Leaderboard

Popular Content

Showing content with the highest reputation on 11/02/23 in all areas

-

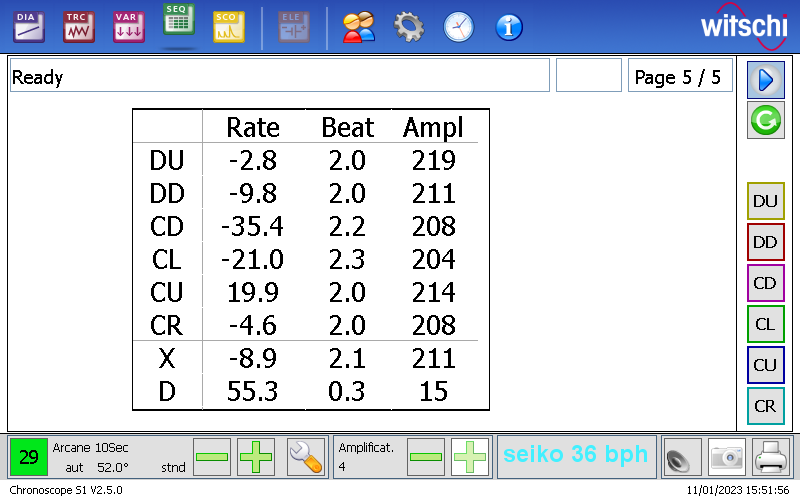

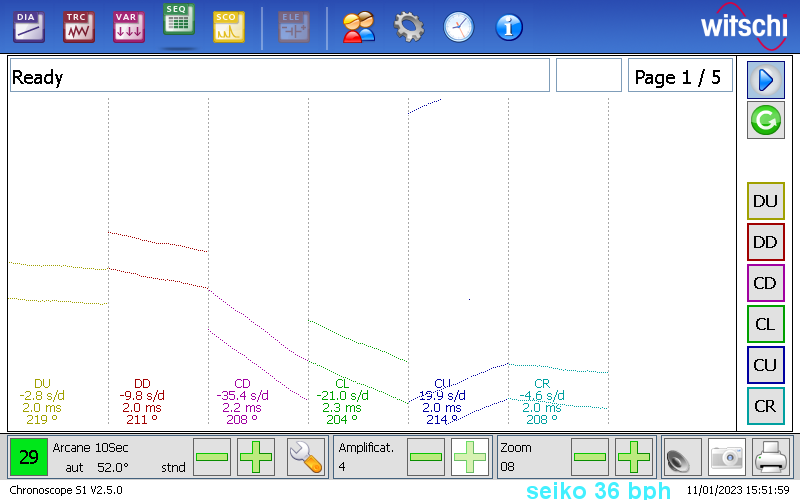

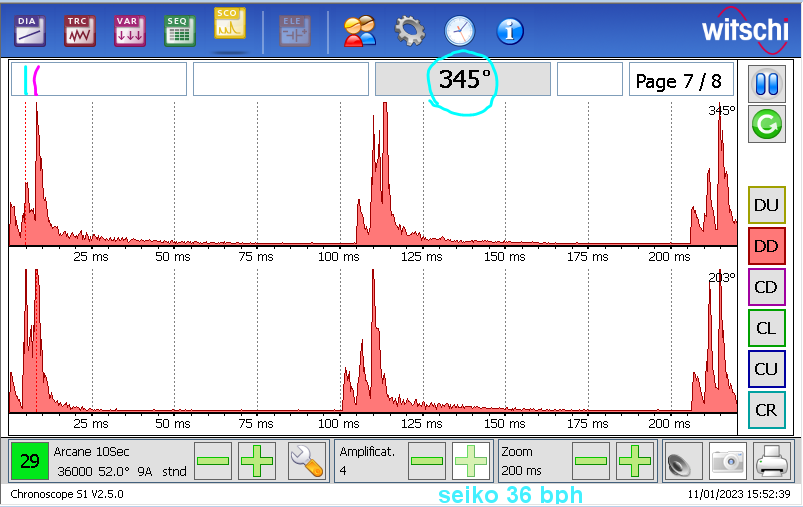

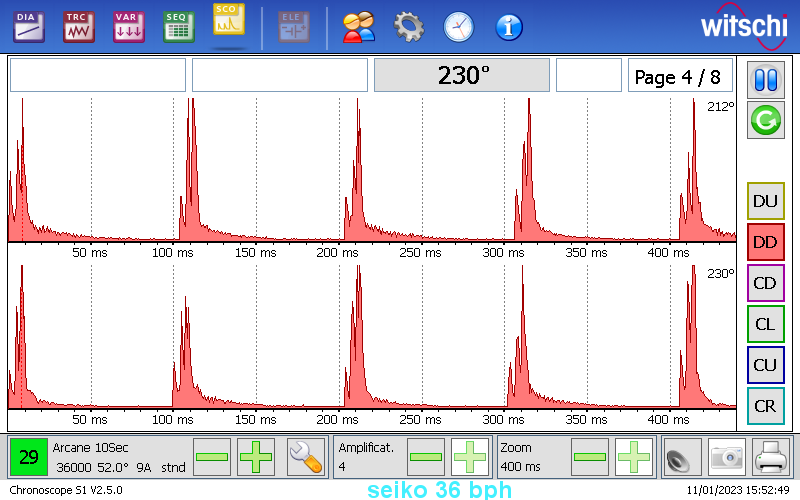

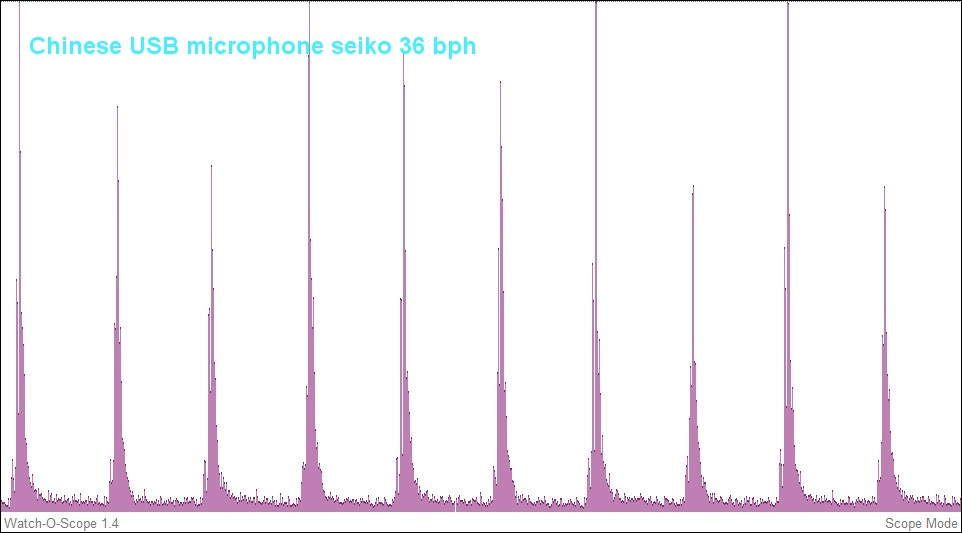

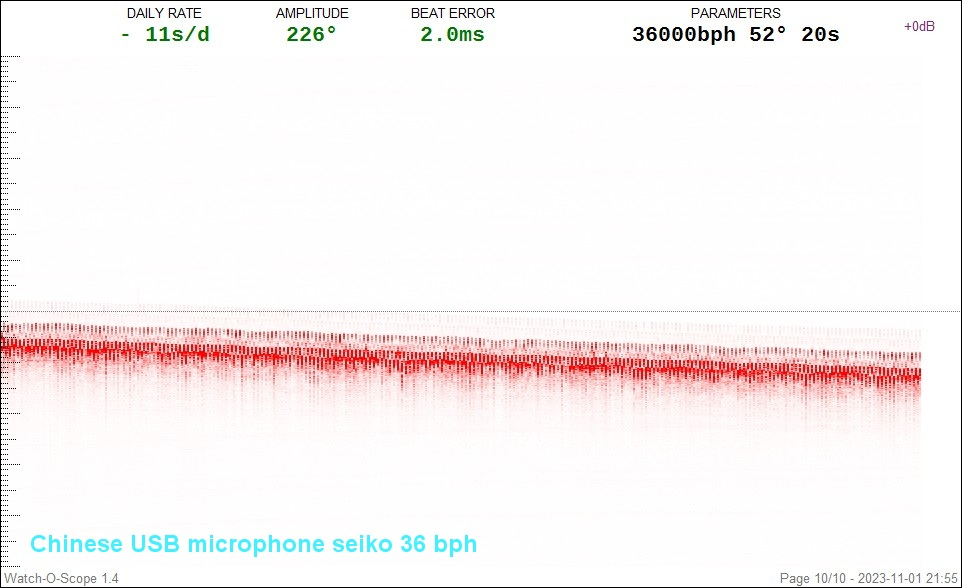

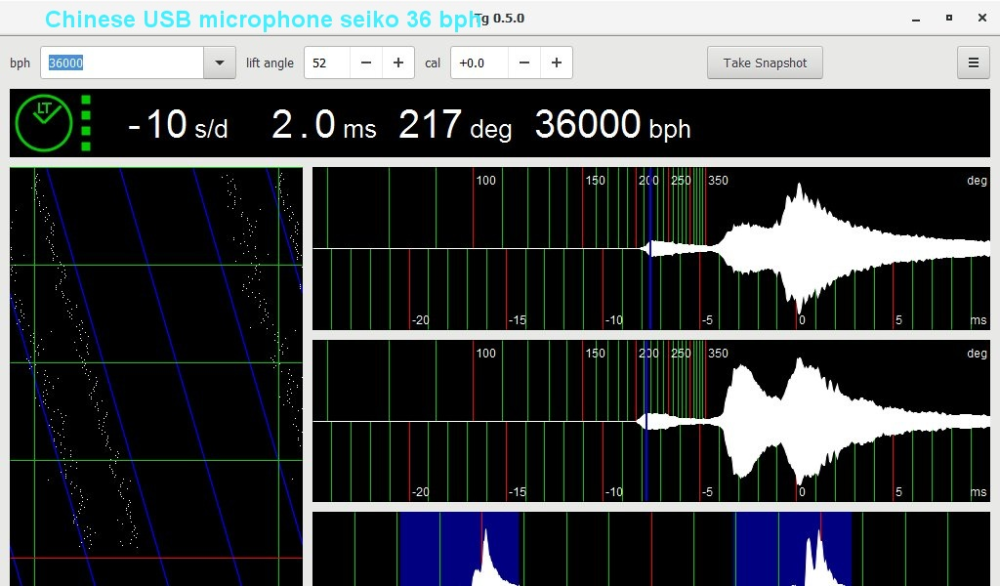

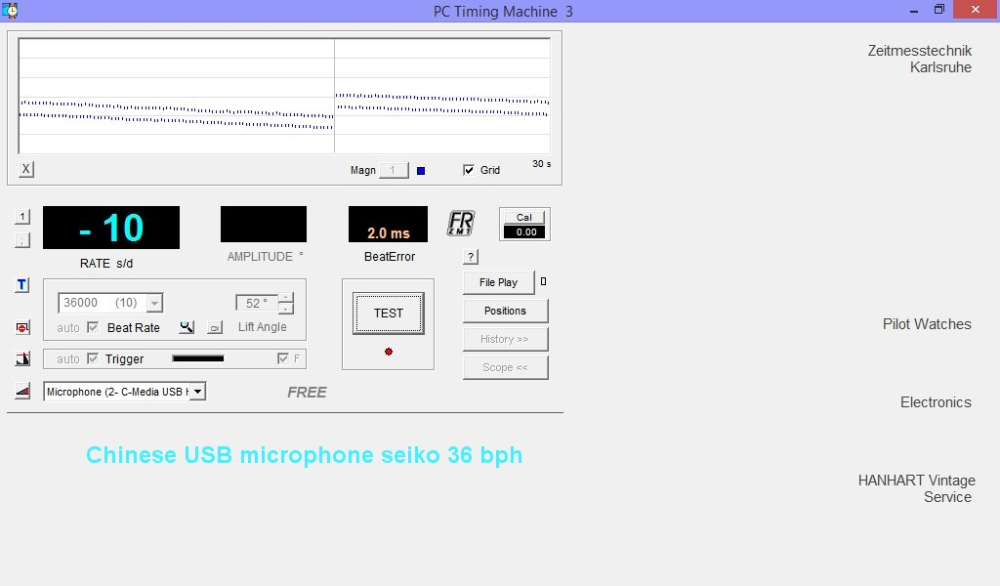

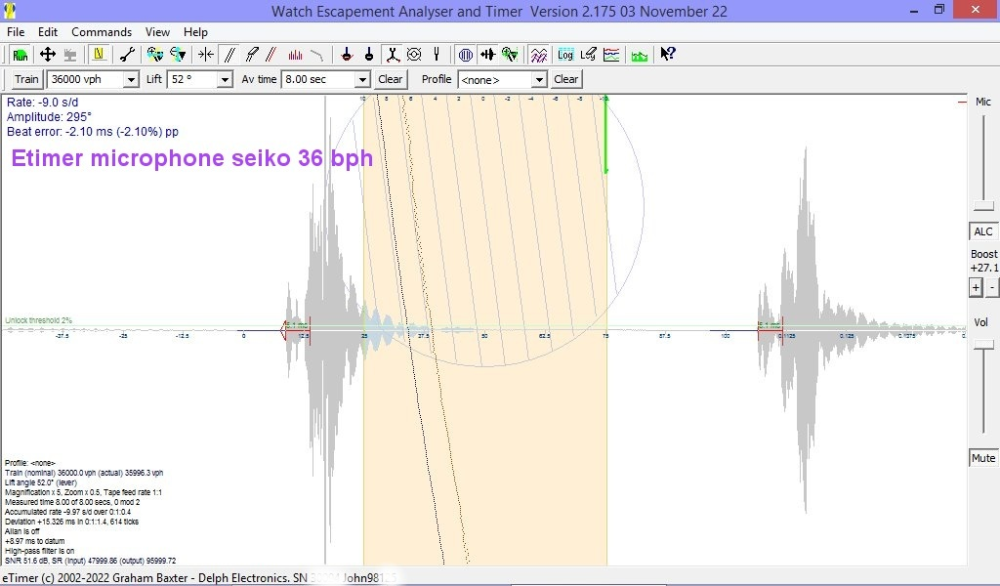

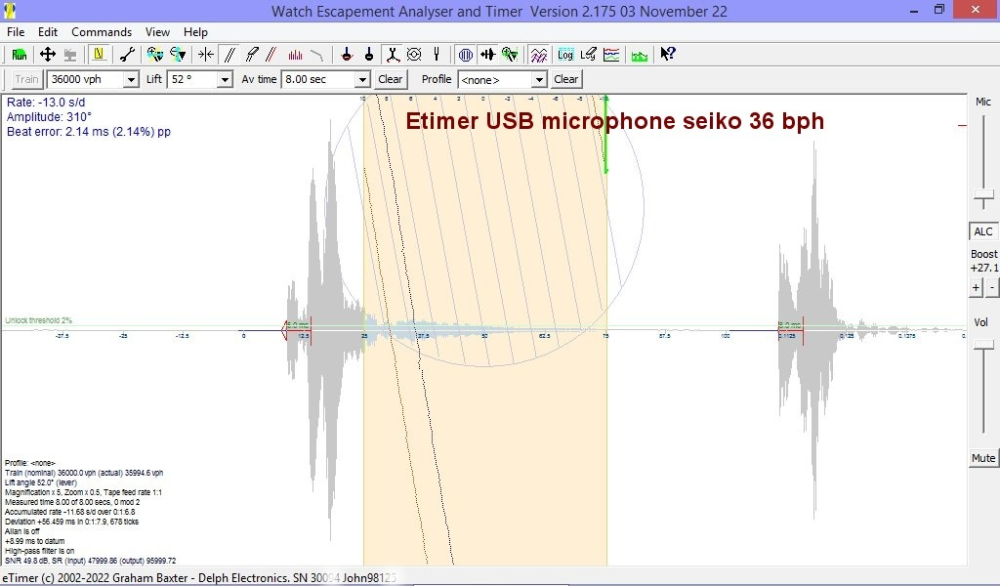

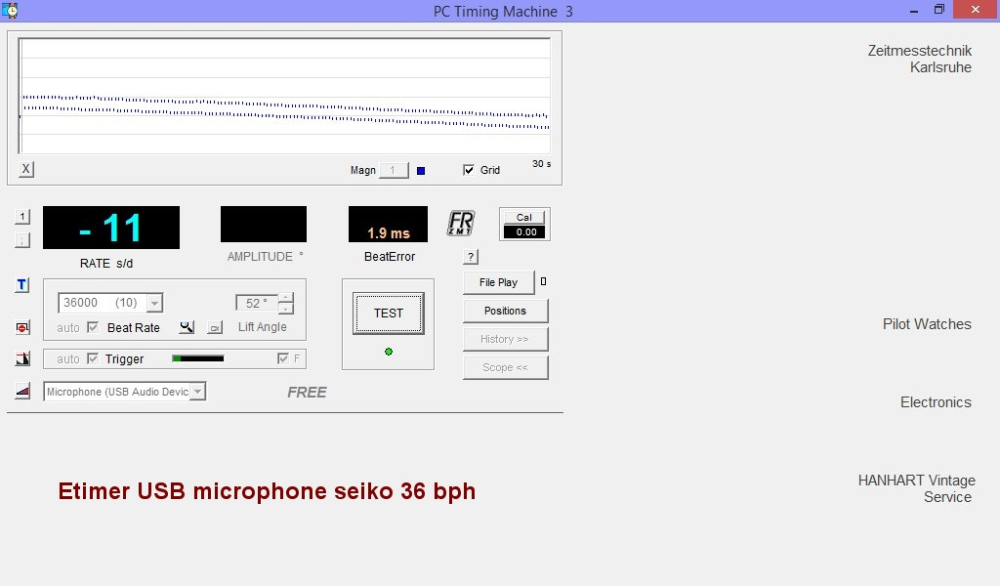

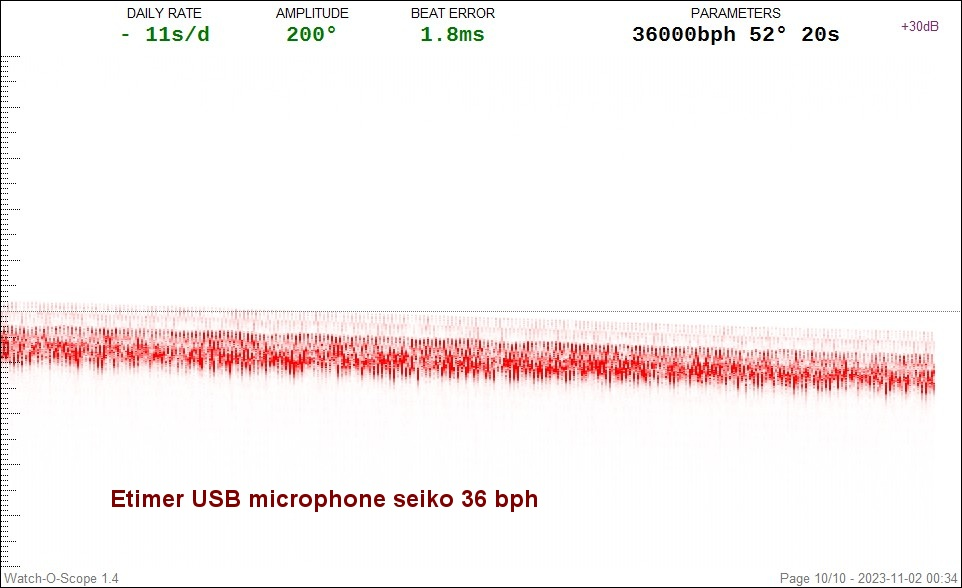

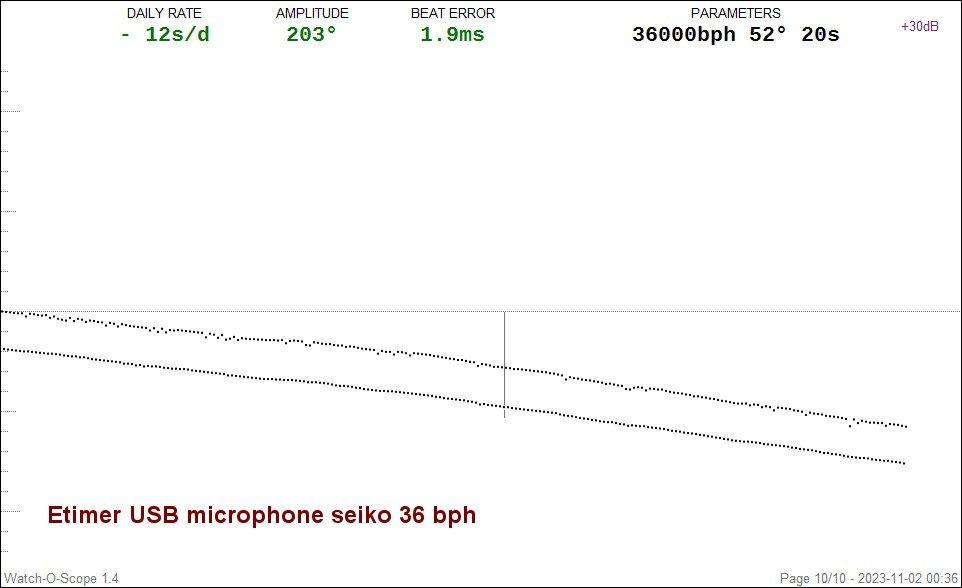

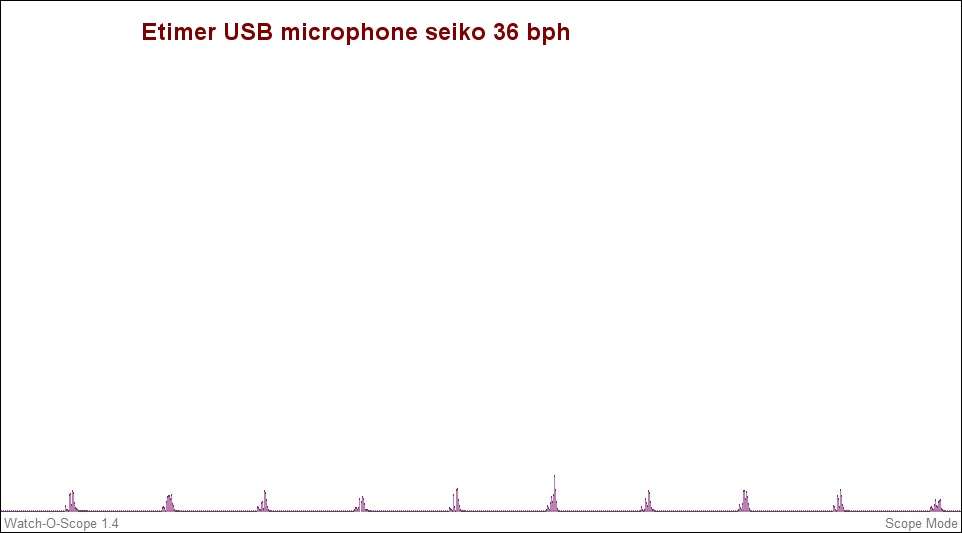

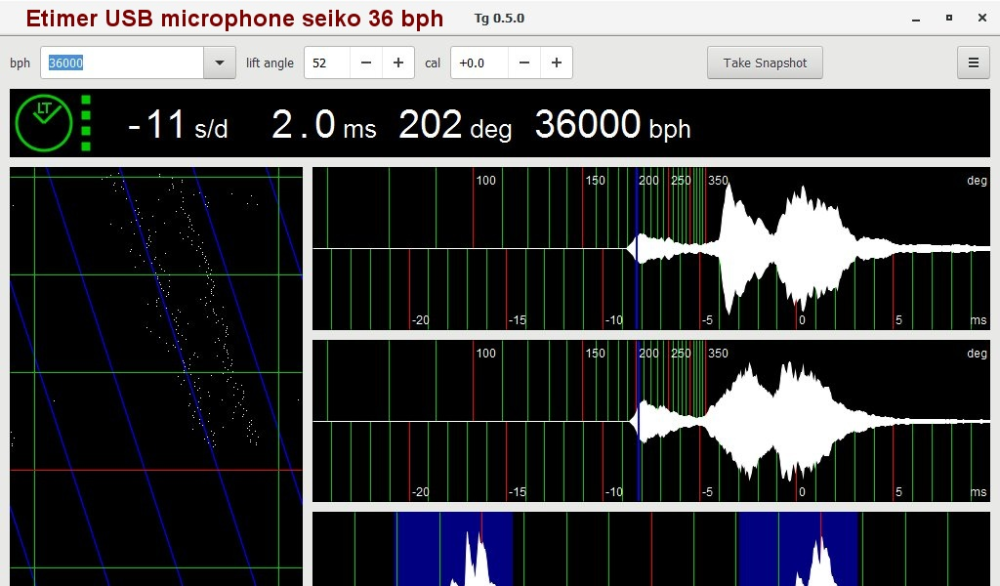

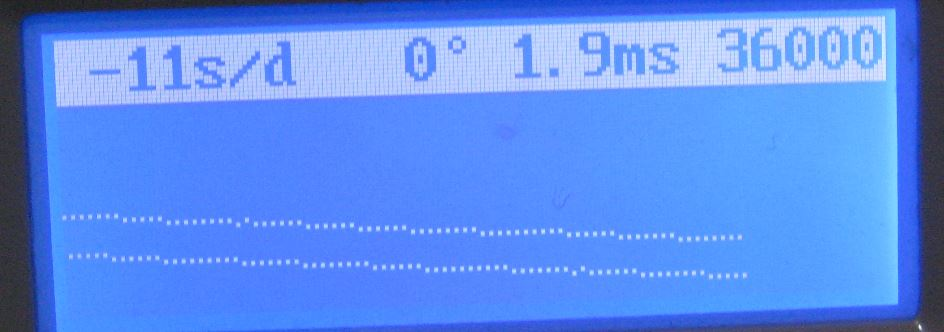

As my watch arrived and thought I would do it timing machine review with it. It might give us an answer to the question of is the original posting persons watch having an issue or is it the microphone giving it an issue or do we have no idea? I took the watch to work to run a timing cycle on it to give us say baseline basically. It also shows you what an extremely expensive witschi timing machine can do with its automatic microphone. Now thinking about the automatic microphone the timing positions don't end up being right because the dial was up normally have dial down and then we end up with the left and right usually gets swapped around so up and down for the dial are not necessarily right but they are up and down the dial it still gives us an idea of what's going on Amplitude for a fully wound up watch the little lower than would like to see