Leaderboard

Popular Content

Showing content with the highest reputation on 10/25/23 in all areas

-

Five and a half years later I can confirm that a bit of silicon grease on the rubber seal makes a huge difference!5 points

-

Other than caliber specific winders, they are often a crap shoot whether they will work well or at all. And yes, there are watches with 5mm barrels, some very expensive ones too! Sometimes the winding arbor is too large, sometimes too small. Sometimes the hook is too close to the winder cap for a given height of mainspring (not much you can do there), sometimes too far (just a bit of a pain usually, except super low profile springs). Sometimes the hook is too large to fit the hole in the spring. Some springs are so thin they want to slip into the area between the plunger and the winder barrel. It's always an adventure.3 points

-

So, I did pull the trigger on the Proxxon Micromat 230/E, and I'm super happy with it and can wholeheartedly recommend it. It's truly a night-and-day difference between my Proxxon and the lousy tool I got from Cousins. The vibrations are minimal and it's so quiet it bothers no one. IMO, worth every penny!3 points

-

I feel your pain. I have 5 sets of different winders and still have to wind a mainspring by hand once in awhile. I discovered this method where you can use the original mainspring arbor to wind the mainspring into your Watchcraft winder barrels. Please have a read of the post below.3 points

-

Rivets? That is a myth perpetuated by those who want to knock Timex because they are not serviceable in the same manor as a typical swiss mechanical. I do agree they are not the best choice to learn on since the techniques learned will not transfer to other repairs. yes they are remarkable devices. Just a small sample here. you may not realize but the screws on the other side of the movement for those models M24 and well up to M109. The M21, M22, M26, M29 were on the back side. Done were riveted together preventing the plates from being separated.2 points

-

Hi I actually use something similar, a Dyson circular filter with the innards removes an like Mike foam cut and fitted. Bonus is the foam can be changed any time you want and the filter frame is larger two. And it says neither Dyson or Bergeron.2 points

-

The silicone must be better as it's nearly twice the price. But then the gel one says 'Bergeon' on the cushion, which must make it better? I'm amazed that people will pay £50 for a blob of silicone just because it says Bergeon. Same with the dial holder, £50 for a bit of plastic with holes in I use the ring from an old cheap cushion. I cut some spongy foam packing to fill it. It works really well, and is free! (But then I'm cheap )2 points

-

What a mess. They need to be re-bushed and make sure they are the correct depth. Never ever just get a hammer and hit it with out thinking, if you are not sure ask on here and provide good clear photos.2 points

-

I see. It seems the wheel is made of brass, is it? My expirience is that polishing brass parts where friction happens like bearings and escapement teeth doesn't bring any good. Burnishing helps beter. But both ways the shape of teeth can be changed, and this change can decrease the ability of the escapement to lock. For this escapement it is essential that the angle formed by the impulse and rest surfaces on all the teeth is sharp and not rounded and the proper angle of the rest surface is not changed by wear on the place where drop of the pin ocurs. If one needs to restore the wheel in a manner that will increase the locking, he must not touch the impulse surfaces, but he should work only on the rest surfaces. The other thing is the pins itself. They wear and they wear much more when surface of the brass teeth is charged with abrasive particles by the dust around or from polishing the teeth with abrasives. The wear of the pins decreases the locking. Pins can be changed, shifted, turned around or upside down, the body of the lever can be shifted on the staff, the table of the wheel can be shifted on the pinion - all this will solve the pins wear problem. But this is in the alarm clocks where everything is big. In You case the easiest way is to change a little the position of the wheel in high by bending it's spockets. This is only if significant wear of the pins is seen. Pins usually are so hardened that they will rather snap than bend In You movement there is no way to adjust the escapement, so only the acuracy of manufacturing is the thing that can guarantee normal performance. If there is no significant wear and still the escapement doesn't lock correctly, then may be someone has changed part(s) of it in the past. And, if the locking is the problem, then I think it should be solved now by moving the escape wheel towards the lever. This means that the bushes of the wheel bearings must be replaced by probes with no holes, the correct distance between the wheel and the lever must be determinated by the help of depthing tool and arcs with bearings of the lever as center must be drown on the probes, Then another arcs with the bearings of the 4th wheel as center and the proper radius must be drown, thus determining the places of the new holes2 points

