Leaderboard

Popular Content

Showing content with the highest reputation on 10/24/23 in all areas

-

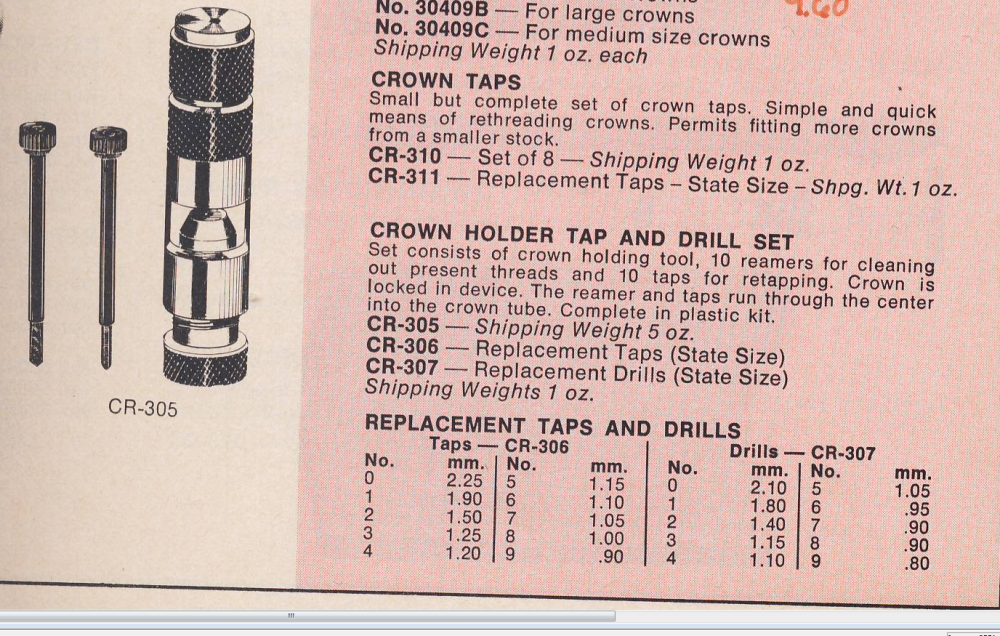

I did figure out where my vintage catalog of tools was and I got a description from the catalog. Notice it does skip over some details. then if you really want pictures possibly much later today maybe. In the meantime description the one side is used to hold the crown in clamp the crown for drilling in thread cutting. Obviously the crown has to fit within a certain size and/or shape where it's not going to fit right. I think to a certain degree the tool itself is self-explanatory if you hold it in your hand. One side is for holding the crown this forms a little clamp you screw in the piece that holds the crown tight against the hole where the drill Goes through. But before you put the crown in you would have to determine something which is how far do you really want to drill? if you look at the other end of the tool with the hole and the adjustable part that is an adjustable end stop. This way you can set how far the drill goes and you do not drill all the way through the crowd as you would have no other way of determining where the drill is.2 points

-

Not a watch, but still pretty exciting. I've been looking for small parts and tools storage solutions, and I found these nifty Bulova "Repair Master" stacking drawers on eBay. I got two of the two-drawer units, and one that's full of parts! The single drawer just showed up and the other two should be next week. They're a little small to hold larger movements, but will be great for my drawer o' random tools and small parts. I have a bunch of tiny zip-top bags on order for corralling small parts.2 points

-

Looks to be a standard chronometer/top grade, the only Breitling specific part being the engraved rotor. The rotor bearing can be replaced if needed, and parts should be readily available. Swapping the whole movement isn't out of the ordinary for such a piece, but 1000 bucks seems quite high even counting they fully refinish the case. I recommend finding an independent watchmaker to service it, should be around half that price especially if leaving the case as-is.2 points

-

I laugh at some of the crap that is in that book. I don't think I have needed that book since I serving my apprenticeship and I didn't find it much help then. My master showed me all that I needed to know.2 points

-

Very helpful, thank you!! From the PDF I learned that the upper escape wheel jewel in question is a Diafix. I removed its spring and cap jewel successfully this morning. (Yay!) Was very careful as I did NOT want the spring to launch. That may be the tiniest little watch part I've handled to date. So far, this has been a fun little watch to work on.2 points

-

The center wheel with longer center tube is for variants of ST96 with date or date/day complications, as date ring takes space which increase the hight of the movement thus longer center tube. Rgds1 point

-

I posted this one when I first picked it up back in July. Came in parts and the automatic works was put together wrong. I learned a lot on this family of movements and really am happy with the outcome as well as the journey. First I will post how it arrived, the for now final, the parts I sourced for replacement, and the latest disassembly for service in case it helps someone else. I had to match every part to the tech sheet and found only 1 missing screw, but the calendar and date rings were toast on arrival. They were good for practice during assembly because they only had the paint removed and I separated the hour wheel from the day ring so that I could work on the calendar and day advancements and see the bridges on the dial side. The original bracelet is a little different with a single link style and needs a little adjustment to get the end covers to lay flat. The watch has been going for about 22 hours with more than 14 hours on the wrist. I am never sure when a full wind is reached on these that have a manual wind function as well. The watch has gained a bit over that time and the timegrapher numbers are pretty decent with not much delta on the horizontal for either the beat error or the Amp. On the vertical 2 of the 4 had good numbers and deltas on the Amp and beat error but the other two are off a bit.1 point

-

1 point

-

In stead of me explaining to you watch this video. https://learntimeonline.com/geneva-stop-work/1 point

-

I believe it’s set up to have 5/6 winds. Before locking. So pre tension the spring to achieve that, it uses the center portion off the spring to maintain a constant tension.1 point

