Leaderboard

Popular Content

Showing content with the highest reputation on 11/11/23 in all areas

-

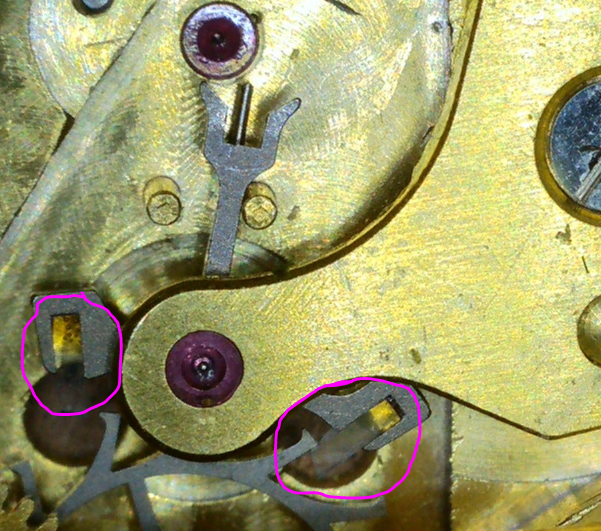

A lot of times with broken balance staffs which are very common on watches that do not have balance protection systems is you can gently push on the balance wheel and see if a flops around. Then at some point we also want to always check to make sure your hairspring is flat it's amazing how much problems hairsprings can cause if they're not exactly where there supposed to be I had a watch this week that the roller jewel was loose so I fixed that it ran great in a dial up amplitude looks spectacular but dial down crashed and burned which normally would be a pivot issue but I traced it to the hairspring was flat must've been just touching the balance Then there's another peculiar thing with this watch have you cleaned it yet or is this the way it came in? You'll notice in the image above swiped from up above I circled something well sort of on the right-hand side your pallet stone is out way too far normally you never see a gap that big behind the stone. So something isn't quite right there and the lock is a excessive and on the other side the lock would be well nonexistent because you don't even appear to have a pallet stone at all. That if you seeking help for parts you going to need a little more than that description. You should be a number under the balance wheel which I can't quite see or there's other ways to figure out what this is.3 points

-

Is the lower pivot missing? Check the side view of the roller/balance...3 points

-

Waggy quote" I assume it is something to do with the cannon pinion?" Exactly the same problem. I realised when I replayed Mark's course material Level 3: Fault Finding c3.1.0 The Initial Inspection c3.1.1 Check The Motion Work. Described the exact symptom. Same as you. Back to a complete rebuild. Disassembly, clean and off I go to apply a fix to the canon pinion. So pleased I've got the right tool on my DIY additions in my staking set. Good this hobby innit?3 points

-

3 points

-

No model number so I will assume that everyone got the right style of cannon pinion. The reason I bring this up is the symptoms are also a classic problem of another type of center wheel assembly that looks like this . Usually when you're assembling a watch you like to try things out as you go rather than an all or nothing approach. So in other words when you put the center wheel assembly like the above image or the canon pinion on you can attempt to turn it with the keyless and see how it feels do you think it feels like it has enough friction? Most the time you should be able to tell that you're going to have an issue at this stage. It's also good when evaluating the watch before cleaning to see how it feels as to whether you think it's going to work or not. Although typically when the watches in the case especially with the water resistant crown the gasket on the case tube can interfere with how things feel it might feel like you have enough friction there but in real life you don't which is why it's best always check the watch out of the case.2 points

