Leaderboard

Popular Content

Showing content with the highest reputation on 10/18/23 in all areas

-

Just finished working on this 70s Paul Jobin 25 Jewel ETA 2772. As expected from ETA, easy to set up and great performance on the timegrapher. I'm wearing it today for a test. BUT . . . I didn't realise until yesterday, when I was casing it up, that this movement joins those ETA movements with the infamous design flaw. i.e. if you don't have the crown in the hand setting position when removing the stem, the clutch is not constrained, and the yoke can come out of the slot. . . . so off with the hands, dial, date mechanism to reset the yoke and clutch I've added a note in big red letters in my copy of the service sheet.7 points

-

Even though what you are saying is obvious, it is well worth emphasizing. If you're not willing to invest the time and effort into figuring out how things work you are going to meet with limited success. There was a time when I believed, or perhaps hoped, that most problems would resolve themselves with just cleaning, oiling, and reassembling, but of course, that is not the case, and had it been, watch repairing would not have been very engaging.3 points

-

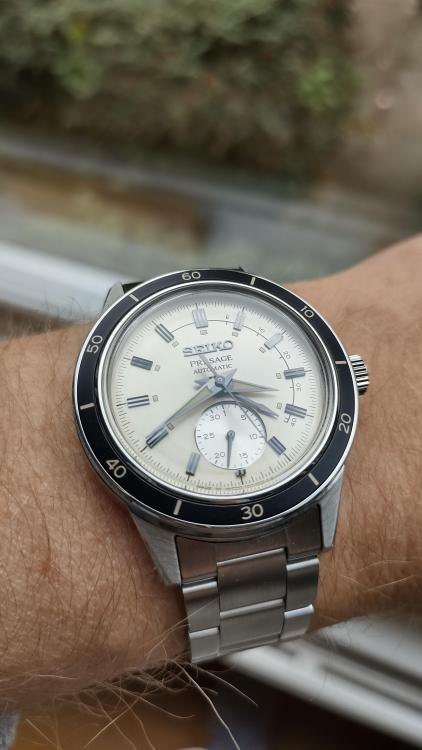

Seiko Presage 1960s style with small seconds style date indicator and power reserve, champagne cream dial. Just bought yesterday in Hong Kong for £365 brand new with Seiko Worldwide warranty. The price was just too good (£570 in UK) Watch shop was in Po Lam area of Hong Kong in the shopping mall and they had 30% off ticket price of all Seiko and 25% off Citizen. Some bargains to be had there. They had the Citizen 'Tsuyosa' for £190 and the new Pantone colours for £250.2 points

-

Hi everyone ! Thanks for all valuable tips! I tried some procedures and the problem has been solved. Basically I removed all hands, cleaned the second pinion, replaced hour and min hands to check a proper sit of them. After this I replaced the second pinion, lubricated the pivot that makes contact with the jewel. I also pulled little the spring the elevate this pinion (not sure if this was ell done). Finally put the second hand with more accuracy and now the second hand is working properly.2 points

-

How super optimistic of you watchie . When i started collecting i thought all i would have to do is buy a strap put it on and away wearing it i would go2 points

-

My dad serviced many thousands of watches from 1947 to 1990. He never worried about radium. He died at age 93. Was not caused by radium.2 points

-

A bit of an anecdote but might be helpful for some real life dealings with radium. A few months ago I acquired a moderate stash of mixed parts off Facebook Marketplace. Some of what was in the stash was around 50 small tins of old watch hands with each tin containing maybe 20-30 hands. All of which were rusty and absolutely coated in flaking radium! Needless to say I wanted rid of them, I double bagged everything and stored it in the garage and managed to find a relevant government email address and fired off an email. I got a response from someone who turned out to be the IAEA representative for our country and lived in my city so he offered to come around to check them out. He ended up taking them away and disposing of them for me but while he was visiting he also offered to scan my work desk and any other areas I used which I gladly accepted. He found no trace of radium on my desk where I do all my assembly. The only suggestion he had was to move the radioactive watches I own out to the garage and open them out there as my workbench is near the kitchen and he had concerns with potentially getting radium on food. The takeaway I had from his visit was that the precautions I take when working on radium watches must be at least semi-acceptable. I put down paper towels before opening any radium coated watch and put on a mask. Once I've opened and removed the dial and hands and placed them in a zip lock bag I carefully fold the paper and throw it away. I then wipe down my desk with more damp towels and wipe down any screwdrivers/tweezers I use and also wash my hands well before starting on the actual movement.2 points