obviously the watch needs to be serviced. Another thing to do someday in the future. Then normal timing should be about 20 to 30 seconds this particular setting for the machine is really fast which as long as the watches running fine is okay but normally should have longer sampling times Then on the oscilloscope we get something interesting that is the amplitude is way too high? But on the oscilloscope it tells us where it's triggering and I put some marks its triggering in the wrong place should be triggering on the second Mark and because it's triggering on the wrong place in the oscilloscope mode it's giving us a happy amplitude that doesn't exist. We'll see more of this problem later on Here we see a little more the oscilloscope the audio sound of this watch is rather interesting is that of course is running really fast and they hairspring is stiffer than you normally find solid as a little different ringing sound which conceivably may bother some timing machines as we'll see later on So for the software I started off with the Chinese microphone to see what all the various software have will do with it. The oscilloscope in watch-o-scope is pretty good little One of things the software as is raw mode. It's kinda like turning the oscilloscope on its edge and looking down at it and then stacking them together is a really looking at a whole bunch on oscilloscope traces across the page of that makes any sense at all probably not but it is a interesting mode.. This is where if you had background noise like they hairspring was bumping into something it would be a lot easier to see than in the normal oscilloscope what tends to go by so fast and slow harder to find patterns. Then to the other software same microphone and I hate their graphical display it makes it look like the watch is having a serious issue. There is supposed to be some newer versions but they don't run in the PC. But this is what we want to see is how this compared with yours and at least the numbers look more or less correct. On the different software oh and I never calibrated the software in any of these because when you change the microphones depending upon things that changes the calibration which is why some of the numbers may be off but this software does seem to work really well much better than some of the other stuff which gets unhappy with things at times Then this software didn't like the USB microphone with the high-frequency watch. I've used it with lower frequency watches and at least from memory it seems to work so I switched to its microphone which initially it plugged into the PC or in this case a netbook Now notice on the oscilloscope have the amplitude it looks really spectacular and if you look at the oscilloscope were not triggering where were supposed to be. The software it typically works fine but when you're playing with four different pieces of software different microphones I probably don't have all the settings quite correct. Otherwise to run all these tests would take way more time than is willing to spend Oh and yes the software can do a lot of things I'm just using it to quickly evaluate the watch for the purposes discussion Then minor problem with the microphone plugged into the netbook none of the rest of the