Leaderboard

Popular Content

Showing content with the highest reputation on 11/07/23 in all areas

-

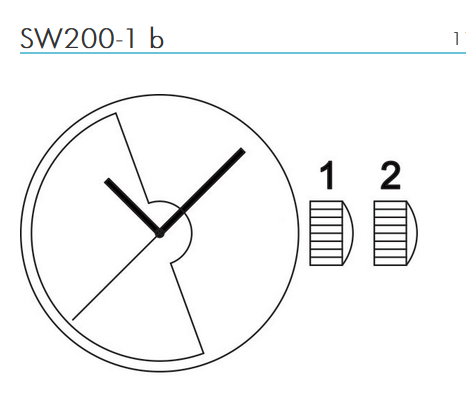

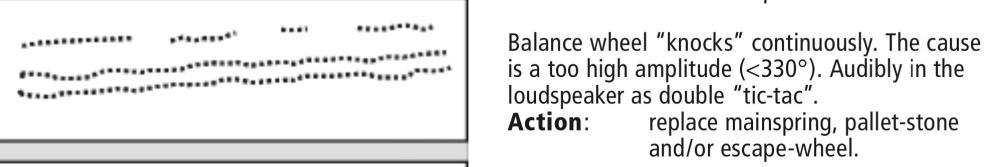

This question was asked multiple times here … Reason is usually a faint 1st pulse of the tic noise that is missed by the TM now and then. The TM will fetch and print the next higher pulse (usually 3 in one tic noise). This can mean an escapement issue (e.g. too small drop lock) but most times just an audio issue, the TM has problems to recognize a quiet pulse #1. It is not a touching hairspring (random dots!). It is not knocking (which in real looks very different from the posted picture). Frank5 points

-

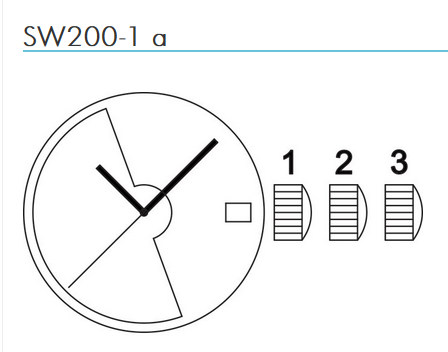

You may well find out that it's less of a "ghost" position than you think. The Sellita SW200-1 comes with a date complication. It's probably not cost effective to remove it for non-date watches so you may well find that under the dial on the non-date version of the watch is a fully intact date complication, the only difference being the date window in the dial.4 points

-

4 points

-

Is it a knot ? Or is it not a knot ? Ive had coils jump inside each other, you can work it up to one end, the cock stud end with a fine needle. Fried was a bloody master of hairspring untanglement. If i can find the video, i once counted the number of times he said tangled and untangle, it was a lot, yes I'm a very sad and strange individual . Hairspring 101 i think it was, let me find it and come back. No it wasn't 101 I'm talking out my arse, but this is Henry the hairspring wizard performing his mystical art . https://youtu.be/egCwtMMoOCU?si=4LDRlpfqWVXKUHET3 points

-

Just arrived today. Tissot Seastar automatic with a 2481. I really like the cushion case and this may be my daily wearer for quite a while. Some very minor adjustments only. Added a Barton silicone band that is extremely comfortable on the wrist. I need to look up the serial number but must be early to mid 70s.3 points

-

I get my fix by helping the members out on this wonderful site. I'm still learning new things on here all the time and I was working on high grade clocks mostly for nearly 30 years.3 points

