Leaderboard

Popular Content

Showing content with the highest reputation on 10/30/23 in all areas

-

Hi. Just serviced a very slim Mappin and Webb 1970s gold dress watch. This is a 25 years service presentation watch which jeweller's used to supply back in the day. To my delight it had a Favre Leuba twin barrel 255 hiding inside - my favourite movment. A deeply clever design and a joy to work on. Despite clear evidence of at least two services, it ran at very poor amplitude. However the trace was clean so after a good scrub and lubrication the mainsprings were extracted. I've done three of these over the years and every time old mainsprings had been left by servicing watchmakers. This is unfortunate since the layout allows the two barrels to be removed in seconds. Jeweled barrel bridge - posh eh ? The barrel design is unusual because the winding ratchet wheel forms the top cover and arbor thus saving height and complication - see pic. A different approach is needed to replace them which seems to deter servicing watchmakers. The replacements should be 1.50 * 0.07 * 285 at 7.0 mm diameter - GR 4052 will do. The excellent Gleaves & Co supplied mine. The fun starts when you find the central coil is too large for the arbor hook to engage. I use two methods. The strong cheap flat tweezers fit inside the small barrel and careful squeezing will allow you to tighten that curve enough. The internal post in the barrel will help prevent snapping the spring - be gentle. Plan B is to temper the spring fixing point to a brown colour using a temperature controlled soldering iron and then bend it around a drill shank slightly smaller than the desired end loop size. Both work with patience. Hope that helps guys.5 points

-

what on a group for we share our knowledge you don't do share the secret location of treasure? I remember one of the US auction houses decided to have a store where they would get rid of things that weren't desirable for the auction. although that definition is rather interesting I will give an example in a moment. once a week new items would come out usually the more collectible items would disappear instantly. But a lot of the stuff didn't sell right away sometimes it was even discounted and the prices were still fantastic. But then of course word got around and soon there was nothing good to be found. then the company was unhappy with how the store functioned and they closed it down. But I have hopes someday it will come back hopefully. Here's an example of something it was undesirable for auctioning off. You see anything wrong with the dial? oh and as this is a watch repair discussion group not a watch collecting group primarily. The reason I point this out is on watch collecting groups people love to see pictures of watches and even on this group people love to see pictures of watches but as this is a repair group I like to see movements. As interesting as the dial is I mainly purchased the watch for the movement or the movement that was in this case. So for me I can live with a dial lets less than desirable in fact I find this one quite amusing and with the bonus nearly perfect movement although I believe in their description it had think of the definition of micro scratches and on the movements. Yes that would make the movement so very undesirable. So basically I have a mint movement with amusing dial for $160 and it Time although now it needs to be serviced several years later. Another project for the future3 points

