a universal part numbering system. Even different generations of watchmakers call parts differently.1 point

-

1 point

-

Hi Guys, The decision is simple: turning a new staff that will meet the sizes and entire situation of the movement, no mater what has happened to it in the years. By the way, European pre 1900 watch movements were not unified at all, so no spare parts for them , no point to search for parts and donors, but only making new parts is the only way of restoring them. If one wants to be antique watch movements restorer, then he will need to learn how to make parts, no another way. Not only the bridge can be different. Stone settings may be changed and thus the free distance between endstones (which is the staff lenght) can become different. The staff lenght is not the only one important size: the positions of the roller and the balance wheel in high depend on the staff sizes. So, the first thing to do is to determinate the needed sizes of the staff by using the position of the stones, the lever and the lever bridge in the movement. This is something important that must be learned right. If one knows that, he will easy know if a staff from some supplier's list will do or not and will avoid ordering wrong parts.1 point

-

Found some information on the caliber 50. Basically looks like a really big watch you should Be able to a use a watch timing machine the regulated. Also the same rules would apply like a watch for how you set up the regulating pins the escapement etc. https://calibercorner.com/looping-caliber-50/ You will have to use a translation program possibly depending upon your language skills and towards the bottom there is a picture of the parts list https://forumamontres.forumactif.com/t39683-mouvement-looping-51-8-jours Once I realized that there was a parts list available I found you some parts listings. One of the unfortunate problems of the existence of parts list is that conceivably there was servicing information. But typically we only get parts listing because that's all people care about. 1893_Looping 50, 51.pdf 3728_Looping 44,45,50,51,62,63,65.pdf 4380_Looping_ClockParts.pdf1 point

-

Unfortunately I don't. He was using a Chinese industrial digital microscope. The software was entirely in Chinese. And my Chinese has regressed to nursery school level. I'm am working on that and keeping the technique I've developed to myself for the moment. And as @nickelsilver mentioned in another post, the 218/219 is much easier to phase to a silver oxide battery than the 214. But unfortunately, the Accutron collector community has a preference for the 214, as evident in the prices on eBay.1 point

-

It looks like a friction fit jewel you just need a jeweling tool to push it out.1 point

-

That is a very interesting idea - do you remember what sort of frame rates the camera was using to achieve aliasing? My question from this is; what do you do if the index finger travel is out of specification? Is there anything to do or are you looking at replacing the fork? In the end, my watch was about 7 seconds out before weight adjustments. Im pretty sure I did not "phase" this thing anywhere near correctly (thanks everyone for the discussion!) so perhaps I lucked out. I did buy a few more accutron projects before realising what I had taken on - I am both more and less confident I know what I am doing going forward now... My next project is to find a case for this movement I found in a lot of other movements. Again thanks everyone for the discussion.1 point

-

1 point

-

Pick up this Stuhrling 90050 as a non runner found quicky the Mainspring had come un-hook from the arbor or the arbor came un-hook from the Mainspring however you like to say it Also the crystal was cracked. I fix the Mainspring problem just to see if it would run and it did but on my Timegrapher it needed some TLC so after the service and a new crystal and also a new Silicone watch band I had not too bad of looking watch. Just to note the movement used it this from my research appears to be one of the 2650 Chinese standard automatic movements (PTS): 2650SSZ. It’s 20 jewels and non-hacking. Stuhrling blued the screws and added some minor engraving.1 point

-

Many thanks to everyone for this warm welcome. Knowing to have a community as a back for sometimes delicate operations, encourages me and makes me feel safe. Hope to give that back in the future.1 point

-

Hi Martin. The two slots are indeed pry points for removing the bezel, there is a chance that once it’s removed the movement will drop out. Checkout the clips at the back do not swivel out on a hinge pin to release the movement, will have a look for the 8609A sheet.1 point

-

1 point

-

When I was buying straps for the Oberon I recently refurbished, I got a 1-piece black leather strap, but it didn't work with the chunky Oberon case. Turns out it fits between the lugs of the Spaceview and looks pretty sweet. What I'd really like is a rally style strap, but they're impossible to find in 17mm. I also noticed the watch is gaining 20-30 minutes a day. So I'll have to address that at some point.1 point