-

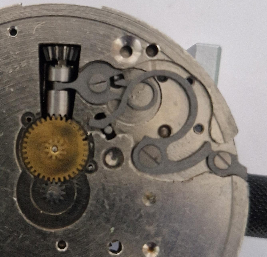

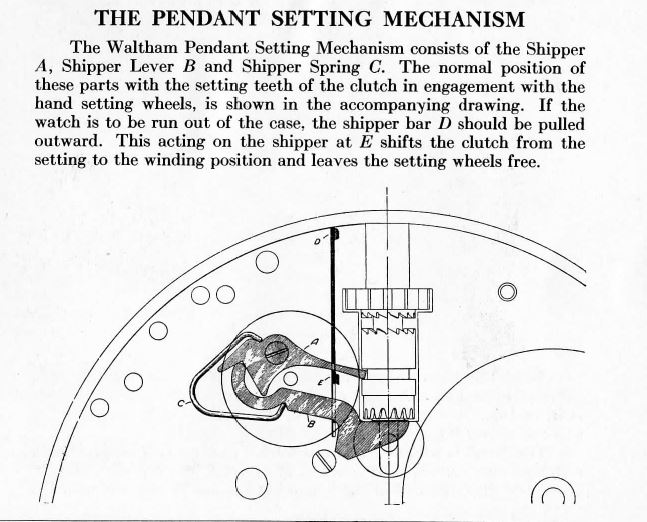

Once again were dealing with confusing terminology. Evolution of watch setting? At one time you had a key to turn the cannon pinion. Early watches that was on the front side later generation was on the backside evolution sometimes was on both sides. Then to get away from that they start to go to different systems lots of different systems. This is where you find things like the lever works nice for putting it in different modes like when it's in your unwinding of what's out your in setting. Makes it much easier to make the watch with the added bonus of keeping you from setting your railroad watch. So in the case of railroad grade watches pocket watches it is a requirement to have a lever for setting to keep you from accidentally setting the time Here's an image that I swiped off the Internet of what the lever on a lever setting watch would look like. So typically you would unscrew the bezel but not always you can have hunting cases where you push the button the lid opens up. But you'll typically see a little piece of metal that you use your fingernail to pull out the watch will go into setting. Then the evolution of winding and setting where the case holds the stem. Usually with the sleeve it holds the stem in either the winding or the setting position that is not controlled by the watch itself. Which becomes a major problem if there's a problem with the sleeve or is not adjusted correctly or they can be a big pain if things are right on your case. So this means that typically American pocket watches out of their case go into setting mode like this image that I swiped from up above. So you can see in this mode when the watches running it is driving the setting components sometimes it will do that quite nicely with no apparent problems and other times depending upon how much friction it will definitely cause writing issues of some form. Then another image that I swiped up above the watch in the service mode you'll notice it has shifted the keyless components back into winding. Sometimes when you flip the lever you do have to push something in to shift the components they may not actually moved by themselves initially. So now the watches in service mode or mode work and run out of the case. Then as I previously mentioned like the evolution of the keyless lots of different systems. For instance some Hamilton watches have a blue colored screw visible on the other side that you rotate to put it back in the winding. Or for instance here's an image of how Waltham Does it.2 points

-

I managed to fix the second hand properly and it the issue has not appered again. Thanks2 points

-

2 points

-

2 points

-

I have tried several ways and the only way that seems to work is to remove the spring from the balance and staff so it looks something like this (you can leave on the stud): Then using an old oiler and starting from the inside from a position where the spring is good, place the oiler between the coils and then slowly work your way around the coils from the inside out until you work out the problem. This is MUCH easier said than done, and of course you have to replace the spring back on the staff and balance once you are done. I have tried several 'shortcuts' that always ended in disaster, so this is the only way that has any chance of success. Maybe there are some hairspring 'black-belts' out there who know a better way, but this is the only way that I have tried that works - albeit a huge pain in the ... to do.2 points

-

Were all learning here and we all make mistakes I'm not sure if this is a mistake or not There's no need for an apology2 points

-

2 points

-

2 points

-

I just clame, that in some cases the untightening of the screw leads to increasing the free play, in some cases to decreasing, and in rest of the cases doesn't change the free play. What will happen depends on many things, like if the fixating pins are straight or bent, if bent - in which direction, are there under the cock 'dots' made by punching with sharp punch for 'adjustng' the free play and so on.2 points

-

If one knows how to check endshake, which is so simle to do, then He will never put shime just to check if the endshake is insufitient. Furher more, it is good to understand if the endshake is correct or not, but not just to see if the watch works with the shime. And yes, my experience with guding newbies is that the most common reason for low amplitude is that they have done something wrong to the hairspring, especially if it is Breguet hairspring. If, for example, the locating posts don't hold tight, then the cock itself is usually heavy enough to press the pivots and cause the balance to stop rotating, if the screw is not tightened.2 points

