Leaderboard

Popular Content

Showing content with the highest reputation on 11/05/23 in all areas

-

Hey all watch peeps. I thought a great idea for a new regular thread that would help the tool collectors among us ( which is pretty much all of us ). I've had a few wins just lately and I'd love to see the rest of us take something back from the Bay as well. I spend some time looking for bargains and often see stuff that i already have that would be put to good use by other members that i know dont have them or are saving up for something in particular. After a fair bit of practice I've started to get a feel for a sale outcome, often putting in last hour offers below starting prices that sometimes get accepted or cheeky offers on relisted items that initially get overlooked. Its just about drawing members attention to a potential bargain and can even be aimed directly at a member whom you know is searching for a staking set or a jewelling tool or whatever. Members could post up what they are searching for, regular ebay scanners can shout out a sighting or something else that might be of interest.1 point

-

1 point

-

End shake must be checked when the wheels are free of tension. Release the main spring and check it - I guess it will be OK. The problem is not the end shake, but lack or bad function of some of the clicks in the winding movement.1 point

-

That's a very early example, and someone has adapted a pulley to it. Originally the pulley would be clamped to the part itself, and turned with a bow. Later versions have the pulley as part of the headstock, with a screw adjustment to position it so the drive finger makes proper contact with the wheel. If you need to work on a part that doesn't have a wheel, like a bare balance staff, you use little fish-shaped clamps that can be driven by the finger. In the pics you can see the headstock end of a modern tool, the knurled knob at the far left moves the pulley along the headstock runner for positioning. The runner is a simple bar with concentric V pip in the end for the pivot to ride in. There are different sizes for different pivots. In the second pic are more traditional yet still "watch size" drive dogs, some clamp-on drive pulles, a set of the "fish" with the tool to open them, and some other drive runners (top of pic). Those have slightly tapered shafts and are to hold parts with holes through them. The ends are female cones and they would be held in a dead center lathe; these are useful for working on hour wheels for example- but nothing to do with the Jacot.1 point

-

Hi gents, I've been out of town in business trip, so before I left, I took the watch to a local watch maker, he took the pallet fork and the balance wheel and in under 1 minute the movement was ticking . He really made it look easy. I don't know how he did it, but he did. Good news then. The movement has all the pieces it needs to work. I left the store so he could build the remaining parts and complete the watch, since I was in a hurry and had to leave town. He told me he had quite a few services in hands, so it could take a while. I said no problem, I'm not in a hurry to get it back. Thanks all for the kind input.1 point

-

Ok, so... no. That's not it. Tried all four positions and it never runs true. I also couldn't see any off-centered-ness of the arbor square itself. I'll have the new ratchet and arbor towards the end of next week, I hope.1 point

-

Hi @JohnR725! Once again many thanks for taking the time to reply in such detail! Oh dear... that doesn't sound good. Perhaps I was heading down this path too. However I did have a strategy in mind: Movement - I started with a mostly intact 752 and wanted to restore this properly. At worst, secondhand parts or removing rust from existing. Case - 166.053 I purposely chose one that would have had a 752 to begin with. This is a one-piece case so I don't have to worry about a case back. It came with a crystal which I "choose" to believe is original. Im not sure how these movements are retained in this case tho the movement came with a split stem and one case clamp. For the purpose of this project Im locked into whatever 166.053 would have come with in the wild. Dial - unknown. This is where I think the project might break down. I do not know if I will be able to source the correct dial for this case or if there are substitutes. This is on me and I wouldn't be asking the forum anything other than "do you know possible part numbers for dials for this case". Hands - Honestly, I was going to go with whatever fits for the moment.... I certainly don't want to annoy people here. This might be a slow burning project till I can source the parts I need - or, sadly, may have to be abandoned if it proves grossly uneconomical to finish (there is an element of fun in all of this so Im willing to accept reasonable cost overruns). Your answer has been immensely helpful if only to inform me that the problem is a lot more complicated than I first thought. The information you have provided here is outstanding and has given me a lot of insight into how to search for Omega parts going forward. There is a lot to take in here so let me digest and see what I can find - I will post some better (angled) pictures of the setting when I get chance. Otherwise the movement has been through the cleaner and actually looks great considering the amount rust it had on it. I would love to get it running. Thanks again, Bob1 point

