Leaderboard

Popular Content

Showing content with the highest reputation on 10/23/23 in all areas

-

I'ts like another post how to bend pin pallets to change the depth of escaping to the escape wheel. It's in one of De Carle's books so it must be right.3 points

-

Quick update, Last night I had a heavily corroded rotor with thick dark green scaling on it (looked like shiny bottle green glass), I tried to scratch some off with a finger nail, but it didn't budge so I dunked the whole rotor in regular store white vinegar for around 30 mins. When I looked after the 30 minutes I saw that the green corrosion was now more of a lighter matt jade green colour with white frosting (??) around it. Whilst still in the vinegar I used a bit of pegwood to poke at the corrosion (more out of curiosity than a serious attempt to clean) and to my surprise most of the corrosion crumbled away easily. A further 30 mins in the vinegar and the rotor was completely corrosion free. The exposed brass that had been lying under the corrosion was clean and shiny and the nickel (?) coating on the rest of the rotor was not damaged at all. Great result and my go-to solution from now on, much more sympathetic than using abrasive methods. Thanks to all that suggested this.3 points

-

Its running with 185 amplitude after an hour of full wind down to around 140 after 12 hours dial up …if you’re all in on these pins for fun not profit may I suggest this blue lube from Doktor Tillwich that Ranfft recommended in a forum post… …he claimed an improvement of twenty degrees and I will attest. A couple drops on the pins and let it run down. I was doing Bradley Mickeys and Minnies for the kiddies what had BFG pins and it did the trick. Our always helpful Jon tells of oiling the metal roller, too- I believe a drop on some paper transferred to a flattened pegwood then dabbed to the roller. lube the pallet pivots if you want, too3 points

-

That's not the beat error. At the very least there seems to be an issue with the escapement, possibly a number of other things, but it's not the beat error.2 points

-

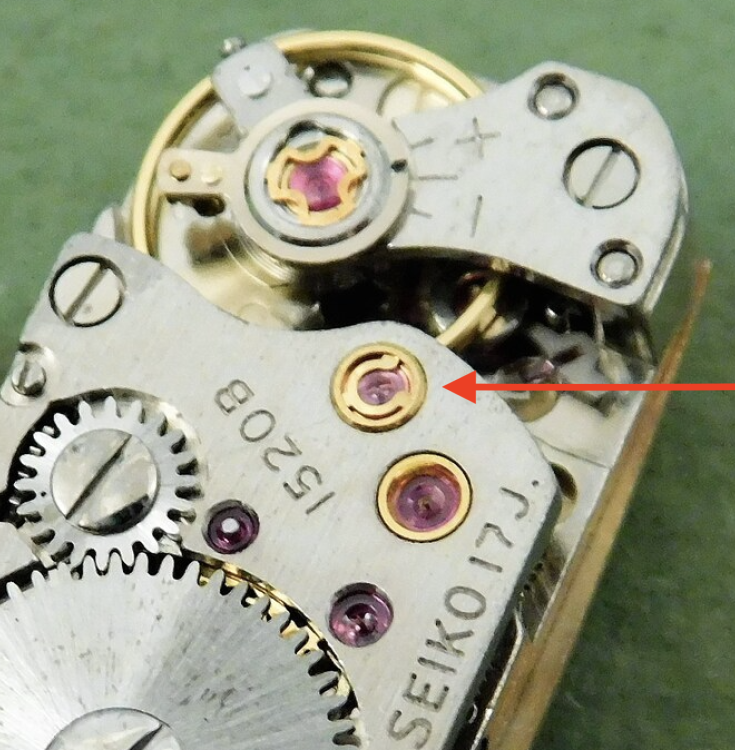

Greetings folks, I'm in the process of cleaning a ladies Seiko 1520B movement from the mid-70s. The jewel situation for the escape wheel is new to me so I thought I would post it here for sake of interest and discussion. On the dial side of the watch, there is what I would consider t be a 'normal' jewel for the escape wheel. However, on the watchmaker side, the jewel has a capstone and shock protection. This is new to me. Are there other movements that employ shock protection on one side of a pivot but not the other? Cheers!1 point