-

2 points

-

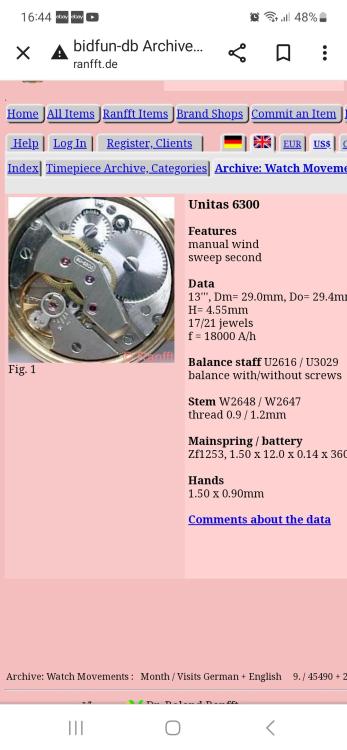

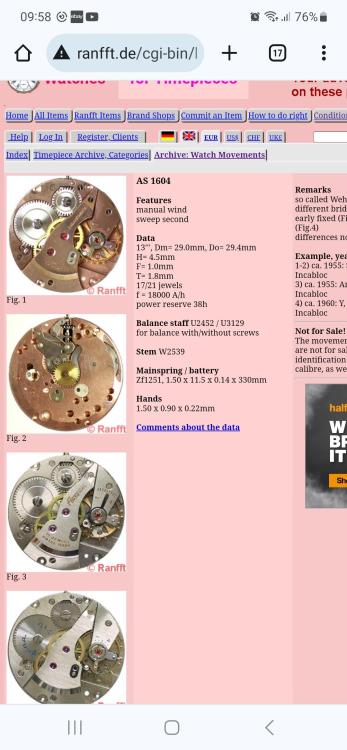

Hi Richard on ranfft the picture is for a 6300N. Which looks very like the picture posted. Ther is a logo under the balance I can make out that looks like the Unitas marque. If thorp can confirm this and the calibre by removing or taking a closer look I am a numeric dyslexic.2 points

-

Hi lower balance pivot broken off . Donor movement required or balance re staffing.2 points

-

Yes you will pay silly money for branded items. Just buy the same item but not branded. I have a lovely handmade ostrich skin strap on my Longines Admiral, £35 from Cousins. (and being a fellow Yorkshireman @Neverenoughwatches, we do like to take care of the £££s )2 points

-

Just to mention, that feeler gauges usually are made fron spring steel and it will never get as soft when anealed as tool steel or silver steel can be2 points

