Leaderboard

Popular Content

Showing content with the highest reputation on 11/12/23 in all areas

-

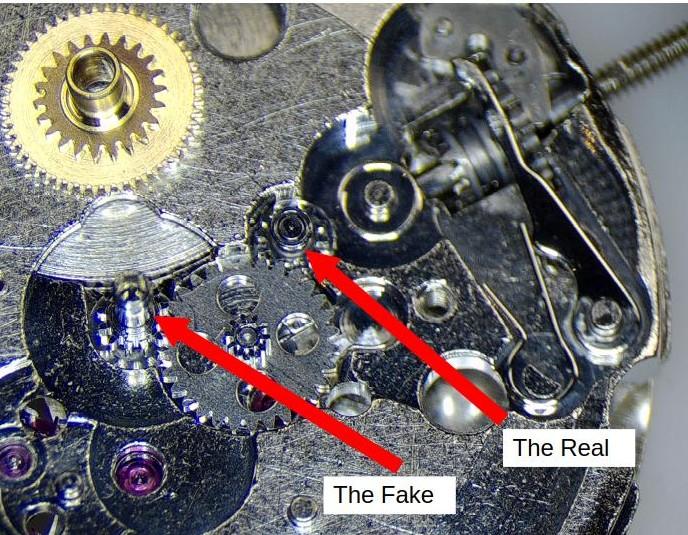

Thanks for the help, greatly appreciated, this was one of those strange movements where there were what looked like 2 cannon pinions, one on the center wheel where you would expect to see it and another more stubby one on the third wheel. I have done one of these in the past and remember that the friction came from the stubby third wheel cannon pinion and not the 'fake' one on the center wheel. I have used my new toy and applied the dent (?) to the stubby wheel and I felt the standard 'clunk' as it slipped into place on the third wheel then I reattached the minute and hour wheels and placed a hand directly on the 'fake cannon pinion' on the center wheel to see if it would move - after a cup of coffee I came back to find that the minute hand had indeed turned. Now to put it all back together properly. PS I know they aren't really a fake and real cannon pinion, but I'm not sure what they are supposed to be called, I am sure someone will enlighten me3 points

-

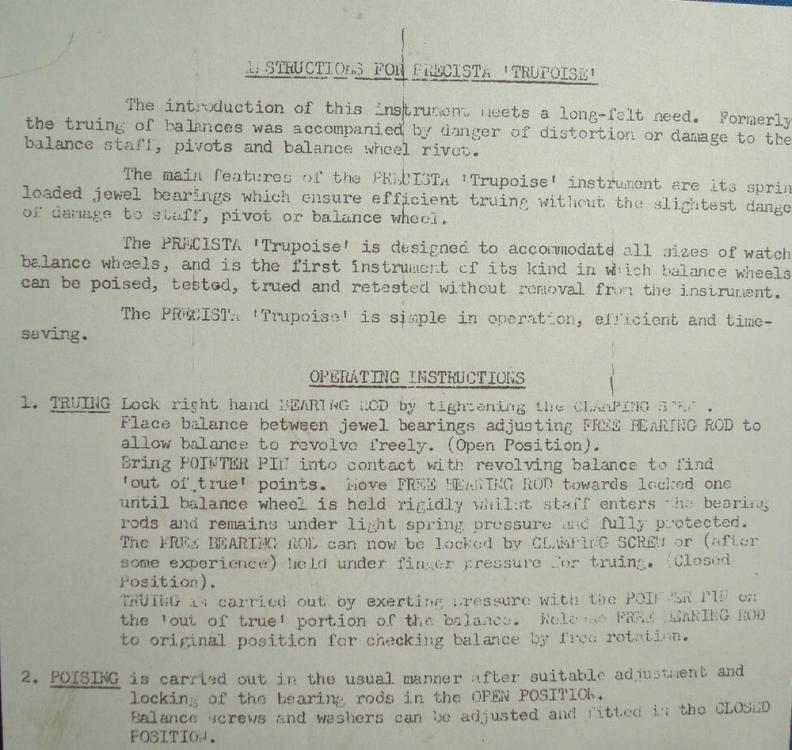

From the instructions: "Formerly the truing of balances was accompanied by danger of distortion or damage to the balance staff, pivots, and balance wheel rivet." You can read the entire instructions in this post. Are you sure you understood the instructions, or am I missing something here? How should a balance be held to be trued? BTW, I honestly don't mean to sound arrogant but fear I might come across as such. I am genuinely curious to learn more or find out if you possibly made a mistake in assessing the use of this tool.2 points