-

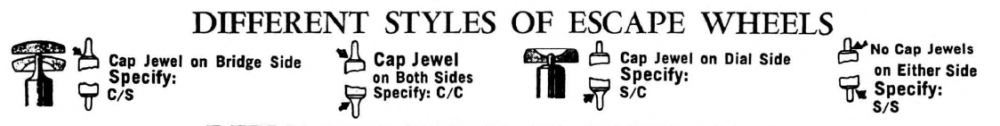

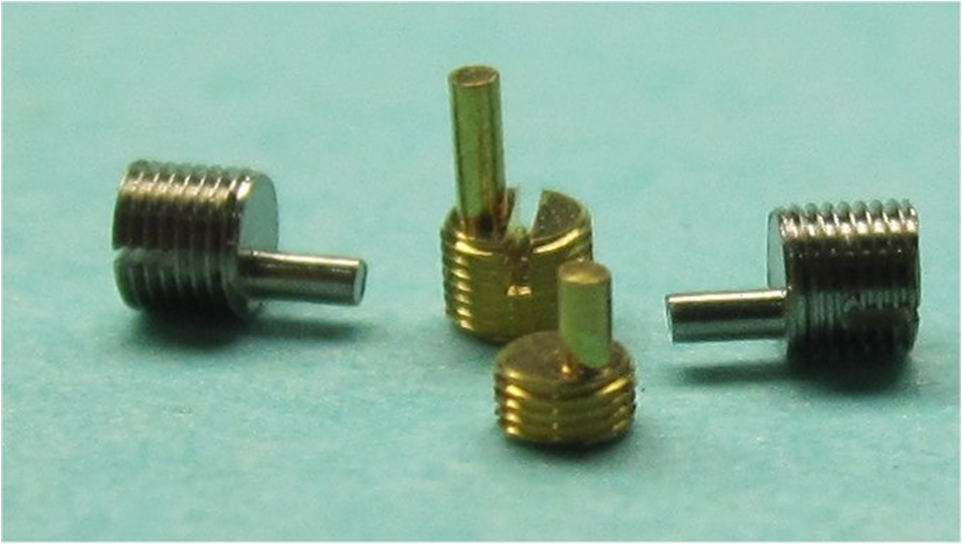

in other words is visible it's there to impress you were you impressed? that's why it's not on the dial side is impossible or harder to see and nobody to impress their. I've attached a PDF of common things and I believe this jewel is shown in the bestfit book here's an example of escape wheels. Not unique to Seiko where you might have a end stone and then a course that changes the pivot. You might conceivably have a watch that has different jewel accounts and you can end up with different escape wheels action you have to specify when you're purchasing not in the case of the Seiko can still have a part number if you can get a parts list. But this kind of thing does lead to confusion if you're wondering escape wheel and the pivots are wrong. 02. Items common to all Seiko watches.pdf1 point

-

Yes, although you don't have to. However, if you use the holders designed for the press then you don't have to worry about lining up the holder to get the plunger aligned to the center hands, which for me is one of the biggest benefits of this press. With a normal movement holder you can make it work by covering the holder mount with something flat but then you have to align the plunger to the hands every time. Of course, if doing a chronograph or sub-seconds watches you need to move the holder regardless. Someone uploaded a 3D design so you can print out a platform for the press. You can also 3D print the movement holders so you can have a custom holder for any movement you use with the press.1 point

