Leaderboard

Popular Content

Showing content with the highest reputation on 11/04/23 in all areas

-

I think the concensus is that most of the time the barrel holes don't need polishing, if they do then a soothing broach is the way to go.4 points

-

3 points

-

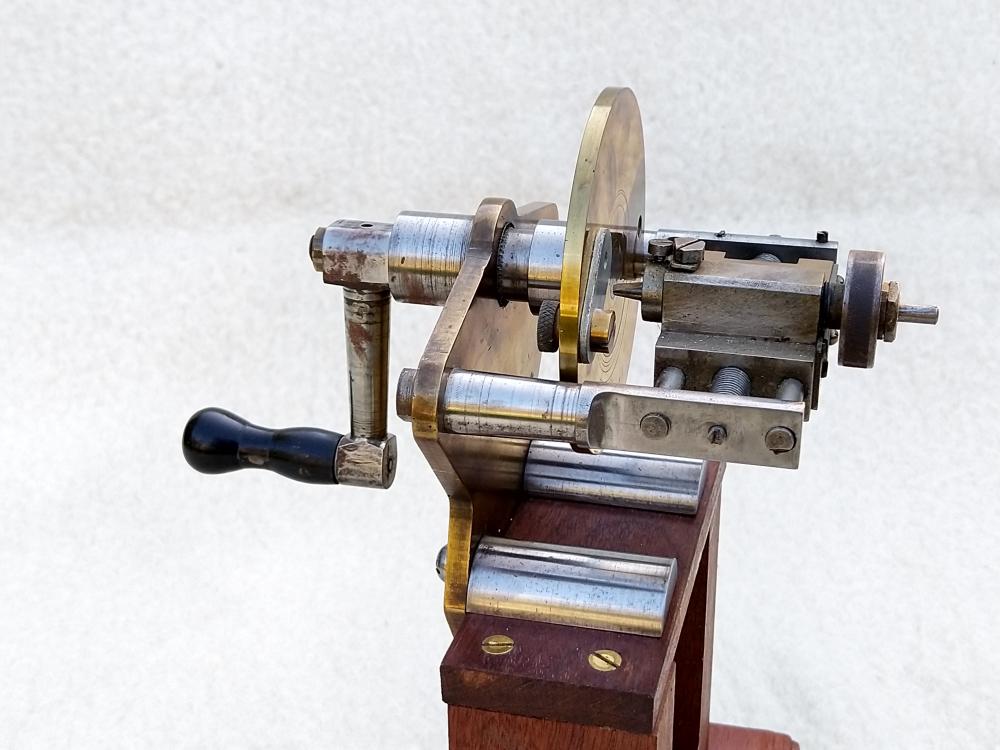

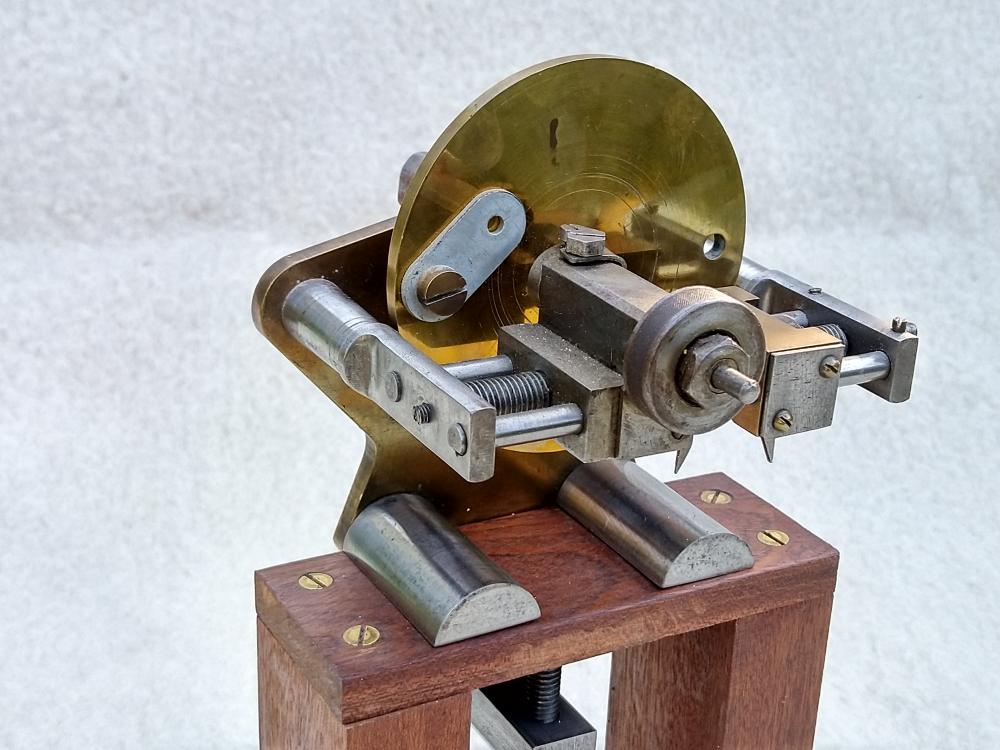

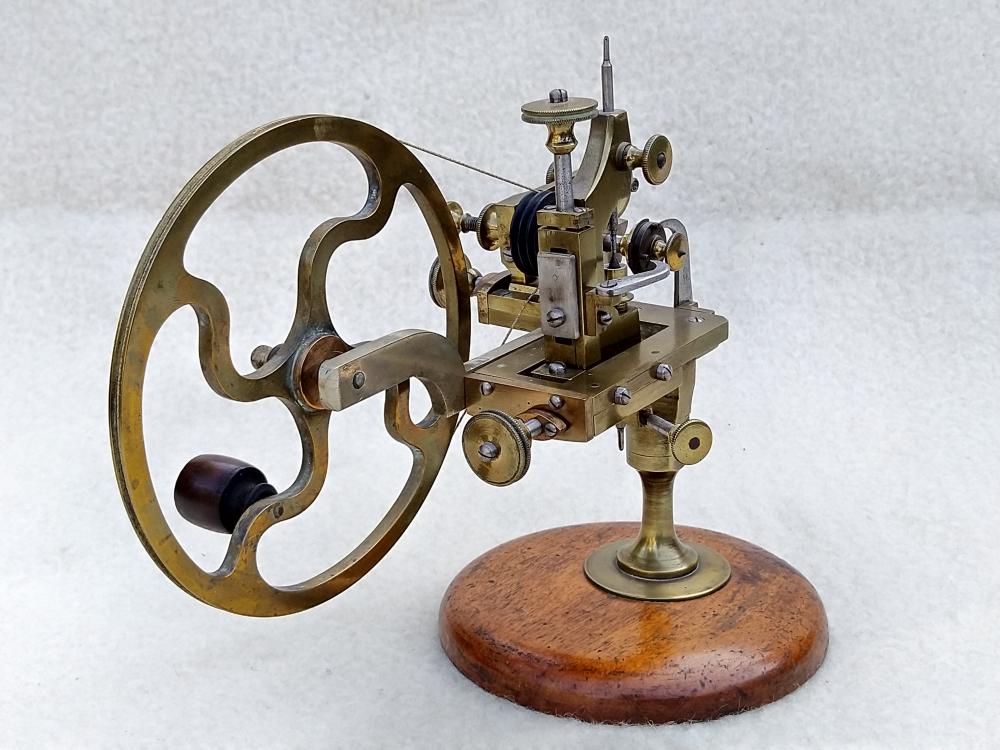

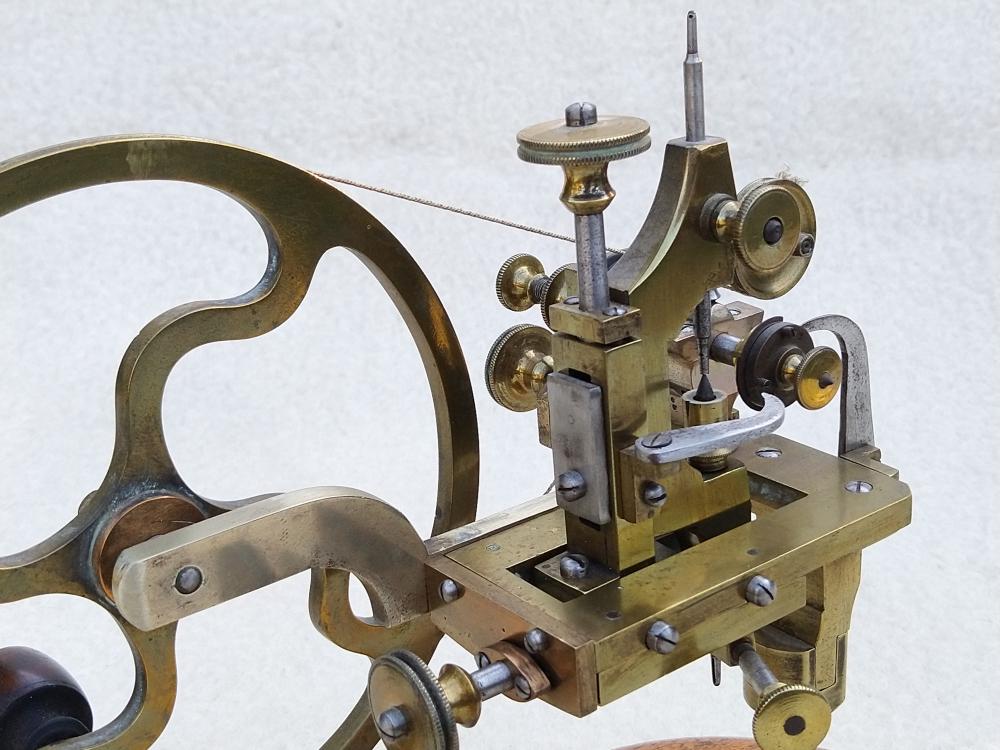

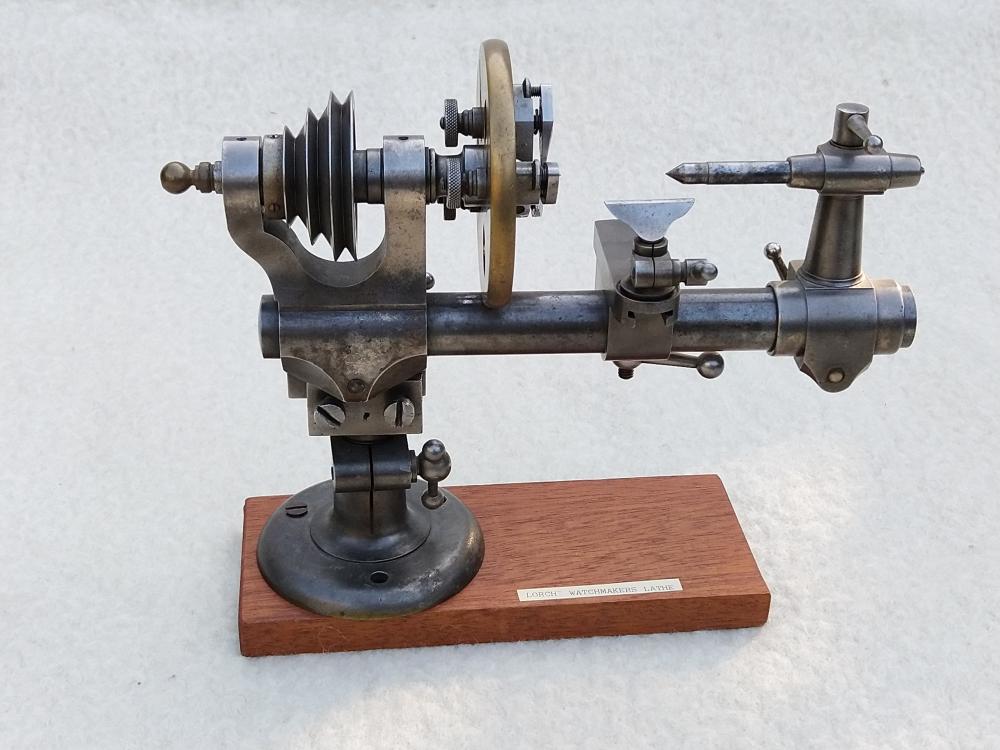

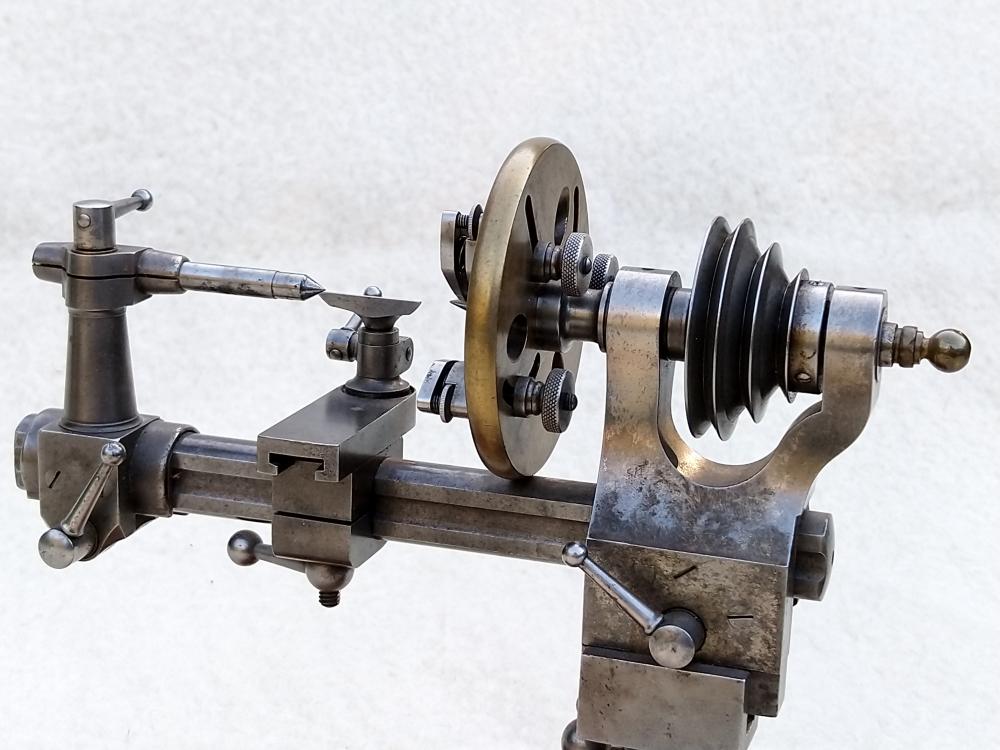

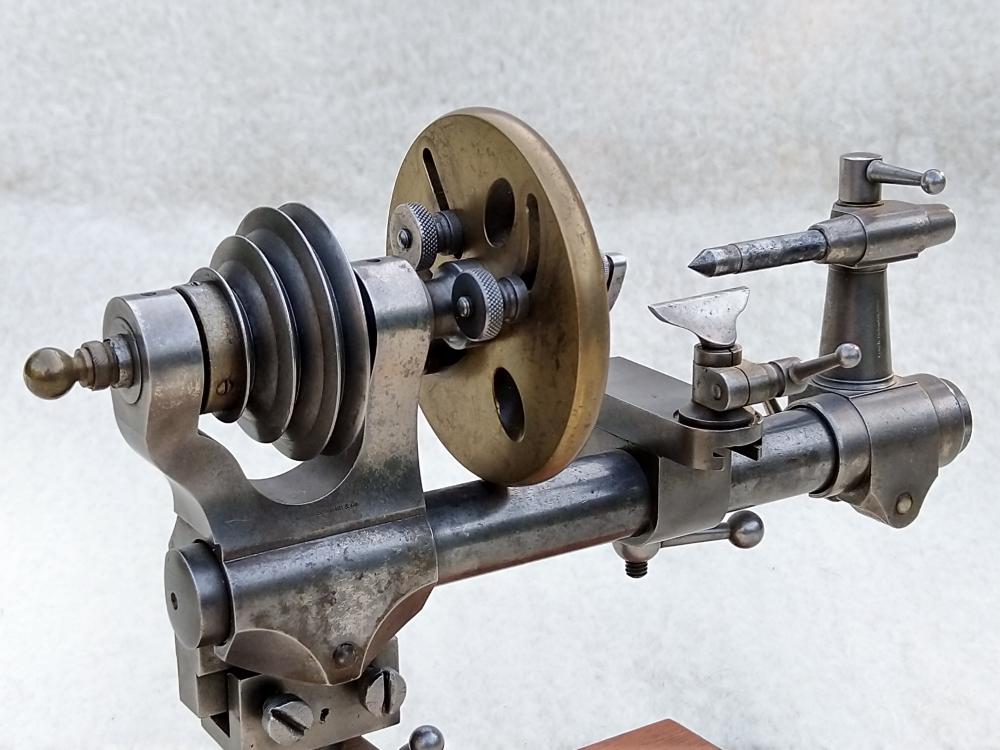

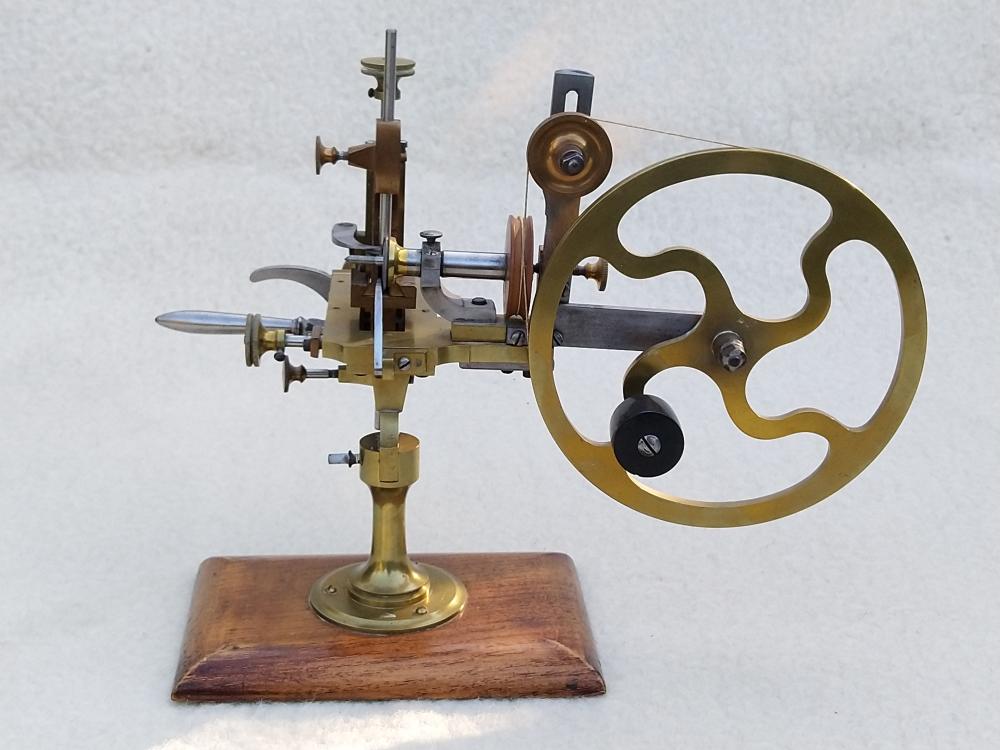

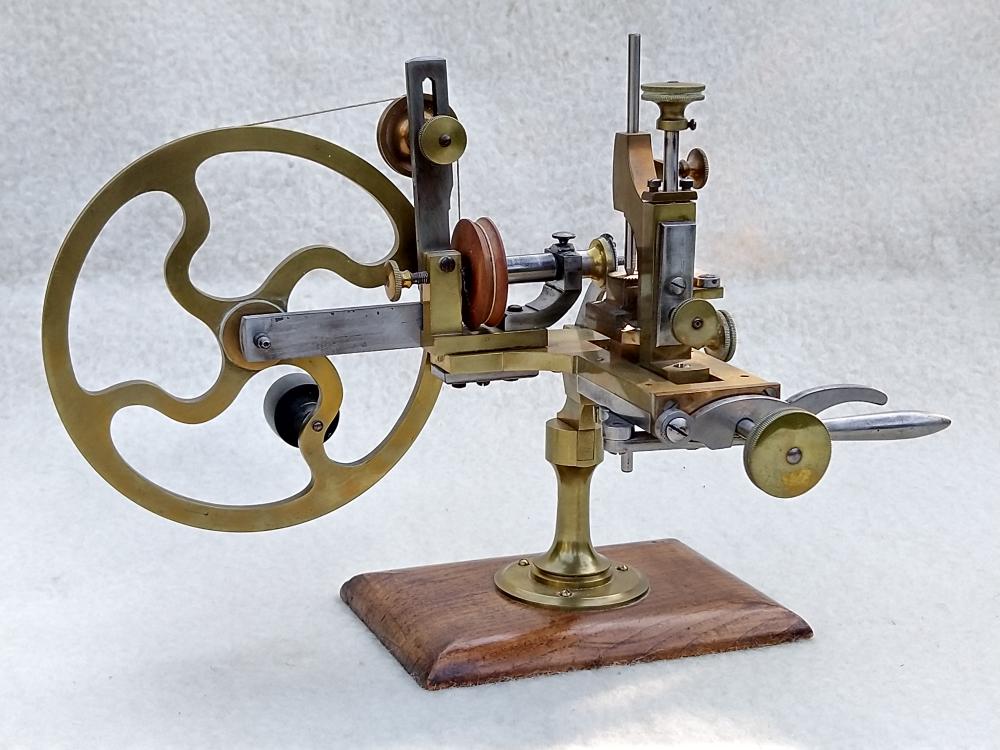

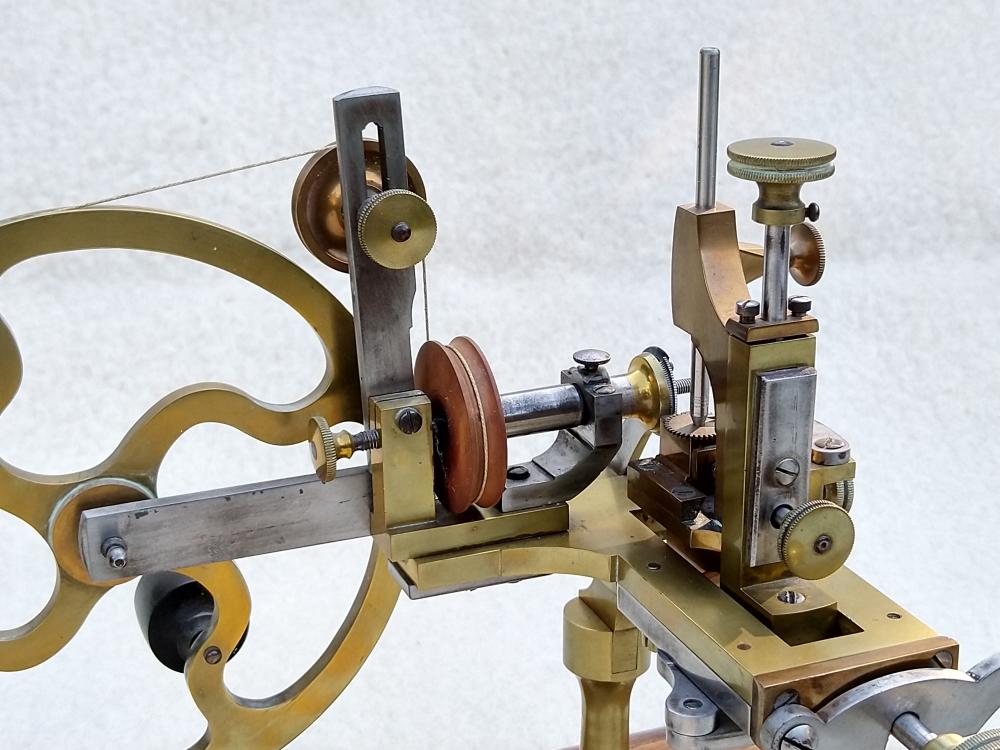

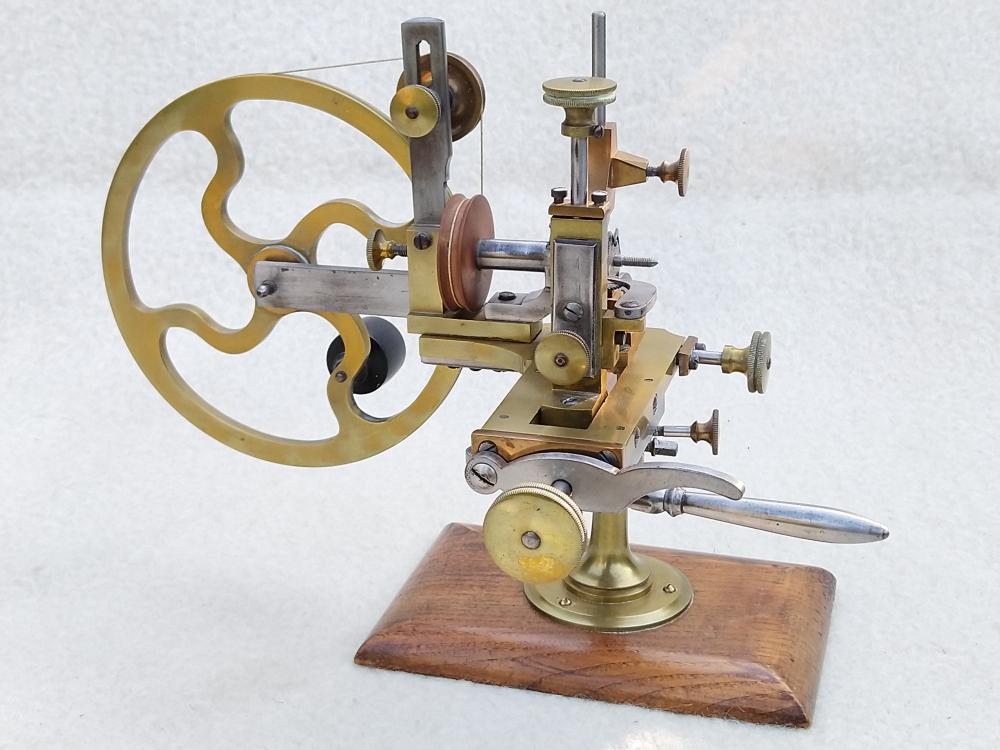

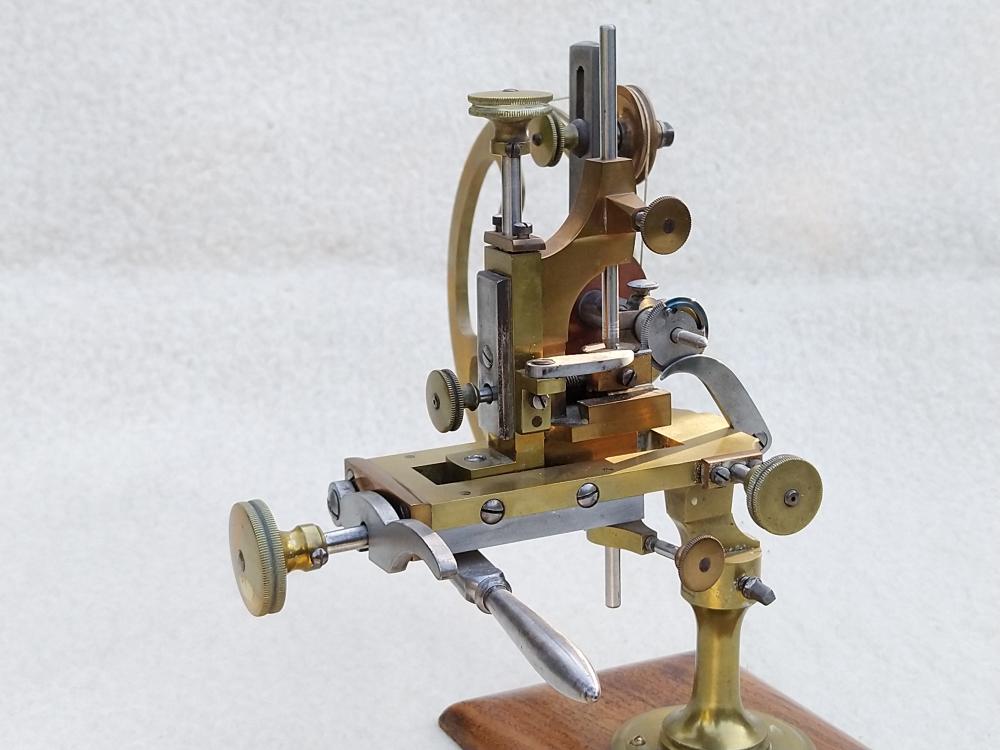

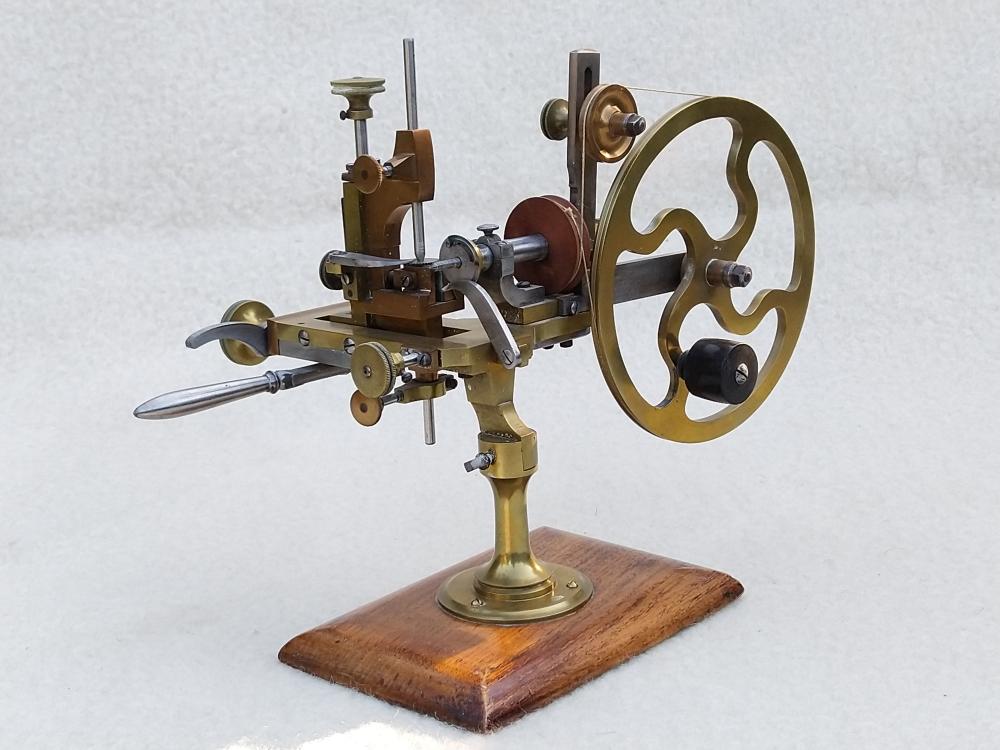

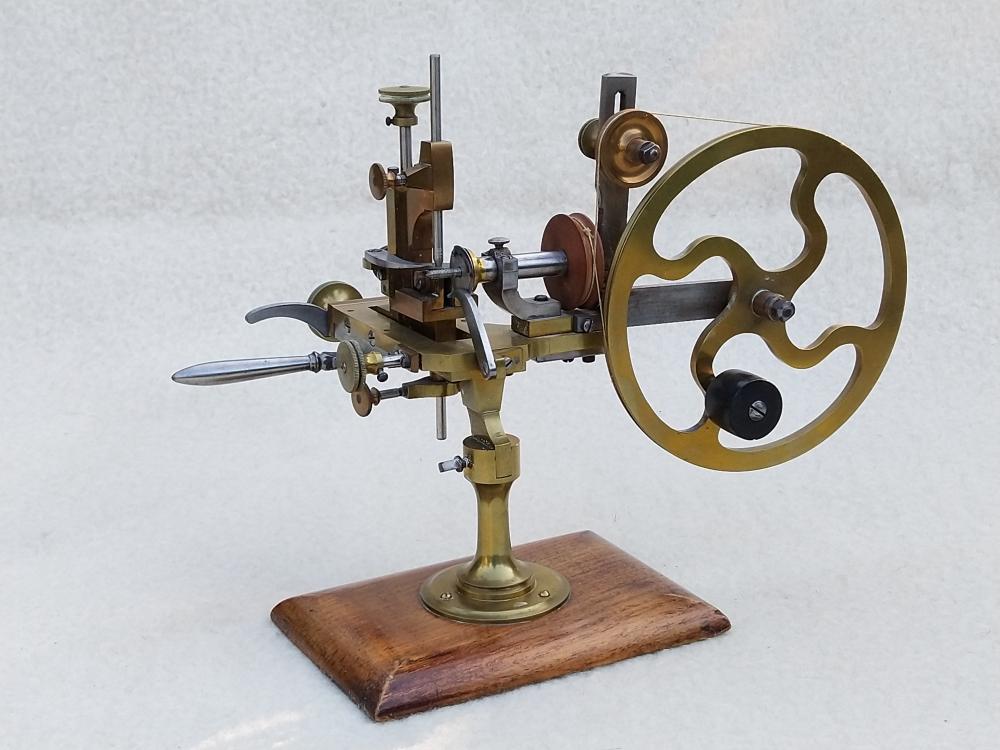

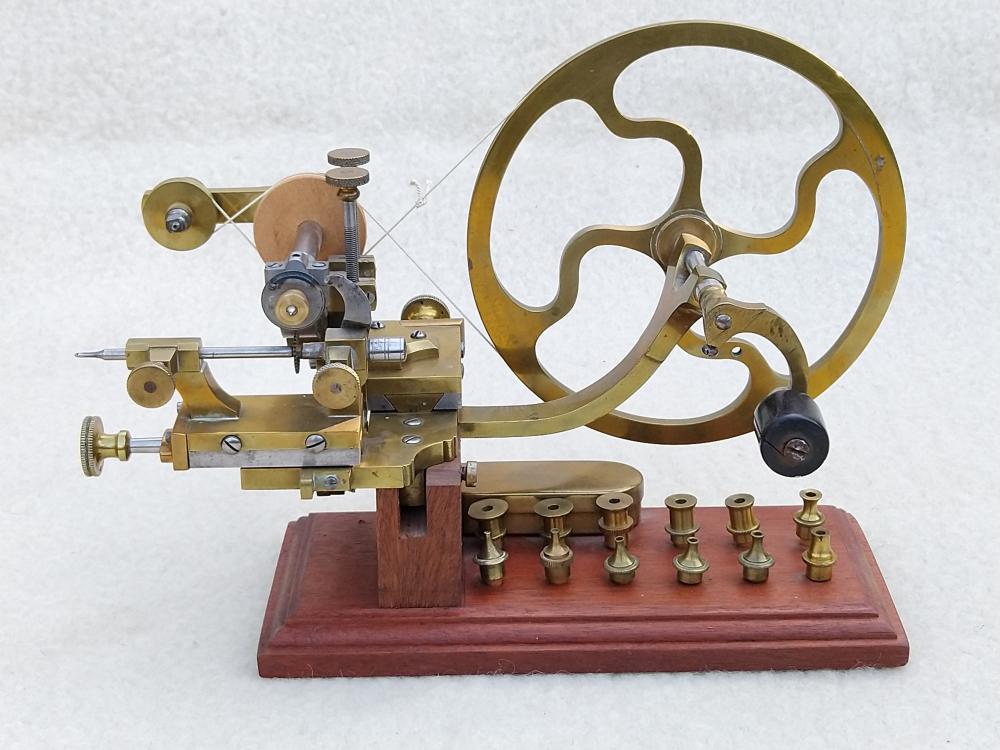

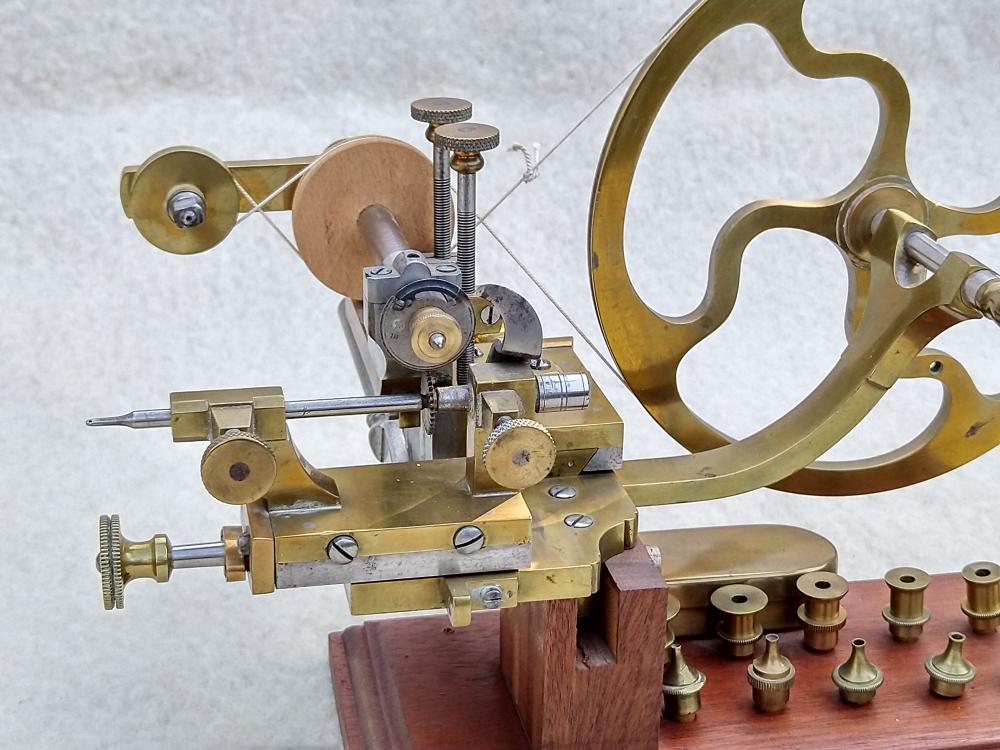

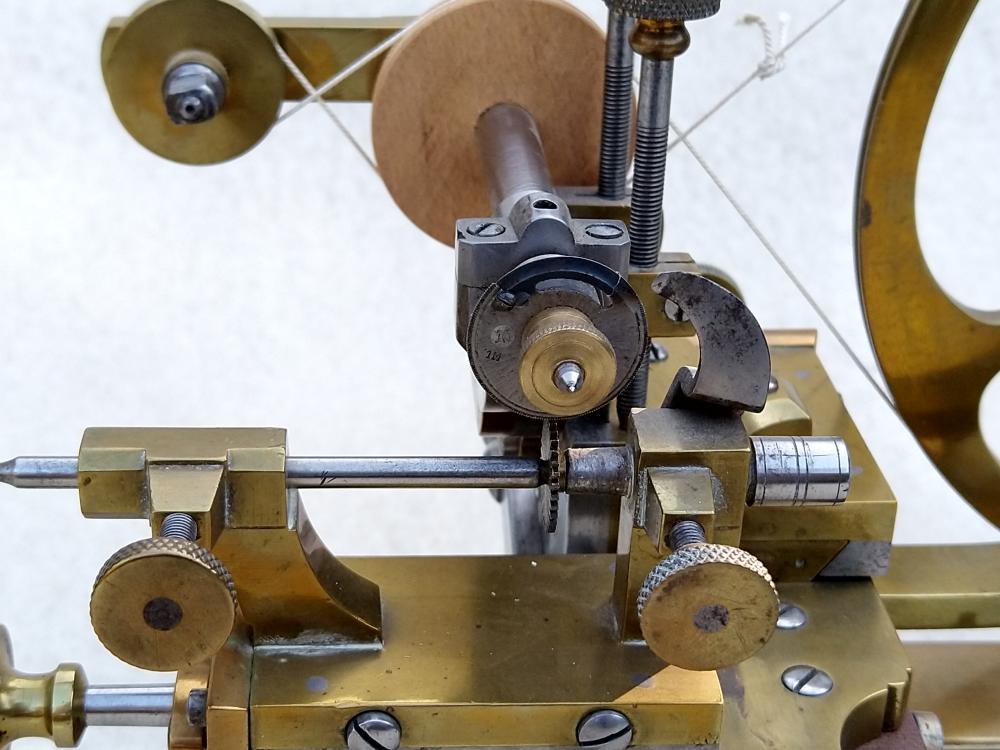

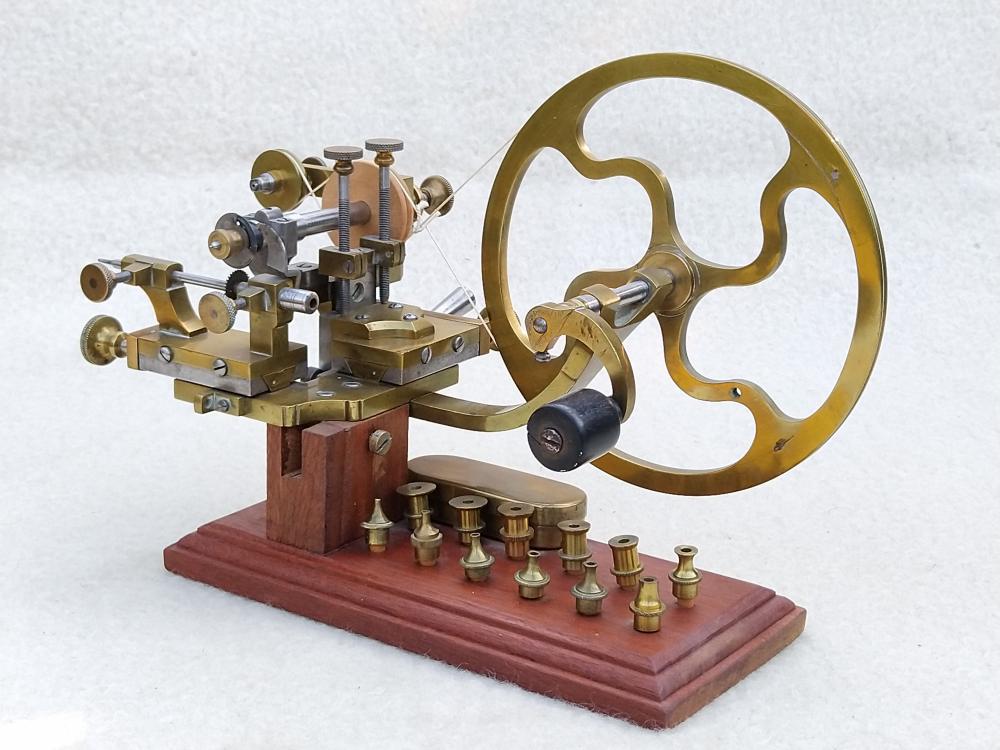

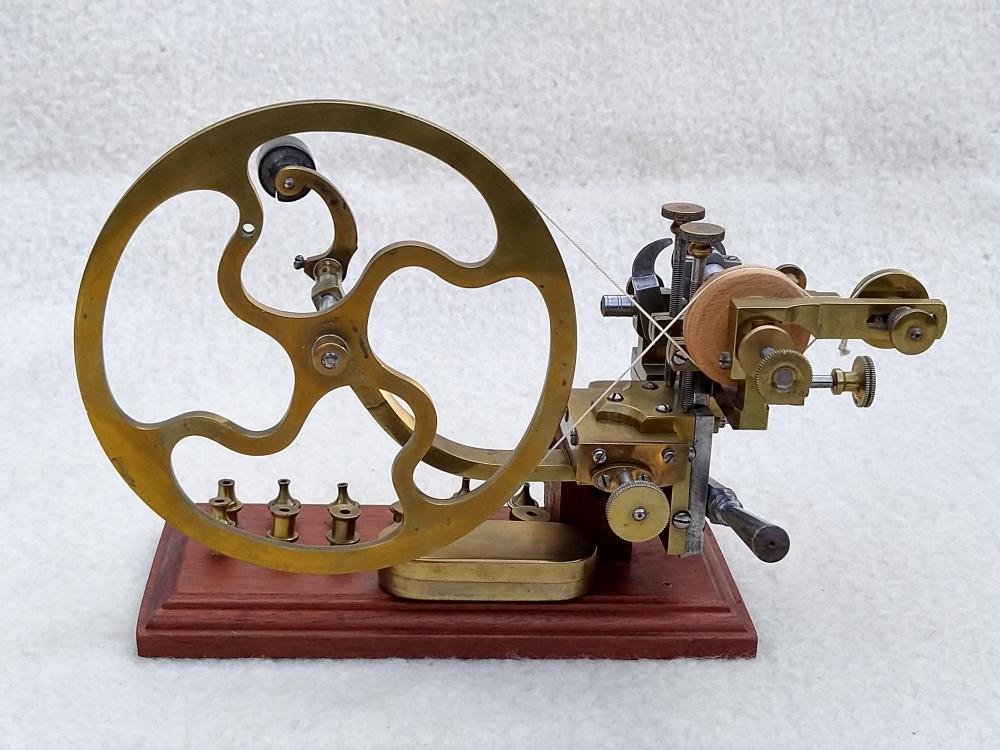

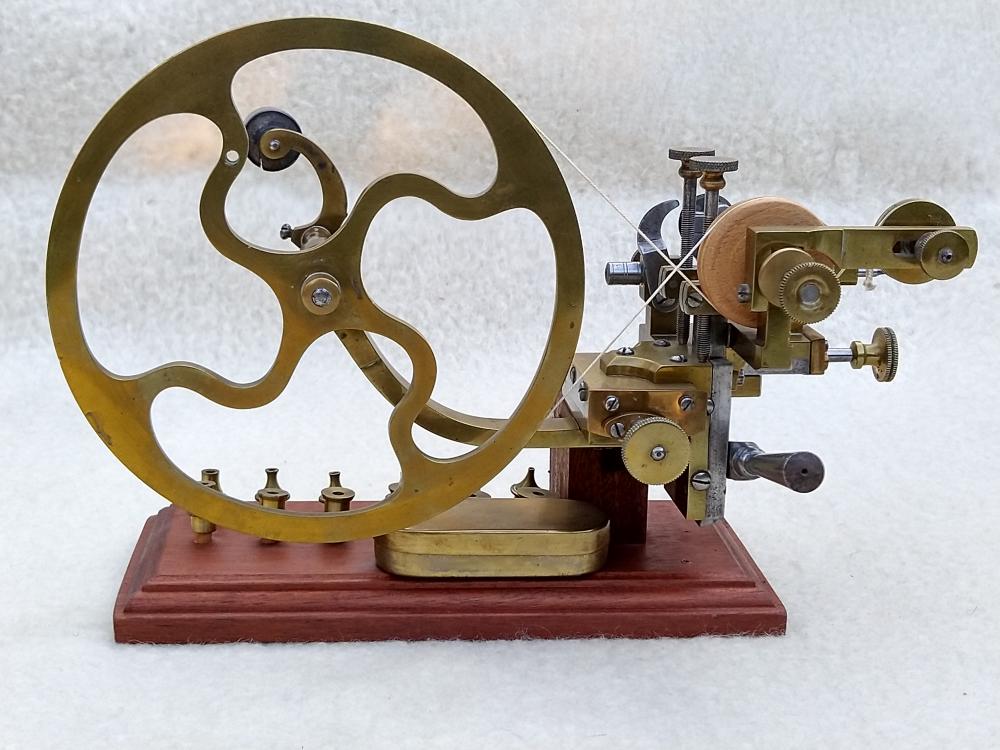

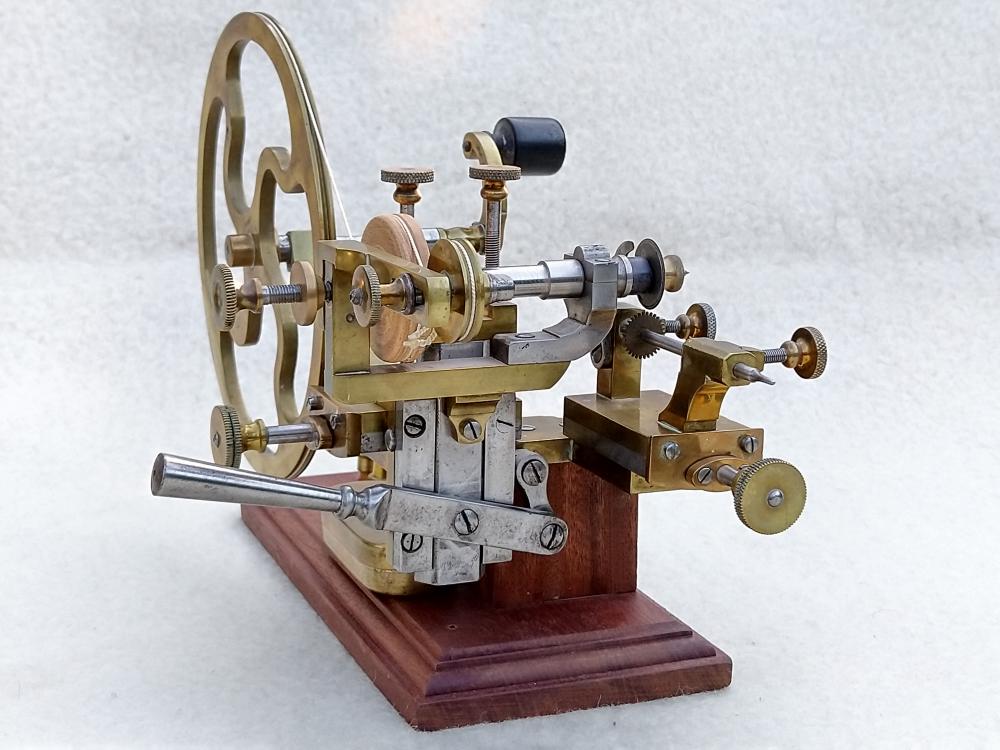

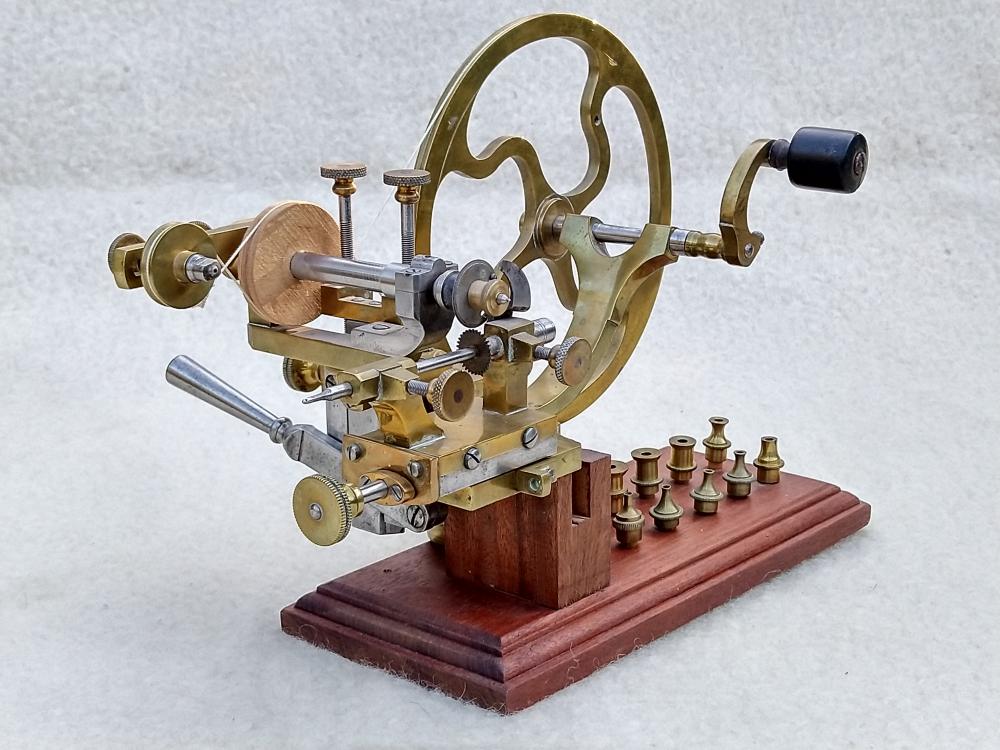

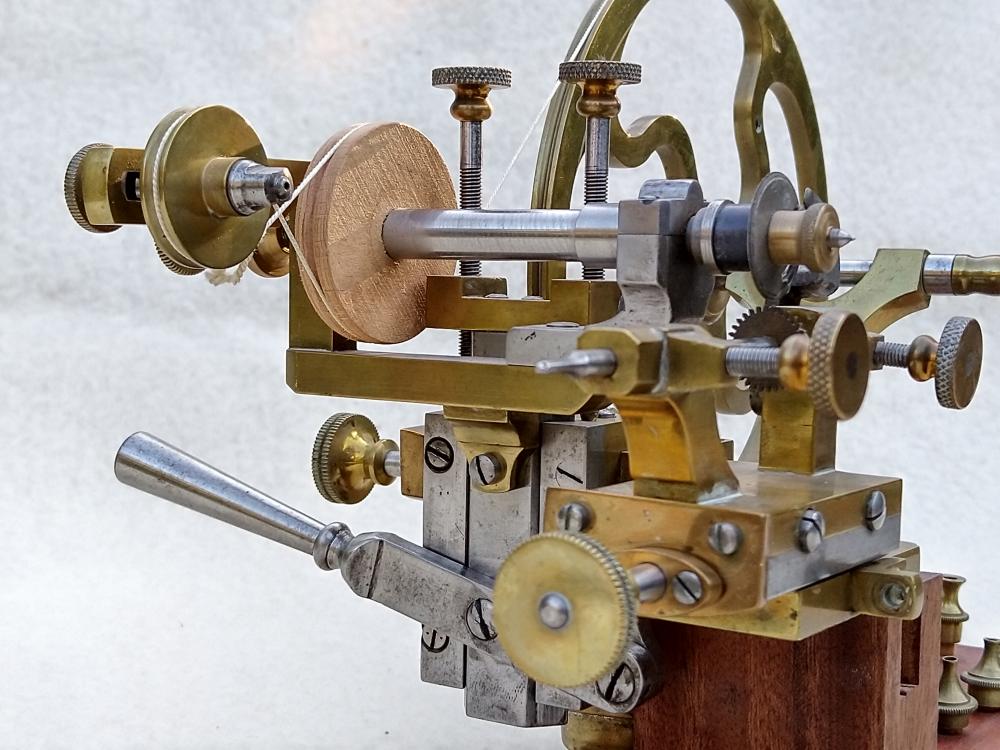

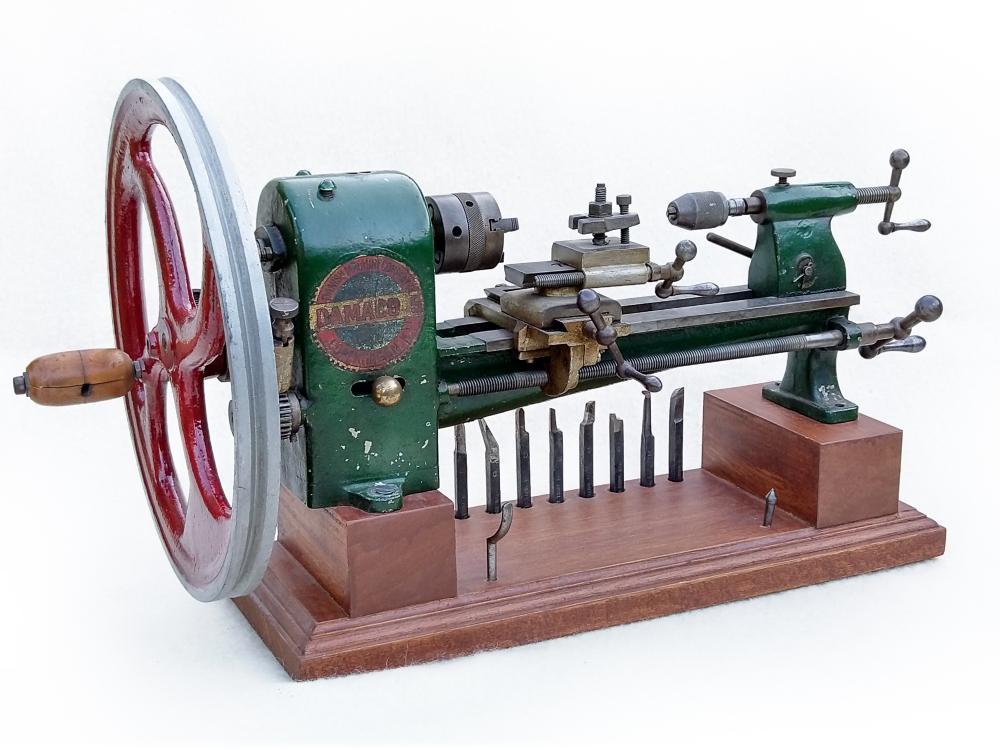

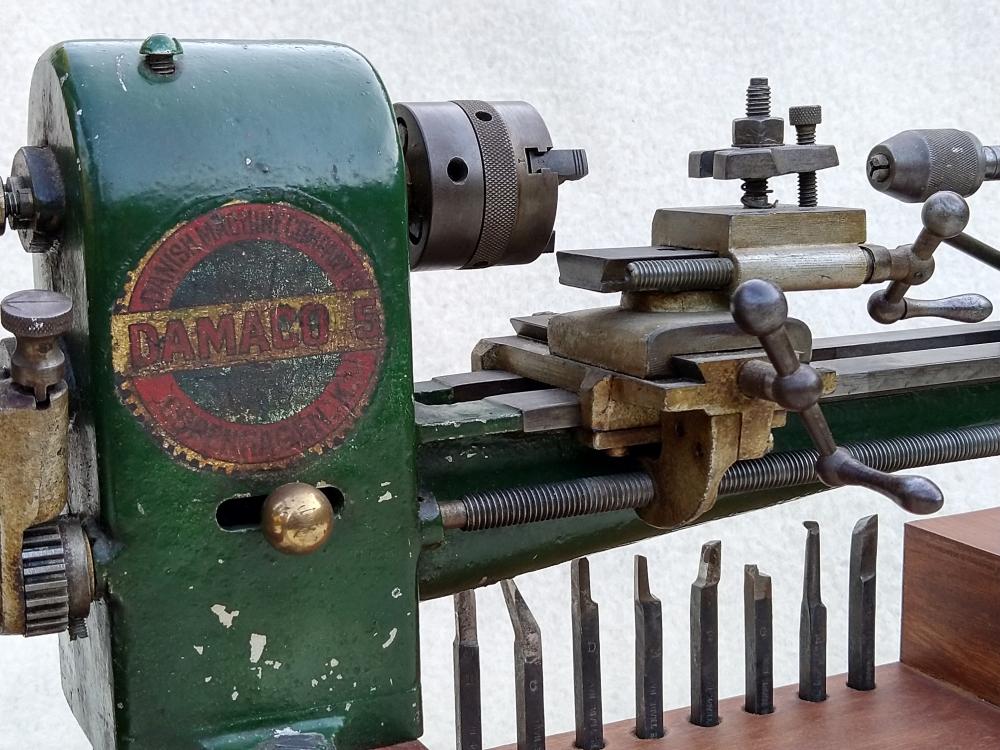

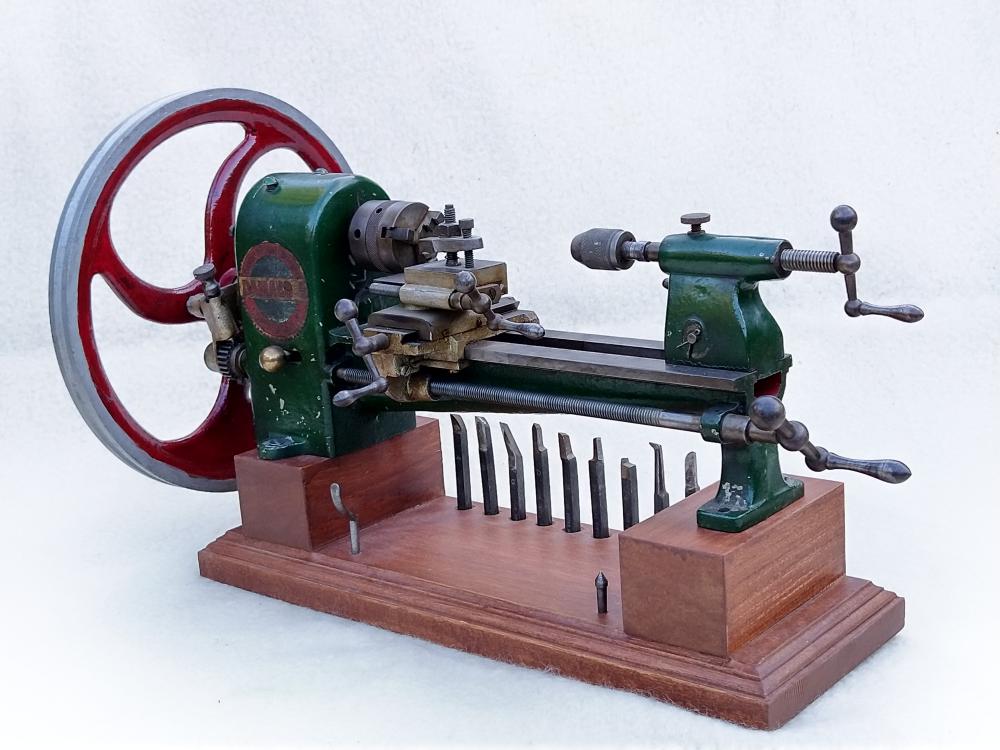

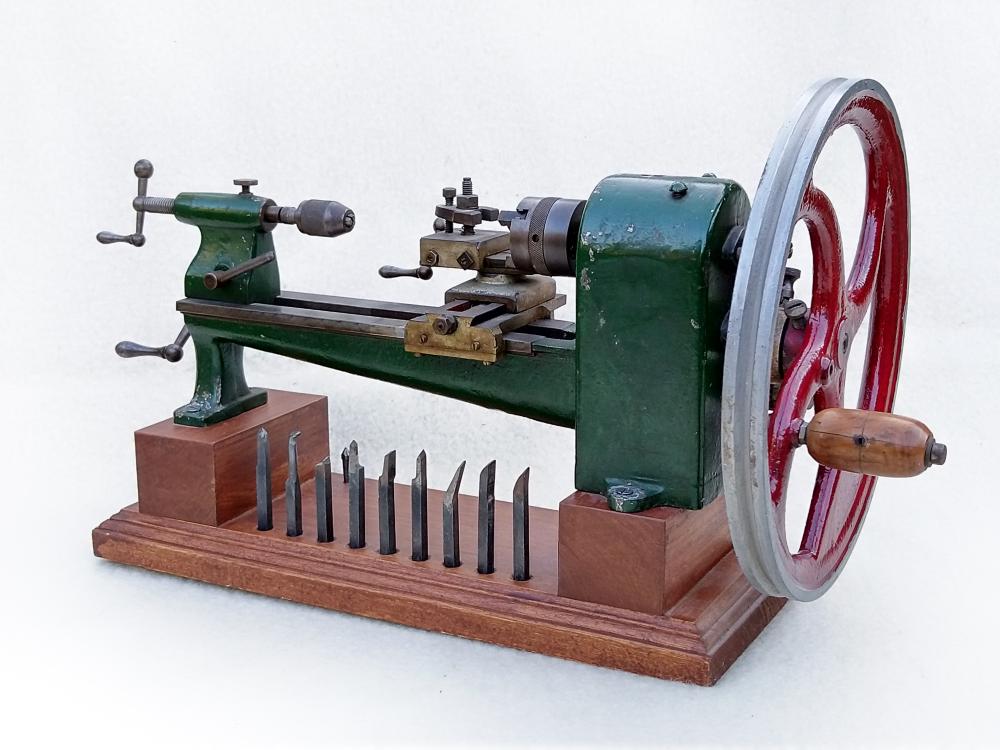

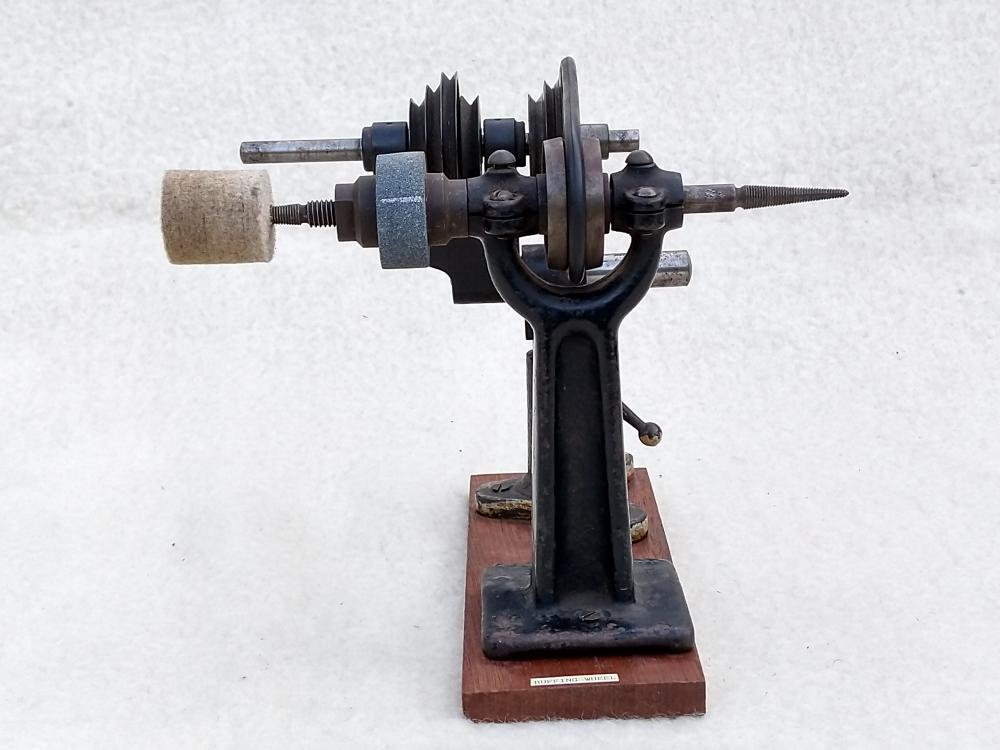

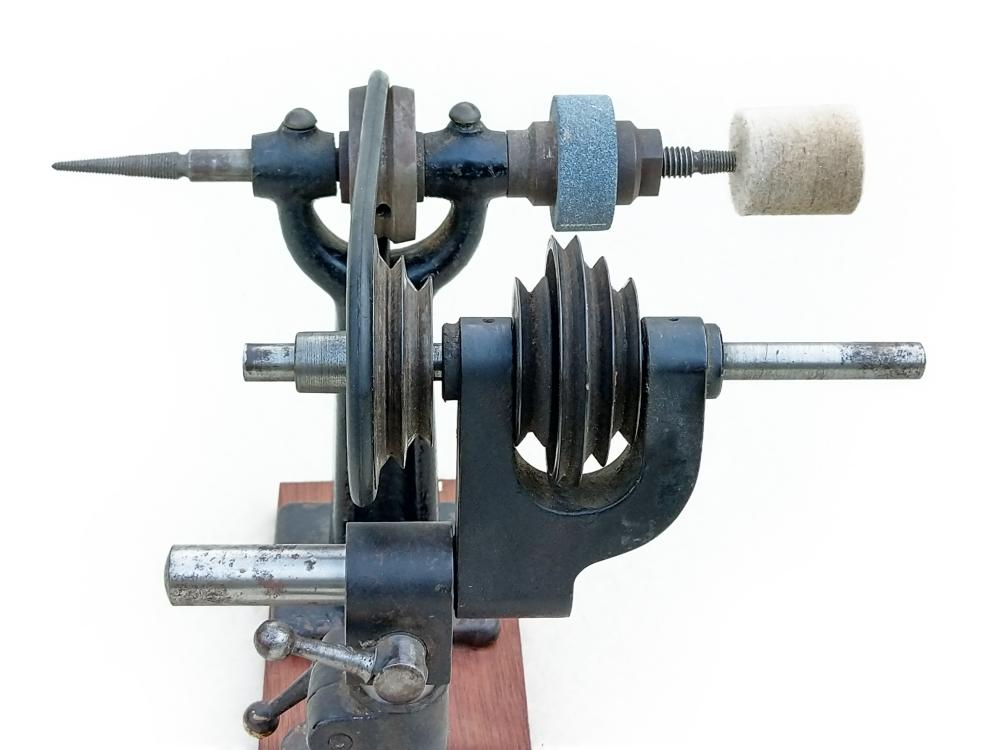

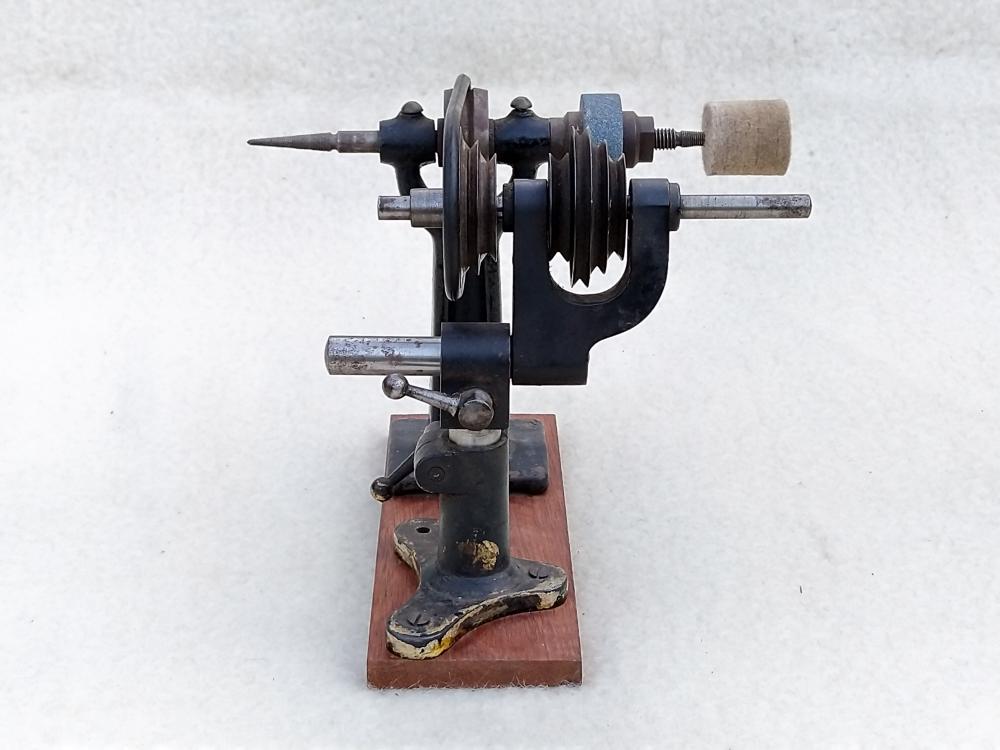

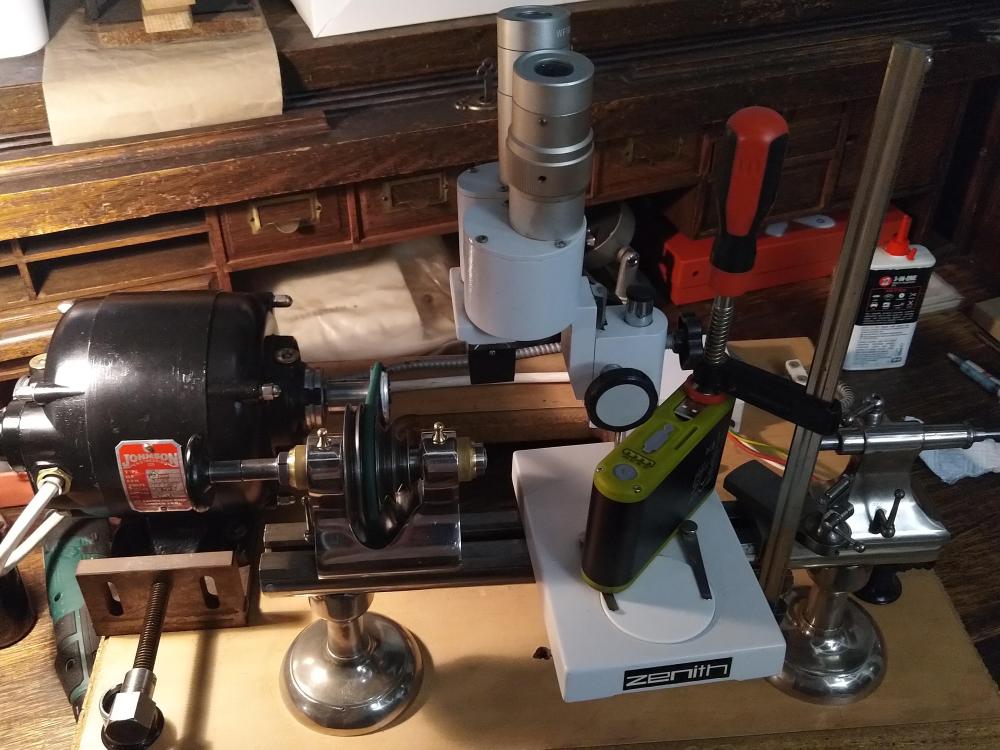

And the most important news: Today the first time ever I used a watchmakers lathe which I actually own for something useful: pencil sharpening a balance staff. The setup is sort of temporary, but was good enough to do my first steps with the watchmakers lathe. It had to happen sooner or later. I have been working to put together a watchmaker lathe since at the beginning of September in my free time, but the first lathe after so much work/cleaning/thinking and head scratching seemed to be a dead end. This one works though, i will need a new pulley for the motor should I keep the current 1 phase AC motor or a new motor and I will need to make a new stand, but I am slowly progressing. I received invaluable help throughout the cleaning process and setting up the lathe for which I am thankful.3 points

-

Small dog, children grown and on their own, and my in-laws told me specifically no returns. LOL2 points

-