-

I think you'll find this is probably quite common with a lot of watch companies. It's cheaper to buy one movement than several movements. I have the websites of the company that manufactures the movement and you'll find that the 200 – one comes in two versions. So this version as your so-called ghost position but that's for setting the date Then there's this version which is what you would like to have only two positions But there are problems with this description there showing. The reason for the problem is if I download the tech sheet for the one without the calendar I get the tech sheet for both of them. That's because in real life there's only one movement. You have a movement that has a calendar or you have a movement that does not. Sometimes when they do not they might even have a disk there that's just blank I've seen that we take the dial often there's a calendar disc. https://sellita.ch/index.php/en/movements1 point

-

Thanks, The tool came today and I must admit I'm impressed with the quality for $115 US. I've already used it to move a jewel .13mm (center wheel too tight on an eta 2472). Worked as advertised. Thrilled not to have to purchase a donor movement. To your point, both pushers and anvils are 4mm. Jay (levine98)1 point

-

I see somebody beat me to the answer. As some were up above it was stated American pocket watches out of their cases typically go into setting a mode. So people assemble the entire watch before worrying about whether it runs will find that they don't usually run well out of the case as the trying to drive the entire setting mechanism. So the watch companies usually but not always had a way of putting it back into running mode which is what that is for. The other reason for having this feature is the movements are typically sold without a case and then the case was available separately in this way the watches could be running out of the case when you're showing Thereto the customer. Oh and then each watch company typically did this differently so you not go to find the exact same on any of the pocket watches. Plus there tends to be an evolution so it's conceivable different watch companies may use different systems. Ideally when assembling a watch once it gets to the basics then you a check it on your timing machine and verify that it actually runs before making the assumption that it is going to run perfect. Sometimes it's even nice to just let it run overnight in that condition I do that quite a bit because I don't want to case the thing up and find a surprise of it wouldn't even run overnight for some unknown reason. Then you didn't mention did you clean the mainspring? Or did you replace it?1 point

-

Hi, the watches weren't runn8ng when i got them, cleaned them in lighter fuel, then 2 lots ofv99.9% alcohol They stopped on their own, I did check they still had power by seeing if they wound any more. Ah, I've got it in the other position, thank you.1 point

-

1 point

-

I don't know for sure but I think your reasoning is correct. I have a watch with only the hour and minute hands but the movement should have sub seconds. The brand probably bought a job lot of movement and adapted them for their purpose.1 point

-

If I correctly understand the terminology, by " knot" you mean Hairspring is not " kinked " or " bent " or " twisted" rather there is a " knot" . ie; only one circle of the coil has tangled, actually its done the 360 degrees then passed under itself. In which case detaching the stud from the spring is practically a must. Best to seperate the coil from the balance staff. Lay the coil on top of a white sheet of paper laid on flat star foam. Needle pin the collet through its hole onto the starfoam. Starting from the collet, run a needle through the circles of the coil, driving the knot to the pinning point until the coil is disentangled. Easier shown than explained. I have had 100% success with this approach. Rgds1 point

-

That looks to be an additional noise as the 2 traces from the escapement are complete. Whereas on justin's the pattern is being pulled from entry jewel trace, like the oscillations are unequal at different points.1 point

-

I do use the term 'galling' as well. 'Picking up' is a term that has obvious, immediate significance.1 point

-

@Michael1962 thanks, yes I know that feeling of a thread galling on an Inconel 718 part and costing several tens of thousands of dollars all due to someone skimping on an few pennies worth of copaslip. Now I remember that copaslip was banned in the North Sea after I moved to Canada, never clear why and rumors I heard said it was found to have carcinogenic properties, but this was just hearsay, this is of course after years of me elbow deep in the stuff. I half remember that we switched to a nickel version, I think - it was a while ago! However, seeing that it is still on sale, I now doubt if the stories I heard were true. I applied the lithium grease with a tooth pick, and just a barely visible thin film, I intend to do the same with the copaslip or nickel version.1 point

-

The process you are describing is called galling and is caused by the transfer of microscopic amounts of material between two sliding metal surfaces, especially if there is a significant contact force between them. If you Google anti-galling lubricant for stainless steel you will find a plethora of specialised products for preventing galling ranging from reasonably priced to out of this world expensive depending on how demanding the application is.1 point