-

Is it just the bare movement or is it in the case with the hands dial etc.? Then I don't suppose you have access to a timing machine? Really nice for diagnosing running problems helps to show things you can't see with your eyes What was the condition of the watch before it was serviced? The definition of servicing involves taking it apart perhaps cleaning how and what lubrication's did you use? One of the problems with self taught watch repair is your learning how to service but it's not necessarily structured learning. In other words you've learned how to disassemble and reassemble a watch have you learned well all the things outlined below? Interesting theory you have here you do know that cleaning fixes all problems don't you? Go on look at the discussions on this group typically people start off with cleaning a watch because that fixes everything. It's only When cleaning doesn't fix the problem with this the fun begin. In order to understand how to troubleshoot something you would have to understand how it actually works. This is why made the reference to structured learning versus independent study. The independent study here people learn how to take a watch apart and clean it they do not necessarily understand how it works. Versus in a classroom situation depending upon the school classroom and/or instructor it typically learn how the watch works. Understanding how the watch works how the escapement works how to adjust the escapement etc. all help for troubleshooting problems. Oh and your troubleshooting method reminds me of I took electronics before he took watch repair. They had something called a half split rule it basically divided item in half and see if one side or the other works. For the most part I don't use the half split rule it just isn't what I use but. I did use it once for a peculiar software problem and it brought up another problem. It turns out I Dividing the item in half and the very last section is where the problem what's. In order to do troubleshooting you would have to understand how the watch works. This is why made the reference to structured learning versus learn as you go where you'd typically are really learning other than how to take a watch apart put it back together which is a good thing to learn because breaking things is very very bad. But typically people don't take the time to study how all watch works are all of the aspects of the watch. Versus in classroom situations where they can go through all of this in a structured way. In other words you get the learn every single aspect of the watch plot it also depends upon which school you go to and even the instructor can make a big difference This is why made the reference to structured learning wares in a classroom situation depending upon the school he went to when you went etc. etc. But a lot of schools they do have structured learning you learn how the watch works you learn how the escapement works you learn how to adjust things you don't necessarily learn how to troubleshoot. Because often times and factory settings they don't have to troubleshoot they just replace everything. Oh and then in watch repair for troubleshooting providing you grasp its usefulness and did not become a slave to it timing machines can quite helpful. Because there's a lot of problems it only will show up on a timing machine unfortunately not all problems show up on a timing machine you can still have problems the timing machine may or may not show them unfortunately.2 points

-

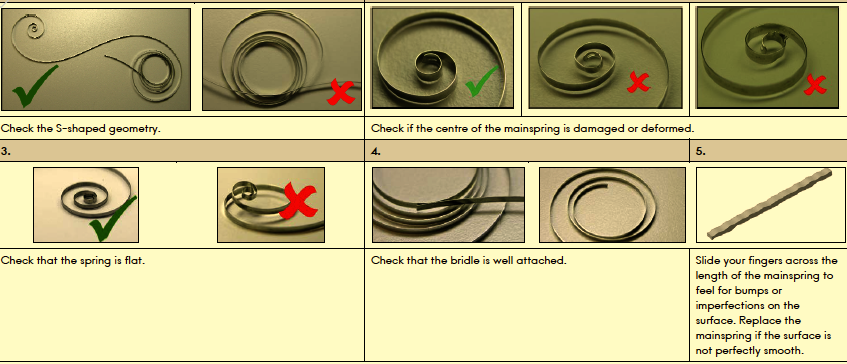

In a watch all the components more most of them have to function within specifications. If your mainspring isn't functioning correctly as you can see it's going to ripple down affect everything else. What's interesting with Omega is they have a guide for recycling a mainspring as they call it. The mainspring in this case is for an automatic watch little different than yours but the principles apply. What's interesting is if you are working on a Swatch group service center they don't even do this they just replace the entire mainspring barrel because they have an infinite supply of These. Here's a little section on the mainspring you don't have the bridal parts you can skip that. Notice step number five the mainspring should feel smooth and by the way when you're all through with this you're supposed to wipe it off with the lip free cloth before you inserted him. So in a dance imperfections and other stuff will cause the mainspring not the slide very well at all causes a heck of a lot of pressure in the barrel and if it doesn't slide right well you get no power in you definitely don't run for the required length of time as you're finding out. Based on your description I would purchase a brand-new mainspring as there's no way to fix this.1 point