-

Typically with American pocket watches they have serial numbers. All of the components typically the plate components occasionally the mainspring barrel and an even seen an hour wheel one time will have a partial of the serial number. So the balance bridge is wrong you should build a look on the bottom and see if the serial number at all matches probably just one or two digits will be there but that will tell you if it's the right bridge or not. Then there's always the possibility that somebody has bent the bridge to accommodate the wrong Balance staff. Then welcome to vintage. This is why a vintage pocket watch repair is not recommended for people new to watch repair because rapidly you can end up with lots and lots and lots of problems. Then you can also end up with lots of variations as you're finding the parts book that indicates one part may actually in real life indicate lots of parts lots of variations. Plus of course others have worked on the watch before you and Possibly/probably modified and/or changed things.1 point

-

I suspect the seconds wheel. Can you show us a very close up photo of the end where you nipped of the second hand pivot? Sometimes there is a jewel in the tube of the centre wheel. If you cut off the second hand pivot completely, there isn't any pivot left to seat in the jewel hole.1 point

-

1 point

-

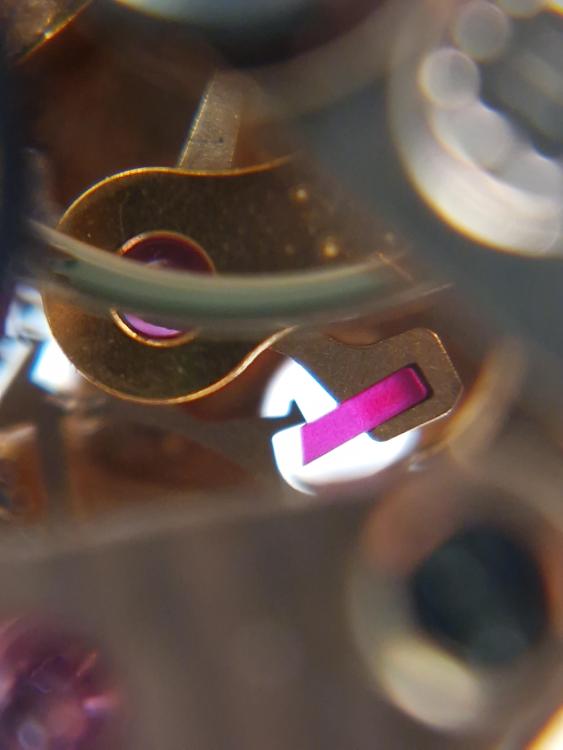

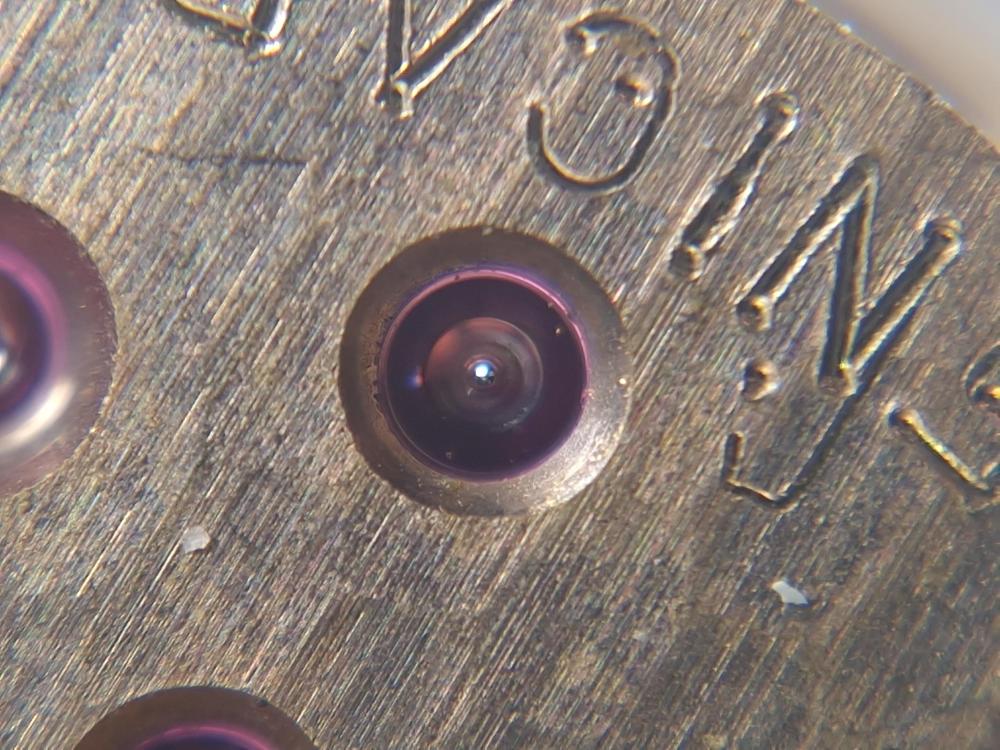

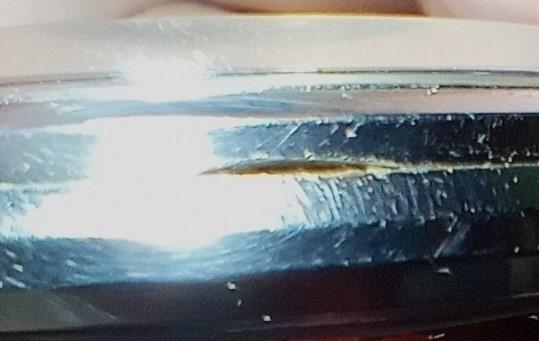

Ok, well, I've played around with it for a little while. Here is a first review : 0. Of course, a lot depends on the quality of your phone camera. I have a pretty good one in my Samsung S22. 1. The device is held to the clip by a magnet. It works ok, but not great. 2. The object needs to be WITHIN the transparent part of the "microscope" (see red arrow). Even 1mm outside of it (like the recess of jewels on a bridge) and it won't focus. So, if you want to inspect a small part individually and it fits into the space - great. Here's a picture of a very small jewel (cracked). 3. Note: you need to use 3x to 7x digital zoon in addition to the "microscope". Without zoom, you'll only see a rather small circle on your phone screen. 