Leaderboard

Popular Content

Showing content with the highest reputation on 11/06/23 in all areas

-

If we put this into perspective, we have Lee, a relative beginner like many of us here by the sound of it. He may or may not have the specialised tools to fix this in the proper professional way . Needing a jewelling tool ? a staking tool ? , a jacot ? or maybe just some parts that fit correctly. A shim under the balance cock may fix it, it doesn't have to be a permanent fix and its clearly reversable, nothing altered in the watch so no harm done. No its not proper its just a bodge. We get what John is saying, it might fix it but the actual fault is still unidentified, will Lee learn anything from it ? A bit maybe as long as he understands its not the actual solution , which I'm quite sure he does. The thing is to learn whats really going and why a watch behaves in certain manner, and a harmless bodge or two along the way can be forgiven . It can even teach us what not to do. Yey so we're all winners3 points

-

3 points

-

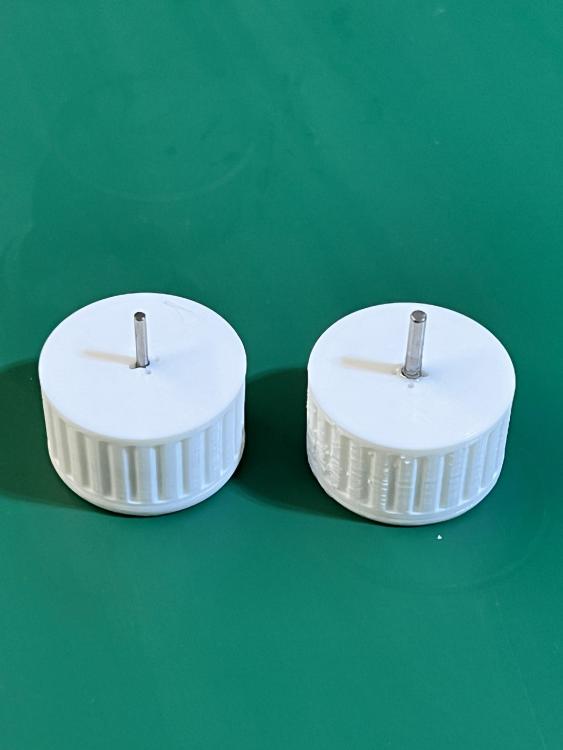

I have been using the 3D printed winders designed by zero and I am coming to believe they are an excellent option. Even with less than optimally printed parts from my local library, I achieved success after some practice. I have not used traditional metal winders but my suspicion is that it would take a similar period of trial and error before becoming proficient in their use also. I recently purchased two bases, from Andyshap who sells sets on eBay, as the bases with the small holes designed to accept the staple ‘hook’ is the most critical part from a printing accuracy standpoint. Andy’s parts are well printed (photo below), prices are reasonable, and he is a pleasure to deal with. The barrel, plunger and setting base that the library printed were easily good enough to work as designed. The greatest difficulty I’m having with the 3D printed winder is the initial setting of the spring into the drum such that the tail of the unwound spring exits through the appropriate aperture. The wall on the 3D winder being so much thicker than the thin metal wall of a traditional winder makes this initial alignment more difficult. For the price, and ease of procurement (not having to trawl eBay waiting for a good vintage set to turn up) they are tough to beat!3 points

-

I get my fix by helping the members out on this wonderful site. I'm still learning new things on here all the time and I was working on high grade clocks mostly for nearly 30 years.2 points

-

I see I was neither clear to understand nor correctly explained everything in detail as you would John. I am terribly sorry. Best regards2 points

-

The voice of reason! I appreciate all the help and advice. I am totally new to this. I had never even opened the back of a watch until a couple of weeks ago. I will try other "proper" solutions, but if the shim is the only option available to me (without getting into advanced techniques or buying expensive tools) and it gets the watch running I'd be pretty happy. If as a total beginner I manage to dismantle, clean, lubricate and rebuild a watch that wasn't running when I started, I'd consider that a win, and I'm certainly learning a lot, even if its just beginner stuff. I have watched some videos on end shake, but sounds like I should probably revisit them! Thanks all, Lee2 points