software recognized its existence at all. Even though the software above had no problems with its. Fortunately it originally came with a USB adapter and I plugged that in and continued running the tests. Oh and when you plug the USB adapters in of course you need to recalibrate which as I said I didn't do so there will be minor Timing differences Minor differences from this is the last one probably differences of how things are processed. But you will notice rate looks ride amplitude looks right etc. etc. This is an interesting the oscilloscope is considerably less than in the previous version seems to work though but this is where normally normal people would be trying to run the four pieces of software so you and adapted whatever you have and each time it should work consistently. Once again the graphical display sucks as far as I'm concerned but the numbers and stuff look fine That is much as free software is free to get it to work of course you do have to have the proper pickup like I've shown in images reverses your bug microphone or whatever's being used way up above in this originally done. I was using microphones not designed for picking up watches will be problematic. More than once in this discussion group we've gone off in the wrong direction based on software that wasn't functioning properly. Then Chinese 1000 timing machine. Initially it seemed to take a little along her to figure out what it was trying to do but once it figured it out it's working perfect. One of the reasons I like the Chinese timing machines or any physical timing machine is they just tend to work. Although for those nitpicky people the witschi timing machine is both hardware and software particular machine we have is running Windows CE. I occasionally have to turn it off and Back on because it gets confused over something. Oh and as far as I know the watch that I received hasn't been serviced in any time I have no idea when. There's no marks on the inside case back I doubt it's ever been serviced and based on the case back itself I doubt the watch was used very much at all does seem to be a really nice condition. Although the regulator isn't quite right like to see it and it is a little out of beat but still very interesting watch to have.4 points

-

3 points

-

It was common practice to punch and close holes in watches and in clocks way back. Materials were not around like they are today, watch and clock makers were not around in villages or towns, blacksmiths were always about, it was not uncommon to take your watch or clock to the blacksmith. I don't recommend closing holes by punching, re-bushing is the way, you can do a lot of damage by trying to close holes by punching and it certainly doesn't do the pivots any good.3 points

-

Rixy, that makes more sense then the name I came up with. From experience the movement is not as old as 1811, mid to late 1800's I would say.3 points

-

Not sure if it was clear but was under the impression this is a steel spring? In that case there are grades, but it's more about the number of coils and their spacing really. If alloy then I doubt Omega used less than Nivarox 1 or equivalent, but most of the time you can get a grade 2 or even 3 to rate within spec with some work.2 points