I would agree with that knebo, the post i made was 7 months ago, since then have discussed other topics regarding the potential charging of of watch part materials using an abrasive paste. Its something that should be considered, I still see folk on YouTube using autosol, diamond paste on something they shouldn't . Better to use something that cuts or compresses without discharging abrasive particles2 points

-

At Long Last the Fight for Parts Supply is Going to the High Court Cousins battle with the Swatch Group is now heading to the High Court in London. However, after the ruling in Switzerland, the case in London commences with arguments that you might not be expecting. Anthony Cousins explains the details below:- It has been more than a year since I last updated you on our legal battle with the Swatch Group to overcome their refusal to openly supply spare parts. Doubtless some of you will think that we have gone quiet because we have given up, but nothing could be further from the truth. When we started this process, I made a commitment to keep fighting until we won the day, or had exhausted every available means. That fight has continued and has now reached a significant milestone. In December of 2021, the Commercial Court of Bern gave a verdict that ran contrary to the most fundamental principle of British and European Competition Law, which is that no matter can be decided without consideration of the impact upon UK consumers and competition in the UK. We supplied the court with overwhelming evidence to show that watch owners are suffering substantially higher prices for servicing and repair, are waiting significantly longer for their watches to be returned, have an extremely limited selection of locations where they can obtain service, and are frequently obliged to have work done to their watches that is not necessary and that they do not want. We also asked the court to engage independent expert witnesses to advise them on how British Competition Law is applied and decided. The Bern Court refused to consider any of that evidence, declined to employ any expert witnesses, and determined that Swatch was “objectively justified in changing its supply chain. In so doing, the Bern Court did not consider at all any of the evidence we provided on the impact of Swatch’s cessations of supplies on UK consumers and competition in the UK. As we reported in August of 2022, we appealed against this ruling to the Swiss Federal Supreme Court (FSC), pointing out in detail why the interests of consumers