-

2 points

-

Not a watch, but still pretty exciting. I've been looking for small parts and tools storage solutions, and I found these nifty Bulova "Repair Master" stacking drawers on eBay. I got two of the two-drawer units, and one that's full of parts! The single drawer just showed up and the other two should be next week. They're a little small to hold larger movements, but will be great for my drawer o' random tools and small parts. I have a bunch of tiny zip-top bags on order for corralling small parts.2 points

-

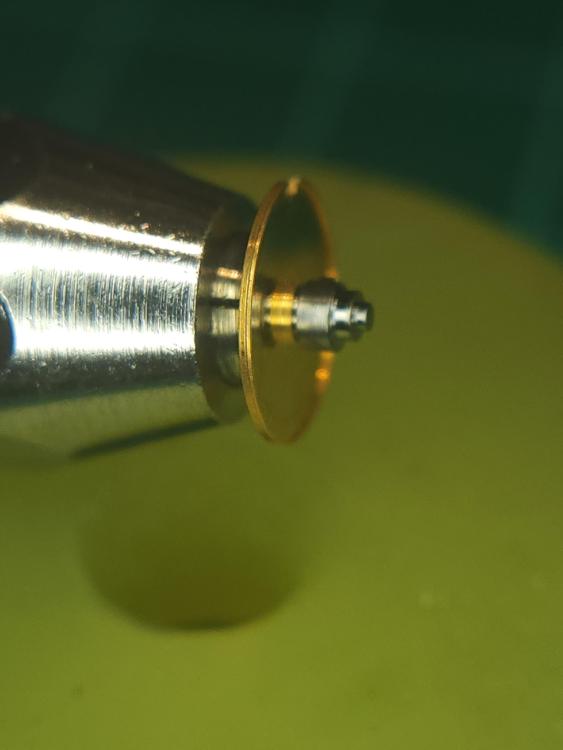

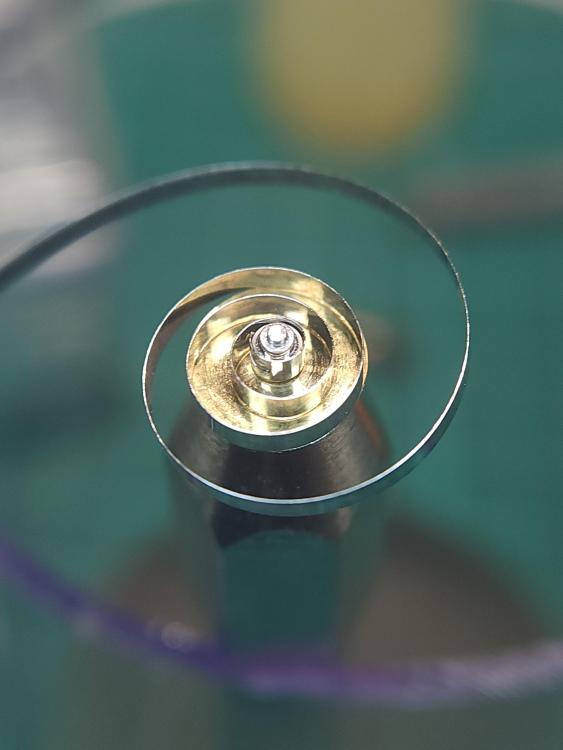

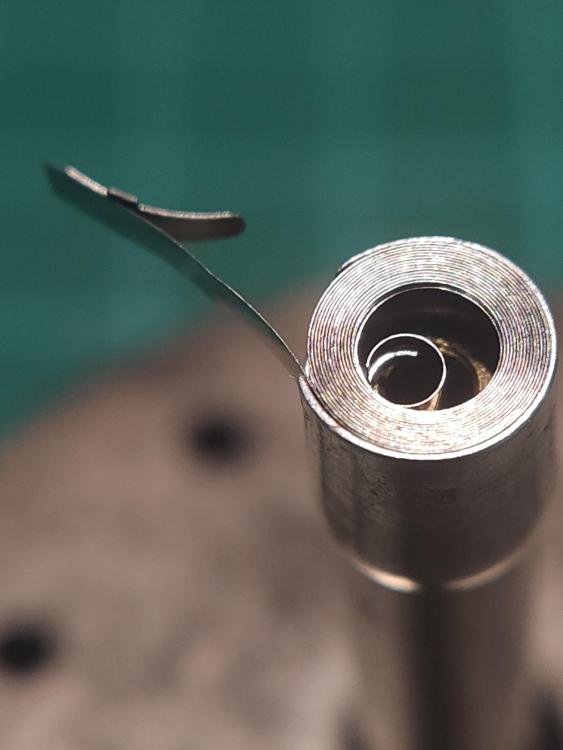

What do you do when the correct size mainspring winder you have has an arbor that looks like this? This is exactly the situation I encountered last night. I was servicing a Slava 2428, twin barrel movement. The barrel is so small that the only winder that could fit was a Watchcraft #2. But my arbor looks like it got chewed by a dog. I remembered a post a couple of months ago about a homemade mainspring winder using a plastic sheet and a pinvise to hold the actual watch barrel arbor. Then it hit me. I could mount the barrel arbor into a pinvise and wind it directly into my winder. Initially when I tried it, the mainspring kept twisting and buckling and wouldn't wind nicely into the winder. I had the idea of cutting a washer to cap the open end of the winder. When I finished doing that, I looked at the washer and thought it looked a lot like the barrel cap. I took the barrel cap and realized that the barrel cap fits perfectly. So I mounted the spring and wound it into the winder easily.2 points

-

Apologies for re-raising this issue, but I would like to put my own spin on it (pun intended), I would like help on getting started in the world of lathes. I have reached the point where not having the ability to make parts on a lathe is starting to hamper my watch making development. However, I have never owned or used a lathe and have no practical knowledge of them, quite an admission from a 25 year Chartered Mechanical Engineer who is also a Fellow of the Institution of Mechanical Engineers.... but there you go! I can design in 3D CAD and program for a 6 axis CNC machine, but stand me in front of a manual lathe and I wouldn't have a clue. Anyway, back on topic.... I am a great believer in the 80:20 rule, so looking for a set up that will allow me to cover most of what I need (when starting out anyway) without breaking the bank on getting all the bells and whistles that would sit on the shelf for 99% of their lives - I can work on those over time. I am also looking for a setup that isn't some obscure brand or setup/size, as I want to be able to look up instructional videos etc. Not having any experience I need a volunteer(s) to "lead me by the hand"....."Scott, buy this and this and this..... there you are done!" kind of thing, also, any recommendations on YouTube/videos and other resources on using a lathe for watch making would also be great. Confession over... and thanks in advance for the help and advice.1 point