-

1 point

-

Is there such a thing as a 3mm clone? I thought they were all 4mm. Some real Horias are 3mm. It's just the diameter of the base of the pusher/stump. I don't think there's any practical difference. Whatever you buy make sure it's 4mm so you can use new Seitz pushers if needed, they are 4mm and can be used with 4mm "Horia".1 point

-

1 point

-

1 point

-

1 point

-

Im somewhat embarrassed that I didn't think of doing that first - I tend to rely a bit too heavily on Google! Thanks again @JohnR725 this information goes way beyond anything I found myself. I will post an update if Im able to progress.1 point

-

Hi depending on how you cleaned the watches with and what you used to clean them with you should check the pallet stones are not loose as the cleaning agent may have softened the shellac holding the stones in place. Did both watches run before you worked on them.1 point

-

This must be costing Cousins a significant amount of money, and they should be supported not just by this community but by all businesses who are at the mercy of monopolistic practices. Surprised that they can't get other businesses to become involved as Intervenors. It's something we do when taking cases to the Competitions Appeal Tribunal.1 point

-

The Evolution wood and nail blades are great, they do them for rip saws as well. They have zero hook on the teeth which makes they safer when working with hard materials. Probably why waggy got into trouble a high positive hooked tooth would drag any material in hard for fast cuts on soft stock. Very lucky man Waggy, you were nearly with a couple of digits less to wag Ahha just the thing I'm looking for, somewhere in a watch book i have is a made up device of 2 wooden domed cups for clamping a watch glass. Nice bit of turning there rambo ( haha my nickname when i started work nearly 40 years ago ). Dont know if you use it but Peg. Polyethanol glycol , used to stabilise wood blanks for turning. I used to then dry them out in a microwave when the missus was out1 point

-

1 point

-

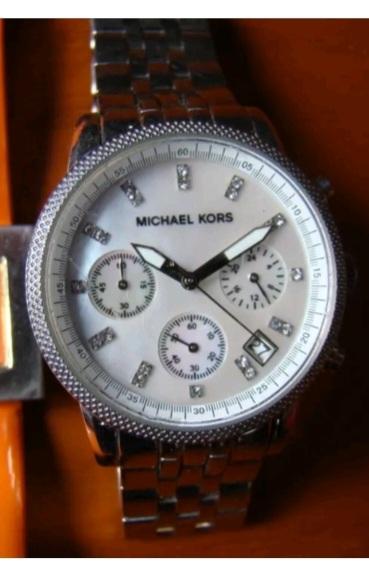

Haven't posted a 404 for a while, but i snatched these up last week for a measly £6.50 for 5 watches. Technically £1.30 each, i feel like a cheat as 3 of them are garbage, well 4 really but i need at least 2 to get within the specified. So i would have to pick the Limit and the Michael Kors ( yes shock horror a fashion watch ). The Limit visually case and dial is in perfect condition, inside i suspect a broken click spring as the click isn't engaging the ratchet also the timesetting is extremely sensitive so possibly the cannon pinion needs a little tighten. The MK i thought might just have been a fake but it is actually genuine, inside is quite wet , not totally sure if its water or battery leakage, seems too much for acid but there is no rust either. New movement is around 12 quid, not bad for a 150 quid watch . The mineral glass is scratched up and the bevel edge is chipped in places, so that also needs changing, but i fancy a go at dressing out the scratches and re-shaping the bevel if anyone has an idea. Not sure how i managed to post this in the wrong thread but I'm not writing all that again1 point

-

Hi Lee, If the diameter of the enstones is correct and they are placed with the flat surface towards the pivots, the free play will not change, no mater if the stones are thicker or thinner. If the stones are smaller in diameter, they may not rest on the ‘nest’ in the setting and may lay directly on the hole stones, thus reducing the free play. The same may happen if the stones are placed with rounded surfaces towards the pivots. You must check the free play of the balance – it should be the same as of the lever or escape wheel for example. Just slightly move the balance wheel up/down with tweezers and observe the free play. You should look at the distance between the hairspring collet and the cock, but not at the balance wheel itself. This distance must slightly change, showing there is healthy free play. What @Nucejoe advices – to untighten the screw of the balance cock – it not always leads to increasing the free play. I will advice to do the free oscillations test – remove the lever, the balance in place, turn the balance wheel to 180 degr. and release it to oscillate free. Count the oscillations to full stop – for a watch like this, they should be about 100 in horizontal positions. See this video – the oscillations count there is more than 200, just to see what I mean and how the oscillations must be count1 point