and competition are always paramount. Our experience of the FSC has not been good. Twice before the Bern court ruled in our favour, and on both occasions the FSC changed the Swiss Civil Code and found in favour of Swatch. Although our arguments were entirely correct, it came as little surprise when in September of last year, the FSC refused our appeal and found again for Swatch. It is outrageous that a foreign jurisdiction thinks it can alter the basis of a UK law, without even asking for any opinion on this from this country, and at the same time ignore a wealth of factual evidence that has been placed before it. I have no doubt that the Swiss judicial system is not a suitable forum to give rulings on British and European law, but explaining in detail why is an issue for another day. However, for you as the reader to understand what actions we have taken subsequently, it is necessary that you understand some basic points about why the Swiss had the right to rule on British and European law in the first place. Brexit had not happened when the case started back in early 2016, and an agreement existed between the EU, Switzerland, Iceland, Norway, and Denmark, called the Lugano Convention. This treaty deals with how cross border disputes between parties in the different countries should be managed in the courts, and in simple terms stated that all the signatories to the convention recognised each other’s judicial systems as being equal, and gave each other the right to rule using whichever country’s law was applicable. In our case this meant that a dispute between a British company and a Swiss company about a matter of British (and EU) law could be dealt with by either country’s courts. When we first wrote to Swatch about taking legal action, we told them that we would be taking them to the High Court in London if they did not resupply us within three weeks. To avoid that, they brought a claim against us in the Bern court without, however, telling us that they were doing this. But this did mean that the proceedings were supposed to be dealt with using British and EU law, not Swiss law. I am not going to detail the whole case again here, but for what follows to make sense, there are four significant points I must explain about how this relates to the Lugano Convention in our case. Firstly, the UK was (when the case began) bound by the Lugano Convention because it was a member of the EU, but when Brexit happened half way through our case, the UK was no longer part of the