-

2 points

-

2 points

-

Hi Lee, If the diameter of the enstones is correct and they are placed with the flat surface towards the pivots, the free play will not change, no mater if the stones are thicker or thinner. If the stones are smaller in diameter, they may not rest on the ‘nest’ in the setting and may lay directly on the hole stones, thus reducing the free play. The same may happen if the stones are placed with rounded surfaces towards the pivots. You must check the free play of the balance – it should be the same as of the lever or escape wheel for example. Just slightly move the balance wheel up/down with tweezers and observe the free play. You should look at the distance between the hairspring collet and the cock, but not at the balance wheel itself. This distance must slightly change, showing there is healthy free play. What @Nucejoe advices – to untighten the screw of the balance cock – it not always leads to increasing the free play. I will advice to do the free oscillations test – remove the lever, the balance in place, turn the balance wheel to 180 degr. and release it to oscillate free. Count the oscillations to full stop – for a watch like this, they should be about 100 in horizontal positions. See this video – the oscillations count there is more than 200, just to see what I mean and how the oscillations must be count2 points

-

2 points

-

As a test, Loosen cock screw to release pressure on pivot. To create end shake one can shim the cock, or mainplate can be gauged or move the settinig. PIvot end wouldn't know thick or thin end stones apart. Rgds2 points

