Leaderboard

Popular Content

Showing content with the highest reputation on 10/28/23 in all areas

-

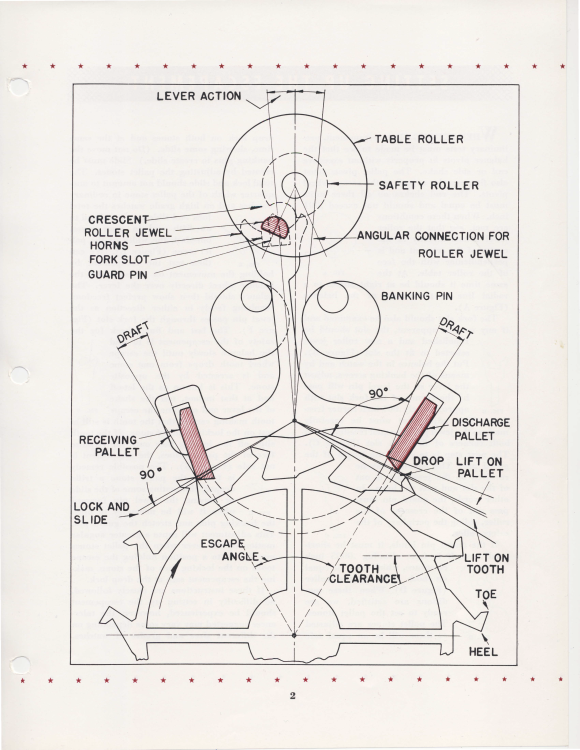

If I'm making a fork from scratch it's extremely handy to use a depthing tool to set the drop lock. In particular on high grade swiss stuff the fork often is in a channel machined into the mainplate, with banking happening on the base of the fork end near the horns at the end of this channel. Once drop lock is good, the banking area of the fork is filed until the fork can hit drop lock plus some slide (run to the banking) which is total lock. After all that the horns are filed for clearance, and finally the guard pin fitted. It would be really hard to do without a depthing tool. A good depthing tool.4 points

-

If I'm checking a watch escapement, I would normally check the horn clearance and make sure there is safe lock. Then guard pin clearance which should be smaller. Then drop lock, which should lock, then total lock (banked). If there is excessive total lock, but the run to the banking is large, then drop lock is (generally) small, but run to the banking large, so I close the bankings. If there is excessive total lock, and drop lock is large, run to the banking minimal, I would move the stone(s) as long as there is enough safety with the horn clearance. At a certain point you may find that you still have excessive drop lock but can't move the stones in any further as horn clearance is too large. This is either a design or manufacturing defect, or someone filed the horns at some point. Bottom line is drop lock is independent of the banking pins, and can be observed using a depthing tool- which while useful when making a fork is also useful when working on full plate watches. Once you have decent drop lock, horn and guard pin clearance can be (painfully) checked in the watch, and eccentric bankings can be closed so that they can be opened to "bank to drop" (this is found in older texts, opening the banking until drop lock occurs), then open a tiny bit more to permit slide and total lock. Even with the lovely Hardinge tool which effectively converts a mainplate into a 3-way depthing tool, setting drop lock is a pain on full plate watches with the fork and balance on the full upper bridge. And drop lock really is the base.3 points

