Leaderboard

Popular Content

Showing content with the highest reputation on 11/10/23 in all areas

-

7 points

-

I am an amateur without even formal online training, but, I have adopted the practice of reinstalling the balance complete on the main plate with the balance bridge and, if i remember to, without the top and bottom chatons. Which of course have to be maintained separate from each other, as they may not be identical. I use jars of L&R 111 and i forget which L&R rinse in a heated ultrasonic bath. And then i regard one-dip as a final rinse for the hairspring.4 points

-

I received a shipment of books today, checked one of them online and turned out it can be downloaded without restrictions: https://wellcomecollection.org/works/j3jqsphj "A history of watches and other timekekeepers / by James Francis Kendal." Enjoy!3 points

-

What frequency is your timing machine saying you are running at? I believe the balance are interchangeable, in the sense they will tick in either movement. But if you have a 21,600 balance in a watch that needs 18,000, you are getting an extra tick each second. 12 seconds extra per minute. You observed the minute hand making a turn in 56 seconds, so the math doesn't seem to work-except, often the higher beat watch will have 20 or so teeth in the escape wheel, and the other gearing has changed. On that note, for a "family" of calibers, often the center distances didn't change even though there were gearing changes to allow raising the frequency. In some cases the gearing can get mixed up- so maybe you have a 4th wheel meant for an 18,000 beat watch but a 21,600 balance, or something similar; it can get a bit complicated.3 points

-

I think it's more along the lines of work hardening. This is definitely a thing with the steels used in watchmaking, staffs no exception. If I'm repivoting and my drill starts to slow down in cutting, if I keep going until it's properly dull, the next drill has a heck of a time breaking through the hardened (extra hardened) surface at the bottom of the hole. With a Jacot tool you put a surprising amount of pressure on the pivot while working it. Some metal is removed, as evidenced by the black deposit on the burnisher, but it is also work hardened. That said, if removing say 0.01mm off the diameter of a 0.10mm pivot, there is a burr left at the end of the pivot that must be removed with another burnisher in another operation. Perhaps this is along the lines of metal being "moved", given the pressure. I bet if I put a piece of pivot steel (heat treated) in a vice and squeezed on it again and again it will move. Or when cutting a thread with a thread rolling die, this is all moving metal (not heat treated). Nonetheless the Jacot is making a hard skin through work hardening, that's the point of the tool (and, the pivot is nicely supported, it's just the best tool ever!).3 points

-

Picked this up on ebay for a total of $308 after shipping. The pictures on ebay made me think it was stored in an attic for the last 40 years. I took a chance. It showed up today. Not shown in the pictures are the three genuine L&R jars, stars, and lids. I could not wait, so I tore down the motor to find what I expected...wires with cracked insulation. So I rewired the motor, cleaned and oiled the bearings, reassembled and voila!! The base is mostly cleaned up and I am considering a complete strip and re-paint. To my surprise, the 750 ohm stock rheostat was fully functional as was the 220 ohm heater resistor. This baby is gonna clean up nice!! The guy was asking $250 and it sat on ebay for a week or two, so I offered $225 and he accepted. Add tax and $55 shipping (or so)2 points