convention. The UK government applied to join the convention, and whilst waiting for a decision from the other members, held that any case started under Lugano rules would continue to be bound by them. Over a year later, the EU was still refusing to agree that the UK could join the convention, so the rules applicable in our case became somewhat less clear, and indeed before the final appeal was heard at the FSC, the Swiss courts declared that the convention was no longer applicable, and the final appeal was conducted under different rules. Secondly, all EU members use the same wording in their competition laws that appears in the EU Treaty, the only minor and required difference is that where the EU Treaty says ‘in the EU’, the UK Competition Act says ‘in the UK’. As part of the Brexit process, although the basics of UK Competition Law stayed the same, Section 60a was added to the Competition Act which allows UK law to deviate from EU law, so the two cannot be considered to be the same. Thirdly, under the terms of the Lugano Convention, if a matter is decided in one country then all the others are bound by it, and the courts of those other countries cannot review or overrule the decision, or hear the matter again, even if they are certain that the foreign decision is wrong. This is part of a wider legal principle known by the Latin phrase “Res Judicata”, which loosely translates as “This has already been Judged”. The point of this is to prevent a matter being repeatedly litigated, and to avoid conflicting judgements in different countries. Fourthly, under the terms of the Convention, the only action another member country can realistically take, is to refuse to recognise the foreign decision if it is ‘contrary to public policy’, but this has to be something other than the law applicable to the decision concerned, for example if one of the parties right to a fair trial was breached. As highlighted in the point above, it is not possible to argue that the Swiss courts did not apply Competition Law correctly. That would be ‘reviewing’ the case, which is expressly forbidden. Keeping these four points in mind, the actions that Cousins have now taken can be understood. When Swatch wrote to us in 2016 to say that they had lodged their claim with the Bern Court, there was a delay whilst we were waiting for the papers to be served on us. In that time period, we lodged our claim at the High Court in London in the expectation that the proceedings in Switzerland would not be