-

Hi @Bluescrew, Actually, vibrating hairspring without vibrating tool is comparable with watching TV without armchair. It is more convenient to rest in armchair while watching TV, but it is still possible to do without. The main problem is where to source hairspring that will be suitable. And, the answer for me is usually in different Soviet and Chinese movements, I have plenty of them gathered to use their stones, screws, hairsprings and whatever will be useful. The hairsprings that seem to look suitable, have to be tested with the balance wheel. Usually the collet doesn’t fit to the place on the staff, but small ball of Rodico helps to attach the collet or the end of the bare spring to the balance for the coarse test, which will determine if the hairspring is proper for the balance wheel The idea is to find hairspring that gives little lower frequency, so shortening will bring the frequency to normal. BUT, at least 10 coils must remain on the spring – shortening it more leads to bad isochronism. Then, if spring passes the test, it’s collet may be replaced with the original one, or reamed in order to fit to the staff. Then, hairspring on it’s new place and balance is vibrated to find the correct length of the spring, then the remain cut and the overcoil formed. For the vibration I only need a big watch with the same BPH ticking loudly so I can hear it clearly, just like metronome. Look here, I have showed restoration of a pritty battered Omega 265 movement, which I believe has similar hairspring as 27.3 I have replacet it's hairspring with one from Poljot 2609.2H, as I remember2 points

-

That me, i used to have hair and eyebrows and ears and pupils etc, i never used to be red either.2 points

-

Hi Willow. The name is, I think, 'National Society'. I looked this up and it is the education division of the Church of England, founded in 1811 and still in operation today. It established many of the Church of England schools (for the education if the poor) across the country so the clock was most likely hanging in a schoolroom somewhere when it was new.2 points

-

UPDATE I can now definitely confirm what nobody, including myself, could really believe. The ratchet wheel is NOT ROUND. I put it in my staking set, holding it perfectly centered with regard to its hole. Now look at the video/gif. I drew the red line into the video to make it more obvious. Looking from above makes it even clearer, but more difficult to film.1 point

-

A problem you will have is sourcing raw hairsprings. Plus an Omega spring is expectedly high grade, I guess grade No one or two, not sure, so help please @nickelsilver . Next you may look into Chinese ones, there good luck finding someone who knows what they r selling. You might match any grade spring with the balance you got then it keeps good time but Omega isn't just good. Omega Where gold more than glitters. Rgds1 point

-

I get into trouble if i mention British precision springs, so i wont mention them . Last time i looked the forum had quite a few thousand members, if we all chip in a fiver we can set up our own hairspring making company. How hard can it be ?1 point

-

1 point

-

1 point

-

I think that was a common process, same principle as a vibrating tool except you have the convenience of a purpose made frame with the genuine article. I do have a Luthy tool and have used it twice, its great fun1 point

-

I as well…I do recall an illustration or two in one of the dusty books the elders seem to eschew what showed a brave soul vibrating a hairspring with a pocket watch. Technically possible I suppose…I’m away but will try to find later. It was a brave chap for certain…1 point

-

You might laugh Rich, its not easy chatting up women looking like that, I'll set my dog on you I cant fix anything though the tools are far too heavy1 point

-

And good god, you are tiny! Must be great, though, for inspecting watch movements and fault-finding.1 point

-

Might that be Nucejoe ? Hes the only other besides me that has hairspring fascination that i know of Come on prominent member Joe , spill the beans matey, i have a candidate for a raw hairspring acquisition come vibrating experiment1 point

-

Thanks all for continuing to think about this! The problem was there BEFORE I closed the holes with my staking set. That was an attempt to fix the problem (at that point, I though the excessive side-shake was the cause). Closing the holes didn't make it worse, but also didn't help. Also, the barrel itself seems to move nice and round without any up/down wobble (when looking into the movement sideways where center wheel and barrel teeth are meshing). True. I agree. I can literally see the wobble just by winding it half a turn (with screwdriver on the blench block). I don't have a mainspring winder so I'd have to buy another mainspring if I remove it (and this one is rather expensive). Sorry, you'll probably find that annoying if you are offering good advice and I'm not following it. To avoid getting on your nerves any further, I'll take my chances and get a new ratchet wheel + screw and arbor. I found a good deal on eBay. We'll be smarter afterwards.1 point

-

1 point

-

1 point

-

I get that Rich but i was thinking it might have only just been clearing the side of the bridge. Maybe something has happened during dis and reassembly that has taken up that gap. So multiple issues, i really cant imagine the ratchet wheel has become deformed . We are all just guessing really until the shape of the ratchet wheel has been confirmed. Ahhh we're all missing something, to add further to it was running and winding before. Maybe it was just clearing the bridge before but it hasn't just been dis and reassembled has it ? Something else must have been changed to cause this. Knebo said that he was proud that he'd closed the arbor holes in the mainplate and barrel bridge. Arbor hole positions shift ? Bent plate or bridge ?1 point

-

Welcome. Stand back and be ready to be amazed by the best forum in the known universe.1 point

-

It can't be an issue from the factory though, it was running and winding before.1 point

-

It's hard to determine whether the ratchet wheel is eccentric or not from a photo. There might be lens distortion or if the photo is taken a little off axis. Do what @Neverenoughwatches said. Remove the mainspring, then reinstall the arbor and barrel cap. Put the barrel assembly back into the movement and check the meshing of the teeth. This is so weird. I can't imagine how it's possible for the hole to drift off- center.1 point

-

Hi Waggy, I had a go at my own watch straps for the first time a few weeks ago. I will not be giving up my day job but the ones I have made are passable(ish)... So here are my observations as a fellow beginner. I started with the following kit: Super-basic all-in-one leather working kit off ebay for £20 (contains skiving tools, knives, needles, slickers, pricks etc...) A tube of Evo-Stick contact adhesive £6 Leather dye-pen £8 (the exact colour depends on the leather you are working with and the colour of the edge of the leather) Tokonole edging gum 120g £13 (this is going to last a long time) Some different types of linen thread (flat and round) Some 1mm(ish) leather scraps £15 25cmx25cm (make sure the scraps you get are long/wide enough, especially if you are doing simple one-piece fold-over straps, should get a few straps out of this) I bought all of this on the understanding that the end result would look rubbish and I would give up after the first attempt so I went cheap on the tools. Even then, I was not doing this to "Save Money" on straps. The cheap tool kit was actually serviceable but clearly not professional. I independently bought a second multi-headed edge skiving tool and frankly it was a waste of money as the skiving blades we dull and did not cut. The one in the kit was sharp. The simple diamond pricks that came with the kit (you can also get from ebay/ali-express) do work, however I noticed that they tend to cut the leather at the corners of the hole which can be wider than some of the thinner threads. I have bought some (significantly) more expensive "olive-shaped" pricks to see if this resolves that particular issue. Im finding 3 and 4mm spaced pricks to be appropriate for the straps Im making. Im currently using an existing strap as a template and eyeballing the rest with a metal ruler - possibly not the best approach... Good luck! Best, Bob1 point