-

Same here, the top off a jar or tub , cups that you fit under sofas to protect the floor and then cut foam packing to fit inside. The foam from an old yoga mat works well or those fit together foam floor mats. I'm put off by those gel or silcone cushions, I'm off the opinion that they can catch and break of a sub second pivot or an extended 3rd wheel.1 point

-

I'm sure it would work better if you wrote Bergeon on it ! I did search ebay for some sort of silicone gel which could be used as a cushion. But I mainly found they were only flesh coloured and sold in pairs for ladies Still, if you don't mind a flesh coloured cushion, they're a 1/10 the price.1 point

-

Despite the fact that Solvil Et Titis are arguably no longer the brand they once were, I must admit there is something about this little dress watch that hits the spot. It is (perhaps obviously) a 404 club candidate, however I was surprised to find that if purchased new, a very similar watch from their "Classicist" range on their Singapore site comes in around the $300 SGD (£180 GBP) mark, so hopefully the are still producing watches of reasonable quality.1 point

-

Terry, Yes, I’ve heard of it - I am actually refurbishing one myself, to go along with my similarly-ancient L&R Junior. That’s one of the really old L&R machines, which came with the non-logo H-5371 jars with metal screw caps. Some of the wiring is consistent from one cleaning machine to another, but the actual schematic really depends on the model of the motor involved. The open-frame style machines from that era seem to have used fairly generic motors made by Hamilton Beach for their shake mixers, and they are non-reversible so there is no “Reverse” or ”Auto Cycle” switching involved. (Unless you open them up to rewire, which is a mod I can explain more about if you are interested). Can you provide a picture of the motor and a description of what model and manufacturer information is listed on the nameplate? Glen1 point

-

1 point

-

1 point

-

Have a look in the tools section of the forum, there is a 3d printed mainspring winder set designed by a member here and also sold on eBay by another member here. here you go, worth a look and both folks involved are very helpful Tom1 point

-

1 point

-

1 point

-

"Anachron is said to be a better performing alloy than any Nivarox incarnation which is why it's used on the Top and Chronometre grades." Link here. Considering it's a luxury watch and movement, just don't go to town with your glass fibre brush. If unsure, take a very light brush under strong magnification to see what it does.1 point