-

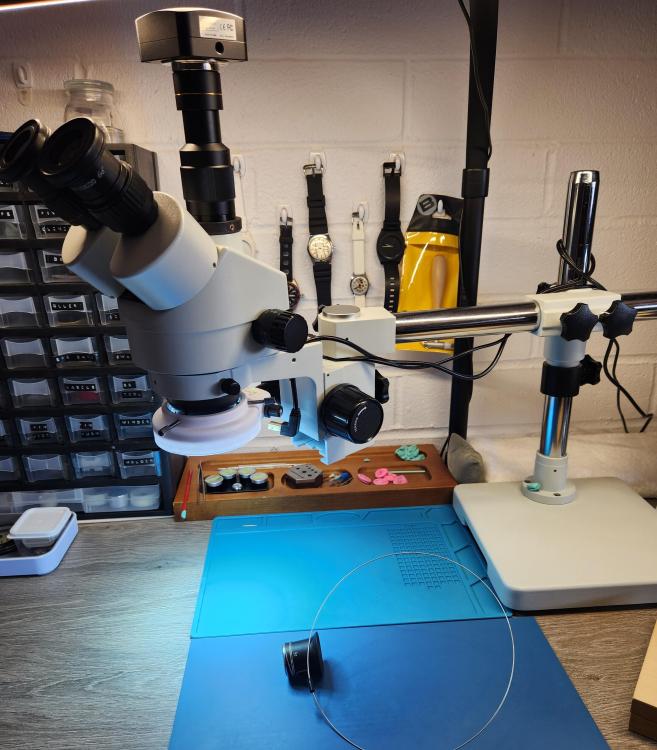

I know this has been covered but wanted to share my experience. I have read all the threads in this subforum and know this is all been discussed in length and it boils down to personnel preference. I think that a stereo microscope is an essential tool and most watchmakers should have one for their low bench. for the other 10% of work on a high bench a 2.5 (inches of focal length) Bergeron loupe is what I use. I got the trinocular and back earlier this year it cost $498.00, all in (without the camera) with the Barlow lens, shipping, tax everything. As Alex Hamilton on his youtube channel and Klaas on Chronoglide says, it is a game changer and WILL make you a better watchmaker. You can't work on what you can't see. You can tilt the head so that your hands are not in the way (this is set at about 6% - i know because on my photo cropping tool I can rotate the image and it gives me ! degree increments that I can use to line up the horizontal lines on the scope). I have a range of working area under the lens of 15 to 20 cm, depending on the zoom. It also has another 12 cm of "play" to adjust the range to fit anyone's bench and chair heights, and seat to eye level height. The eyepieces can be adjusted to individual eyes both focus for differences in eye strength and width to get the center of your eyes in the center of the lens. The cups can be rolled back on the eye pieces for glasses the same as birding binoculars and adjusting the eyepieces is exactly the same as on field binoculars in that you use your dominant eye to fine tune the focus in that eyepiece (with both eyes open), then leaving your dominant eye open block it (you can close it but technically you should have both your eyes open when doing this adjustment) and adjust the focus on the other eyepiece. Klaas does a similar adjustment discussion on his youtube channel as well as a couple of other useful tip on setting up the scope. Hope this helps someone interested in obtaining and setting up this tool. Here is my set up. Yes, I know I have carpet, but I do have a chair mat and a nice padded professional stool. Thinking bout adding a second mat and sliding the other one over that will get me to a hard surface under the entire work area.3 points

-

Nekkid Watchmaker did a you tube video in which he had a gold watch back restored. I can't remember if it was engraving that was removed or damage that needed filling but he found a specialist operator in the jewelry quarter in Birmingham who was able to match the colour of the gold perfectly and using a laser welder build the material back up by welding gold wire into the voids and then just polish it back. Completely invisible restoration without any plating. So it is possible. He didn't say what the cost was though.2 points

-

I don't think MIG welding is capable of such fine welding work. A micro TIG might be able to pull it off. But I think the best bet would be laser welding. Some specialist goldsmiths might be able to do the job for you.2 points

-

Another 0.99 pence unwisely spent on a Soviet era basket case. This time a Poljot cal 2614.2H based Sekonda with signs of having endured a hard life. There appears to be rust on the hands, and some flaking of the dial. I am quietly confident that if the rust is superficial, then there is a pretty good chance of this running without too much effort. Here are a couple of much nicer examples, without the optional crusties.2 points

-

Can't get the name at the moment but leave it with me. The name is not the maker it is the seller, many jewelers had their names put on clock and watch dials, all we know is it was sold in London. There might be marks on the movement or on the back of the dial but they will be makers of the clock repairs some even put the date of repair. It is stupid I know, but thank goodness for there stupidly. With close inspection it is possible for someone who has a good knowledge of clocks to spot the difference in the movements, the plates are not so thick, the pillars are poor in finish, steel quite soft and the finish of the complete movement poor, screw threads poor finish you can tell they are modern. I mentioned the bezel and hinge as that is easy to spot. Hope that will help you in the coming years.2 points

-

normally I would blame the stupid dictation software but looking at the definition that is probably the word that I actually used I suppose alternative with an push the jewels all the way and. Never know it dictations going to do but I'm sure I actually did use the word shoving..1 point

-

depending upon how old the original plastic is it can do all kinds of things with time. Like a lot of the early plastic crystals are made out of cellulose nitrate and it produces nasty fumes and will rust the hands right off the dial. the later crystals of course don't do that if it's a plastic crystal I prefer it to be pressure fit. Not necessarily press fit but pressure fit this is where you put the plastic crystal in your crystal press ill hold it by the outer edge near the outer edge on one side you press on the inside and the crystal itself will bow in word you put the bezel first before you do this so basically the crystal shrinks and you push the bezel down and then when you release the crystal is held nice and tight so it's not pressed in because usually the or sometimes the bezels are slightly tapered the hold the plastic crystals that way suppressing isn't what you want to do I don't know where you'd get a sapphire crystal from that would be the right shape and size I don't think they may come normally for pocket watches. Here's a place that has glass crystals they should have which you want http://whitescrystals.com/1 point

-

If the engraving was filled with 9k gold and then plated with 9k gold to make the colour the same, it would be still 9k gold.1 point

-

That's what she was suggesting. But there are different colours of 9k gold and there isn't "a spare bit" of the watch she can use to fill it. She has just messaged me actually, giving me the details of a specialist place. I have messaged them to see what they are saying.1 point