-

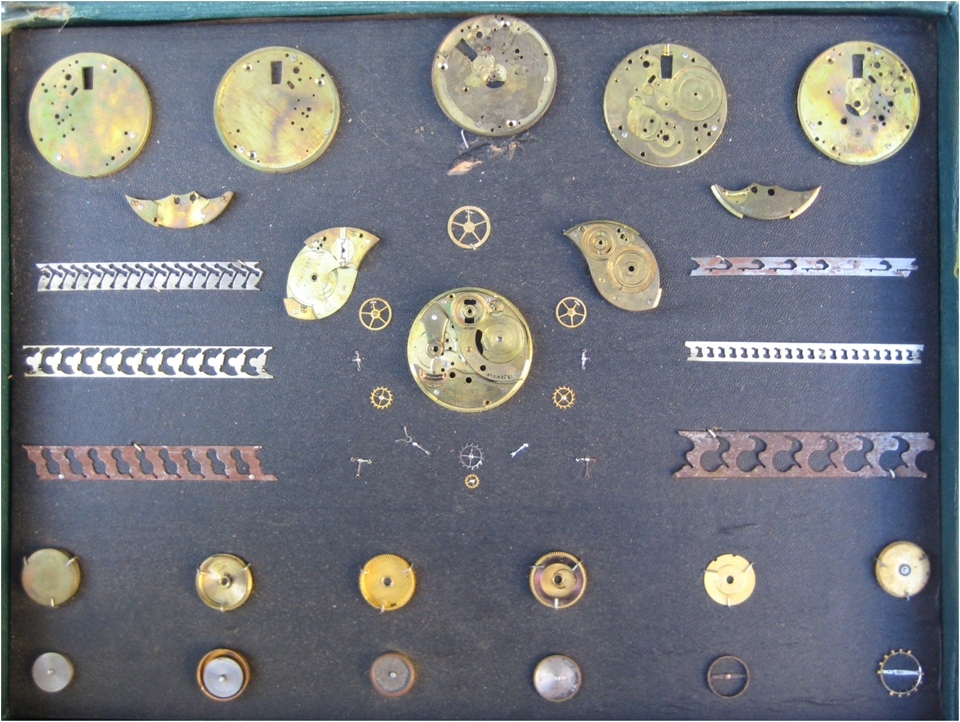

I was always hoping that somebody would just come up with 3-D printed version. Because trying to purchase one of those off of eBay there always dreadfully expensive. But in the absence of one get an American pocket watch with movable banking pins and start moving them around and see what happens. then just in case you're curious about how much movement the banking pins can do here is an example from Elgin3 points

-

2 points

-

I bought the 16mp camera for my AmScope trinocular microscope, and I have to say, it's fantastic. While it is a luxury, I do post a lot of photos, and holding a loupe to my phone is less than ideal, and the ability to get close up video will be fun for the Accutron repairs I've been doing. Additionally, I bought the calibration slide to go with it, and the software lets me measure things to within a fraction of a mm. For example, trying to find the diameter and width of a flat case gasket when I don't have the original. It's just super cool and thought I'd share.2 points

-

Found these up in a Colorado mountain town and thought that they were a really cool display pieces. Supposedly these were salesmen's samples. I ended up with the light background one. I also picked up a nearly complete K&D Series 600 staking set for a good price from the guy and some other small tools. It was worth the trek up there.2 points

-

Really enjoying my new lathe and just received my copy of "The Modern Watchmakers Lathe and how to use it" what a font of knowledge ! I have started playing with adapting winding mechanisms and and will this weekend attempt my first balance wheel improvement. Nice to be back after a difficult assignment all the best...Jules2 points