-

2 points

-

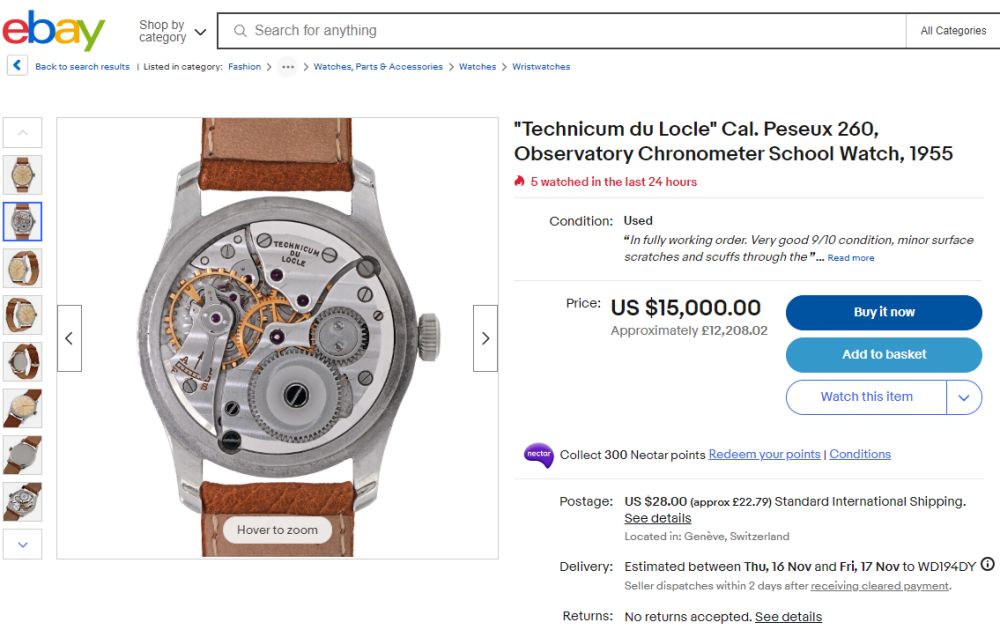

This is an iconic movement from the heat of the chronometer trials of that period. They were made in small quantity, massive mainspring massive balance, tiny escapement. Rare. Numerous independent watchmakers have used this movement as a base for their work, which adds to its rarity and desirability. I don't know if this is a fair price, but given what some independent watches go for if I had the cash I'd buy this. Cooooool watch. (Very few were cased. Most were in "test" cases. The ones "found" by the independent guys were unfinished kits mostly, finished by them. No COSC certification, haha)2 points

-

I, too, use Eveflex in a similar way.2 points

-

Are you sure you have the right balance-cock assembly on your watch ? Balance out of AS 1717 ( a 18000 beater ) fits in AS 1863.2 points

-

Put the watch on the timegrapher, adjust the rate as possible closer to 0 s/day, do not change the position and observe the second hand. Is it making one revoluton exactly per minute, acording to another trusted timer/watch?2 points

-

No master metalurgist here, I have seen a proceedure done which seem to yield good results. Light up some charcoil, spread on it a 5cm cake of ash, place the piece on top of the ash, cover it all with 5cm more ash. The ash; 1-Regulates the amount of oxygen fed to the charcoil, 2-Spreads heat rising evenly. 3-Takes the charcoil to completely burn 10 to 15 hours, as the flow of oxygen to it is regulated by the ash. After twelve hours, the piece is cold and need not quenching in liquid.2 points

-

I'm not convinced that "metal displacement" is a thing, or works as he says. He says that "friction and heat" move the metal. As steel does not become malleable until above 500-600°C, I'm not convinced. The scratches move material out, so I guess enough pressure and friction could push some back in to the grooves.2 points

-

I agree. I use Eveflex on occasion, but always with the softest inserts, and maybe for 5-10 seconds at a time. It is more of a cleaning technique than a polish. I defer to the Jacot tool (which I'm still working on improving my technique) when actual pivot work is needed.2 points

-

If you look through the comments on this video you’ll find my thoughts on it. Alex Hamilton showed this abomination in a video as well. I’m pretty sure I can do a good job of screwing up pivots without spending $200+ on this thing to do it for me. Tom2 points

-

WTF? Did you hear this from Buck Fiden?2 points

-

The title of this post is the title of the below video (EDIT: Luckily, the video has been taken down!): I get concerned when someone promotes polishing wheel pivots with Eveflex and thinks that it could possibly replace a Jacot tool. The problem with Eveflex is that it polishes the pivot completely wrong. With Eveflex, the pivot is polished from the top side and makes it conical. With a Jacot tool, the pivot is polished along its long side, the only disadvantage is that the diameter can decrease, which, if necessary, can be corrected by installing a jewel with a slightly smaller jewel hole. In addition, I strongly doubt that Eveflex, like a Jacot tool, works per the "metal displacement" principle. Having said that, I use Eveflex myself, but I always use the very softest version, always polish the pivot by hand and only for a short time. I see it more as a deep clean than a polish, but clearly, it makes the pivot cone-shaped, but so little that it is not measurable or visible and therefore negligible. The video uses an electric rotary tool, only the second softest version of Eveflex, and the polishing goes on for what feels like an eternity. It will make the wheel pivot cone-shaped. I note that the video does not show the results of polishing the pivots of a third wheel, a fourth wheel, or an escape wheel. It makes you wonder why To each his or her own, but I strongly advise against using the tool in the video. Your opinions?1 point

-

I don't like the video. If I was still watchmaking I wouldn't touch the tool with a barge pole. Speed is not everything.1 point

-

For shaping a jewellers saw and file will do the job nicely. I can't imagine using grinding tools on such a small part1 point

-

Unfortunately it's common these days. I had a problem with ebay the other day, a potential buyer couldn't bid on my item. There was no way to contact anyone for help. Only "online support" like Cousins, an automated assistant and the suggestion to as the "community". It's infuriating. You would expect a company the size of Cousins to have a contact number. Pity we can't find the phone number of the Director and phone him at home. At the bottom of the main page is a link to "Website Feedback" asking for suggestions for improvements. Maybe we get a lot of us to all suggest a help phone number? I always pay with a credit card as you get protection : "Section 75 is an important UK consumer protection law made in the 1970s that means your credit provider must take the same responsibility as the retailer if things go wrong with a purchase". So if you used a credit card, contact them, they have a duty to sort it out.1 point