-

2 points

-

2 points

-

I ended up changing my order to the microscope with no camera. After doing some more digging around YouTube, I ended up ordering the Hayear 14MP camera. Significantly cheaper from AliExpress than Amazon.2 points

-

I just pulled the trigger on an Eakins version of the AmScope SM-4TP. It was significantly cheaper, factoring in that the Eakins one that I got comes with the 10X and 20X eye pieces, 0.5X and 2.0X Barlow lenses, 48MP 2K camera, C mount bracket, ring light, simul focus, and dual boom stand with tilting head feature. It was just under $442 out the door. AmScope is currently having a 15% off Veterans Day sale and the Eakins price still beat it. https://www.aliexpress.us/item/2251832821477621.html Not sure just how good (or bad) the Eakins cameras are, but hopefully good enough for photos and videos of the disassembly. I'm looking forward to using this. My digital microscope is pretty good, but working through an optical microscope sounds much better.2 points

-

This is something different it made me smile. A classic folk song, the clock starts ticking when the old man is born, then time takes its toll. It was written in 1876 by Henry Clay Work1 point

-

Hi All, I have several hobbies that works with gas. Beside Harley and Cadillac I started to collect watches as my other child dream. Especially with Harley and Cadillac signs. So I have several Bulovas with Harley-Davidson logos and different cheaper brands with Cadillac on dial. Next was Solomax / Chateau Cadillac (I know it is nothing to the car brand) and several American brands (some with thanks to several years service for these bike and car companies). My dream was to have a 1964 Omega that is the same age as my cars. Now I have more (1944, 1958, 1964, 1964). After collecting a small bunch of pocket and wristwatches, I realized they need service. Even if I want to trade or sell, would be more calm if know what I have. The future have to be more clear and want to care with about 4 brands (for example Omega, Solomax / Chateau Cadillac, Hamilton, Waltham). So I am here to learn.1 point

-

I don’t have room to fix cars so watches it is. We’re all here to help…and I’ll add snark for free1 point

-

1 point

-

8 day strike. Rack striking, this particular gathering pallet was not popular it was prone to wear. It strikes on a gong. Date no later then 1930. The hands are in the style of spade. The movement looks in good condition.1 point

-

1 point

-

Hi looks very similar to the junghans J80. Have a look at the site. Ranfft junghans J80 for a comparison.1 point

-

1 point

-

I live in Budapest, Hungary. My nickname is after a frozen engine. Fagyi V8 (fagyi = ice cream in Hungarian). My picture is coming from an ice cream and a V8 logo combination. Most of the time USA is my source, since I often have to buy parts for my cars. Tools, seals, crystals are from local horology shop, they sell even for repair shops and enthusiasts. Pictures about watches later.1 point