-

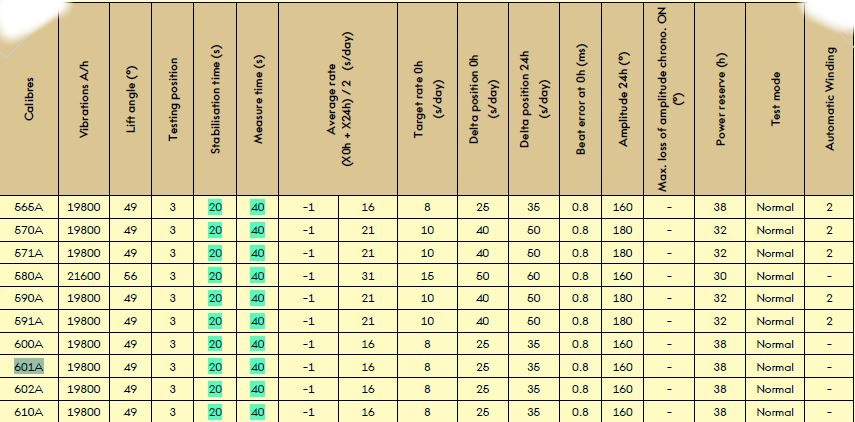

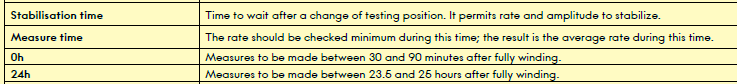

One of the problems with amplitude is typically measured when the watches fully wound up and as nice as that is that's not overly helpful. What is it like 24 hours later? A lot of it depends upon the watch some watches are relatively linear until the very end others will start off really high and slowly taper down just depends upon the watch. Usually watch companies could care less about amplitude fully wound up they only care about timekeeping an amplitude 24 hours later. Omega is interesting in that some of their watches they can be happy if the amplitude is lower but of course it still has to keep time and run the required amount of time so for instance Omega specs for your watch is Now the reference to 24 hours is actually specified as this So at 24 hours your watch should still be running and the amplitude should be at least 160°. Then your definition of a decent rate does not fit with what Omega thinks. Typically watch companies do not like negative numbers so as you can see they would tolerate a negative one second all the way to +16 with a target of eight seconds plus not negative. The timekeeping isn't quite right If you service the watch what did the mainspring look like? Usually even set Common with blued steel mainsprings when wound up really nice and tight or fully wound up still can produce decent amplitude typically they just won't run forever the amplitude will usually drop off. Very common with blued steel mainsprings but your servicing the watch what did the mainspring look like? I don't suppose we can have a picture of the timing machine results a lot of times we might see something in the image you don't. Then just some minor specifications for timing for instance you wind up the watch nice and tight and wait at least 30 minutes and maybe a picture of the timing crown down Then 24 hours later you can do the same thing and we can see how it looks.1 point

-

1 point

-

All A-11 and A-17 military watches should come to me. @markr is not qualified to deal with them.1 point

-

Right- that indicates that there are other issues. What lift angle are you using on your machine? It should be 49 degrees; if you are set to 52 (I think that's the default on the Chinese machines) you will see your amplitude go further down when set to 49. But even at around 210, that is far to low to be considered healthy.1 point

-

In my experience low amplitude and short power reserve is never a tired mainspring. Even blue steel ones. It could be that someone bodged in an actual weaker (thinner) spring that was on hand in the past to get it going and out the door, but if the length is correct- i.e. when you wind from fully unwound you should see about 6 to 6 1/2 turns of the ratchet wheel, it should still hit the power reserve or close to it. My guess is there are other issues causing the low amplitude and eventually the short power reserve.1 point

-

Strangely enough I remember the plastic thing from a long time ago. It's probably not considered a movement part is probably considered a casing part possibly would referred to as a gasket even though that's not what I would call hit. So we need access to a casing list for your watch.1 point

-

Yes a little practice, but your odds of success are many times greater than using the winders, at least in my experience on Seiko springs. For all other springs where possible I use the winders with good success. Also, not sure if this makes a difference, but on the Seiko barrels the cap tends to sit on on the outer diameter of the barrel slightly below the lip of the barrel body, this means that the spring is completely flush whit the top of the barrel. on a swiss barrel the cap fits inside the barrel body on top of the spring, meaning that the spring sits below the top of the barrel when winding it. I have had several occasions where spring has burst out of the barrel (usually when I am trying to wiggle out the winding arbor from the barrel winder), and I suspect that this is because the barrels on Seiko's have no room for error, unlike the swiss versions which give you a small amount of wiggle room before the spring would be free of the barrel, perhaps the winders are not precise enough to work with a spring which is completely flush and need that little bit of wiggle room? At least if you are hand winding you can see and adjust if it looks/feels like the spring is starting to peek over the top of the barrel?1 point