-

Indeed, photographic evidence of my hubris was the real mistake!1 point

-

1 point

-

1 point

-

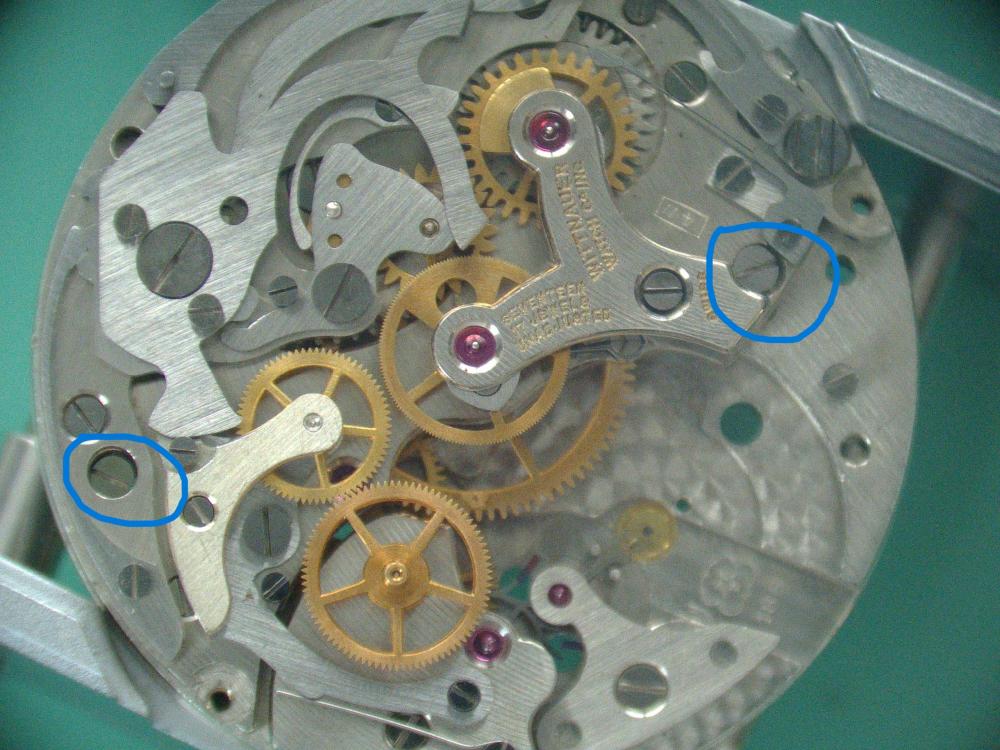

ADVICE: DO NOT TOUCH THE DIAL WITH BARE FINGERS!!! Now, picture of the movement from the back side needed. The screws that hold the dial will show there1 point

-

We will need a picture of the movement. Quite a lot of movements (especially older ones) have dial feet that are held in place by screws that are accessed on the back of the movement, not on the side. If this is one of those and you try levering it of as though it is a friction fit you will not be happy with the result.1 point

-

Hi Hector, Actually, the depthing tool is not a tool for escapements adjustment. It is an useful tool that You are going to use when someone brings to You a box full of all the wheels and parts from a watch or clock but without plates and asks You to build a watch or clock out of this parts. It will help You to position the wheels between the new plates at the right distance from each other in such manner that they will be geared(?) correctly. Here I offered it’s use as in such movements as OP’s it is not possible to observe and operate the escapement from above, but only from aside, and this makes work with the escapement much inconvenient. I didn’t say impossible without it, and using of the tool is not unavoidable. It just would make life easier. In modern style movements, where lever has separate bridge and everything is seen from above, such toll is not needed for escapement adjustment. Further more, the method I offered is apliable only if one of the pallets in it's correct place, as the metthod uses the position of this pallet as reference for the other pallet positioning. If initial position of the first pallet is wrong, the method will be still apliable, but then corrections of the both pallets will be needed in a manner that one of them will go in antd the other out in order to make the lever's tail decline symetrically as much to one side as to the other. I would advice to open the banking pins when adjusting pallets positions and when adjustment is done, to correct the pins position as to ensure the needed minimal clearences and that movements 'run to the banking' are greater than zero.1 point

-

I found a complete movement for this project. The seller claims it is working, and as you can see it has a higher standard of finish, so hopefully the finished article will be presentable. It even appears to have a bow which may work to replace the one that is missing. If not, I do have quite a good stash of bows so I should be able to come up with something. I can always fabricate one if necessary. One final bonus was that it was cheaper than a balance staff, and saves me the chore of replacing that.1 point