-

1 point

-

The problem with dictation software is goofy wording of speech. It's either goofy wording or no wording at all or basically take it or leave it but a bushy change the wording you can kidnap a students or hire somebody to kidnap the students and Walter Raddatz steal the vibrating tool probably there's laws in Switzerland their frowned on. Although in the past with it used to publish the newsletter where is in the newsletter they would have the special projects that students were working on can't quite remember what is called there was an exams course above the basic course and students would do special projects like possibly vibrating hairspring although that would be pretty basic so I'm not even sure it would qualify as a special project maybe something to get you warmed up. Astronomer by the thinkers like one PDF the newsletter in existence and all the rest are physical. Don't even think they have any of them on their websites they probably don't do that anymore now that the school is too big and too diverse. So a lot of times in the special projects people would make stuff make a lot a replacement parts restore watches and of course vibrated hairspring1 point

-

Oh one of the things to remember is is this a good friend? Yes I know the YouTube videos make watch repair looks so simple. But in watch repair videos have you ever seen a video on my first watch was my girlfriends, my wife's some other family member or close friend or somebody and they had sentimental value and now they're extremely angry at me and the watches broken? How many of those videos have you ever seen? The unfortunate reality of watch repair his every one break and destroy things but you're more likely to have accidents when you're starting out and having to explain to someone why the watch no longer runs somebody really needs to a video about which basically says you should work on friends watches and nothing that's valuable that can't be replaced As long as your Omega is not too old unfortunately yours is it goes in between there is cross references to monitoring numbering system. As soon as you get the modern numbering system we find way more parts availability etc. On my favorite parts site we get your watch without the letter S which looking at the physical bestfit book all the 27th go back to the base caliber of 23.7 but with the exception of the second link nothing I have has the letter S and I don't know what that means or What it changes you will notice the second link the references to the TE 12 and three no idea what that means. Then on that website all of them are 23.7 S Where is in the bestfit book none of them have an S? http://cgi.julesborel.com/cgi-bin/matcgi2?ref=OME_23.7T2 http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Omega_23_7S_T2 So now what you're going to need is a time machine to go back in time if you are back far enough you will find that there a individuals that ran companies that would vibrate the hairspring for you in a bargain price. Somewhere I've snipped out the advertisements conveniently of not finding them in the computer. Unfortunately they've all retired on other business and who knows where they hairspring is a vibrating tools disappeared. Then we have covered hairspring vibrating before quite a bit need a hairspring of the right CGS characteristics. Then supposedly in one of our prominent members keeps telling us you can vibrate hairspring without a vibrating tool but as of yet he has published an article on how to do were all looking forward to that or not. It depends upon the individual but learning to vibrated hairsprings is a really tedious boring horrible task that no one in the right mind should ever have to endure yet the schools still torture their students to do that So for instance here's a school in its fancy huge building with lots and lots of courses versus the early days really only had one course and they rented space in another building. Look at about one minute and 40 some seconds you can see their torturing a student by making them vibrate a hairspring. Probably being done for the school watch that they're making. Which does become interesting because the schools that are still teaching hairspring vibrating like our local college they're still doing it they seem to have an endless supply for hairsprings for 6497. Anything else he needed a hairspring for is going to problematic https://youtu.be/4w27i3JnxY8?si=qzdZMmHdTyPbmE83 So yes we really cover the procedure somewhere else in the group. So you're going to need hairsprings which are almost impossible to get or if you're really really desperate somebody covered the lunacy of well basically was a waste of time but still quite interesting there are companies out there that will make hairsprings for you but they want to make hundreds and thousands of trillions and this person thought he had a lot of watches where he would have a hairspring made the reality was it's a bit pricey as they really want to make thousands of hairsprings. One of the reasons raw hairsprings are no longer available is the Swiss rather than making generic CGS hairsprings rest of vibrate would rather supply the company with the unique hairspring for their watch or they will vibrate the spring for your watch but still they want to do hundreds and thousands of trillions and it's going to be pricey. So we've covered this all before of what you need is the hairspring pins, the collet's of the right size unless a course you can save yours we have to somehow get the pin out. Possibility of the stud although you should build the salvage the one you have. Of course a vibrating toward be nice but it is a pain in the ass to learn how to use the things they do need some practice hairsprings balance wheels etc. to practice on because it's not instantaneous skill set learn. Although the students in the modern schools only do one or two hairsprings so how hard can be? Then you need a hairspring of unknown CGS we don't care what it is. Then you vibrate with that and run some after it's been discussed somewhere else in the group you can calculate out the correct CGS hairspring you need and a lot of luck finding that. It's probably best to keep an eye on eBay hoping that another watch comes up that you can steal the balance wheel and/or hairspring from But There is that problem we all have lists of things that were looking for that will show up sooner or later everything shows up on eBay sooner or later it's the later aspect that becomes a problem. The other probably have when you're waiting is if you can't visually look at the watch and see a part number of model number that jumps out instantly that means whoever is selling that watch movement won't know what its is and they will describe it like vintage Omega and that means basically get stuck looking at all the vintage Omega's hoping that you're going to find yours someday oh and shortening hairsprings only works if they're flat because we start shortening over coil you'll have to reform the band and that's going be a really complicated it would be best to start with a flat hairspring of suitable size or basically get the vibrate at how hard could that be there is a school up above how expensive could that be? Oh and they probably have a waiting list. Maybe you could drive one of the students to vibrate a spring for you except of course they don't have access to hairsprings anymore than you do. The only hairsprings they have probably now are the ones for the students watch. At one time they went ahead three sizes hairsprings available for the various calibers they were working on a learning on and nothing else.1 point

-

It's nearly impossible to find complete balances for these old Omega's. I have two 26.5 T3's awaiting hairsprings. With an overcoil, nigh on impossible I'd say. But if you do perfect the technique, could you knock my off a couple for my T3's please1 point