-

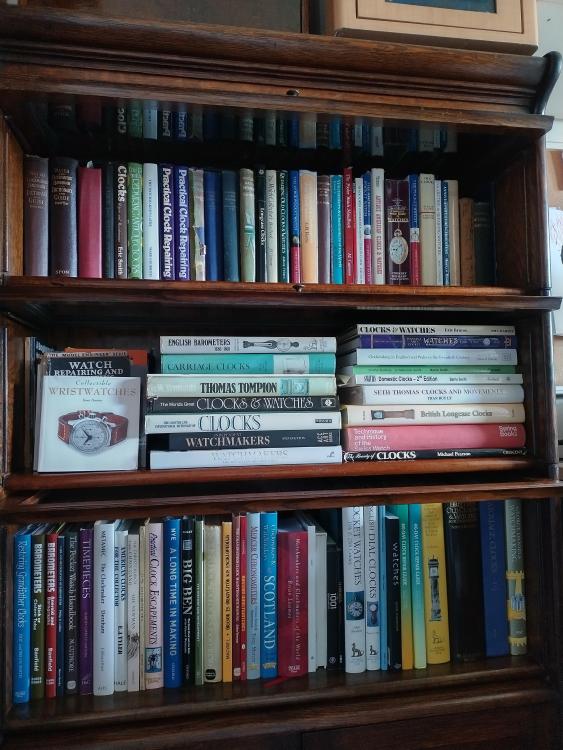

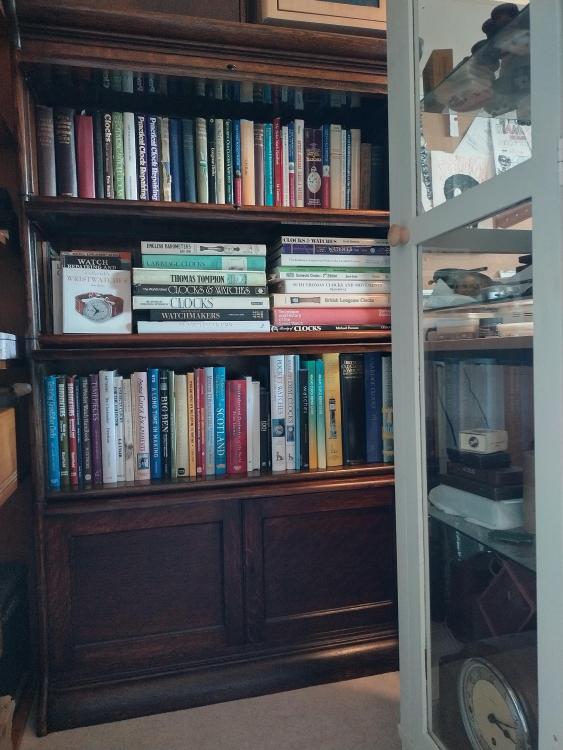

The file rest was not needed this time. Only reason is there because just like with the lathe I had to take it apart into pieces, clean it bit by bit, lubricate it and putting it back together, in one of my lunch time I quickly put everything I cleaned together, its a very fresh setup had no time to play with it much. The file rest came with the lathe, but I got no T-rest or collets so I had to borrow them from another 8 mm Lorch lathe, the one which seems to be a dead end project. A slide rest also came with the lathe, but had no time to clean it yet. However I spent some time to clean and restore a very nice book shelf so the books which were just piled up in my room on the floor finally got a nice place to be:2 points

-

The reamer spindle sits in a hole drilled into the side of the wooden block Rich Tom2 points

-

Just found another youtube video with a Superocean being serviced. Very clear images of it with the bezel off were present. So I have answered my own question: Yes, the screws are functional, and they have very noticable lock-tite on the threads. So I will soak them in an appropriate solvent and then see how much damage the inner spring suffered. Thx to all2 points

-

Its great to learn and with this hobby there's a great deal to learn, you can always revisit the watch and give it a proper seeing to when you've bankrupt yourself buying tools. Oh wow did i just give you a horology headbutt i do apologise Lee Lol just messin with you Nev. Anyway under the cock dots, in the Uk thats a type of after dinner pudden known as 'spotted dick' . i shall jest no more, horologically known as gouging. Still Joe, the gun joke was funny kinda.1 point

-

I just clame, that in some cases the untightening of the screw leads to increasing the free play, in some cases to decreasing, and in rest of the cases doesn't change the free play. What will happen depends on many things, like if the fixating pins are straight or bent, if bent - in which direction, are there under the cock 'dots' made by punching with sharp punch for 'adjustng' the free play and so on.1 point

-

OK, nothing too exciting here but I wanted to post something to show I am progressing...lol. This belongs to a friend of mine...a guy that used to work for me. It was his grandfather's watch and he was very close to him. When my buddy found I was doing watches, he asked me to fix it (along with three other watches!). This was the most interesting. The service was uneventful except for a busted mainspring. I found one on ebay from a guy have bought from several times before--a good vendor. Now, this is an automatic, so I used my YamaLube for the breaking grease. However, since this is a NOS modern mainspring, I did not do any additional oiling. This may be controversial as some say they come lubricated and others may disagree. We shall see. I had some trouble putting the clip on the oscillating weight. At first, I did not see that the arbor had to be aligned to the kerf in the weight. It was rather difficult to see! The microsope revealed the truth. The case ring was quite unusual as it had the gasket embedded in it--something I had never seen before. It was old and dried up and flaked into the workings of the watch. I had to thoroughly remove the residual gasket material. I did not replace the gasket so will warn my friend that it is not going to be waterproof. It is running and keeping good time.1 point

-

Haha how did i know you were going to say that Nev ? We can go on all night with this. Give the cock a tug with a bit of rodico . Btw i dont actually give a monkeys if that sounds rude Haha Joe really thats getting close to the knuckle mate.1 point

-

1 point

-

Haven't you noticed I do that a lot. Perhaps you're misunderstanding or were both misunderstanding is it a temporary diagnostics or is a considered a permanent solution to some unknown problem? Because typically on these discussions shimming is recommended and that seems to be the end of the problem. Perhaps with the problem for both of us would be let's look at the individuals who recommend shimming if shimming fixes the problem would you consider that the fix or are you using it as a tool for diagnostics? Then I would still prefer people learn how to check for end shake and recognize what it is. Plus learn how to do just the general checking of does everything look right. Does the balance wheel oscillate if you gently shake the movement for instance as opposed to oh dear my watch doesn't run I didn't see this coming. Not that we don't all have that.1 point