4. To be able to use it on anything in an assembled movement, like inspection of jewels or pallet fork lubrication, I needed to break off the transparent plastic. While I had to break it a bit, I can still reinstall it for photos like in point 1. Having removed it, the light is no longer diffused and shines from an angle. Still usable, but not ideal. It is very fiddly, because the fixed focus tolerance is literally 1mm. Incredibly hard to stay in focus. I was still able to get this shot (note: non-serviced scrap movement): 5. Now, I've posted my best two shots after 30min of trying. In sum, I'm not fully convinced of the device.... 6. ....especially in comparison to the other macro lens that I bought. The Apexel 12x/24x lens: https://www.shopapexel.com/products/professional-12x-24x-advanced-macro-lens Basically, it's like @VWatchie's lens with an additional/optional second 2x lens (thus combining to 24x). It has no light, but I found it less bulky and overall easier to use. And importantly, there is a slightly larger margin of focus. I.e. the phone can adjust focus a little bit - maybe within a tolerance of 3-5mm. That helps a lot. I took this picture with it: In the end, I'll properly use this one much more. Both with the single 12x lens as well as with the second lens. Light is a challenge, though, especially with the double lens because you need to be very close to the object (~5mm),giving you very little chance to shine light in between. The consequence are pics like this: That's it for now. More to come eventually.1 point

-

Many of the American clocks are of poor design and the pivot holes are too close to the edge of the plate. Can you upload a photo of what needs re-bushing. If you have a lathe you can always make one.1 point

-

I have. My experience is that the blades are soft trash. I prefer this https://www.cousinsuk.com/product/microshock-case-opener-horotec?code=C03101 point

-

Yes, I bought on Amazon (.fr), but posted a country-neutral link (when I open an Amazon.com link on my phone, it wants to switch the whole country setting of the app...). I got today and will test in the evening (if my wife lets me). I'll post pictures soon!1 point