-

Message from Anthony Cousins:- At Long Last the Fight for Parts Supply is Going to the High Court Cousins battle with the Swatch Group is now heading to the High Court in London. However, after the ruling in Switzerland, the case in London commences with arguments that you might not be expecting. Anthony Cousins explains the details below:- It has been more than a year since I last updated you on our legal battle with the Swatch Group to overcome their refusal to openly supply spare parts. Doubtless some of you will think that we have gone quiet because we have given up, but nothing could be further from the truth. When we started this process, I made a commitment to keep fighting until we won the day, or had exhausted every available means. That fight has continued and has now reached a significant milestone. In December of 2021, the Commercial Court of Bern gave a verdict that ran contrary to the most fundamental principle of British and European Competition Law, which is that no matter can be decided without consideration of the impact upon UK consumers and competition in the UK. We supplied the court with overwhelming evidence to show that watch owners are suffering substantially higher prices for servicing and repair, are waiting significantly longer for their watches to be returned, have an extremely limited selection of locations where they can obtain service, and are frequently obliged to have work done to their watches that is not necessary and that they do not want. We also asked the court to engage independent expert witnesses to advise them on how British Competition Law is applied and decided. The Bern Court refused to consider any of that evidence, declined to employ any expert witnesses, and determined that Swatch was “objectively justified in changing its supply chain. In so doing, the Bern Court did not consider at all any of the evidence we provided on the impact of Swatch’s cessations of supplies on UK consumers and competition in the UK. As we reported in August of 2022, we appealed against this ruling to the Swiss Federal Supreme Court (FSC), pointing out in detail why the interests of consumers and competition are always paramount. Our experience of the FSC has not been good. Twice before the Bern court ruled in our favour, and on both occasions the FSC changed the Swiss Civil Code and found in favour of Swatch. Although our arguments were entirely correct, it came as little surprise when in September of last year, the FSC refused our appeal and found again for Swatch. It is outrageous that a foreign jurisdiction thinks it can alter the basis of a UK law, without even asking for any opinion on this from this country, and at the same time ignore a wealth of factual evidence that has been placed before it. I have no doubt that the Swiss judicial system is not a suitable forum to give rulings on British and European law, but explaining in detail why is an issue for another day. However, for you as the reader to understand what actions we have taken subsequently, it is necessary that you understand some basic points about why the Swiss had the right to rule on British and European law in the first place. Brexit had not happened when the case started back in early 2016, and an agreement existed between the EU, Switzerland, Iceland, Norway, and Denmark, called the Lugano Convention. This treaty deals with how cross border disputes between parties in the different countries should be managed in the courts, and in simple terms stated that all the signatories to the convention recognised each other’s judicial systems as being equal, and gave each other the right to rule using whichever country’s law was applicable. In our case this meant that a dispute between a British company and a Swiss company about a matter of British (and EU) law could be dealt with by either country’s courts. When we first wrote to Swatch about taking legal action, we told them that we would be taking them to the High Court in London if they did not resupply us within three weeks. To avoid that, they brought a claim against us in the Bern court without, however, telling us that they were doing this. But this did mean that the proceedings were supposed to be dealt with using British and EU law, not Swiss law. I am not going to detail the whole case again here, but for what follows to make sense, there are four significant points I must explain about how this relates to the Lugano Convention in our case. Firstly, the UK was (when the case began) bound by the Lugano Convention because it was a member of the EU, but when Brexit happened half way through our case, the UK was no longer part of the convention. The UK government applied to join the convention, and whilst waiting for a decision from the other members, held that any case started under Lugano rules would continue to be bound by them. Over a year later, the EU was still refusing to agree that the UK could join the convention, so the rules applicable in our case became somewhat less clear, and indeed before the final appeal was heard at the FSC, the Swiss courts declared that the convention was no longer applicable, and the final appeal was conducted under different rules. Secondly, all EU members use the same wording in their competition laws that appears in the EU Treaty, the only minor and required difference is that where the EU Treaty says ‘in the EU’, the UK Competition Act says ‘in the UK’. As part of the Brexit process, although the basics of UK Competition Law