-

I think you misunderstood @JohnR725. I for one know that shimming isn't the answer and checking for end/side shake is of importance but using a shim as a temporary measure may be used in diagnosis. For example, the balance doesn't run freely, once shimmed it does, probably end shake is the issue and needs to be addressed. I am still an amateur with much to learn so correct me, if I am wrong. I amongst many value your advice.1 point

-

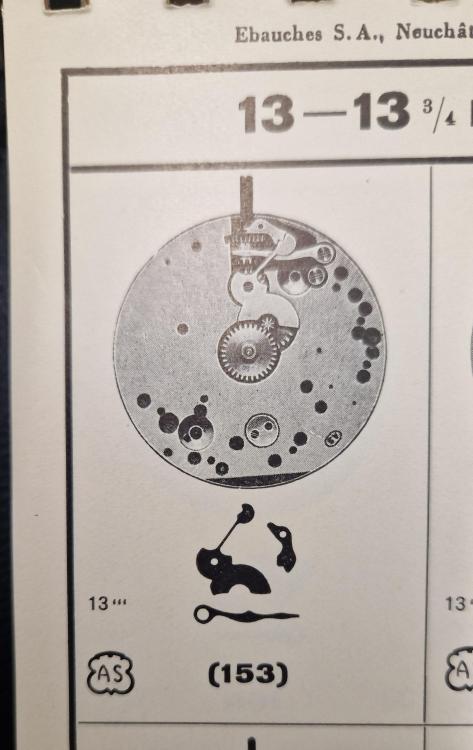

Peseux 70xx series, maybe a 7040 or something like that. They're nice movements.1 point

-

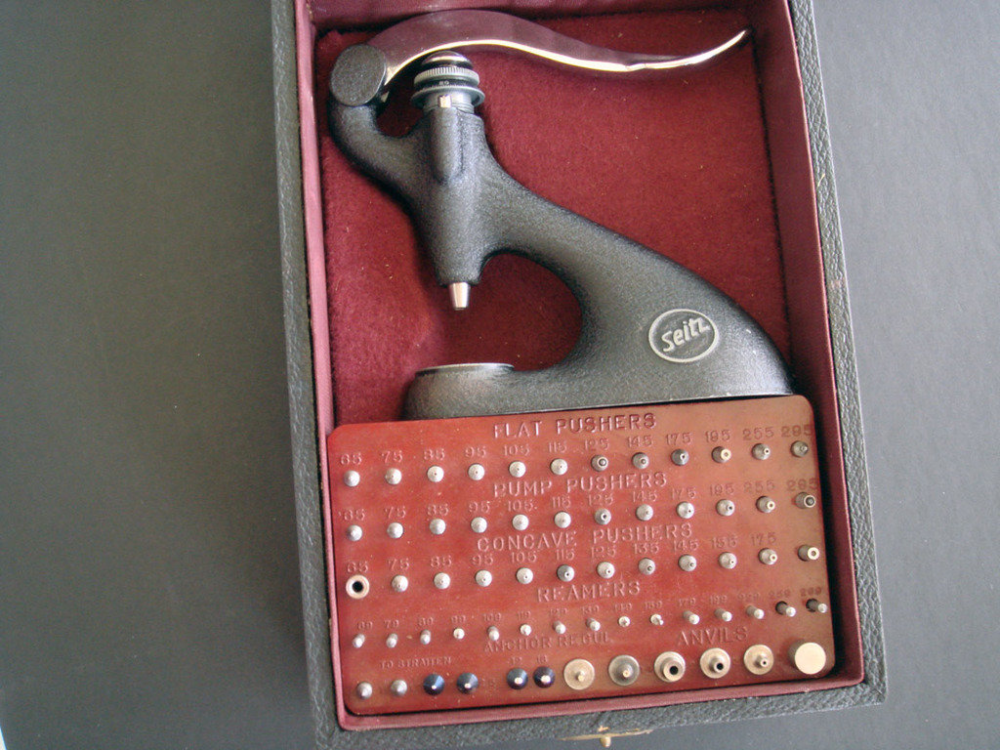

I don't need to watch the video to see which is best. I know and I had the Seitz complete set. I was given to me by my master when he retired.1 point