-

Guys, I have never claimed that banking pins are not important and further more – to get rid of them. This is a nonsense. Please, try to read this instruction for pallets depth adjustment, which I pointed, and have written it back in 2012. The first thing I say to start with there is ‘Straighten the banking pins!’. As this is written for a movement made in 70’s, which means modern one, straightening the pins means ‘Bring them to their right position!’ And, this is because in the pallets adjustment I have used the banking position as reference for the pallets position. Made this way, the adjustment in the end is correct, but this is right ONLY if all is originally made or suitable for this movement. If, for example, the pallets has less sloped impulse planes, the locking will be too deep, and if planes are more sloped, no locking will happen at all. This kind of adjustment is the one that has to be made if the things are totally messed, or if no pallets at all in the lever and everything must be done from the beginning to the end. And there beginning means banking position, and end means receiving correct locking in the end. But, if we don’t need to go all the way from beginning to the end, and see clearly that just a correction is needed, and it is clear what this correction has to be, it is naturally to do the correction, and check the result, but not to start from the very beginning of the process, as it is no needed. I will claim again here, that locking is different thing and is not the same as total lock, and the locking happens without participation of the banking pins. And no matter what one will do with the pins, if locking was bad or not enough, it will not change. Of course, if the pins are in wrong position, they must be adjusted. But if the pallets position is correct, wider pins than needed will only result as little lower amplitude, and narrowed pins just slightly than needed will result in rubbing of imp. stone in horns or guard pin in roller or just stop of a tooth of the esc. wheel on the very edge on the end of the imp. plane of the pallet1 point

-

1 point

-

Hi Nicklesilver, this all sounds like reverse of doing the clearance checks before adjusting a pallet stone ? Which also makes sense if you are starting with nothing. Even more sarcasm, someone always has to go one better Who has one of those big escapement models to easily illustrate what happens when things are moved around. Anyone ?1 point

-

that's why the new recommended procedure is to unscrew those pesky banking pins and toss them in the trash as they're not needed at all. as all they bring his misery because they're in the wrong place getting rid of them is a good thing I only wish I'd known this sooner.1 point

-

I kind of figured the same Hector, the locking is dictated by the escape wheel only with no involvement of the banking pins to limit the lever travel. I am happy to be proved wrong though.1 point

-

Hi. With due respect the clock is a different animal, it’s way more robust and of a different construction and materials which are able to stand greater strain. But having seen some spring ends literally torn back and broken I some times wondered who wound it, perhaps a gorilla. I think they wind it up then one for luck?.1 point