-

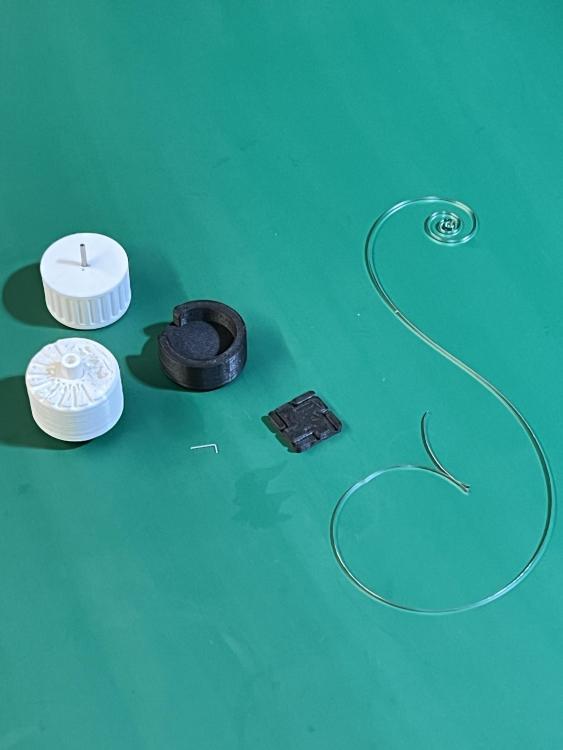

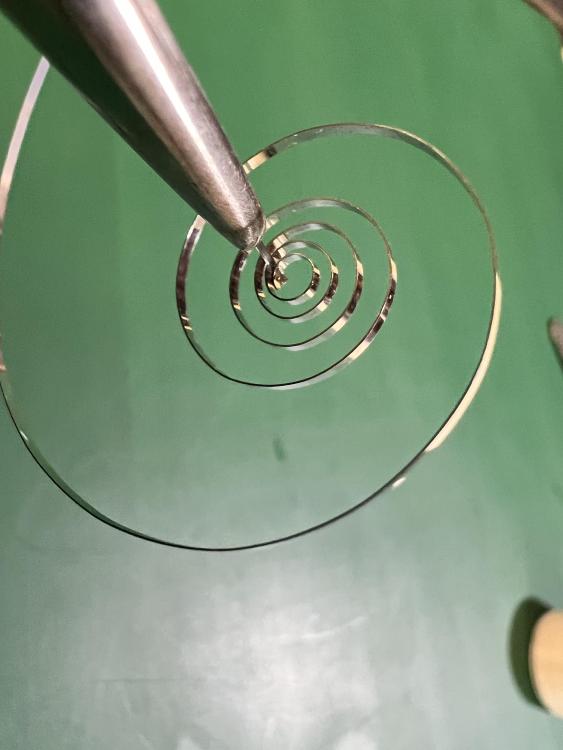

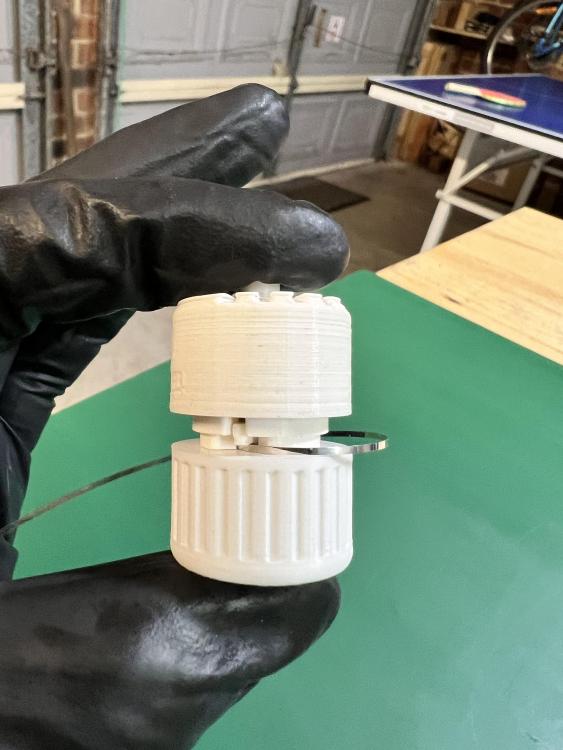

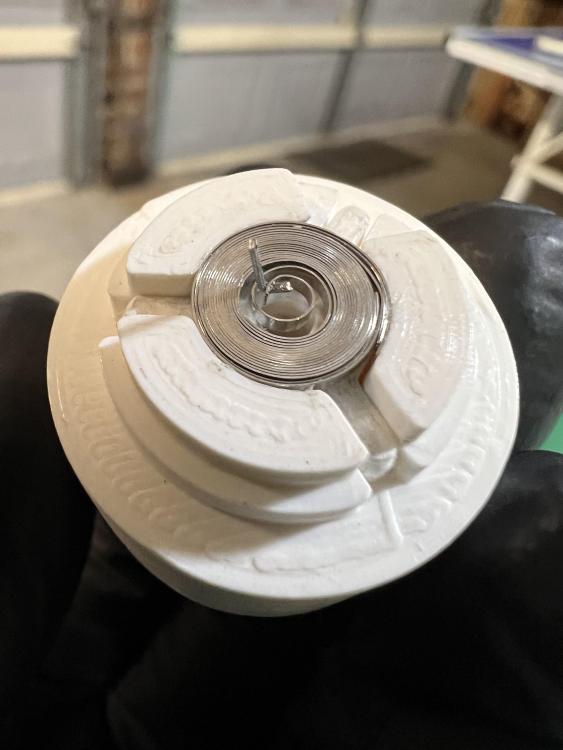

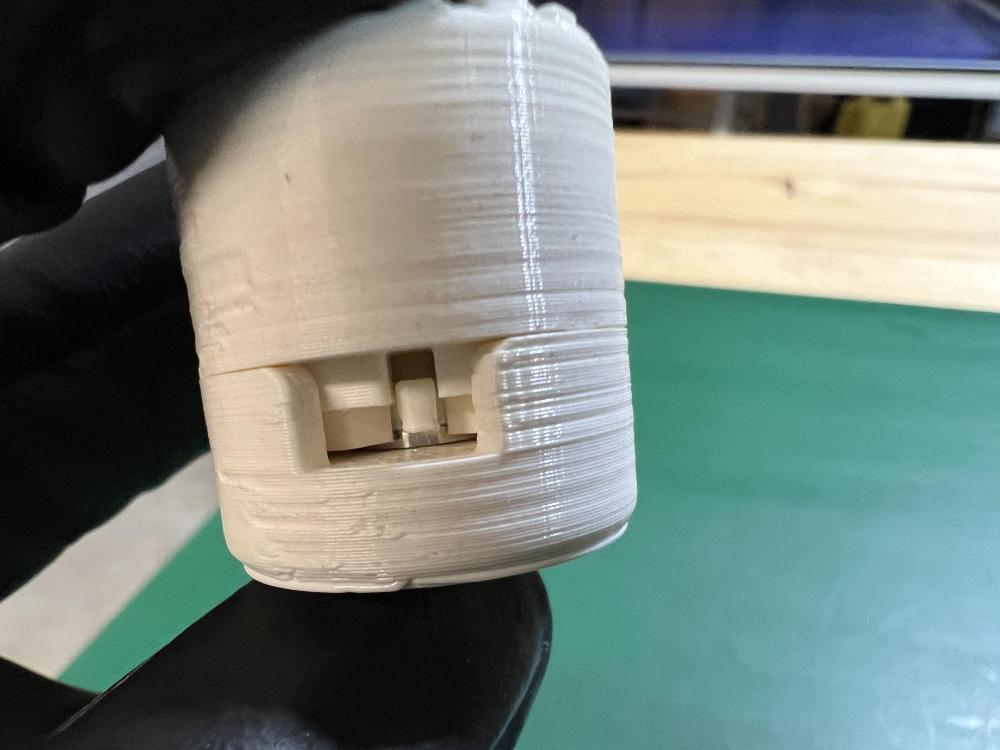

I have been practicing with the 3d printed mainspring winder and I have settled on a process that is giving me very good, repeatable results. What follows is a picture story board of my process that I hope may assist others considering this device as a primary spring winder. Firstly here are the collection of components that will get our spring back into the barrel: the winding barrel, the winding base, a plunger, a ‘setting’ bowl, a staple cut into the shape of a hook, and finally a clean spring from a seiko NH35. The square plastic piece is a jig for cutting the staple to size, however I am finding that I don’t really need it and can comfortably eyeball the correct size. Next, and perhaps it’s unorthodox but I use tweezers or small pliers to place the staple hook into the spring eye, going from outside in as suggested in the GitHub users guide: Next, instead of placing the spring on the shaft of the winding base, I place the spring into the barrel as I find this is the easiest and least frustrating way to ensure the spring tail exits from the correct winding aperture, and without any of the spring sitting on top of the barrel wall such that it would prevent the barrel and base closing together: Now take the winder barrel, with the spring in situ, and place it on top of the base. The shank of the hook will line up with an appropriate hole in the winder base, sometimes gentle guidance is required with fine tweezers: With the barrel and base snugged up and held together, I use slight finger pressure on the plunger which helps keep the spring in a flat plane as it feeds into the barrel this preventing any tangling: Now wind until the bridle approaches the winding aperture and help feed the initial bit in by hand before winding the remainder into the barrel: Note carefully allow the base to unwind and then lift the base off to reveal the wound spring with staple hook still in place: Carefully remove the staple with tweezers before placing the barrel into the setting bowl and pushing down with the plunger. The wound spring will sit proud of the barrel by about 1/3 mm: It is now the simplest matter to line the slightly protruding spring up with the metal barrel and plunge it home:2 points