-

1 point

-

Mechanical watches can be quite interesting at times. The timing machine is listening to the sounds of the escapement controlled by the oscillation of the balance wheel. The timing machine does not care about the hands or anything else it only cares about picking up the sound of the ticking watch. So you can have a absolutely perfect timekeeping on the timing machine watch that can have other issues as you've now discovered. So balance wheel oscillates at a frequency. The gear train of the watch is to reduce the frequency down so that the hands revolve at the correct rate. When I was a young student in school working on an Omega watch I had your exact same problem. We ordered a replacement wheel and the watch did not keep time. This comes up for unsuspecting Rolex collectors the exact same thing. Your ending up with the same problem here is a series of watches that were made in differing frequencies. Where the base caliber is 18,000 and later versions basically identical watches came in other frequencies. So the difference would be the balance wheel but oscillates at its correct frequency and just a couple of the gears in the gear train that a change the ratio. So eager to assemble the Rolex for instance will mix-and-match and then you have a serious problem. So timing machine can be very happy with the rate of oscillation of the balance wheel. But you do have to have the right gear train ratio to go with your oscillation timing machine cannot measure that. I suspect if you take out the offending wheel and compare it with the gear that should be in there and look at the number of teeth on the gear and/or pinion You will observe that they do not have the same number of teeth.1 point

-

It was clear from the beginning that the balance is not ‘wrong’ and it is something about the ratio of the train. When just the balance is the ‘wrong’ one, then the movement will gain or loose more than 4 hours /day: 21600/18000=1.2 24x1.2=28.8 28.8-24=4.8h/day 24/1.2=20 24-20=4h/day Now, that You had changed the 4th wheel, we have correct ratio to the second hand. Hopefully all will be OK, but still the ratio to the 5th wheel has to be checked. Changing the wheels between one family of calibers with different BPH not only leads to wrong train ratio, but to incorrect gearing, as the wheels have different modules or diameters. That’s why, the wheels must go together as a set and not to be changed between sets with different BPH. But, as You see, sometimes the movements work without stoppings, even with wheels from different sets, despite the wrong gearing.1 point

-

Haha, Do you remember the emoticon wrt forum use to have of the guy plucking out his own hair , I miss the guy. Balances are interchangable , balance completes are not. Gears of the train too are for different beats. We should have a thread on Dr ranfft's site, tons of info is packed in it. Rgds1 point

-

All the feeler gauges I've bought are hardened. They wouldn't be much good otherwise. I bought some cheapies for this purpose, and cannot drill, file or cut them without annealing. I've no problem with hardening or tempering. For tempering, I put a handle on an old watch case filled with brass shavings. Held over a spirit lamp, it's easy to get the correct colour. I've ordered some powdered charcoal, going to use an old box spanner as my cylinder, and hope a hand held gas (propane/butane) torch will provide enough heat.1 point

-

Along the lines of what Joe said, for annealing small pieces I put them in a tube with powdered charcoal, heat the whole thing up to red, and let cool. Works great. For larger things like the end of a clock mainspring that needs a new hole, I do the flame in the air thing, letting it cool as slowly as possible. It doesn't get fully annealed but enough to drill with HSS drills, and file easily. Bergeon and others used to supply carbon steel sheet in 0.10mm increments, but not for some time. I've been trying to find a supplier of it in thicknesses that correspond to watch parts without a whole lot of luck. McMaster in the U.S. has 1070 steel in interesting thicknesses, in the annealed state (but they don't ship to Switzerland). I saw these guys in the U.K. who say they will sell in small quantities to hobbiests, and seem to have a decent selection in both hardened and annealed state. CS70 is equivalent to 1070 and fine for watch parts, CS95 (1095) is probably a little better. Both easily hardened with a torch and oil quench. It's definitely easiest to start with the material in the annealed state.1 point

-

When you let the watch sit around - what position is it in? Is the difference dial up vs dial down?1 point

-

I use diamond wheels and burs for this kind of work. So that saves me doing heat treatment. If I want to soften hardened steel, I heat it with a spirit lamp till dull red for around 20 to 30 seconds then allow it to cool slowly in the air. Getting it back to spring temper is tough. How do you do it?1 point

-

Because it's too hard to drill, saw or file. It's easy to work once annealed, and it's easy to harden and temper once shaped.1 point

-

Feeler gauge steel already has the correct temper for a setting lever. Why do you want to anneal it? If you soften the steel, you will need to reharden and then temper it again.1 point

-

@RichardHarris123 Richard, have you had a look at straps on cousinsuk? I got a nice alligator one for a friends longines watch, it was about £80 iirc. They do straps from a couple of quid upto quite high end. Tom1 point