admissible. Normally, a claimant has only three months to serve the papers on the other party, but because of the extraordinary nature of how the Swiss proceedings played out, we applied to the High Court for extensions to that time period, and in the end were granted a very exceptional ten of them. This meant that when the final FSC verdict came in, we still had a live claim that we could use. After lengthy consultation with our UK legal team, we identified two ways in which we believe the UK courts have valid reason not to recognise the Swiss decision, which in turn would allow us to bring the case again in the High Court, and have a British Judge decide a matter of British law concerning British markets and British consumers. Firstly, both the UK and Switzerland are signatories to the European Convention on Human Rights (ECHR), and it is contrary to public policy for the terms of that convention to be ignored. A crucial part of the ECHR is that parties in a legal action ‘have the right to be heard’. For this requirement to be met, it is vital that any evidence offered is considered by the court hearing the case. This did not happen in Bern. Secondly (as I explained above) after Brexit, UK Competition Law had the right to deviate from that of the EU. The Bern court did acknowledge the addition of Section 60a to UK law, but continued to regard UK law as being the same as that of the EU, and made its judgement on that basis. It is therefore true to say that UK Competition Law has not been applied at all, so it is not correct to claim that the matter has already been judged. In July this year, we served our High Court claim on Swatch (UK), and had the High Court start the process of serving on Swatch Group and ETA in Switzerland. The process of serving on foreign companies takes a few months, but Swatch UK received the claim within two days, and were required by the rules to enter a defence within six weeks. As we expected, Swatch responded by stating that this matter was already decided, and they applied to the High Court to have the claim struck out. We objected to the application on the grounds that I have explained above, and after some debate back and forth, it was agreed that there would be a one day hearing before a Judge in the High Court in order to decide whether or not the Bern verdict should be recognised in UK law. In simple terms, if the Bern decision is recognised, then there is little else that we can do. However, if the Bern decision is not recognised, then