-

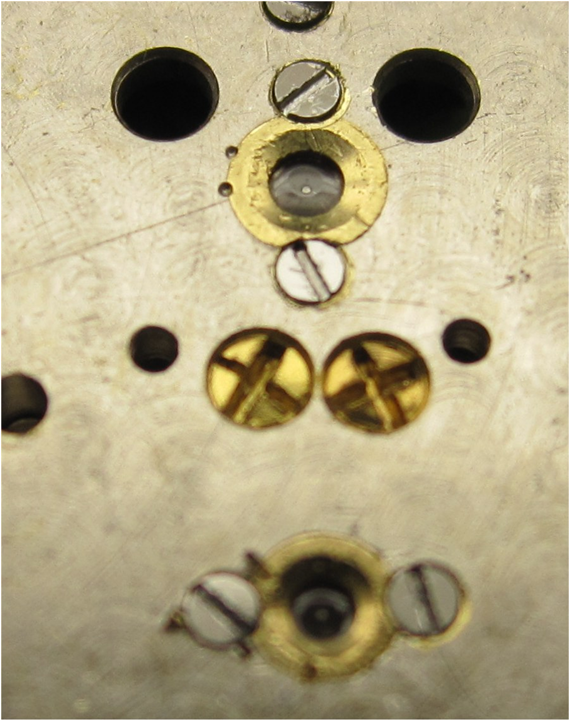

not all the pictures are out of focus for instance this one is focused and let me snip out something if there's any out of focus that's because were only looking at a tiny section and I find sometimes the snipping tool loses a little resolution. the reason why were looking at this particular section is where looking for the banking pins that don't exist kind of. It's been milled into the plate which means they're not adjustable. Okay creative souls conceivably might file them but typically they're not adjustable. Now the problem with the group is everybody has their obsessions which is why we work well as a team. So for the escapement everything has to be right not just one component all of it and it has to be checked in a specific order otherwise you're wasting your time. one of the problems on a discussion group is everybody has their obsessions which if we get around everyone's obsessions we work well as a team. the reason I keep bringing up an American watch is that's what this discussion is about and American watches at least vintage present different challenges then Europeans although not unique challenges as you can see banking pins are adjustable and typically on American pocket watches you have to assume that they've been adjusted. Which means they have to be put right before he can play with the jewels which also can be adjusted. so unfortunately working on a pocket watch you get stuck checking the escapement and cannot assume that anything is right without verification especially if you're having an issue. typically with American pocket watches under the dial you'll find this or on 18 size watches it will be on the other side and British full plate watches will be on the other side. so that X marks the spot and their adjustable and yes they do get adjusted. So every single American watch you look at you have to check that they're in the right place. As they'll have all sorts of interesting consequences with worst-case the watch doesn't run at all.1 point

-

1 point

-

1 point

-

Looks like an issue with one pallet jewel: draw too low and pallet fork not at the banking pin or a very very low 1st esc. noise on one side (too low for the TM). Frank1 point

-

1 point

-

Have a look here, it's a useful website : https://www.mikrolisk.de/1 point

-

Honestly don’t think so. My father-in-law is an extreme introvert who lives completely in his head (retired mathematician & physicist). In spite of his genius, even when he was vital he couldn’t refold a paper map or figure out how to work the car radio. I know he never wore the watch and doubt he ever even knew it was an automatic wind (because he would never have bothered to associate “Thin o Matic” with auto wind. anyhow academic now—he suffered a stroke 3 years ago and lost his wife of 67 years during the pandemic—doesn’t wear a watch or say much of anything now (we take care of him). He honestly doesn’t even remember when he got it from his grandmother, but does know she gave it to him sometime a long time ago (must be between 1959-1961). my wife found it while cleaning up/sorting through some of his stuff since she is responsible for ensuring his things are in proper order—she wants me to restore the watch so he can pass it on to his oldest (my brother-in-law) when the time comes to sort out his legacy.1 point

-

Not sure about other Seiko movements since I have only worked on the 6309 movements. If you order the GR2534X from Cosine UK which is what there web site call for you will find the inner coil to be too big. What you need is the GR25341X or ETA2892A2. I have since fixed 3 6309 movements using the GR25341X without any problems. This a lot cheaper than finding a Mainspring winder that will work.1 point

-

I'm not entirely sure what the first video is explaining? Isn't the fork jumping back due to a mislock on one tooth ? And easing the pallet jewels onto the esc teeth could quite easily avoid that mislock, surely the speed of the jewel coming into lock affects that . Failing to mention involvement of the roller, impulse pin, fork horns, gaurdpin and safety roller looks to be missing out a lot of information, altering banking pin location changes how far the lever travels from side to side affecting all those clearances. The main reason the clearances are checked first before moving the pins. If i have this correct both the amount of sideways travel of the lever and jewel position in the fork slots affects the depth of lock but depth of lock does not affect the clearances at the balance which is why jewel positioning is made last. I think John was suggesting if the banking pins have been moved then its far easier to reposition them back to where they should be rather than moving the pallet jewels which may be in the correct postion anyway. As BOTH a short jewel depth AND a wide banking pin position Can cause light tooth locking causing a mislock. Oh dear, i think we need the # Forum Associate Refriending Team # otherwise known as the "FART" squad. . Come on peeps lets not get upset with each other, we're supposed to all be calm gentile watch folk.1 point