-

Nooo, dont regret it, buyers remorse is the worst, depends what you paid for it. You'll figure it out, the clone anvils do fit, the quality isnt great but they can be improved with a little work.1 point

-

You have all the reamers which is good as long as they are in good shape, i know the reamers are quite available if not. The reamer sprindle looks to be missing though. All the pushers with my 4mm horia clone fit my seitz pusher spindle and the 4mm clone anvils fit the seitz base, not perfectly, but useable1 point

-

There is much missing - unless you have a source to economically replace pushers you would have been better off investing in a more complete set IMO… …the pieces need to be sorted to their correct place so I can’t tell how useful the set will be for you but if you have the more commonly used sizes for the movements you’re servicing there’s some utility there…1 point

-

Did the Ebay photos show anvils or did the description say they were all missing? I'll admit that I would be a bit dark if that happened to me.1 point

-

Please let us know if Nev was right, its been bugging me since you posted the question1 point

-

1 point

-

That sounds possible and would be the solution to the mystery why on earth it was fine before my service (because I'm sure I'm not able to reshape a wheel or move it's center). Still pretty bizarre! Could it have come from Tissot like that? But I'll try the four positions!1 point

-

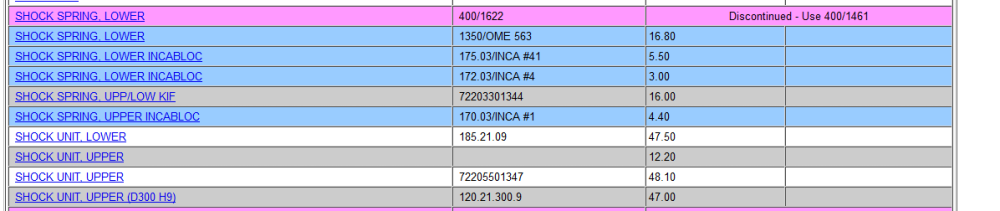

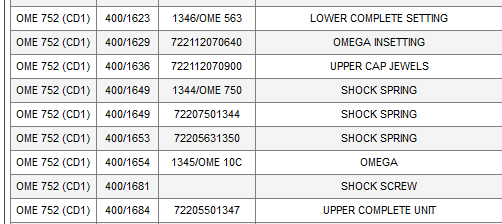

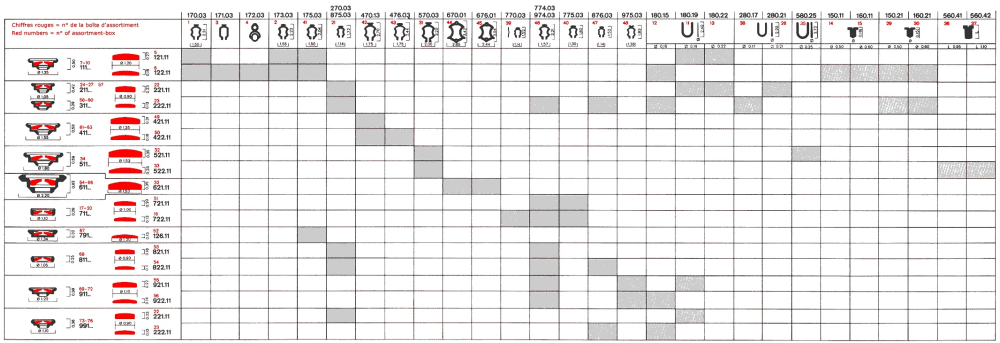

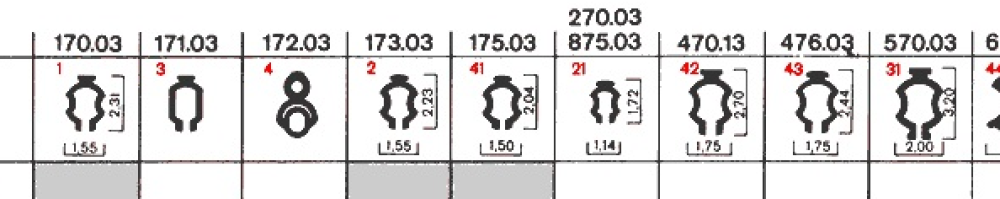

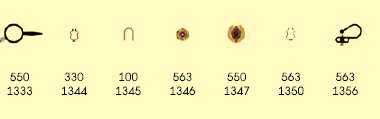

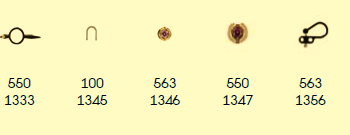

It looks like from the images your rusty movement is cleaning up quite nicely. I've inherited a few rusty Omega movements over the years and they are never going to look as nice as yours looks. Just a little clarification here? Last person on the group claimed to be restoring a particular Omega watch reality was trying to mix and match whatever and whatever it didn't really work well for us or his discussion with us. In this particular case you appear to be restoring a particular Omega watch and you would like to restore it back to its original condition? That we can work with as you're not going to be mixing and matching things that aren't quite right. It sometimes very hard to help somebody on discussion group if for not sure where they're going in other words let's combine several different Omega watches and make one that is going to be a nightmare versus let's see if we can restore this watch. Yes the sad reality of watches getting cannibalized and the parts worth more than the watch itself. So yes looking at the parts list that does appear to be the correct part number. That is if you would like the Omega part may be the generic part would work just fine as they would be identical except the rose gold spring would be gold plated instead. This is where the website at the link below comes in useful. So far everything seem nice and straightforward until my brain is tired and yes I know you had pictures provides it didn't quite stinky and right away. So yes we have a problem or you have a problem that let's see what we can do about it. For instance this is a main plate from an Omega watch supposedly yours but doesn't agree with yours doesn't? That's because Omega has upgraded and it should be reflected in the parts list but the cousins parts list will be out of date and it's not always reflected in the newer parts lists. So for the particular main plate up above this is what the spring would look like the hold the jewel assembly conveniently missing from yours. Then