our current claim will continue and a longer hearing will be timetabled at which the evidence will be considered, and a ruling will be given under British Law. We are very confident as to what that ruling would be. On Monday of this week the administrative team at the High Court processed possible dates for the hearing, and it has been confirmed to us this will be the week commencing 26 February 2024. Whilst I am sure that there will be much interest within the watch repair world, this case has far greater significance. The Bern decision is not confined to watch parts, but covers wholesaling and other forms of distribution of any product in any market. If that decision is recognised, then small businesses in every sector who can not compete with the buying power of their larger counterparts will find themselves either out of business, or under the direct control of the manufacturers, and the big loser in the end will be the consumer. I never imagined when all this began that Cousins would end up fighting to uphold the basic principles of UK business law, but if that is what we need to do in order to preserve the right of our customers to continue to offer their services to UK consumers as they have done for Centuries, then that is what we will do. I will keep you updated as matters progress. Regards, Anthony2 points

-

Well, I've now read - polinum and polinox - autosol - Timesaver - lapping paper - nothing, just smoothing broach (with oil) - and of course rocking horse poo on unicorn horn. I'll openly admit that I don't know what I'm supposed to do. That's why I'm here on this forum. However, looking closely at your 'likes', I gather that you probably suggest that the smoothing broach is the best option. Is that a correct deduction?2 points

-

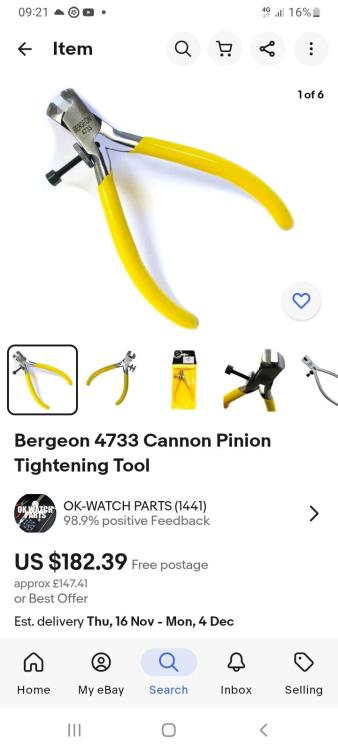

I have both of these . The top one has a needle to slide the cannon pinion onto that prevents it from being crushed while tightening the detent, mine i posted in tool of the day as a mystery tool some time ago. The Bergeon one employs a different method of using impact on the chisel with a hammer. You can clearly see the v anvil that supports the cannon pinion on both. For that you would want to supply your own internal support such as a brass rod or needle. There is also another type like the Bergeon that has a depth stop for the chisel, i obviously have that one as well . Bergeon also do the pliers some folk just make them from nailclippers and add an adjustable depth stop.2 points