-

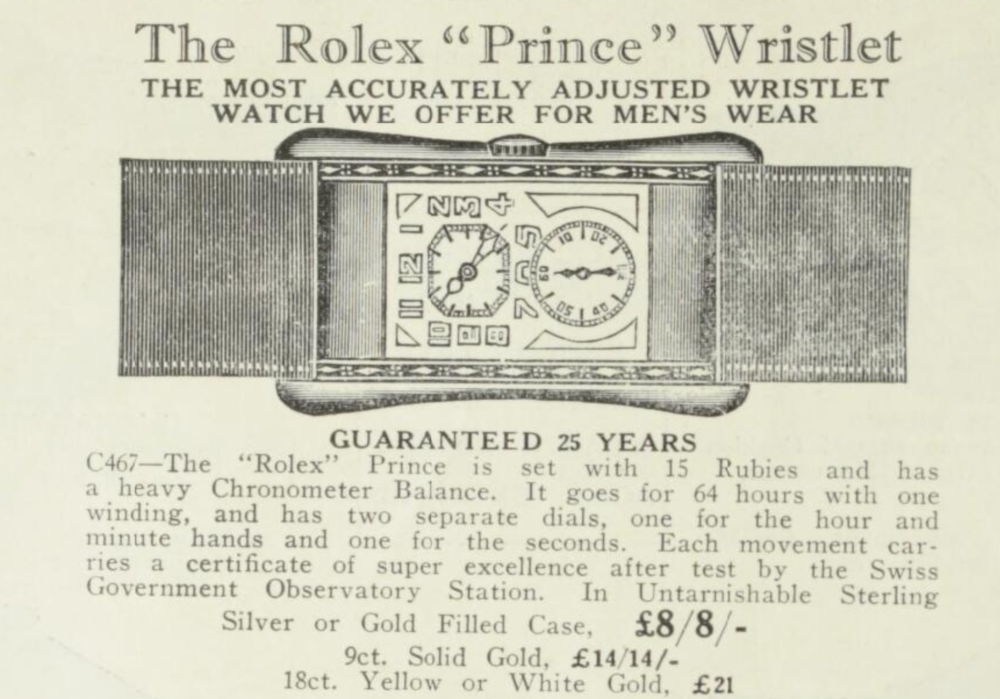

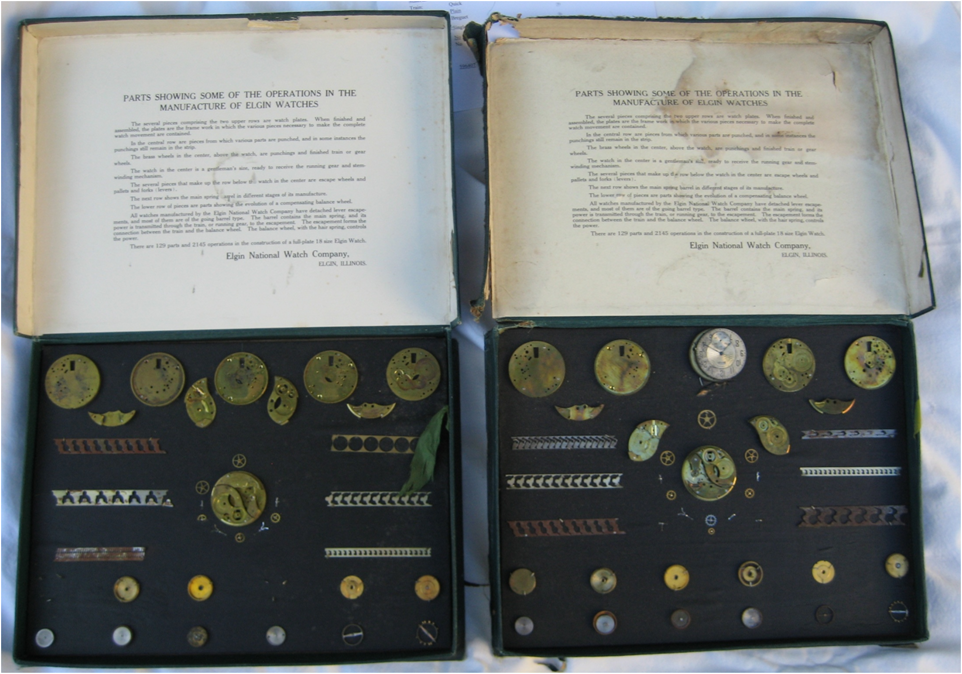

which interesting is yours are nicely framed and it appears to be one specific watch. Somewhere I've seen this before I think somebody on this group may have posted a picture previously. than the Elgin watch company had something sort of similar. Not nicely framed but in cardboard boxes which have the problem of basically the effect of time and water. Then not so much one watch but more of components used to make a watch more like showing how the watch parts are made where they come from etc. the steps of making the watch. Then if you read the text indicates is for an 18 size watch but the reality is both of these are 12 size watches. found on the inside lid is this label the interesting aspect is they're not exactly the same.1 point

-

I was initially so excited by this method of setting the pallet jewels that I went on eBay and almost bought a depthing tool. But a little voice inside my head told me to hold on. From reading the earlier post about banking pins, I realized that the position of the banking pins are not transfered to the depthing tool. Hence the depth of the locks cannot be set accurately using this method. Perhaps @JohnR725 can review the method and weigh in on the matter.1 point

-

Thanks Thor, turns out there was a much easier way to confirm it's a fake. Serial number is 813124, which popped up on another forum: https://www.watchuseek.com/threads/seiko-presage-sprb46j1-authenticity.5260007/ So yeah, 100% a fake watch. Bummer! The crystal glue/gasket situation, from my research the old hardlex should have been glued in and essentially is a massive PITA to remove. According to the guy that sells the only box shaped sapphires I can find on the internet, the new sapphire needs to be glued in. I've got all the parts, and the watch is disassembled, so I'm still going to service and repair it, but how unfortunate! Glad it's not my money though.1 point

-

4R35A has 23 jewels. The rotor is definitely wrong. I haven't taken the dials off of any of the newer models, so I can't comment on that, but I would think at least they would put their manufacturing date codes on there like they did on all of the older models I've worked on. I couldn't say for sure though. I've done a couple Hardlex to sapphire upgrades, including some on newer watches (most recently an Alpinist), and each one of them had a crystal gasket (nylon/plastic type).1 point