-

1 point

-

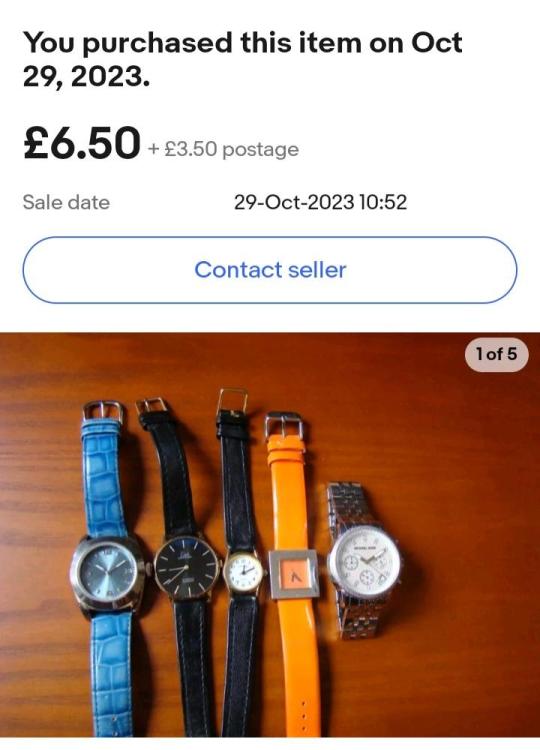

Haven't posted a 404 for a while, but i snatched these up last week for a measly £6.50 for 5 watches. Technically £1.30 each, i feel like a cheat as 3 of them are garbage, well 4 really but i need at least 2 to get within the specified. So i would have to pick the Limit and the Michael Kors ( yes shock horror a fashion watch ). The Limit visually case and dial is in perfect condition, inside i suspect a broken click spring as the click isn't engaging the ratchet also the timesetting is extremely sensitive so possibly the cannon pinion needs a little tighten. The MK i thought might just have been a fake but it is actually genuine, inside is quite wet , not totally sure if its water or battery leakage, seems too much for acid but there is no rust either. New movement is around 12 quid, not bad for a 150 quid watch . The mineral glass is scratched up and the bevel edge is chipped in places, so that also needs changing, but i fancy a go at dressing out the scratches and re-shaping the bevel if anyone has an idea. Not sure how i managed to post this in the wrong thread but I'm not writing all that again1 point

-

Thanks for this. The end stones I was using are very slightly smaller in diameter than the original ones I lost. I think they are not so small that then can drop below the lip of the chaton "nest"), but the ones I will try next are a little bigger and certainly that shouldn't be a problem then. The end stones are certainly the correct way up (flat site inside the chaton). I will try the free oscillations test when I get it all back together. Thanks Lee1 point

-

I just purchased the E25 from Aliexpress. I can confirm it is a very well made and precise press. It only comes with a couple of flat faced aluminium dies, however. Can anyone recommend a good set of dies they have purchased from Aliex? I have some mineral glass crystalled watches but could see myself also going for something with acrylic crystals. Thanks in advance.1 point

-

I see that somebody else mention the spindle is always hidden. Which brings up a problem on eBay where the typical seller has no idea that exist at all. Personally for me the most important aspect of the tool would be that the reamers Are in good condition. As typically and that is the only purpose I use the tool for. Before you start rushing in purchasing things for your tool did you notice something different about it? I don't know if anyone else noticed there is something a little bit different about yours well there's several things must compare with what we normally perceive is a normal one Identical tools except they're not. Not obvious unless you already know what you're looking at seeing as how I have both of these. Yes the early days were these things were considerably cheaper and purchasing two of them would allow me to make one good one kind of. The amusement of things you cannot see in the pictures. The tool on the top is made out a cast iron I believe it's solid cast iron it's rather heavy. The newer generations are made out of cast something is as rather lightweight although I've never heard of anyone breaking of it. Then I don't know how many variations of these exist? What you want to do is measure the hole in the base and then asked somebody on the group to measure there's and make sure the size is the same before Ordering anything them out in the base if the whole is not right. I don't remember what size mine was but it was modified to fit the modern pieces. I've also attached the book C can see all the exciting things that ritual is supposed to have. Seitz book.pdf1 point