stayed the same, Section 60a was added to the Competition Act which allows UK law to deviate from EU law, so the two cannot be considered to be the same. Thirdly, under the terms of the Lugano Convention, if a matter is decided in one country then all the others are bound by it, and the courts of those other countries cannot review or overrule the decision, or hear the matter again, even if they are certain that the foreign decision is wrong. This is part of a wider legal principle known by the Latin phrase “Res Judicata”, which loosely translates as “This has already been Judged”. The point of this is to prevent a matter being repeatedly litigated, and to avoid conflicting judgements in different countries. Fourthly, under the terms of the Convention, the only action another member country can realistically take, is to refuse to recognise the foreign decision if it is ‘contrary to public policy’, but this has to be something other than the law applicable to the decision concerned, for example if one of the parties right to a fair trial was breached. As highlighted in the point above, it is not possible to argue that the Swiss courts did not apply Competition Law correctly. That would be ‘reviewing’ the case, which is expressly forbidden. Keeping these four points in mind, the actions that Cousins have now taken can be understood. When Swatch wrote to us in 2016 to say that they had lodged their claim with the Bern Court, there was a delay whilst we were waiting for the papers to be served on us. In that time period, we lodged our claim at the High Court in London in the expectation that the proceedings in Switzerland would not be admissible. Normally, a claimant has only three months to serve the papers on the other party, but because of the extraordinary nature of how the Swiss proceedings played out, we applied to the High Court for extensions to that time period, and in the end were granted a very exceptional ten of them. This meant that when the final FSC verdict came in, we still had a live claim that we could use. After lengthy consultation with our UK legal team, we identified two ways in which we believe the UK courts have valid reason not to recognise the Swiss decision, which in turn would allow us to bring the case again in the High Court, and have a British Judge decide a matter of British law concerning British markets and British consumers. Firstly, both the UK and Switzerland are signatories to the European Convention on Human Rights (ECHR), and it is contrary to public policy for the terms of that convention to be ignored. A crucial part of the ECHR is that parties in a legal action ‘have the right to be heard’. For this requirement to be met, it is vital that any evidence offered is considered by the court hearing the case. This did not happen in Bern. Secondly (as I explained above) after Brexit, UK Competition Law had the right to deviate from that of the EU. The Bern court did acknowledge the addition of Section 60a to UK law, but continued to regard UK law as being the same as that of the EU, and made its judgement on that basis. It is therefore true to say that UK Competition Law has not been applied at all, so it is not correct to claim that the matter has already been judged. In July this year, we served our High Court claim on Swatch (UK), and had the High Court start the process of serving on Swatch Group and ETA in Switzerland. The process of serving on foreign companies takes a few months, but Swatch UK received the claim within two days, and were required by the rules to enter a defence within six weeks. As we expected, Swatch responded by stating that this matter was already decided, and they applied to the High Court to have the claim struck out. We objected to the application on the grounds that I have explained above, and after some debate back and forth, it was agreed that there would be a one day hearing before a Judge in the High Court in order to decide whether or not the Bern verdict should be recognised in UK law. In simple terms, if the Bern decision is recognised, then there is little else that we can do. However, if the Bern decision is not recognised, then our current claim will continue and a longer hearing will be timetabled at which the evidence will be considered, and a ruling will be given under British Law. We are very confident as to what that ruling would be. On Monday of this week the administrative team at the High Court processed possible dates for the hearing, and it has been confirmed to us this will be the week commencing 26 February 2024. Whilst I am sure that there will be much interest within the watch repair world, this case has far greater significance. The Bern decision is not confined to watch parts, but covers wholesaling and other forms of distribution of any product in any market. If that decision is recognised, then small businesses in every sector who can not compete with the buying power of their larger counterparts will find themselves either out of business, or under the direct control of the manufacturers, and the big loser in the end will be the consumer. I never imagined when all this began that Cousins would end up fighting to uphold the basic principles of UK business law, but if that is what we need to do in order to preserve the right of our customers to continue to offer their services to UK consumers as they have done for Centuries, then that is what we will do. I will keep you updated as matters progress. Regards, Anthony1 point