-

I don't like the video. If I was still watchmaking I wouldn't touch the tool with a barge pole. Speed is not everything.2 points

-

This made me smile, a quote from: R.W.Symonds - Thomas Tompion his life and work "It should be understood that Elizabethan clocks, both weight- and spring-driven, were exceedingly poor timekeepers: they were so erratic that they needed to be corrected daily by the sundial; and watches were even less reliable. In these days of Elizabeth and James I, a watch was a costly article, and generally speaking more expensive than clock. Owing to its small size greater skill was required in its making. It was usually set in an elaborate case, either in silver, gold, or fire-gilded brass, and pierced, engraved or chased. Cases of crystal, studded with jewels, or enamelled, were also used. The high cost of watch confined its ownership to the wealthy members of Elizabethan society. The following story of a watch owned by the mathematician and philosopher, Thomas Allen (1542-1632), illustrates how little acquainted with watches were the ordinary English folk of those days. He was generally acquainted, end every long vacation, he rode into the countrey to visitt his old acquaintance and patrones, to whom his great learning, mixt with much sweetnes and humour, rendered him very welcome. One time being at Hom Lacy in Herefordshire, at Mr. John Scudamore's (grandfather to the lord Scudamore). he happened to leave his watch in the chamber window-(watches were rarities)- The maydes came in to make the bed, and hearing a thing in a case cry Tick, Tick, Tick, presently concluded that that was his Devill, and tooke it by the string with the tongues, and threw it out of the windowe into the mote (to drowne the Devill.) It so happened that the string hung on a spring of an elder that grew out of the mote, and this confirmed them that 'twas the Devill. So the good old gentleman gott his watch again."2 points

-

Hello all I want some mid quality Watch straps. They seem to come in either cheap or expensive, £8 - 12 or £150 plus. There must be a compromise.1 point