-

Guys cannot believe it but I finally found the replacement balance. Perrin in Canada had it for sale and snagged it up. Thanks for your help on the repair. You guys are the best1 point

-

Yes, hoping that is it. I tore the movement down again and paid extreamly close attention to the third wheel—it is an odd configuration in that the 3rd wheel has three sprockets to it—top is attached to the shaft and drives the sweep second hand pinion, middle is a free floating spacer and the bottom drives the forth wheel. Anyhow I did pull out some debris from between the sprockets, and reassembled the movement. Right now running as it should be I’m going to let it run 2 or 3 full wind cycles before buttoning up with calendar works and dial again to make sure the movement stays stable. There is one other issue, but I’ve decided to let it ride having put so much time into this project—whenever I try to get beat error below 1.0 using the stud armature, the timing and beat error goes way off. So I’ve decided to just live 1.2 beat error, strong amplitude anf ~0-10 sec per day in all positions.1 point

-

I recently bought a Star Lathe from Switzerland, 1920's more or less. I am learning watch makers turning but I am familiar with larger lathes and would recommend it. Nice solid lathe up to you. lets learn together best Jules By the way I also bought the book "The modern watchmakers lathe and how to use it" Archie B Perkins, what a book I haven't finished it yet but highly recommended. Cheers...Jules1 point

-

1 point

-

Have a look in the tools section of the forum, there is a 3d printed mainspring winder set designed by a member here and also sold on eBay by another member here. here you go, worth a look and both folks involved are very helpful Tom1 point

-

As almost all watchmaker lathe makers are now defunct, it's good to get a brand where you will run into accessories and parts without too much trouble. I strongly recommend going with an "American" style lathe, with what's called a Webster Whitcomb bed. Here some quality makers are Derbyshire, Levin, G. Boley, Boley Leinen, Wolf Jahn, and Lorch. Of those, my absolute favorite is Boley Leinen. One of the main reasons being that the tailstocks always line up, from one machine to the other, mixing and matching*. They also accept commonly found 8mm collets from Schaublin, Boley, Leinen, Levin, and others, in my experience. Some of these machines are made to take 10mm collets- you definitely want to stick with 8mm, far more available second hand. I would go for a machine that comes with a collet holding tailstock as it opens up so much the utility of the tailstock. A lot can be done freehand turning (well, all, if you really want to), but having a slide rest is incredibly useful. Unfortunately most made for this type of lathe leave a lot to be desired. After all my years doing this, I have never found anything close to the quality and utility of the slide rests from Levin. They don't come up for sale everyday, but are worth what they go for. Watch out- they came in both metric and inch versions, metric being the preferred one. You can find boxed sets with loads of accessories, but most of the little bits and bobs will sit in the box unused as they have done already for decades. A good basic lathe, a good slide rest, and a good set of collets is enough to have you making parts. I use my lathe daily and it's rare to need anything other than that. I do have some scroll chucks and such with are handy for certain work. Some info on Webster Whitcomb *On the Boley Leinen- there were two "eras" older and newer. Older ones had a very slightly different bed size, and wont mix with the newer ones. Newer ones always have straight black locking levers for the head and tailstock, older have more bulbous fancy ones. You want the newer style. The machines were made with both plain bearing and ball bearing headstocks, either is fine, the latter tending to be more expensive. And finally, I've read on other forums (check out Jerry Kieffer's posts here) where some folks have been super happy with Sherline lathes even for doing tiny watch parts. As an adapter is required to use 8mm collets, I have a hard time imagining that you can chuck up a small part and get it to run truly true, and there are some other limitations. But those machines are very affordable brand new, and can do some stuff that is very difficult on a watchmaker lathe, like cutting screw threads. For new machines, the only one I can see as being worth any investment is the apparently very high quality Chinese made CZ-50. It appears to be a sort of homage to the ball bearing head Leinen machines, and they have a lot of very happy customers. I think the base price is around 6k dollars for the lathe with collet holding tailstock and cross slide, so not something one would buy as a first machine necessarily unless that sum is palatable.1 point