-

1 point

-

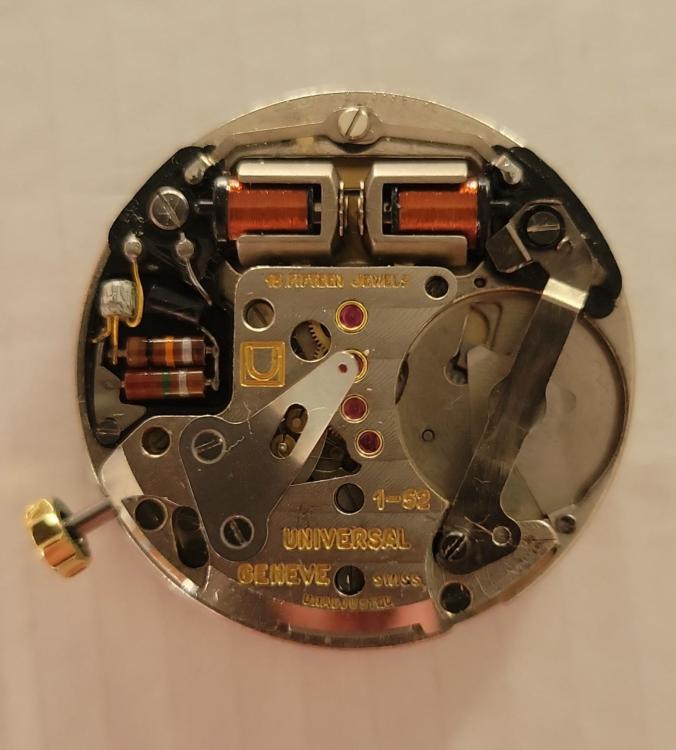

BTW, I am not really setting up a service center. I bought another house about 100 miles away to be close to my son's family (being a grandpa!). We plan to spend about half and half between the two homes. I agonized about my time away from my watch shop and did not want to replicate it. Sooooo, I decided to focus on accutrons at the remote location because I only need a small subset of tools to work on them. Aaaaand...I have about 50 accutrons in a box waiting for service. I have yet to work on the first one, so I am starting at ground zero!! But...I have many smart friends on this forum who will nudge me along.1 point

-

I'm over in India at the moment, and this chat brings to mind the "Delhi Alps" also known as the "Great Delhi Garbage pile", a 65m - 220ft high garbage dump which is actually quite impressive in its sheer scale when you see it in person. It is obviously a hazard, and it obviously pollutes the water table, and the air, due to the regular uncontrolled spontaneous fires it suffers from. Uncontrolled dumping has resulted in some alarming levels of all sorts of interesting toxins, including, according to various reports, radioactive medical waste, heavy metals (lead acid batteries I would imagine accounting for a fair amount of that), chromates, mercury, dioxins (caused by partial incineration in various fires over the years) and all the usual toxic suspects. I suspect that a lot of the waste disposal sites in the UK from the 1950s through to the 1990s would have similar levels of these toxins per ton. All told, I think a few watch and clock hand are not gong to make a huge difference to the amount of crap we are pumping into the environment, but none the less, we should be trying to make some effort to dispose of them carefully.1 point

-

Absolutely. What I will say is that while technically the amounts involved are very small, and the risks are low, if everyone follows this advice, then there will be elevated levels of radium at every landfill and incineration site, since any "securely sealed" container will stay "securely sealed" for about 5 seconds once it enters the back of a trash compactor (aka bin lorry). Having said that, this is small beer compared with for example the beaches on the Fife coast near a former WWII era scrap merchant which disposed of large amounts of luminous instrument dials by burning in barrels and discharging the resultant mildly radioactive slurry down the Fife coast. https://www.bbc.co.uk/news/uk-scotland-edinburgh-east-fife-63515856 Not to mention the disposal by Timex Dundee of barrels of lumed dials from fishing trawlers into the North sea. Out of site and out of mind seems to be the British disposal policy. That didn't end well at Dounray. https://www.bbc.com/news/uk-scotland-highlands-islands-54085592 Low risk, throw it in the trash, don't tell anyone, and let the council burn it. What could possibly go wrong that is worse than what has already gone wrong?1 point