-

Yes they hairspring goes through the cleaning machine even with ultrasonic. If it's a watch it has balance jewels it can be removed. After everything is off the main plate balance wheel goes back in with its bridge screwed back down. Jewels are removed and intact that can run through the cleaning machine as the bridge on the plate install protected Pocket watch balance wheels either placed in a tiny basket or separately. As far as I know I've never had a problem from running it through the cleaning machine in the cleaning machine at work can spin quite fast we can hear it's spinning. You just don't what the balance wheel or anything else bumping into the balance wheel I suspect you have some scrap pocket watch balance wheels or even wristwatch. Run into the cleaning machine and see what happens as long as their separate are not able to fly all over the place I've never had a problem. Plus they come out nice and clean. Just remember no matter what she do always check your roller jewel especially on vintage watches they tend to get loose. I don't think that's the cleaning machine is just whatever it was that you using to hold them in place. Sometimes there loose before you even run them through the cleaning machine like the one I re-shellac today. Which is probably good I caught it ahead of time it might a full enough to cleaning machine. On the other hand the cleaning machine does have a really tiny little drain basket to catch things.1 point

-

1 point

-

An advantage of your aproach is that adjustor arm can no farther move as pin is inserted, disadvantage of it is you might touch/bend the spring while trying to insert the pin in the hole. Rgds1 point

-

1 point

-

Remove autobridge with the rotor attached, you see 3 small screws on underside to unscrew and take the rotor off. Good luck1 point

-

No pictures or part numbers? Where did you find out about such a tool? The problem is not everything is on the line at least where you can see it. My recommendation would be to find a watch material house that can purchase from Seiko and have them look on their online listing that we can't see.1 point

-

You run it through the cleaning machine the same as you run everything else through the cleaning machine. Although I do like to isolate my balance wheel from anything else it might bump into so usually put it in its own thimble basket.1 point

-

I bought a bracelet from strapsco.com. I thought it was adequate quality for the price.1 point

-

https://www.ebay.com.sg/itm/224377149905?mkcid=16&mkevt=1&mkrid=3423-175132-2357-0&ssspo=MPr5TDAPRyu&sssrc=4429486&ssuid=v36TsHWBSw-&var=523164307352&widget_ver=artemis&media=COPY You might want to keep this eBay link handy. I suggest that you practice on a scrap balance wheel first. Hairspring manipulation is advanced stuff and requires calm nerves and steady hands. An oiler might not be the best tool for the job. I use a sharp dental probe (because I'm a retired dentist). My mentor uses a bent sewing needle, jammed into the end of a pegwood. I find that using a curved tweezer in the left hand and a probe in the right hand works best for me. Place the hairspring on a flat piece of glass, with a white piece of paper under the glass for contrast. When you pinch the hairspring with the tweezers, allow the tweezer tips to go all the way until it rests on the glass before closing the tips of the tweezers. This stabilizes your hands and give better control. Likewise, the probe should also rest on the glass for stability. The secret to curving the hairspring is pinching the hairspring at the correct spot and gently stroking the part you want to bend with the probe. Experience will tell you how much to flex the spring to form it to the shape you want. If you do it enought times, reforming a hairspring is normal as oiling a shock jewel. And as John says... practice, practice, practice. Good luck.1 point

-

I have a can (may be empty now) of One-Dip in my desk drawer, and I was never impressed with its effectiveness. I only used it a few times because it just didn't get the job done as well as the L&R solutions in my usual US process. Last I checked, that was the consensus. It sounds great on paper to be able to clean a balance with little or no agitation, but that's just not how it plays out in practice with the stuff. I, for one, will not be mourning its loss. I'll probably hold onto the can for giggles so I can show my grandchildren how crazy people were (I was) way back when keeping such dangerous chemicals in my desk drawer like radium tablets and heroin cough syrups.1 point

-

We discussed this a little while ago Watchie, the general opinion is that its a pretty crap idea risking pivot destruction, quite surprised at Matt promoting it. Apart from the fact that only the center part of the pins can used in this way. Nah mate the Jacot rules this one, this tool Galaxy pon polisher ? Gets "nul points" from Richard the terrible1 point

-

If someone could provide a suitable, cheap, safe alternative to one dip that I can easily access in Australia I'm all ears.1 point

-

This is unfortunate classic problem of watch repair and YouTube. Typically on YouTube whoever's making a video will always make it look easy. The reality of watch repair is like anything else that requires practice lots of practice. Preferably practicing on things that are disposable not practicing on live watches were problems have occurred. Microscopes are such interesting devices for instance a lot of them look identical. But visually looking the same doesn't mean that they are the same.1 point