-

This trio. Regarding my post above on the Buler, what are the two buttons on the LHS of the case for? I have had a look at the photo of the movement, am I correct in thinking that it is a Baumgartner movement? Also, do the buttons on the LHS of the case both serve to move the lever to brake and release the balance? Am I correct in using the term 'hack' so the the time may be adjusted?1 point

-

Just keep practicing it will soon pay off and i won't take long.1 point

-

Well, getting up early maybe has helped. I have the winning bid at the moment. I just won. I so hope that I have done the right thing.1 point

-

Thanks - Don't think I have seen that one before. I have watched both this and Alex Hamilton's similar post. I can definitely improve my technique here!1 point

-

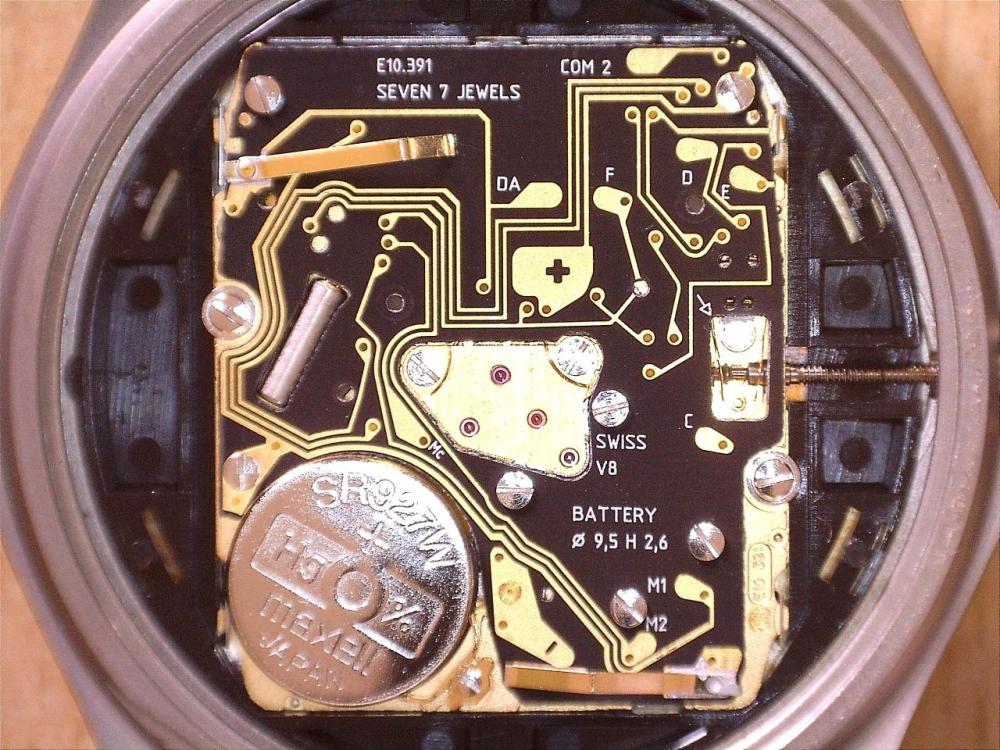

My daily watch is an Aerospace I bought back in 2003. I did used to get it serviced by Breilting. In one service they upgraded the movement. A battery service used to cost me about £75, and a "full service" every 6 years was about £350. But they had polished the case and strap, and it came back looking like new. This was about 10 years ago. Now I do the services myself. It's not difficult, the ETA service sheet has clear instructions on what to do. The problem is that the movements, an ETA E10.391 in mine (which is similar to the 988.432) are difficult to find. So be careful (though I just did a search on ebay, and found a couple for sale in Egypt for about £200) It is a lot to pay, but you will get a 'refurbished' watch. Personally, I would find a proficient independent watchmaker and ask for a quote.1 point

-

1 point

-

Hi. According to Dr Ranfft. 3600 it is. Measure the inside of the case where the glass fits with a vernier then add 0.01 to the figure this will give a good fit. You will need a glass fitting tool to compress the acrylic to fit. Are the hands missing or just want tightening up a bit. Fitting tools are available on eBay at not too great cost.1 point

-

Another Molnija (Молния) USSR pocket watch. I seem to be on a winning streak with Molnja having not seen any decent examples at anywhere near the 404 club membership standard for a very long time. Just in the last few weeks I've managed to find a couple of interesting examples. This one is an 18 jewel version with original chain, box and Sekonda guarantee. There were no pictures of the movement in the listing but here is a similar 15 jewel example. .. and its 18 jewel cousin. As you can see, some of them are quite nicely finished. If you want to know a little about the pedigree of the movement, you could do worse than to read this article -> http://cgi.linuxfocus.org/~guido/molnija-pocket-watch/ This was just a few pence beyond the 404 club rules, but given that it came in such good original condition, I think it may just qualify for an honorary membership.1 point