-

Well, The place of the pinion where the wheel sits is a little conical. That's why the wheel wears this way - conically - in other words - the size of the 'hole' is smaller on the one side than on the other. Turning the wheel makes two cones fit oposite, thus the normal tightness of the fitting is reached. Without need to tighten anything. I am wondering, didn't You try what i said??? This is so simle and takes no more than a minute!1 point

-

1 point

-

I tried a few different things with mainspring winders to avoid forking out the money for a Bergeon set. 3D printed winders, 3D printed winder barrels with a couple of Bergeon arbors, and a cheap Chinese set. Each had their issues. What I settled on was a modified Chinese set of winders with a couple of Bergeon winders. By modified, I mean that I drilled out arbor holes on some of the winders to be able to accept larger arbors. This made the set more generic than caliber specific. With the Bergeon #6 and #8 arbors factored in, I have a variety of arbor sizes from 1.5mm to 3.5mm. So, it is easier to find a suitable combo of arbor and winder for a given mainspring. This has worked for me so far, but haven't yet tried it with a Seiko mainspring. When I need a right hand arbor and only have a left hand (or vice versa), I have some brass washers that I have drilled out for different diameters to press the mainspring into as an intermediary.1 point

-

You'll be surprised how easily these type of friction pinions come apart. Sometimes when the hour hand is tight, just using a presto hand remover will pop the pinion off with the hands. I would hold the tube in a pinvise and carefully lift the wheel. It usually comes apart without much force. To fit the wheel back in, I just do the reverse.1 point

-

recently on this group somebody indicated they lived in a super tiny house and they didn't have a lathe. So unfortunately not everybody has a lathe. So that option is out. by the way minor problems with the tool like for instance how common is its existence? then the tap size for vintage versus modern I'm not sure that's the same. In other words are 18 size case is probably something different probably.1 point

-

I'm not sure you are grasping what the problem really was and why we were saying it was difficult. When people start watch repair they need to practice disassembling and reassembling things without destroying them. This means we recommend disposable watches in this particular case that was interpreted as Timex disposable watches. As you said servicing them is easy because you do not disassemble them but that defeats the purpose of why these watches were purchased. These watches were purchased for the purpose of disassembling of them and disassembling a Timex and putting it back together successfully is not what a newbie should the doing or even attempt to do. basically we have a miscommunication here of what is required for a practice watch.1 point

-

I worked on a lot of Timex movements early on, they are not that difficult if you follow the Timex service instructions. Generally, you do not take them completely apart as you would other watches (although you can), but there are some things to be aware of. For instance, the dial tabs can be a problem, if they are flexed too much they can break. None of the Timex movements I have worked on were riveted, I don't know why people keep saying this. You can find service info in the document stash that I maintain, here is the link - https://drive.google.com/drive/folders/0B-IKHN7WFKiwY3JMMDJnMld2SE0?resourcekey=0-7myGNNAUiShb5ihA-o6PnA&usp=share_link Cheers!1 point

-

Having received and tested the "Bergeon 6400 for various shapes", I can now confirm that it indeed works with various shapes (maximum width 45 mm). It feels like a really solid tool and it works very well. Expensive yes, but I can confirm that it does its job. Lifting the old crystal off and setting the new the crystal in on the Poljot was a job made very easy and fast with this tool. The only thing I'm not perfectly happy with is that the arms that grab the crystal are pretty hard to push all the way out to 45 mm. It feels like the inner diameter of the rubber seal is too narrow. Perhaps a bit of silicon on the rubber seal might make it a bit smoother!? Then again, it's not every day we need to lift a crystal that large. As already discussed, the needs for a crystal lift are limited. Nevertheless I'm happy to have one in my "arsenal of tools".1 point