-

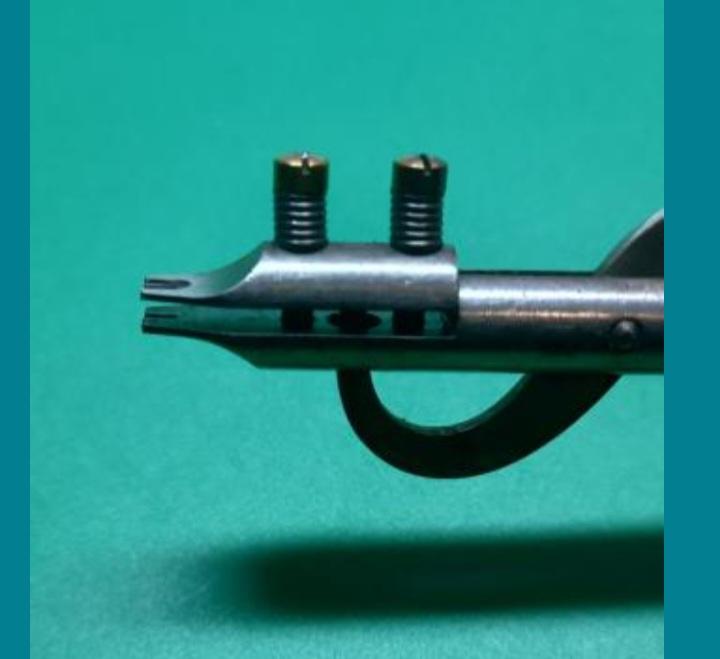

Flaming heck! How does that work? Two prongs into and under the cogs. But surely the angle will be massive from the round thingy?1 point

-

1 point

-

For the offset? Is it different to the normal Presto tool? Genuine enquiry.1 point

-

1 point

-

You think that’s bad from cousinsuk? Rich, just ask for one at a jewellery shop or AD, my friend was quoted £800 for a longines strap, hence him coming to me Tom1 point

-

Thanks for the links and documents for the Longines 428! I found a spec on Emmywatch for the mainspring as 1.00x0.110x320x9.5 and found it on Cousins UK for £7.30 and ordered it. As a back up I found the barrel complete in a NOS package and ordered that too as my skill with mainsprings is still not to the level of certainty to get the one into the old barrel and some of the generics need to have the arbor end worked to fit the specific caliber arbor and that is also a skill in development. I am a firm supporter of Cousins UK and shop there first when they have the parts I am looking for. Definately what I thought it was as broken very close to the arbor. Couple more photos of the partial disassembly in case it helps someone. Once the spring / barrel comes in I will post in a fresh thread.1 point

-

I experience the same type of issue with my digital microscope camera in regards to recording. I resorted to using the HDMI interface to connect up my laptop and used that to do the recording and take photos.1 point

-

I got my first 404 club entry. Bought it for $4.25 ($10.60 with tax and shipping). Pretty rough but it runs. Has a pretty unusual (at least to me) band. Had to use the super glue trick to get the case back off. Cannot tell the specific movement, other than it is labeled Lavina Watch Co. I cannot find much info on DeFrece or Lavina.1 point

-

I have the same microscope/camera. Until recently I had no complaints but the camera has started acting up. It will stop recording for no reason, sometimes after a minute or two, sometimes after 10 minutes, sometimes it records normally. Really frustrating when I look up and see that the camera had stopped recording who knows how long ago. I've tried several different micro SD cards, recording in 1080 vs. 2K, doesn't seem to matter. Some other frustrations include not being able to adjust the exposure while recording which is an issue because if the exposure is perfect while zoomed in, when you zoom out it is so bright everything is blown out and you have to stop recording, adjust exposure and then start recording again. Also, unlike any camera I've used before recorded videos are only numbered sequentially if you don't delete files from the card. I also wish it had a microphone port as there are times I want to make an audio note while I'm working on the movement. I forget why now, but I ended up replacing the the c-mount adapter included with the scope with one off of ebay. BTW, one trick that you may need is when you stop a recording and then want to start recording again, it usually doesn't respond to the record button. I've discovered that you have to (for some reason) hit the button to take a picture and then you can start recording again.1 point