just to make it clear for everybody zoomed into your image of what you're finding which agrees with the plate and the spring but unfortunately doesn't work for your watch at all does it? Then from your plate I don't suppose we do have a slight angle shot I can't see if there are slots or cuts in the outer edge I have a suspicion what it is but I can't quite see it. But no matter what it is not the same jewel assembly as found in the watch above Then to add to the confusion let's look at the parts list found at the link below and as a heck of a lot of parts which tells us what we already know revisions. Then from another websites because sometimes they get updated in different orders see if they make any better sense of this mess. Now another image for Chamblee we can use generic if we can figure out which one it is based on the parts list numbers or possibly we can use an Omega once again a figure out what were looking Let's zoom in on the part of the image above Okay so the old uses 172.03 which will not fit on your watch at all. But as a guess 175.03 should fit that's why you need a slight angle view as it looks like there should be a slot for that to go into. Now we just need to figure out what jewel of those with that spring or if you're like on eBay look for a new hairstyle one? But I'm reasonably sure of Omega doesn't necessarily change the part numbers because in stock that have the newest and not the old parts and on eBay it could be new old and as you find not entirely the right one of Oh and this is where if you had a friendly material house to talk to you would explain your problem and they would get you the right part. Where online doesn't necessarily explain all of this. Yes there really are physical material houses existing in the world some of them not online You can try a process of elimination and I'm somewhat guessing it may be perhaps this http://cgi.julesborel.com/cgi-bin/matcgi2?ref=X\ZDXJUH Only because it has a different part number. Then how about some more confusion parts list yours is Yours came from 2013 mine is slightly newer and 2016. Let's look at the parts images Let's look at yours should be identical but they're not. Notice how you have part 1344 missing from up above. Then you don't even have the older spring is your list is newer than the older one. It's the problem of revisions of the main plate. Cf. yet the right part for the right age of your. Plus of course notice how the part numbers for your lower jewel assembly are identical when they're not very unhelpful and no I don't know if you can substitute a newer one for the older one I'm guessing not. Plus and thinking from the way the picture shows in the way the parts description is in a newer style it may be an entire assembly that doesn't actually come up and perhaps I'm not sure if my answer is of any help at all because I'm not actually sure what you should be purchasing other than what you should not be purchasing. If you do take the 400/numbers you can go to the home page of the company at the link below and do a search and they come up but the description sucks and there's no pictures. Then because the physical bestfit book is too old none of these tools are listed either http://www.julesborel.com/s.nl/it.A/id.24948/.f Not sure how helpful is going to be a big problem is it's older So with a foldout what it isn't. You should build get an aftermarket setting but we have to figure out what it is and I'm not quite sure how to do that. Then whoever you purchase from on eBay has to have the newer version obviously which of course will have the exact same part numbers the older version. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=OME_7521 point