-

Interesting? I was looking at the last two mainsprings I bought $10 each and by the time you add in shipping and tax is up to $28 for two springs let's make that $30 that makes them $15 each shipping. So Cousens is cheaper than that I will remember that the next time I need some mainsprings Nice to know that I'm getting ripped off on eBay I thought that was a bargain price.1 point

-

I'm not sure I've ever heard the term crown pin?1 point

-

1 point

-

1 point

-

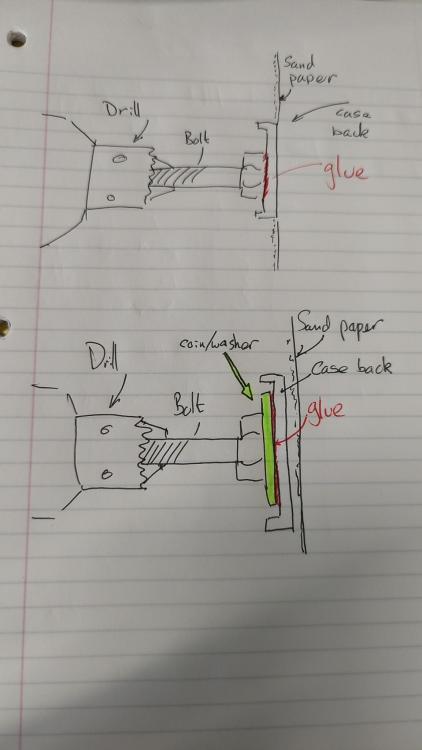

Some interesting ideas, I was thinking, could you file off the lettering from an M12 bolt to get a flat surface and then rough up the surface with a file and super glue it to the back of the case back, then when you are finished remove the bolt with IPA or acetone? you can grip the thread end of the bolt in a standard drill chuck: if the head of the bolt turns out to be too small, maybe you could solder on a large washer or even a coin to the bolt head to increase the surface area? See below1 point

-

Well, no. It is not the mainspring. You have to learn how to investigate such unexpected problems. Most important here is to open the back verry carefully so not to cause the movement to start working again without haveing oportunity to understand where the problem is. Then, You need to understand if the escape wheel is powered or not. If no momentum goes to the escape wheel, then balance will be able to oscillate several times from gentle shake, the pallet wil move from one side to another and the 'scape wheel will move a little forward and reverse, but this movement will be causet by the pallets and not by the train. In this case, the stopp is somewhere between the mainspring and he escape wheel. In some cases momentum may go to the 'scape wheel, but reduced and not enough for keeping the work of the escapement. Then shaking will make the movement work, but with small amplitude and may be it will stop again soon. And may be the amplitude will start to gain and after some time, it will rise to normal. There is another group of problems, that are connected with the escapement itself. For example: the balance seems blocked in position different than it's zero position, and even strong shake doesn't move it. Forcing the balance to zero position or taking it out and putting it on again unlocks the escapement and the movement starts running normally So You first task is to understand which group You have1 point

-

It was a public holiday here in the UAE on Friday, so I decided to put it to good use and work on a watch that has been on my to-do list for a while which is an automatic Zodiac square watch. The build went well, however I am still ironing out the bugs in my scope camera and ended up losing all the photos I took of the pre-build and build this also made the re-build a challenge as the calendar works side was a little unusual (bridge over the cannon pinion). So only have a picture to show of the before and finished watch, the dial was in great shape under a beaten up crystal which I replaced. I didn't do much with the case as the plating was already starting to wear, so just a quick polish with some Flitz. Here is the before: And here is the completed watch:1 point

-

A new mainspring, a strong amplitude, good service with proper lubrication, and a perfect cannon pinion tightness, then there would be no need for any explanation, as there wouldn't be any movement of the second hand in this manner.... lol1 point

-

From the looks of it should be adjustable. Press on the washer thats underside of the bearing ( fig 2 ) to move it until you feel it ( the washer) doesn't want to move any deeper. It can be done in situ Press carefully: DO NOT PUNCH Good luck1 point

-

1 point

-

This link has a slide showing how to use. https://ihc185.infopop.cc/helphand/kd128/kd128pg01.html1 point