-

It's a COSC certified chronometer. The chronometer number is engraved on the trainwheel bridge (you can see it in your picture). The rotor is engraved. Aside from the movement carrying a chronometer certification, it is a "chronometer grade" 2824-2 and will fit any 2824-2 parts without issue.1 point

-

1 point

-

I would have refered your questions over to Master Nickelsilver because I simply didn't know the answers to such detail, parts to it are interchangeable with lower grade ones and good to know they can be sourced. Reversers are sure to need attention or replaced with new. Rgds1 point

-

as soon as I remember in the day time as opposed to right now where should be sound asleep to get some pictures1 point

-

Generally a domed stake bigger than the hole but not too big then broach the hole to suit . Its not something i have done a lot of, so someone more experienced can help you choose the stake size more accurately.1 point

-

I recently received this little gem from my father, who I believe got it from his. I know little to nothing about watches except what I’ve learned reading and watching videos of watch repairs in the last 48hrs. The crystal is yellowed, and cracked along the edge, causing it to fall out of the bezel constantly, and appears slightly damaged by some chemical. The balance wheel’s shaft’s pivot points (what are these called?) are broken, causing the balance wheel to sit on the .... base plate? And not turn freely. Otherwise i think its in good shape. Would anyone recommend trying to replace the balance shaft, or just trying to find an entire balance complete to replace? And the crystal.... should I stay with the acrylic and replace it or use glass and some form of cement to hold it in? Any thoughts, comments, questions, or advice would be super welcome!1 point

-

You are assuming the obvious. He has a finger and thumb on one hand and three fingers on the other.1 point

-

You only have one hand ? and can repair watches, Richard you are a bloody legend1 point

-

So this happened to me again last night when putting the hands on a Citizen 6651A, 26 hours in a day - then it dawned on me what the issue is... of course it was 100% my fault! So here is what causes this: When I put on the hour hand at midnight I turned the hand 24 hours with the winding stem to make sure that the date turned over at midnight, but the hour hand must have been sitting at an angle or slightly low and hung up on the 9 O'clock marker I adjusted the hand and spun it again for 24 hours to make sure all was OK (no hang up this time), but noticed that the date changed around 11:30, not midnight Here's my mistake, instead of removing the hour hand I simply bumped it forward 30 mins by pushing it with a piece of peg wood I then spun it again for 24 hours to make sure all was OK, but noticed that the date changed around 1:00 am, not midnight Here's where I compounded my mistake, instead of removing the hour hand I simply bumped it back 1 hour Now when I then spun it again for 24 hours to make sure all was OK, I noticed that the date now changed around 2:00 am, not midnight.... and so on Eventually I gave up and went for a coffee Whilst drinking my coffee it dawned on me that the lazy bumping back and forward was not slipping the hour hand on the hour wheel, but instead stripping the teeth off the cheap plastic date change gears! So tonight I have to change them out, fortunately I have a donor watch I can steal from. I'm mad at myself for my lazy mistake causing more work and problems and burning parts, but happy that I solved the mystery! Hopefully others can learn from my mistake:1 point

-

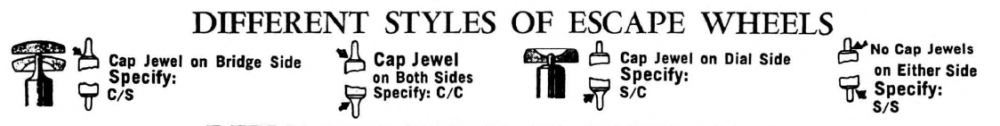

in other words is visible it's there to impress you were you impressed? that's why it's not on the dial side is impossible or harder to see and nobody to impress their. I've attached a PDF of common things and I believe this jewel is shown in the bestfit book here's an example of escape wheels. Not unique to Seiko where you might have a end stone and then a course that changes the pivot. You might conceivably have a watch that has different jewel accounts and you can end up with different escape wheels action you have to specify when you're purchasing not in the case of the Seiko can still have a part number if you can get a parts list. But this kind of thing does lead to confusion if you're wondering escape wheel and the pivots are wrong. 02. Items common to all Seiko watches.pdf1 point

-

Just over £60 that is about right as its a Bim Bam normally you just have a strike movement. The case is Bakelite so the tone of the Bim Bam will be poor. You won't get a nice sound, a wooden case would be much better. The movement is filthy so it will need cleaning and probably re-bushing. There are collectors who collect Bakelite here in the UK don't know about the USA.1 point

-

My experience is, as long as the escapement is undamaged, you wouldn't degrade the watch much by replacing a part with lower grade ones. Rgds1 point

-

1 point

-

Quick update, Last night I had a heavily corroded rotor with thick dark green scaling on it (looked like shiny bottle green glass), I tried to scratch some off with a finger nail, but it didn't budge so I dunked the whole rotor in regular store white vinegar for around 30 mins. When I looked after the 30 minutes I saw that the green corrosion was now more of a lighter matt jade green colour with white frosting (??) around it. Whilst still in the vinegar I used a bit of pegwood to poke at the corrosion (more out of curiosity than a serious attempt to clean) and to my surprise most of the corrosion crumbled away easily. A further 30 mins in the vinegar and the rotor was completely corrosion free. The exposed brass that had been lying under the corrosion was clean and shiny and the nickel (?) coating on the rest of the rotor was not damaged at all. Great result and my go-to solution from now on, much more sympathetic than using abrasive methods. Thanks to all that suggested this.1 point

-

de Carle goes into detail on adjusting pin pallets. Cliff Notes- cutting the pin pallet base and moving the pins…1 point

-

Adjustments to hairspring , terminal curve and regulator slot might be needed at every service time. Make a habbit of making these adjustments as soon as you get to bare mainplate, instal the balance cock assembly on mainplate. See photo, notice how accessable are most parts of the oscilator thus easy to work on.1 point