-

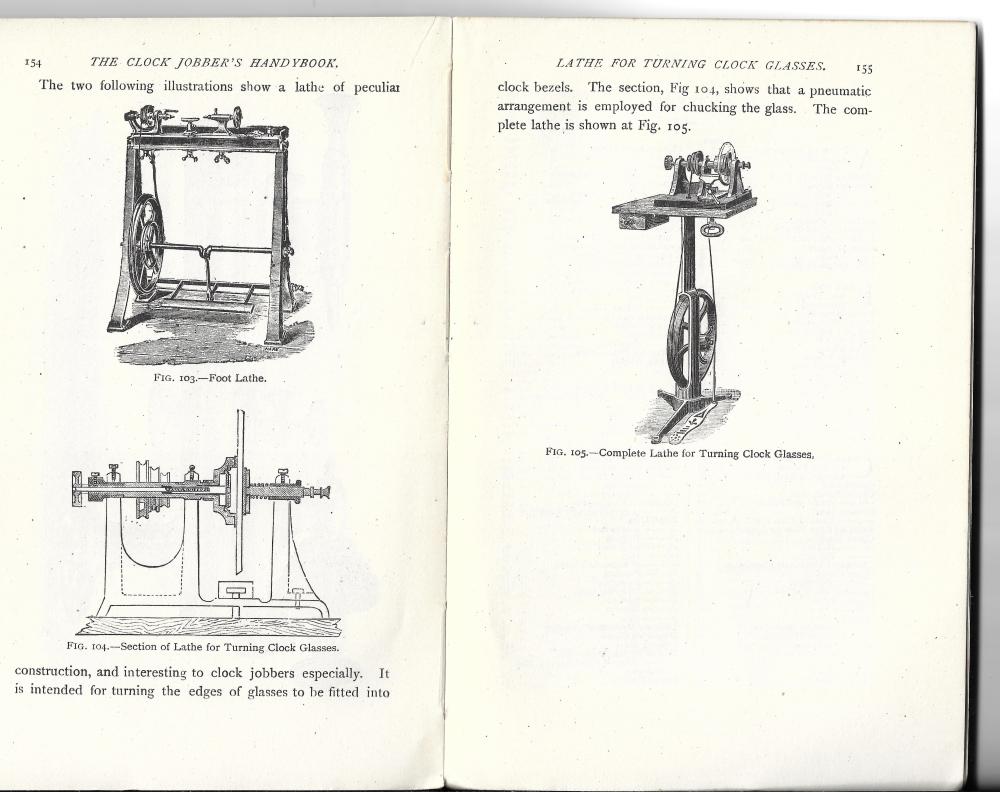

I have an evolution mitre saw with a blade which is eating through nails like butter. The wood I work with is coming from pallets and crates most of the time, and both are full with nails, many times they are re-used/ recycled so not just one set of nails but two, one set mostly hidden. Of course I remove the nails if I see them/find them. The Watchmaker's and Model Engineer's Lathe: A User's Manual book tells you that for heavier clock work you will need a motor with 200 Watts so it should not be able to cause serious troubles but you still could be unlucky i guess. If soft tissues like eyes hit by a sharp object etc etc. Talking about lathes I found something last night in an old book, glass lathe: Cool, huhh?1 point