-

the reason I asked about a microscope is that it has issues. I was in a classroom teaching watch repair and one of the students put the fourth wheel and upside down and couldn't figure out what the problem was. So then I took pictures of the classroom and gave a lecture on how to sit at their watch bench. The problem was he was sitting up way too high looking straight down. Often times people with their microscopes are looking straight down if you're looking straight down you can't see which you need to see in watch repair it's why watchmakers sit so they can look into the watch it allows you to see things better than looking straight down. ideally would like to position the microscope so that you could look in at an angle as it lets you see things better.1 point

-

depending upon how old the original plastic is it can do all kinds of things with time. Like a lot of the early plastic crystals are made out of cellulose nitrate and it produces nasty fumes and will rust the hands right off the dial. the later crystals of course don't do that if it's a plastic crystal I prefer it to be pressure fit. Not necessarily press fit but pressure fit this is where you put the plastic crystal in your crystal press ill hold it by the outer edge near the outer edge on one side you press on the inside and the crystal itself will bow in word you put the bezel first before you do this so basically the crystal shrinks and you push the bezel down and then when you release the crystal is held nice and tight so it's not pressed in because usually the or sometimes the bezels are slightly tapered the hold the plastic crystals that way suppressing isn't what you want to do I don't know where you'd get a sapphire crystal from that would be the right shape and size I don't think they may come normally for pocket watches. Here's a place that has glass crystals they should have which you want http://whitescrystals.com/1 point

-

Hi. Just serviced a very slim Mappin and Webb 1970s gold dress watch. This is a 25 years service presentation watch which jeweller's used to supply back in the day. To my delight it had a Favre Leuba twin barrel 255 hiding inside - my favourite movment. A deeply clever design and a joy to work on. Despite clear evidence of at least two services, it ran at very poor amplitude. However the trace was clean so after a good scrub and lubrication the mainsprings were extracted. I've done three of these over the years and every time old mainsprings had been left by servicing watchmakers. This is unfortunate since the layout allows the two barrels to be removed in seconds. Jeweled barrel bridge - posh eh ? The barrel design is unusual because the winding ratchet wheel forms the top cover and arbor thus saving height and complication - see pic. A different approach is needed to replace them which seems to deter servicing watchmakers. The replacements should be 1.50 * 0.07 * 285 at 7.0 mm diameter - GR 4052 will do. The excellent Gleaves & Co supplied mine. The fun starts when you find the central coil is too large for the arbor hook to engage. I use two methods. The strong cheap flat tweezers fit inside the small barrel and careful squeezing will allow you to tighten that curve enough. The internal post in the barrel will help prevent snapping the spring - be gentle. Plan B is to temper the spring fixing point to a brown colour using a temperature controlled soldering iron and then bend it around a drill shank slightly smaller than the desired end loop size. Both work with patience. Hope that helps guys.1 point

-

Oh dear - The watch came back. Developed a tendency to stop after 12 hours and checking on the Timegrapher we have 185 amplitude DU and similar DD etc - this thing is not happy. So we go back to basics and go systematically from the barrel upwards. There was a little side wear on the barrel arbor hole - very slight but I closed this up with my staking set and got it broached out. No change. Barrel arbor runs freely and little wear apparent. Assemble the train wheels after getting their pivots under the microscope - all clean,true and shiny. All run freely. No change. Pallet guard pin looked very slightly bent down - on this balance design that should not foul anything but made sure it was straight and true. ( The Omega 600 series is very slim and impossible to get photographs or see in this area when assembled )At this point the amplitude increased slightly - interesting. I gave the impulse jewel a test with the tweezers in case it was starting to become loose - looks good but under the microscope there was a slight discolouration. Could this be some coating I had not noticed ? Gave it another good Rodico and clean and hey presto, We have 235 degrees at DU and half wind with a clean trace. So, what have we learnt ? Poor initial observation on my part and sometimes normal cleaning will not shift every deposit. Vintage watches need closer examination and methodical diagnostic skills - they are endlessly entertaining.....1 point

-

I just never understood hole closing with a domed punch. If the hole is worn and egg shaped, wouldn't punching it in the centre of the hole result in migrating the hole even more? I would think the proper way of repairing a worn hole is to centre the hole first, then rebush it. The only time I would consider closing a hole is if I over-reamed the hole for the new bush and the bush is loose. Even then, I would probably use a proper hole closing punch, which constricts the hole from all around. I know @oldhippy would probably frown on this too. He'd say "what's so hard about turning a new bush from a brass rod? It only takes a couple of minutes!"1 point

-

I would go with option 2, you could even give this a go yourself, there are several youtube videos on how to do this, and the equipment isn't too expensive - but I would experiment on an old dial first until you get your technique down. you can just wiggle off hte old feet with your tweezers... like a 5year old with a wobbly tooth You can then use the tool (comes as a complete kit for $50 ish) below to mill a little circular recess in the back of the dial and then glue the new dial foot in place, either super glue or 2 part epoxy Or you can solder new feet on using a set up similar to the one below: Advantage is that if this fails, you can still try the other options1 point

-

In modern automatic mechanisms and what I teach to my students, HP 1300 would be used on the pivots/arbors of reverser wheels, pawl winding wheels, and driving wheels in the auto mechanism. I teach how to service older movements such as Felsa 690 Bidydnators (which have what is known as 'pawl winding wheels') and ETA 1256 which want the servicer to use thinner lubricants. Lubricants have come a long way since then (1940/50's). The reason for using certain lubricants in certain areas in the gear train is a pretty hard and fast rule. Low speed/high torque, such as barrel arbors use a thicker grease, such as HP 1300, or even D5 as the viscosity is high, as you go down the train the viscosity gets lower, so if you have those lubricants, what would be used is HP 1000 on the centre wheel (second wheel)l, HP 500 on the third wheel (dependent on the size of the movement), 9010 on the fourth wheel (maybe 9020), escape wheel and caps use 9010. So high-speed/low-torque wheels use a lower viscosity. Hopefully one can see the reasoning behind this. With the auto mechanism, the lubricant isn't going to affect amplitude as it would in the gear train, so longevity is what one is trying to achieve, so a thicker grease is used. All modern movements use this method for good reason. HP 1300 has a viscosity of 1300 centistokes and 9504 and 9501 which is great for high friction work such as keyless work and chronograph mechanisms has a viscosity of 305 centistokes. To have that longevity a thicker grease is usually used, for the reason I have given. I know I have probably opened a can of worms here, but I do give reasons for which lubricant is used where, and why. If you ask 10 watchmakers which lubricants they use there will be at least fifteen answers! https://www.moebius-lubricants.ch/en/products/greases https://www.moebius-lubricants.ch/en/products/oils1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)