-

Just to clarify a few things ... Watch-O-Scope, and any other purely PC-based watch timer (i.e. not something like MicroSet, which has its own calibrated hardware to do the timing), uses the crystal oscillator in your PC's sound card, not the one for the CPU itself. This oscillator is supposed to work at 44,100 cycles per second. (That's a simplification; it actually works at a much higher frequency, and is divided down depending on the sample rate of the audio being played, or the desired sample rate for recording, but 44,100 is one rate knwon to be supported by all sound cards, since it's the standard rate for CD audio). Unlike the crystal in your quartz watch however (usually 32,768 cycles per second), the sound card rate doesn't need to be all that accurate. If it were off by 0.1%, it would result in a pitch error (when listening to music) of about 2 cents (there are 100 cents between two adjacent notes in a Western chromatic scale). There are very few people in the world who can perceive that small of a pitch error, and most musical instruments aren't even tuned that accurately. Many pop singers can't even come anywhere near that. However, if a program like Watch-O-Scope is using that oscillator to test a watch (by counting the number of cycles from one tick to the next), a 0.1% error is a lot. How much? 86 seconds per day! That's why Watch-O-Scope has a rate correction setting. With the rate correction setting initially left blank, testing a highly accurate watch (which for the purposes of adjusting a mechanical watch, almost any quartz watch would be) will show how much error is due to the sound card. If you test your 0s/d quartz watch and Watch-O-Scope tells you that it's gaining 30 seconds per day, then we know that the sound card oscillator is wrong by 0.035% (30 / 86400 x 100 = 0.035). By telling Watch-O-Scope what the reading is from your assumed-to-be-accurate quartz watch, it then knows what the error is in the sound card's oscillator. That 30 seconds a day correction tells Watch-O-Scope that your particular sound card oscillator is really oscillating at 44,084.7 cycles per second (if according to the sound card your accurate watch is fast, it means that really the sound card is slow). Now that Watch-O-Scope knows the actual frequency of your sound card's oscillator, it can be used to to measure the actual frequency of something else (like your ticking watch). What makes this usable is that most sound cards are relatively stable. Part of this is just that on the scale of mechanical watch timing errors, crystals are pretty stable. Another factor is that the inside of the a computer, once warmed up, is generally at a pretty steady temperature, especially if you have temperature-controlled cooling fans. Now let's look at the effect of sound card accuracy on beat error and amplitude. The beat error is (half) the difference in spaces between ticks from one tick to the next. Another way of looking at it is if you consider every second tick to be correct, how far are the ones in between from where they are supposed to be. This is of course measured by the same sound card oscillator cycles as the watch's rate. However, reasonable errors in the oscillator don't really matter at all for this measurement! Imagine that your sound card's oscillator was off by a whopping 1% (an error that would be detectable by most musicians). Even worse, imagine that it were fluctuating back and forth between -1% and +1% every few seconds (an error that would be audible to almost anyone; remember wow and flutter on tape players and turntables?). That would make the sound card useless for measuring daily rate, but it would have almost no effect on beat error and amplitude measurements. Why? Because 1% is 1%. +/-1% of a day is +/-864 seconds, which would make daily rate measurements pointless. But +/-1% of a 1.5ms beat error is +/-0.015ms. That means a measured beat error of 1.5ms could be anywhere from 1.485ms to 1.515ms. But those would both still display as 1.5ms, since Watch-O-Scope (and other timegraphers I know of) only display one decimal place. So, sound card error doesn't really matter for measuring beat error. Likewise, a 1% sound card error isn't going to affect amplitude measurement either. In fact, it won't affect it at all. The formula for calculating amplitude involves (among other things) dividing the lift time by the total time between ticks. Since both times will be wrong by the same percentage (unless the sound card oscillator is varying really fast), the error will cancel out. To really know how accurate and stable your sound card is, a GPS one-pulse-per-second output fed into the sound card would be ideal. You could run Watch-O-Scope for hours, watching for fluctuations (or use the long-term test feature if you have the Pro version).1 point