-

Hi. The tool clamps on to the top suspension block, which is tightened enough to allow a little movement and adjusted left or right depending on how the anchor is locking. Micrometer adjustment with this tool. I have both the tool and instructions so will try and get them scanned nd posted.2 points

-

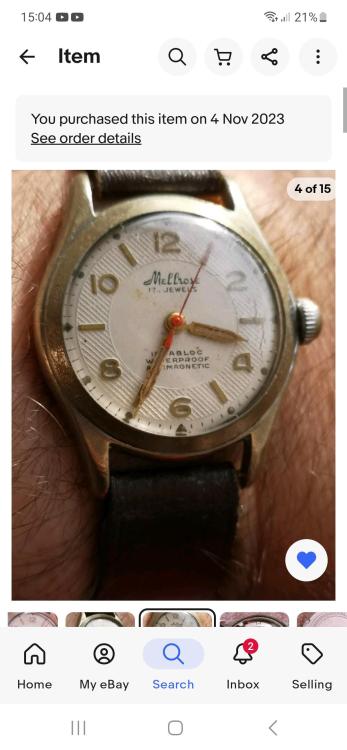

This perfectly sums up my case. Watch is in fact from Ukraine "restored and serviced by master watchmaker". Only this master uses so much oil I thought US troops would invade my home like Iraq. Seller even told me to send it back for "additional repair" but that would be just more damage caused in my opinion. I might have to swap the entire movement as there are no parts for this one.2 points

-

Yes, I know the channel. Nice, and not pretending to be what he's not. And simply enjoyable to watch. But not to be confused with a watchmaking course.1 point

-

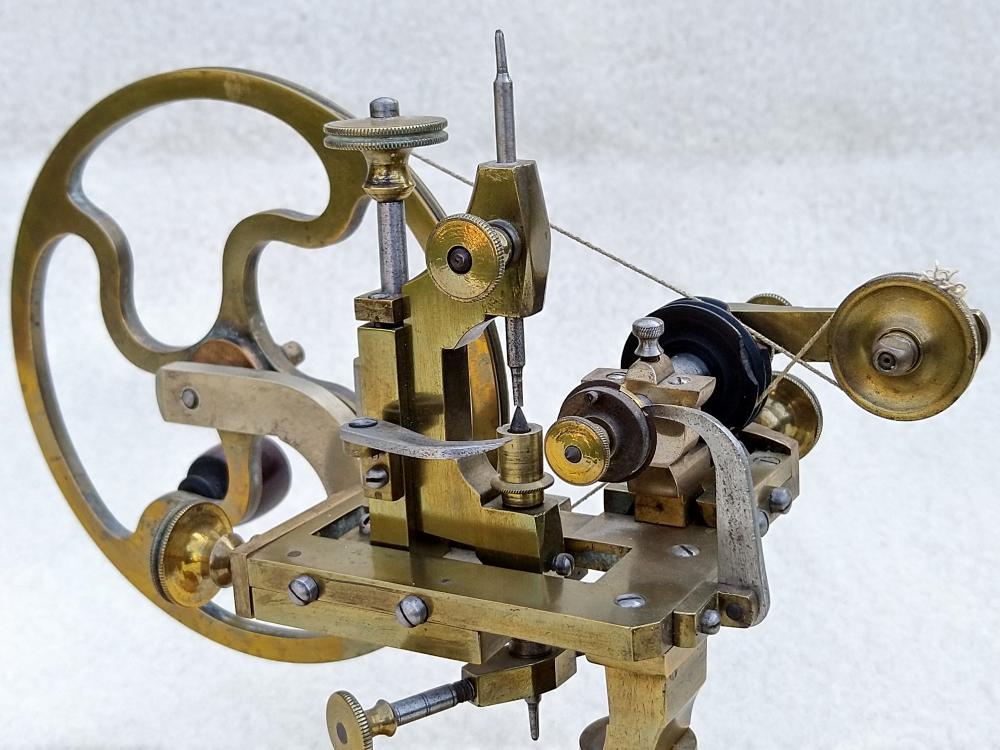

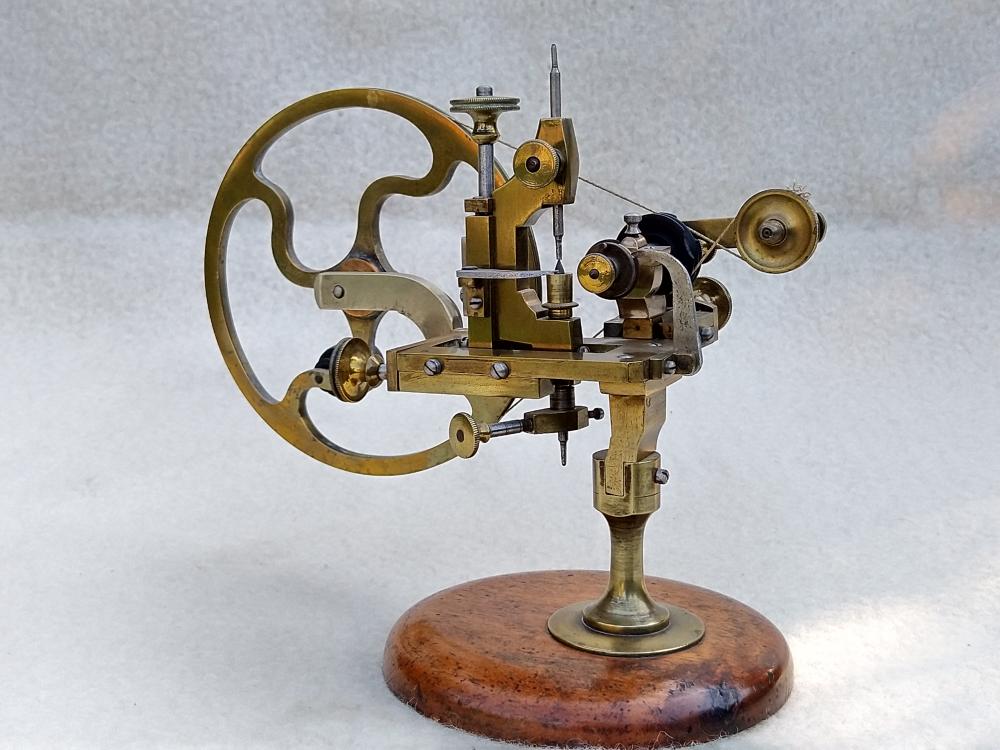

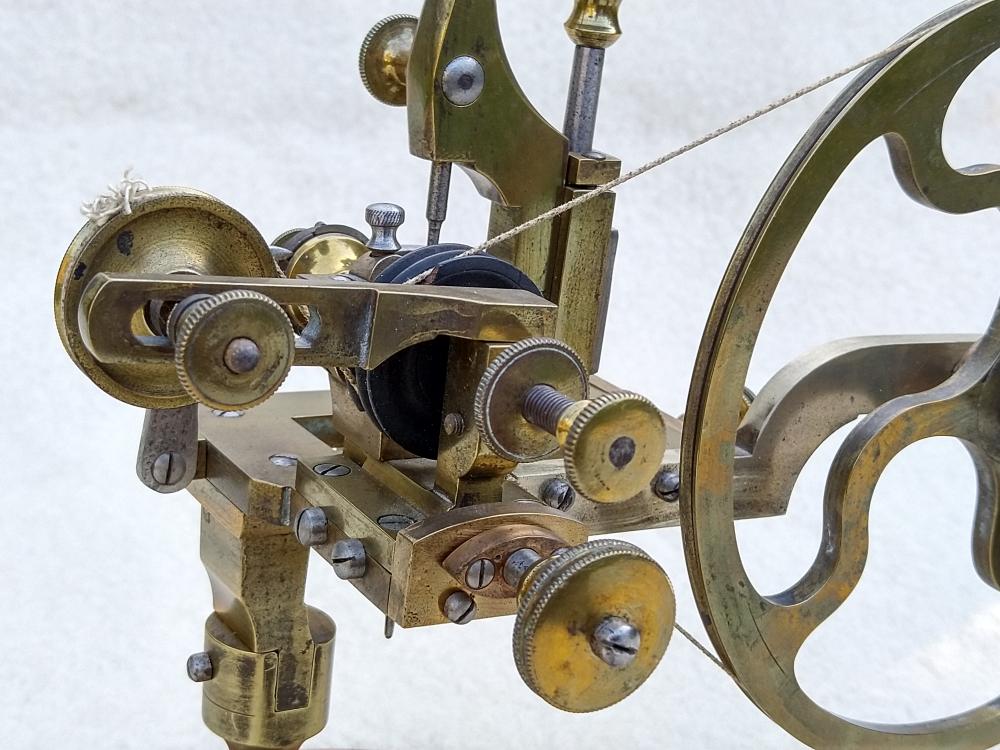

Thinking of crystal lifts we already discussed another one keep an eye open on eBay for one of these really quite nice. Because the design of the tool you can set the depth at which it grabs your crystal for insertion. Don't know why even ask about this tool tells you what it is and that's a really good price. Well sort of a good price in other words it's a good price for something you put on your shelf and it looks really nice and pretty. If you want to use it its missing all the cutters so without the cutters it's basically worthless. Then realistically you would probably never have a opportunity use the tool anyway but it still would look really impressive on the shelf impress your friends1 point

-

Excuses excuses, convert your loft, dig a basement, rent nextdoor Come on mate, do i have to think of everything ?1 point

-

Dont worry you will make space, re- house the dog, sell the children , send the missus back to her parents. Soooo many options.1 point

-

The good of YouTube is it makes watch repair look fun 100% of the time. Versus the reality of where there will be frustrations or other things of annoyance. But the people on YouTube always come across like they actually no what they're doing. Which is fine if you don't know what you're doing they are literally God's. Which is why I occasionally make jokes about that. But as your knowledge increases you begin to realize that your gods are false gods. Oh but may be rich false gods it depends on how many views they have with their videos. The only real test of any of this is re-examining your watch after a year. Do a running a valuation wind it up and put it on the timing machine see how it's doing preferably more than one position. Wait 24 hours is it still running it still on time how does it look on the timing machine. Disassemble it out as everything look this is especially important if this is a watch that you had running every day on your wrist. Unfortunately a watches serviced a year ago that sitting in a drawer someplace doesn't count preferably need something that's running on a daily basis. How does it look after a year. For instance save the little money on those crappies Swiss lubricants that are so expensive purchase something cheaper are they still functioning. All is aggressive grinding compound's are they still aggressively grinding inside your watch? That's really the test of watch repair what does your watch two years after you serviced it. But you never do see that on YouTube because typically to get things to fit within a timeframe skip steps they never go to show you what their watch did a year later or whether the watch runs at all next week. Oh and of course if they have a disappointing outcome less-than-perfect will they ever make a video? I was suggesting to somebody that I know that there's a YouTube channel that what about a video of all the watches you currently can't service because parts etc. were just can't practically be serviced. Or what about the watches are currently working on that don't want to run rights are just don't rerun at all. But I was told that would make for a boring video and nobody would watch that.1 point

-

I remember your posts and you were lucky to be able to get refund. Haha getting what you want then another better deal appears soon after, often how it goes. I agree with our John here that buying tools is a waiting game, upsetting for those of us that are impatient. Thats why i have multiple staking and jewelling sets , if only it was just staking and jewelling sets.1 point

-

Quite true. I would call this one a relative bargain. I recently saw a less complete set go for $432 and a beautifully refinished one (yet missing several pieces) go for a whopping $761. Having some extra stakes or duplicate stakes in the set can obscure that there are missing stakes from the original 100. I bought such a 18R deluxe set off of fleabay and it ended up having plenty of duplicate and missing stakes and a mix of C.E. & Marshall stakes. I ended up returning it (fortunately, the seller accepted returns and I didn't have to pay return shipping). I did research on the https://kanddinverto.weebly.com site to see what should come with the set and used that info to evaluate sets up for auction. My 2nd purchase was much more successful. Minimal duplicates and missing stakes. Hurt my wallet though. I was a bit too impatient, as I was able to find a nice set (albeit a Series 600 set) locally for a quite low price. Now I have two staking sets, lol. I have to figure which I want to keep. Both are nice and close to complete, but the 18R deluxe set has more bells and whistles.1 point

-

Most sellers of tools like these wont know what a complete set would be, some not even aware of what the tool is. Always a gamble, one reason i felt a thread like this would be helpful for those of us not knowledgeable enough to avoid being dupped either intentionally or not. It makes me happy when pros weigh in with a " whoa don't buy it " or a " snap it up its a bargain "1 point

-

Pretty nice K&D 18R Deluxe Staking Tool Set. More complete than many others that I have seen. Missing a few stakes and the little metal tightener pieces for the roller table removers. Of course, the seller didn't list out which stakes are included to compare against the original 100 stakes for the set. Case is in pretty reasonable shape. Though, it looks like someone sprayed clear coat over the label, causing it to bubble up. Price is lower than what I have seen less complete sets go for, but still a good chunk of change. https://www.ebay.com/itm/4045974672021 point

-

Hi Rich, Not sure what this type of gears bridge is called overbridge ? or what, anyway, AS made a generation of movements with similar type of gears bridge. not sure if parts interchange. Rgds1 point

-

1 point

-

Kudos to you, Anthony.1 point

-

1 point

-

We have the same problem here, but slowly clamping down on it. At xmas the village i live in successfully campaigned against allowing 2000 unknown, unvetted male migrants being homed in an old unused university building. Action needs to be taken to prevent potential threats to our communities.1 point

-

John. I know I should say this. But, to clarify.. You are so interesting!!! Both in your factual comments and your research. You really are a help to us mortals. Thank you once again.1 point

-

That's terrible news watchie i had no idea that would be happening in Sweden, my wife is really surprised and shocked. You take care over there.1 point

-

Hello again, I´ve already fixed the problem with the escape wheel. I verified that even without the pendulum it rotated correctly, so I dismantled the anchor and checked everything again until I verified that with a little force from the mainspring it was already working correctly. Then I put everything back together and there it is, working. I'll leave it like this for a while and then adjust the beat. Miguel1 point