-

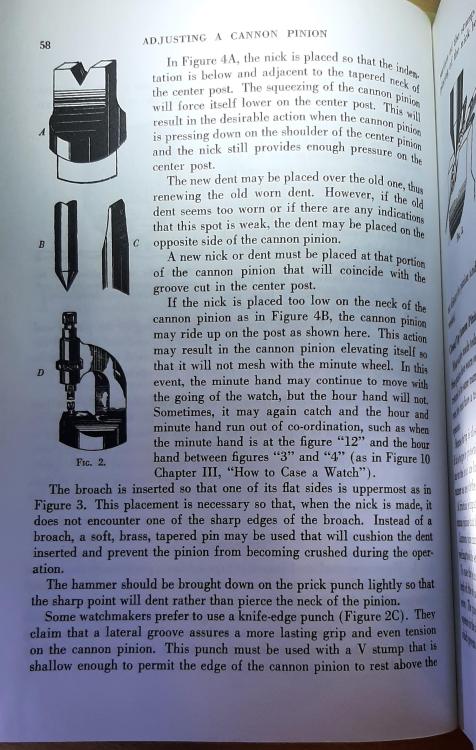

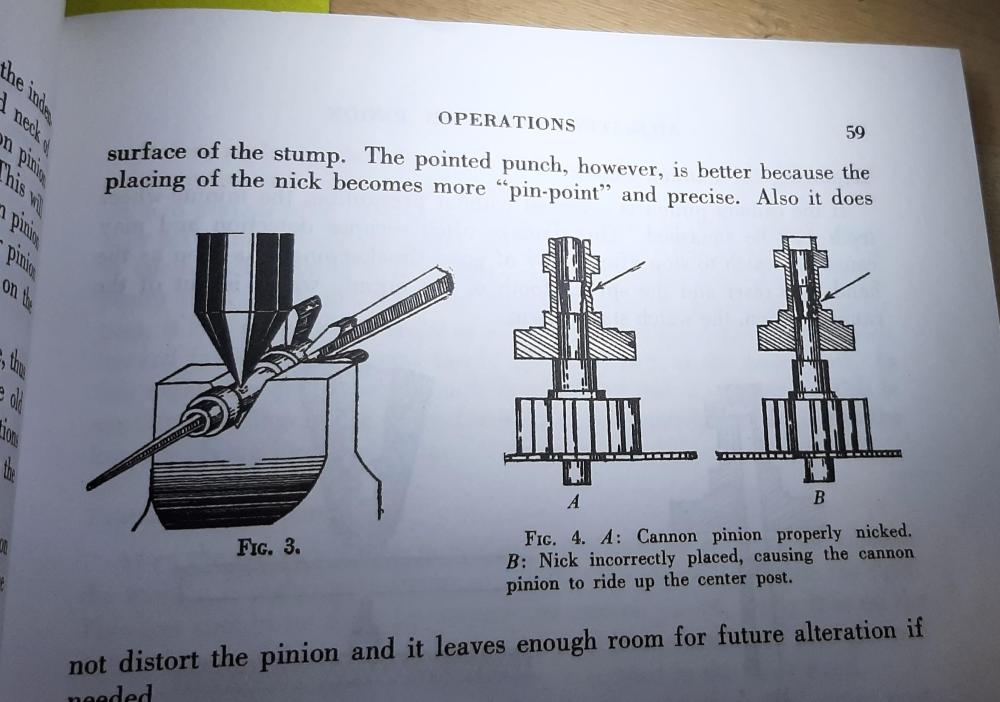