-

Hello and welcome to the forum. One can only reiterate Joe’s advice and look ar Dr Ranfft’s site.1 point

-

1 point

-

I've never tried it so only a thought. Could 9k gold be melted, poured into the engraving and then sanded/ polished?1 point

-

Welcome Jorge. Go on to Dr ranfft website for the answer to this and many of other questions you will come to have. Rgds1 point

-

Lots of info in this thread on the same issue.1 point

-

Thanks! Yes and with my 2 foot magnet bar within reach, I can sometimes find something dropped within the first sweep or two. The problem is with serious pinged parts, but then hard floors don't help much if it is on the other side of the room (which is much less cluttered as well)!1 point

-

Hello and welcome to the forum, where empty pockets are the norm. Always another watch , always another tool. And so it goes on down the rabbit hole.1 point

-

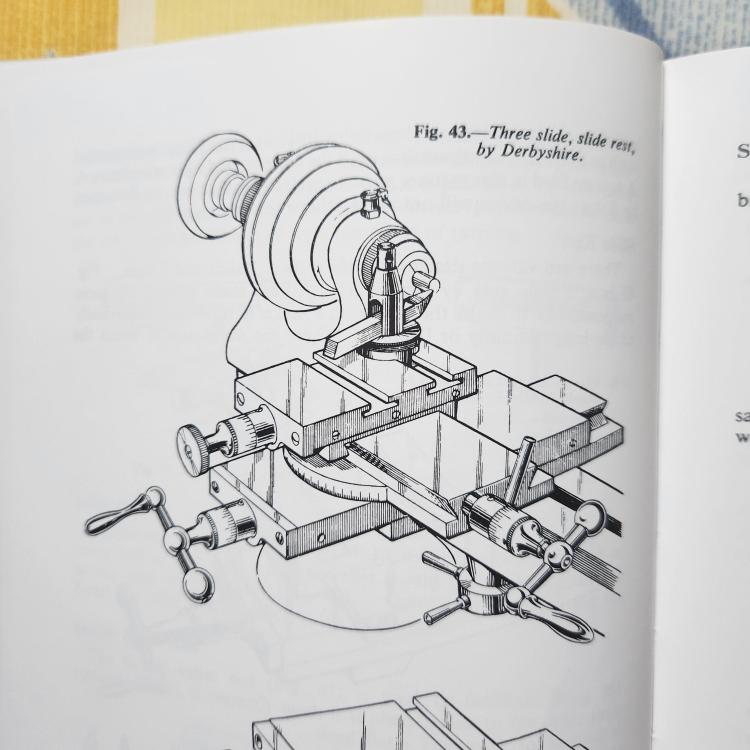

One other thing, this slide rest needs what's called a "shoe" to fit the bed properly. Some rests have what's called a foot (yes, haha), like the first pic, to line it up on the bed and the bottom of the rest sits directly on the bed. Others, like yours, need a shoe like in the right in the second pic. This fits the bed, and fits the recess in the bottom slide of the rest. Ideally fitting both with no play.1 point

-

From what I have read, use double sided tape to stick the dial to the plate and mark through.1 point

-

Hello and welcome. You didn't put your location in your profile, it helps if you require materials.1 point

-

Nice tidy set up Razz, light,airey and uncluttered, i particularly like the tall cabinet on the left. I dont know why folk rag so much on a carpeted floor. If you drop something on a hard floor, it bounces and can roll off to anywhere. With a carpet it stays where it lands, i find a short pile carpet perfect, the old magnet and torch find it easily.1 point

-

https://www.ebay.com.sg/itm/125097758664?mkcid=16&mkevt=1&mkrid=3423-175132-2357-0&ssspo=r_pk29i7r0c&sssrc=4429486&ssuid=v36TsHWBSw-&var=&widget_ver=artemis&media=COPY I use one of these tool holders on my cross slide. It doesn't have the quick change feature but at least it fits.1 point

-

John. Good man you are. You never stop amazing me with your research skills.1 point