-

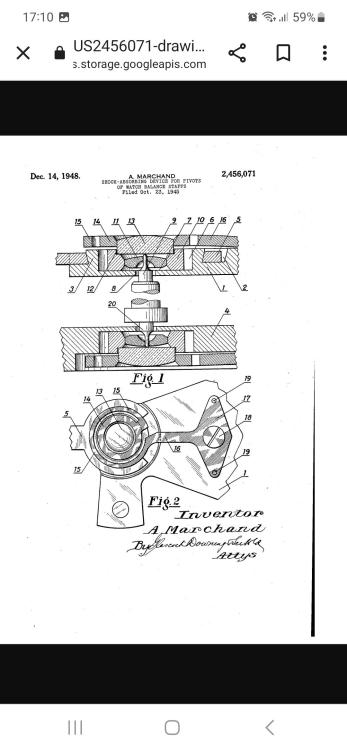

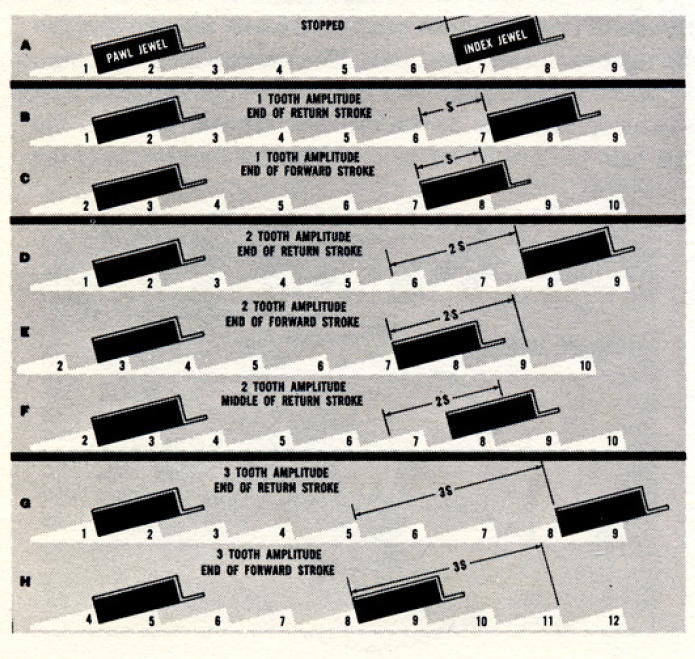

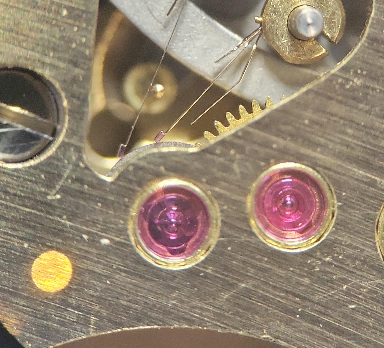

I snipped out something from one ear images I assume you're using a microscope to do the phasing? Now let's look at something else a design improvement I wonder what that improvement was? One of my complaints about people who obsess about using their microscope to see better is you don't. Well you argue with me you do but here's a problem if you look at the two images on the 219 they improved something is even though were looking at it with probably a microscope we can see the index wheel. In your image were looking straight down and you can't see the index wheel which now presents a problem a big problem You can see the wheel next to it that will help but ideally you need to see the index wheel so if you really have to use your microscope which is preventing you from seeing the big picture then tipped the movement holder a little so you can look in because ideally you need to see the index wheel because you have to see what it is doing not the results of what it's doing if it's having a problem now for party your question you didn't ask here's a different image of what phasing is. At work for instance my bosses decided phasing is speed control and he's even asked if I can move the regulator to make up for the speed difference in the answer is no. Phasing can be such a pain in the ass by the way you have to have everything where it's supposed to be an ideally a nice shiny clean index wheel. So what is the purpose of phasing? Phasing achieves something almost magical and you'll have to study the image the magical aspect is as the tuning fork amplitude varies between One and two Teeth as it shows below the result of that amplitude difference is only one tooth is picked up and the wheel spins at its normal rate. This is why in one of the documents I had where it talked about factory specifications they would even run the voltage up to 1.7 V to check to make sure the watch would work with the differing voltages a bad race.Because like in the case of a silver cell battery when it's brand-new and this watch represents such a tiny load initially it's almost 1.6 V. Now what happens if things are not right then if you can see your index wheel it will go up in speed very fast it's not just a variable throttle control of slowly ramping up its speed it will go normal speed double speed and yes it's noticeable but you have to see the index wheel.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)