-

Was mooching around the internet and Ali Express helpfully popped up with an add for the Weishi TS-1, I haven't seen this before and there seems to be little information for it on the web. I think it's a replacement for the Weishi 1000, but this is just a guess. Just out of curiosity, not thinking of getting one, does anyone have any information on it?1 point

-

Looks a little like the set I got, but I think I was a bit more fortunate with the parts, I made up my missing parts from CousinsUK, (link here) the missing bits range from £5-10 each so it could be quite a chunk of change if you wanted to complete the set, but as other have said, if you only replace the commonly used buts you could do it for much less than this, or maybe pick up a set on line and make one good set from the 2?1 point

-

Lexacat will be pleased to here that Tom lol. I hope its there for him . Its one of the reasons i wanted to start the what tools does ebay have to offer. Anyone looking to buy from ebay can get advice first before dropping their bid, here lexcat could have been adviced to ask the seller for confirmation that the reamer is in there. Its another 40 quid on top if he has to buy a new one. Getting hold of the anvils might be an issue as well, but as we know the buying doesn't usually just stop at one of these. A lot of the time its about avoiding unscrupulous sellers. Anyways heres a little lot i picked up over the weekend, likely i was up against one or two of us here, apologies if i pipped anyone to the post. A couple of things i was after in particular the rest are a bonus, one or two might be up for tool of the day mystery. Have a great day everyone and more importantly stay safe out there.1 point

-

The store owner was great about it. Combined the things I wanted into one listing and then I only got charged freight once and not six times like before. SO some tools for watchmaking are now winging their way to me.1 point

-

This is an 'educational' video of how 'master watchmakers' work in some countries. Not for the faint-hearted. @oldhippy had nightmares watching one of his other videos on clock repair.1 point

-

Hi Richard, Thank you for your input. I will get the watch back from my watchmaker friend next weekend. I looked at an Avenger, the bezel is very dissimilar to the one on the Superocean. The one on the Avenger looks quite similar to the one on the Chronomat. I have handled those a bit, and my experience is that on the Chronomat the screws on the bezel hold the makers in place, but I didn't think they held the bezel to the case. I am not sure about this, but that is my recollection. I have attached an image of the model of watch that I own. Above the crown you can see one of the suspected "faux-screws". There are 6 such at each 60 degrees in the middle of the coin edge. It may be that they are secured with lock-tite. When I get it back I will lightly soak these "screws" with a 50/50 mix of acetone and alcohol and see if they still resist loosening. I used to do camera repair and this was the routine for balky fasteners on lenses. I appreciate you taking the time to reply. jimmy Hi again Richard Just watched a youtube video on taking the bezel off a Blackbird (very similar to the Avenger and Chronomat). You are entirely correct, on this style the bezel is fastened with the screws. What I am not sure of is whether this is also true with the Superocean or Superocean Heritage? thx again1 point

-

1 point

-

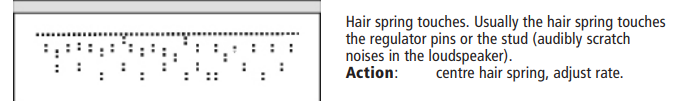

Hi here is the other document might be a bit advanced as yet but contains some good informatiom. witschi_training_course.pdf TM9-1575-War-Department-Technical-Manual.pdf1 point