-

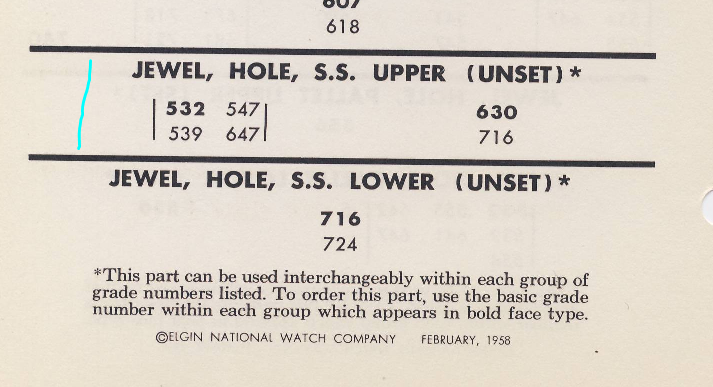

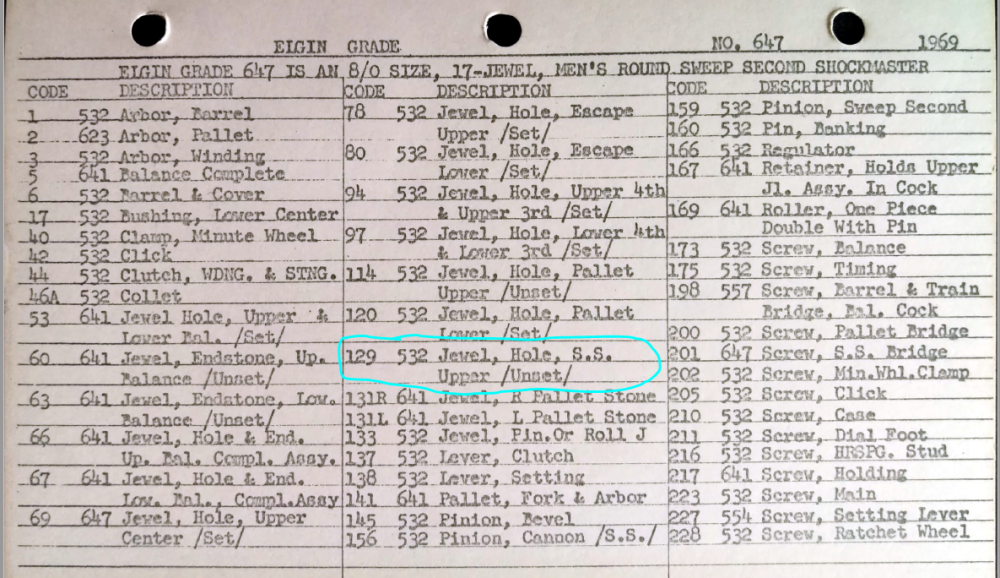

one of the problems with Elgin parts is revision of parts book and how they do things. In the old days the parts book would have pictures then in the 40s or 50s they have a huge parts book with no pictures at all just lots of part numbers still very useful but no pictures then the next generation of parts book blue in color. Is a very interesting book some of the calibers have their own page with no part numbers just tells you whether that part is unique to that watch or what its base caliber's. Then others get lumped in like the next category where all the parts are listed individually and then you can look and see if yours cross references to anything. So your unset jewel cross-references to caliber 532. But we don't get a part number oh we could go and look at my favorite part site and find out that we don't get a part number either in fact we get almost nothing http://cgi.julesborel.com/cgi-bin/matcgi2?ref=ELG_647 now the reason for all this peculiarity is just the way Elgin did things but if you worked in a material house you would know that Elgin did have part numbers but the only people would ever see those part numbers are people access to the parts card index for instance the parts for yours will look like this now we go back to the website now that we know it's a 532 caliber and surprise it's been discontinued. But unlike the website we do have the image up above work does cross reference to other calibers may be to find one of those to steal a jewel from or who knows maybe the parts on eBay cheerleader almost everything shows up on eBay. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=ELG_5321 point

-

Most cross slides only have 2 slide tables. Yours appear to have 3 stacked on top of each other. Can one of them be removed? That quick change tool post doesn't seem to belong to this set. I just checked one of my books. It appears to be a Derbyshire. I think you just need to get a smaller tool holder.1 point

-

I picked up this Elgin pocket watch today for $12 US at an antiques fair. It wasn't running and the sub seconds hand was floating around under the crystal. I think I scored. Everything is there except for 2 small screws, one on the rate adjustment bracket and 1 on the bridge holding a jewel on the 3rd wheel (I think). Anyway, spent about 20 minutes taking apart and pegging some old grease off. Finally got it to where I could put a wind in it and got it going. I count 9 watchmakers marks and the serial numbers dates to 1925. Not sure why I picked Anthony7s thread to post this one but saw the title and thought it was a more general thread and seemed appropriate at the time, so to speak.1 point

-

No. Unfortunately there appeared to be no shellac on them at all when I got into the movement, so their correct placement was entirely unknown.0 points