-

Are you sure it's a unitas 3600? You didn't state where you are from on your introduction, it helps in sourcing parts. Crystals are cheap, buy one the same size and one the next size up. As for height, measure the original and there are technical documents to tell you what style you need.1 point

-

Cannon pinion. I put a broach in to stop it crushing, and use the pointy thing (used to centre the holes) in the staking set. Give it a VERY light tap. Oh you have a new toy. They're surprisingly cheap for a Begeon tool on Cousins, £22. Surely they've missed a "0" off the end?1 point

-

1 point

-

1 point

-

1 point

-

Welcome James, we're all about pictures here, front back and inside. Do you mean the acrylic crystal, if the dial cover has gone and hands have been lost that could be a real pain finding some more. Hands are specific to the movement inside the watch, first task is to identify the movement.1 point

-

A good quality well chosen strap definitely enhances the overall look of a watch. Post one of the watches up in the other thread to get other opinions of what to go for.1 point

-

1 point

-

1 point

-

I buy the Buffalo leather straps from Cousins, priced about £3-£6. They are pretty good quality.1 point

-

1 point

-

1 point

-

I'm not sure if this is the correct size tool. https://a.aliexpress.com/_mL983oM Bulova also has a 3 pronged screwdriver. https://www.cousinsuk.com/product/bulova1 point

-

This all probably sounds like a time consuming and tedious process but I assure you it is much quicker to do than to write out a description, and I can complete the whole process in a minute. I find the most fiddly element is the inserting and removing of the staple hook into the spring eye and I suspect a smaller staple would be more suitable for this particular spring. I think this spring winder excels for a number of reasons: 1. it’s very cheap 2. it’s very easy to print different size barrels to cover any watch size 3. I see in these forums people saying that regular winder are subject to the arbor hook wearing. This is not an issue for the 3D winder. 4. I believe that springs of different thicknesses may not align with the arbor hook of standard winders. For the 3D winder the shank of the staple hook is free to ride up and down and thus position itself as required for the spring thickness. 5. Springs can be wound left hand or right hand in the same winder. All in all, a great option for hobbyists. Well done To Zero for his excellent creation.1 point

-

@RichardHarris123 I have got into the habit of checking cousinsuk for anything first now Richard, often I find them cheaper than anywhere other than Aliexpress. Tom1 point

-

@tomh207, for some reason I didn't consider Cousins. Had a look, huge selection and reasonable prices.1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

I don't advise playing about like that, you are going to disturb the oils. Treat it as a new repair. Many years ago we would replace the complete barrel unit Seiko I think said every 7 years, because the shortage of parts and also they are obsolete it is normal practice to open the barrel remove the spring and clean it just like you would with any watch barrel. If the spring is tired and out of shape then replace it with new.1 point

-

Hello and welcome. I haven't worked on that model so I don't know but someone will advise you.1 point

-

1 point

-

1 point

-

Absolutely balance staffs but really any part. I always check, and anyway do the pivot end last so it gets taken care of.1 point

-

1 point

-

Unitas 3600, or Seagull 3600? The Unitas 3600 is Swiss from the ‘60’s. The Seagull 3600, I believe, is a Chinese clone of the Unitas 6497. Sorry. Unitas 6300 is the Swiss one from the sixties.1 point

-

I received a shipment of books today, checked one of them online and turned out it can be downloaded without restrictions: https://wellcomecollection.org/works/j3jqsphj "A history of watches and other timekekeepers / by James Francis Kendal." Enjoy!1 point

-

Just as an aside I have been experimenting with file formats for storing images in the database record. I have found that .webp image file format generates excellent results - great quality at small file sizes. For example 44 files transferred from my android phone (.jpg format) are 44,164,390 B. When I convert these to .webp at 25% quality they only add up to 3,807,666B or the combined file size is reduced by 91.4%. To my eyes the quality appears the same between the original image and the converted one, even when I zoom in to 200%. I then archive all 44 files into a single archive file (7z) but you could use zip if you prefer to make life easier to upload and reduce clutter. Happy to go into more detail of the conversion and archive process if anyone has an interest .1 point