-

1 point

-

As almost all watchmaker lathe makers are now defunct, it's good to get a brand where you will run into accessories and parts without too much trouble. I strongly recommend going with an "American" style lathe, with what's called a Webster Whitcomb bed. Here some quality makers are Derbyshire, Levin, G. Boley, Boley Leinen, Wolf Jahn, and Lorch. Of those, my absolute favorite is Boley Leinen. One of the main reasons being that the tailstocks always line up, from one machine to the other, mixing and matching*. They also accept commonly found 8mm collets from Schaublin, Boley, Leinen, Levin, and others, in my experience. Some of these machines are made to take 10mm collets- you definitely want to stick with 8mm, far more available second hand. I would go for a machine that comes with a collet holding tailstock as it opens up so much the utility of the tailstock. A lot can be done freehand turning (well, all, if you really want to), but having a slide rest is incredibly useful. Unfortunately most made for this type of lathe leave a lot to be desired. After all my years doing this, I have never found anything close to the quality and utility of the slide rests from Levin. They don't come up for sale everyday, but are worth what they go for. Watch out- they came in both metric and inch versions, metric being the preferred one. You can find boxed sets with loads of accessories, but most of the little bits and bobs will sit in the box unused as they have done already for decades. A good basic lathe, a good slide rest, and a good set of collets is enough to have you making parts. I use my lathe daily and it's rare to need anything other than that. I do have some scroll chucks and such with are handy for certain work. Some info on Webster Whitcomb *On the Boley Leinen- there were two "eras" older and newer. Older ones had a very slightly different bed size, and wont mix with the newer ones. Newer ones always have straight black locking levers for the head and tailstock, older have more bulbous fancy ones. You want the newer style. The machines were made with both plain bearing and ball bearing headstocks, either is fine, the latter tending to be more expensive. And finally, I've read on other forums (check out Jerry Kieffer's posts here) where some folks have been super happy with Sherline lathes even for doing tiny watch parts. As an adapter is required to use 8mm collets, I have a hard time imagining that you can chuck up a small part and get it to run truly true, and there are some other limitations. But those machines are very affordable brand new, and can do some stuff that is very difficult on a watchmaker lathe, like cutting screw threads. For new machines, the only one I can see as being worth any investment is the apparently very high quality Chinese made CZ-50. It appears to be a sort of homage to the ball bearing head Leinen machines, and they have a lot of very happy customers. I think the base price is around 6k dollars for the lathe with collet holding tailstock and cross slide, so not something one would buy as a first machine necessarily unless that sum is palatable.1 point

-

Ok so the hole in red looks to be very worn, oval in shape, the hole in blue looks quite damaged that i cants see a hole. The center bush i cant really tell. A good way to take close pictures is to use a loupe at the end of your camera phone lens, that way you aren't losing detail when zooming in with just your phone. Phones have digital magification which is crap for close ups. He already has one idiot helping him so back off buddy1 point

-

Yes, apologies, just trying to have a bit of fun, but I agree not very useful for @Murks I'll try to be sensible now This is similar to the one I use also, but even using this the taps need to be very light, just let the hammer fall from 4 to 5 cm using only its own weight, and just two or three taps then check. It can take time, but its like a hair cut, they can always cut more off but can't cut more on. Also if its a bushing it may be better to push it out out and use a new one if the damage is too great to repair using a staking tool.1 point

-

1 point

-

1 point

-

First of all, the back needs removing, so is it a snap of screw back? We need photos.1 point

-

The staking tool is not meant to be used in conjunction with a sledge hammer thanks for this advice not many have told me this what can I use instead with the staking tool? if not the sledge hammer.1 point

-

Welcome to the WRT forum. Repairmans who worked on your watch had obviously not taken watch repair courses by Mark Lovic. Regards1 point

-

Maybe a little off topic, but I find buying a whole used movement from ebay often works out cheaper (in the long run) than buying an individual new part(s), depending on what it is of course. The added advantage of this is that you get the unused parts for free and can maybe use them in the future. On more than one occasion I have needed part X only to find out later in the build that I also need parts Y and Z, luckily the movement I ordered will have these parts and I don't need to return to suppliers to order the additional parts. This is especially attractive to me due to the fact that based where I live it can take two or three weeks to get the part from the supplier to my door, therefore needing one part and then another and then another.... could delay a build months. There is a risk of course that you may end up with a movement with the part(s) you want missing or damaged, but it's usually worth the gamble in my experience.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. Some members will be able to help you. I don't touch anything that is quartz or battery powered. My main interest is antique clocks.1 point