-

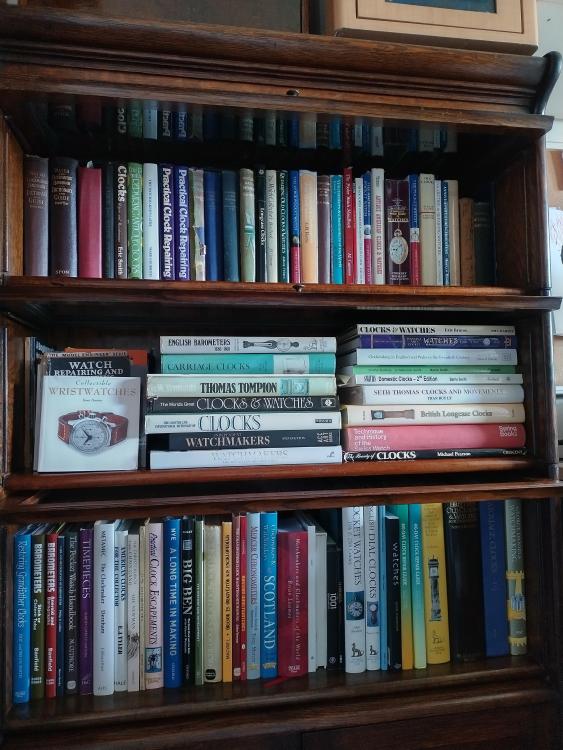

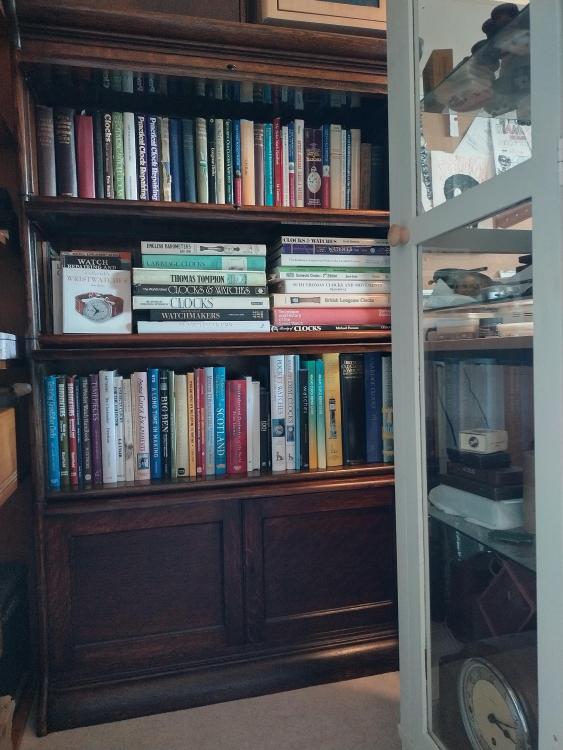

The file rest was not needed this time. Only reason is there because just like with the lathe I had to take it apart into pieces, clean it bit by bit, lubricate it and putting it back together, in one of my lunch time I quickly put everything I cleaned together, its a very fresh setup had no time to play with it much. The file rest came with the lathe, but I got no T-rest or collets so I had to borrow them from another 8 mm Lorch lathe, the one which seems to be a dead end project. A slide rest also came with the lathe, but had no time to clean it yet. However I spent some time to clean and restore a very nice book shelf so the books which were just piled up in my room on the floor finally got a nice place to be:1 point

-

Hair springs are matched to balance wheels so swapping just the h/s could leave you with some interesting timing issues. However, the balance wheel complete (balance wheel, hair spring, and roller) are the same for both the 6497 and 6498, so just swap the whole balance wheel complete assembly and you should be fine.1 point

-

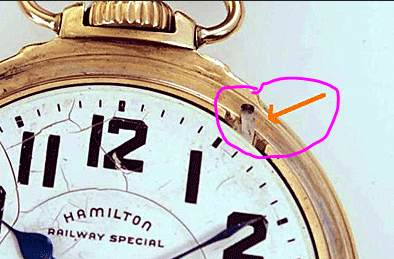

stopping the same place every time is always good versus random which becomes very very difficult to find if the picture is of the watch stopped looks like the secondhand may be touching the minute hand. Occasionally you'll find that the spacing of the hands on one side of the dial are greater than the other side which should be but sometimes it is1 point

-

Hi. Yes the inserts are usually stuck on so removing it and replacing it is quite easy as you have found out. Have fun1 point

-

Yes. This machine can function in 2 modes, soldering and spot welding. The spot welding mode can be used for broken screw removal as well as repairing broken mainspring bridles. If your DIY one works fine, then there is no need to buy another machine. But if you are thinking of buying a new machine, I suggest you wait awhile because I heard that there is a new machine under development that in addition to the above 2 functions, has a 3rd mode that can be used to fill pits in corroded metal surfaces.1 point

-

Farewell my fellow time piece brothers. Wishing nothing but Peace and Happiness to all!0 points