-

1 point

-

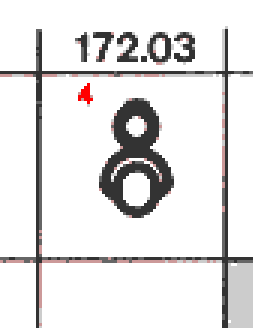

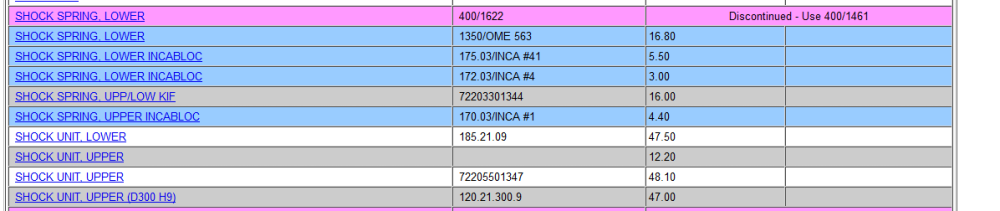

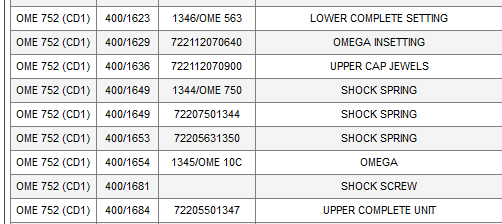

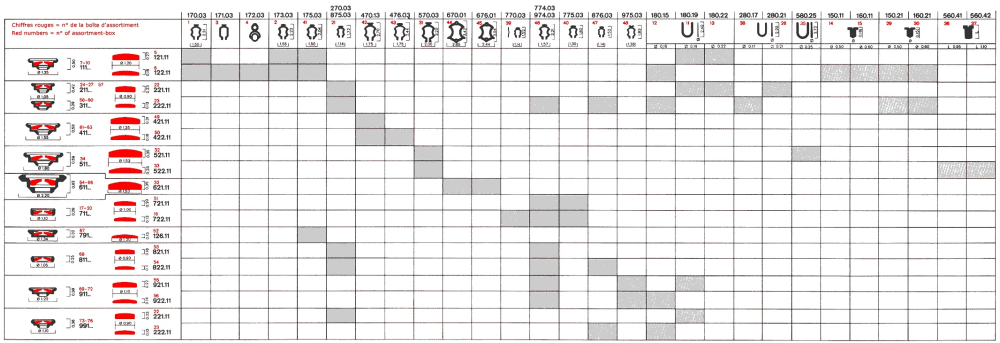

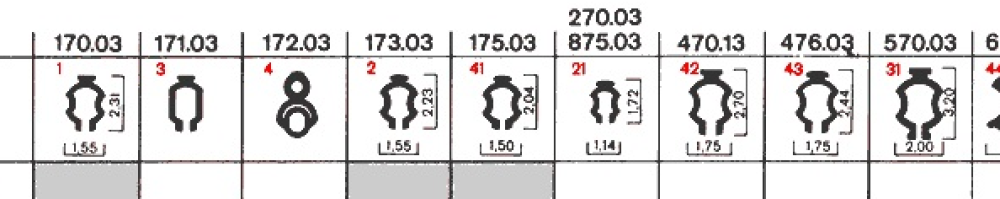

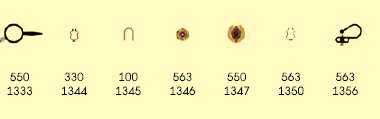

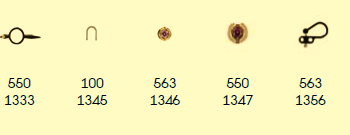

It looks like from the images your rusty movement is cleaning up quite nicely. I've inherited a few rusty Omega movements over the years and they are never going to look as nice as yours looks. Just a little clarification here? Last person on the group claimed to be restoring a particular Omega watch reality was trying to mix and match whatever and whatever it didn't really work well for us or his discussion with us. In this particular case you appear to be restoring a particular Omega watch and you would like to restore it back to its original condition? That we can work with as you're not going to be mixing and matching things that aren't quite right. It sometimes very hard to help somebody on discussion group if for not sure where they're going in other words let's combine several different Omega watches and make one that is going to be a nightmare versus let's see if we can restore this watch. Yes the sad reality of watches getting cannibalized and the parts worth more than the watch itself. So yes looking at the parts list that does appear to be the correct part number. That is if you would like the Omega part may be the generic part would work just fine as they would be identical except the rose gold spring would be gold plated instead. This is where the website at the link below comes in useful. So far everything seem nice and straightforward until my brain is tired and yes I know you had pictures provides it didn't quite stinky and right away. So yes we have a problem or you have a problem that let's see what we can do about it. For instance this is a main plate from an Omega watch supposedly yours but doesn't agree with yours doesn't? That's because Omega has upgraded and it should be reflected in the parts list but the cousins parts list will be out of date and it's not always reflected in the newer parts lists. So for the particular main plate up above this is what the spring would look like the hold the jewel assembly conveniently missing from yours. Then just to make it clear for everybody zoomed into your image of what you're finding which agrees with the plate and the spring but unfortunately doesn't work for your watch at all does it? Then from your plate I don't suppose we do have a slight angle shot I can't see if there are slots or cuts in the outer edge I have a suspicion what it is but I can't quite see it. But no matter what it is not the same jewel assembly as found in the watch above Then to add to the confusion let's look at the parts list found at the link below and as a heck of a lot of parts which tells us what we already know revisions. Then from another websites because sometimes they get updated in different orders see if they make any better sense of this mess. Now another image for Chamblee we can use generic if we can figure out which one it is based on the parts list numbers or possibly we can use an Omega once again a figure out what were looking Let's zoom in on the part of the image above Okay so the old uses 172.03 which will not fit on your watch at all. But as a guess 175.03 should fit that's why you need a slight angle view as it looks like there should be a slot for that to go into. Now we just need to figure out what jewel of those with that spring or if you're like on eBay look for a new hairstyle one? But I'm reasonably sure of Omega doesn't necessarily change the part numbers because in stock that have the newest and not the old parts and on eBay it could be new old and as you find not entirely the right one of Oh and this is where if you had a friendly material house to talk to you would explain your problem and they would get you the right part. Where online doesn't necessarily explain all of this. Yes there really are physical material houses existing in the world some of them not online You can try a process of elimination and I'm somewhat guessing it may be perhaps this http://cgi.julesborel.com/cgi-bin/matcgi2?ref=X\ZDXJUH Only because it has a different part number. Then how about some more confusion parts list yours is Yours came from 2013 mine is slightly newer and 2016. Let's look at the parts images Let's look at yours should be identical but they're not. Notice how you have part 1344 missing from up above. Then you don't even have the older spring is your list is newer than the older one. It's the problem of revisions of the main plate. Cf. yet the right part for the right age of your. Plus of course notice how the part numbers for your lower jewel assembly are identical when they're not very unhelpful and no I don't know if you can substitute a newer one for the older one I'm guessing not. Plus and thinking from the way the picture shows in the way the parts description is in a newer style it may be an entire assembly that doesn't actually come up and perhaps I'm not sure if my answer is of any help at all because I'm not actually sure what you should be purchasing other than what you should not be purchasing. If you do take the 400/numbers you can go to the home page of the company at the link below and do a search and they come up but the description sucks and there's no pictures. Then because the physical bestfit book is too old none of these tools are listed either http://www.julesborel.com/s.nl/it.A/id.24948/.f Not sure how helpful is going to be a big problem is it's older So with a foldout what it isn't. You should build get an aftermarket setting but we have to figure out what it is and I'm not quite sure how to do that. Then whoever you purchase from on eBay has to have the newer version obviously which of course will have the exact same part numbers the older version. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=OME_7521 point

-

1 point

-

Have you done a complete disassembly and thorough cleaning yet? The movement needs to be really clean to work properly.1 point

-

That is quite a common trick. Ebay listing cancelled "There was a mistake in the listing".. really?! .1 point

-

The watch did not sell for what the seller wanted. It’s happened to me a high percentage of the few times I’ve used fleabay. Meant another item, I made a mistake, ‘ already ‘sold’ (then listed again later). Gaming the rules…1 point

-

1 point

-

Yes like a mechanical watch no shortcuts for servicing. Be warned the video skips things that ideally should be done when servicing a quartz watch. He does not have the electrical checks that really should do because of course he probably doesn't have the test equipment and neither do you. In other words you just have to assume that your circuit is working because you don't have the proper equipment and you can't measure the current consumption to see how well things are working. Then as this is a servicing video and not necessarily a procedural video he's missing a really important step. This is where he carefully disassemble such as all the parts and then in the next video he reassembles but in between the watch was run through the cleaning machine which you do not have. Now we get interesting conflict here you would like to learn? But you don't want to spend much money and unfortunately this is watch repair were an endless supply a tools conceivably will be needed. I know how but another video I'm trying to think about what I want to give this video thumb down because it is exactly what you want to do although for unknown reasons he takes the front of the watch a part. The only reason I'm giving you the video is it's the same caliber and he's basically doing a quick cleaning and it's a miracle the watch will run at all the way he's doing this. https://youtu.be/vT6INP4VjE0?si=IUu8sXTl9Pviv93W Oh if you think the hands look fragile just wait until you try to put the gear train of the rotor back together. The videos of putting quartz watches together might look simple but it's not really simply get the gear train in. One thing the rotor is magnetic it keeps wanting to stick to everything in the wheels typically don't like to stay wherever you put them. Oh and there's a classic problem with YouTube videos they never show you the problems they only show you how easy and simple everything is. So a lot of times people come to this discussion group with the thought that watch repairs going to be super simple easy because they saw the video that makes it look easy. To properly serviced this watch is going to be disassembled like marks video shows. Cleaned was some sort of cleaning procedure in other words a solvent until it's all nice and clean. Reassembled and you could probably get by with two lubricants some grease for the keyless and setting parts and that extremely light synthetic oil for the rest of the watch. Unfortunately you're not going to find those lubricants on Ally express as quick look shows mystery oils. In other words zero specification so you have no idea what they really are or are not.1 point

-

The wheel IS ROUND, but it's hole is out of center. But You video is not prooving it clearly, as the wheel is actually not centered by it's square hole. But, it is still pritty obvious that the hole is out of center, even without this video. BUT, if the sqyare part of the arbour is cut out of arbour center too, this can compensate the wheel's hole out of center, if the wheel and the arbour are assembled/matched in the correct way1 point

-

1 point

-

I used to be much into Vostok, Raketa, and Poljot, and 90 per cent of the eBay sellers are in Ukraine (as corrupt as can be). The listings mostly never forget to mention "serviced by master watchmaker". That is, dipped a few times in a can of naphtha, dried with a hair blower, and then some olive oil injected here and there. Well, as long as they tick, who's gonna know?1 point

-

1 point

-

I replaced the battery in a Gucci 3000L , after replacing the watch did not work......the next step was to replace the movement, little did not know the movement 978.002 6 jewel, ETA is very hard to find, the replacement is the is the Rhonda 2 hand movement HQ751E...........after looking , and getting advice , i did not buy the replacement , i bought a circuit board, now I am stuck with a board and i need advice on how to fix the circuit board.......... There is a video by Le Arsi, he has an analyzer, is anybody familiar with this watch maker? or his analyzer? Here's a video1 point

-

Hi everyone, I know I haven't been here in a fair while. Life got in the way of a few things. Anyway, I was looking at buying some of these tools as I have read some decent reports about them. I can't get them in Australia and even though they are made on Korea, the only place that I can find that sells them is in the US. I can't get them from their website. Have to go through their eBay website. Anyway $212 dollars worth of tools and getting charged international freight on every item individually. Postage is working out at half the price of the tools. I have written to the store owner to ask why and whether I should only be charged one smaller fee as I am getting everything at the same time. Thing is, it looks like the freight is an eBay thing and not the store owner, so there may be nothing I can do about it. I'll wait to hear from the store owner and decide what to do after that.0 points

-

That is unfortunately what you get by an "open borders"/"open your heart" policy allowing two million people from Africa and the Middle East into a small secularised country like Sweden consisting of only nine million people. I wish the US and other European countries would take note but they don't, except Hungary and Poland.0 points

-

I have no personal experience of buying watches from Japan, but I'd be extremely surprised to learn of any systematic scamming from Japanese sellers, so you should be safe I think it is common knowledge and consensus that the ethics of Japanese culture is first-class. I just talked with my daughter who's been living in Tokyo since the beginning of August and she mentioned she has never felt safer (unlike the war zone Sweden has become with blown-up houses, firefights on open streets, innocent people injured and killed, and it happens more or less every day).0 points

-

Unfortunately the Laco watch I serviced earlier stopped on the bench and it took me a very very long time to sort it out. The issue with the Laco was that the bearing of the center wheel was worn out and I have not realized that because I did not know this movement and I am not experienced enough. It was actually a bit suspicions when I put it together, but I was a bit tricked as I thought that the movement was a working one and indeed it was working until your luck ran out. The center wheel had too much side shake so depending the position of the watch and what sort of forces had an effect on it when it was moved on your wrist or otherwise it was ticking or not as my tests proved it. Because I thought it was a perfectly working movement when I received it and it was actually running I took it apart again and again thinking that I made a mistake somewhere. Better to say I took it apart completely two times and cleaned and lubricated two times and then when I realized that there is a problem with the power transmission I replaced the mainspring first, but did not help, then I took apart the train wheel a countless time... as I thought... thing is that the center wheel has its own bridge... can be taken out only if you remove the rest of the train wheels and also the barrel bridge, but it is still part of the train of wheel... so when I say I took apart the train of wheels it is only half true... the center wheel was not taken out... Then I asked the Hungarian watchmaker community for help at the same time I fired up my eTimer which is a beautiful piece of timing software came with an outstanding very sensitive microphone. The long term test showed an hourly fluctuation in performance... and what turns once every hour? Yes, the center wheel.... Luckily cousinsuk had brand new center wheel bridge. With the help of the community and eTimer the problem is sorted. I am very very happy about it, it was not just because this watch belongs to my best customer... it was a question over my head asking me constantly... why are you doing this if you cant even fix a simple watch? Before: After: Center wheel side shake: Phew...0 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)