-

Pushing a new mainspring from its ring into the barrel should not present any problems if you have bought the correct spring. If the spring doesn't sit inside the barrel diameter with the ring sitting flat on the rim before you start pushing, then you will have the problem you describe.1 point

-

Yup...too many words. Find a set of K&D winders on ebay. If the arbor is not damaged, they will do fine...once you develop some skill1 point

-

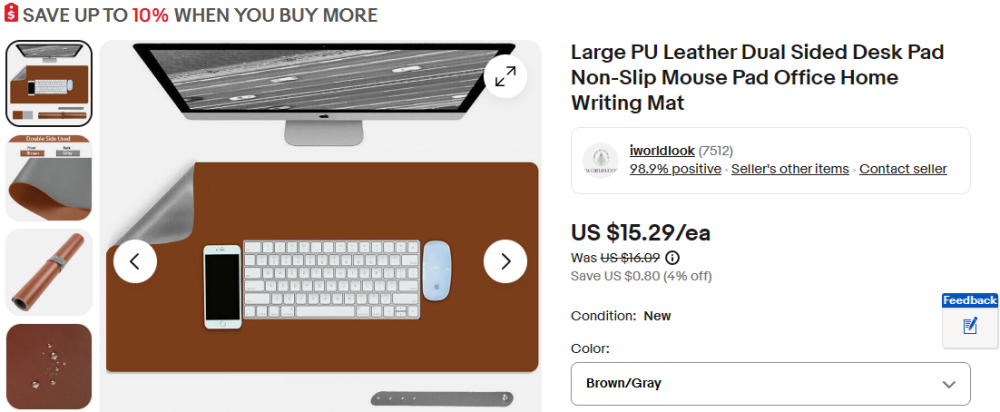

This is the bench pad I have on all of my benches. Search on ebay Get one of these to sharpen your screwdrivers (Esslinger image below) Get a Dumont #3 tweezer. It will last a lifetime. Frankly, the used vintage Dumonts are better IMHO. I have lots of them. Bought a new one and it does not have the same sensitivity as the old ones. Buying vintage on ebay is a crap shoot, however. The screwdrivers I use are Bergeon. My first set was a Christmas present back in 1970. This set below is a good start.1 point

-

Looks to be a standard chronometer/top grade, the only Breitling specific part being the engraved rotor. The rotor bearing can be replaced if needed, and parts should be readily available. Swapping the whole movement isn't out of the ordinary for such a piece, but 1000 bucks seems quite high even counting they fully refinish the case. I recommend finding an independent watchmaker to service it, should be around half that price especially if leaving the case as-is.1 point

-

I laugh at some of the crap that is in that book. I don't think I have needed that book since I serving my apprenticeship and I didn't find it much help then. My master showed me all that I needed to know.1 point

-

I think this is where amateurs can excel and probably even learn more than some pros. Investing time and effort into the fine tuning and study of something cheap, something that left the factory with more work to be done, Its just not financially viable for a pro to entertain. We dont need to factor in time and motion, jeez ive been backwards and forwards, on and off with this fiend of frustration for nearly six months now. Its looks at me with its little sad face from the edge of the bench and says # please daddy can it be my turn again pwweease .1 point

-

I worked on a lot of Timex movements early on, they are not that difficult if you follow the Timex service instructions. Generally, you do not take them completely apart as you would other watches (although you can), but there are some things to be aware of. For instance, the dial tabs can be a problem, if they are flexed too much they can break. None of the Timex movements I have worked on were riveted, I don't know why people keep saying this. You can find service info in the document stash that I maintain, here is the link - https://drive.google.com/drive/folders/0B-IKHN7WFKiwY3JMMDJnMld2SE0?resourcekey=0-7myGNNAUiShb5ihA-o6PnA&usp=share_link Cheers!1 point

-

Hello and welcome to the forum! Before you go any further, please be aware that you are not allowed to promote your business on here.1 point

-

1 point

-

This has a Venus 175 copy if I'm not mistaken. It's possible the coupling clutch depthing to the driving wheel is too tight, but when you engage the chrono it's just enough movement that it lets it run. That'd be the first thing I'd check. Then recheck the depthing coupling clutch to chrono runner. The clutch-driving wheel should be about 2/3 deep, clutch to runner about 1/3 deep.1 point