-

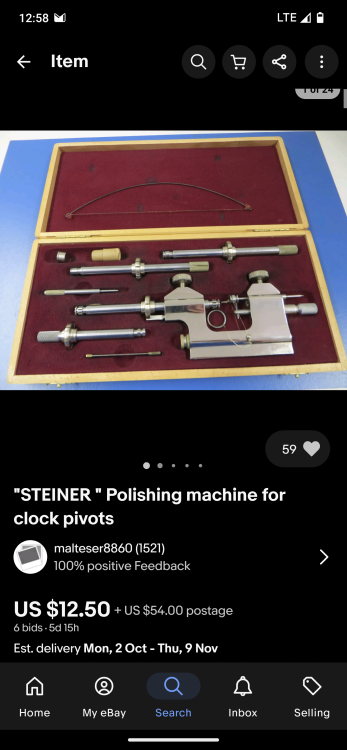

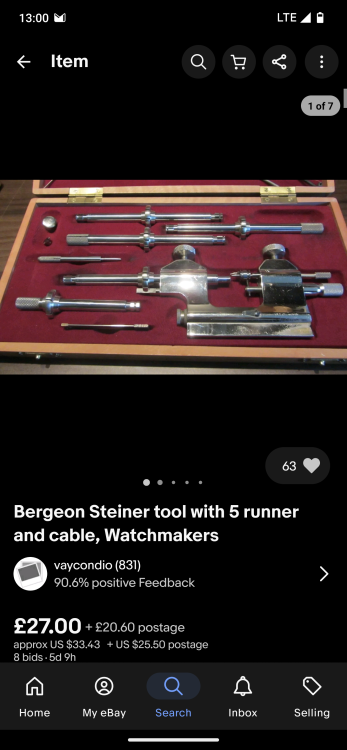

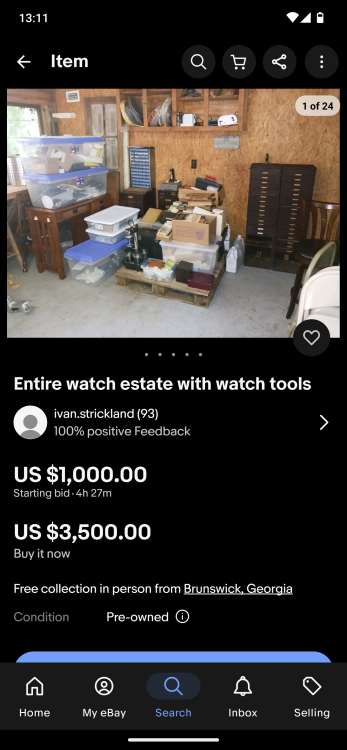

Still a long way to go, but look in great condition and could turn out to be a bargain! https://www.ebay.com/itm/166329068623?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=R53hS8XlR-m&sssrc=4429486&ssuid=WLDexrgWSNe&var=&widget_ver=artemis&media=COPY https://www.ebay.com/itm/266403540790?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=oURkpKIDSk-&sssrc=4429486&ssuid=WLDexrgWSNe&var=&widget_ver=artemis&media=COPY And if only I lived there!!! https://www.ebay.com/itm/175895318421?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=0w7DrVfQQlS&sssrc=4429486&ssuid=WLDexrgWSNe&var=&widget_ver=artemis&media=COPY Watch cleaning machine and staking set, press etc.... A steal!1 point

-

1 point

-

It may have been a solution to fix a bad manufacturing batch of ratchet wheels or arbors0 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)