-

https://www.omegawatches.com/en-us/watch-omega-de-ville-omega-ba-166-0053 Just a reminder something you are unaware of the case number isn't entirely as it appears to be. That really isn't the decimal point in a number it's really a separator in a number. That sounds confusing doesn't it but if you look at the link above notice how it's really 166.0053 for the case number. It's amazing what happens if you have extra zero if you're trying to find it. Now if you go to cousins a lot of times they'll have information but I'm not seeing this. Then if you not seeing what you want to find like the last digits are missing sometimes if you do a partial search you might figure out what the problem is But in this particular case I'm not seeing it? https://www.cousinsuk.com/document/search?SearchString=166 But there's another place to search. If you go to the search page here http://cgi.julesborel.com/ In addition to all those wonderful things you can click and places you can go there is a place for you to enter in something Like for instance ome cs#166. Notice the same thing as cousins I did not enter the last digits just to see what would come up and that's quite an impressive list and there is your case. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=OME_CS^166.0053 Oh and then there's the other amusement with omega you have an exact case number and what does that get you? What becomes interesting with case numbers and omega is it's more of a style number than an actual exact case. Not sure if that's how they actually word it but for some case in the past I looked up I think it came in five different materials. Then the problem with things like that would be that the crystal was not the same number for all the various cases. Oftentimes the crystals will have a ring but that wasn't the difference or his actual physical size difference for one of the cases. Then notice the case clamp number you can click on that and you get this Link http://cgi.julesborel.com/cgi-bin/matcgi2?ref=q[[N`K Tells you all the movements and all the various cases the case clamp is used on. Normally for one piece case like this this should be a ring inside the case that rotates. So you'd have your casing clamps on the movement the move but the drop into the case providing the ring is in the right place the ring is rotated and locks the movement in place. Don't worry are not annoying anybody here as you're doing it correctly. In other words are telling us what you're trying to do is showing us and giving us numbers and you're allowing us to help you because you gave us enough information that we can help you. Plaster giving us an update and that's fine. Unfortunately we all have projects that may take literally forever. That's not an issue either. Oh and it be helpful if you did a search for the number 752 you don't need to specify what watch that is and you get a list of things to look at as we've covered this watch before. I just now did a quick search and I see that somebody was having an issue getting their watch out of the case. But I see we got feedback it looks like maybe the case and you'll have to look at yours doesn't have a locking ring but instead the movement rotates. But in this particular case it didn't rotate when it was in setting position as the stem was out too far. https://www.watchrepairtalk.com/topic/22323-omega-cosmic-752-movement-stuck-in-case-what-would-your-approach-be/#comment-188343 Then one of my annoyances with the search feature is finding things with titles that are not appropriate. Or in other words somebody didn't put their watch model number In the title and not finding something else that you might need eventually.. But we don't worry about that for the other day.1 point

-

Cool makeshift set up buddy . I think your filing rest is at the wrong end though . I love the bench and the lighting .1 point

-

1 point

-

Matey, i think you just need to take a close picture of each of the pallet fork pivots for everyone to have a look. We all just guessing here, lets rule something out and then move on.1 point

-

It looks to me like you haven't got the pallet fork lower pivot located in is jewel hole.1 point

-

Hi if the pallet is wobbling when fitted. Either one or the other pivot is broken off or there is a loose jewel.it should have minimum up/ down (End shake). Or left / right. ( side shake).1 point

-

I retired from watch & clock making years ago due to poor health. I sold most of my tools and all the parts I had at that time, I wish now I still had it all, but I would need a bigger home or a very large workshop to keep it all in.0 points

-

My Seitz tool doesn’t even have a micrometer at all. I think I will still get a horia clone. Tom0 points

-

I used to do woodworking, but gave it up. I was using a chop saw to cut some rough lumber and (unknown to me) someone had driven a nail into one of the bits of wood I was cutting. The saw blade snatched on the nail hidden in the middle of the wood and flung it back at me, after it ricocheted off the back guide of the saw and bending it, I escaped with 3 broken bones in my hand and was lucky. I tried to go back to it, but couldn't shake the fear that it could happen again or worse, spoiling the whole hobby for me. Watchmaking is much less stressful, until I persuade Mrs W to let me buy a lathe I suppose!0 points