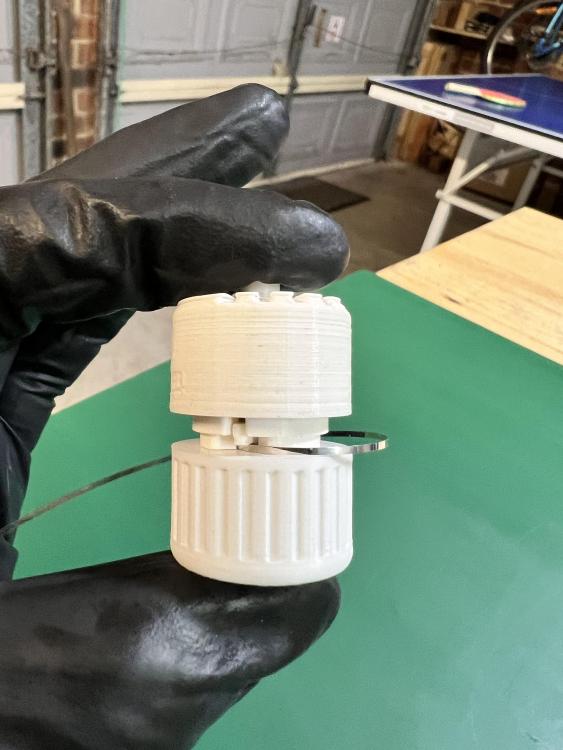

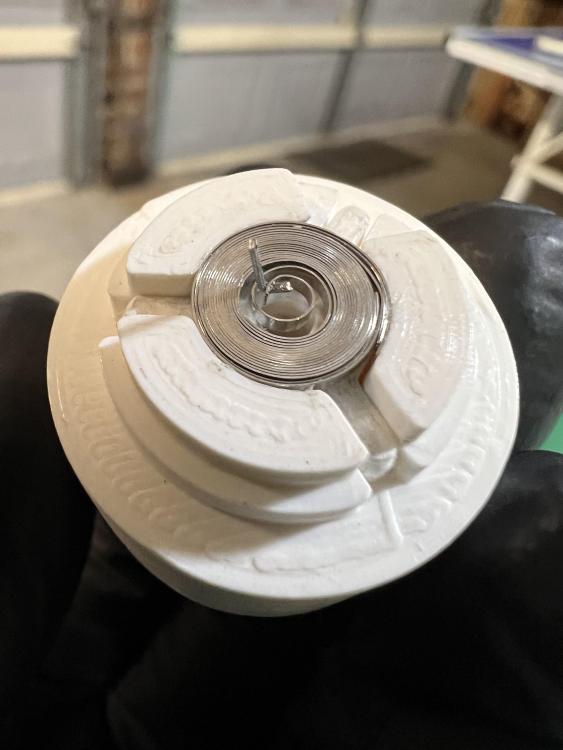

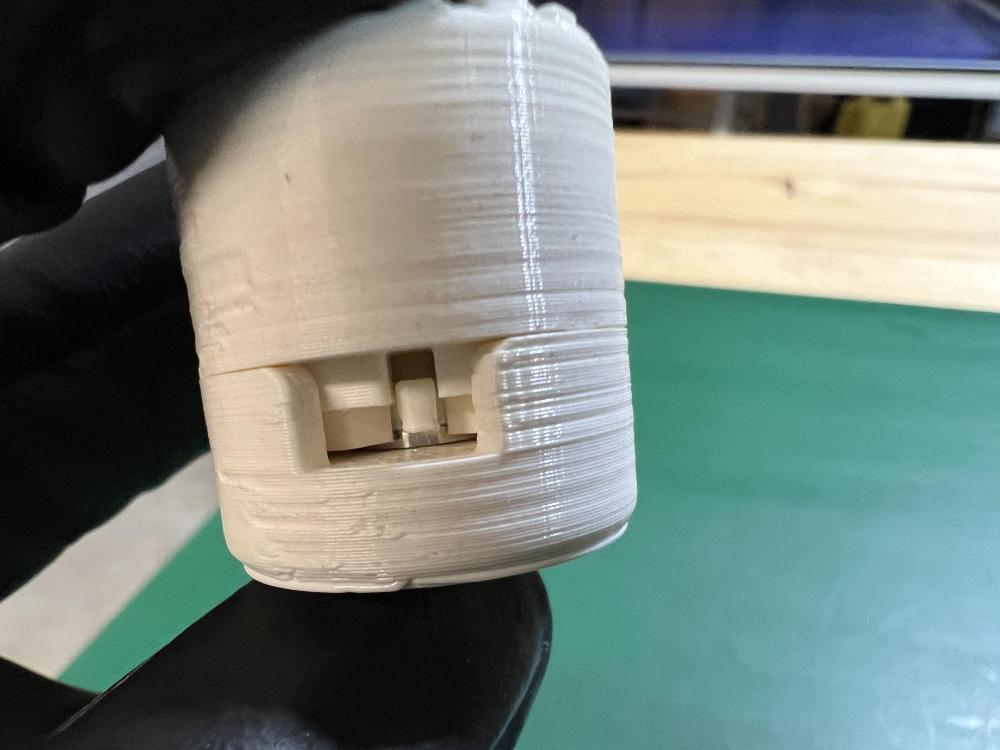

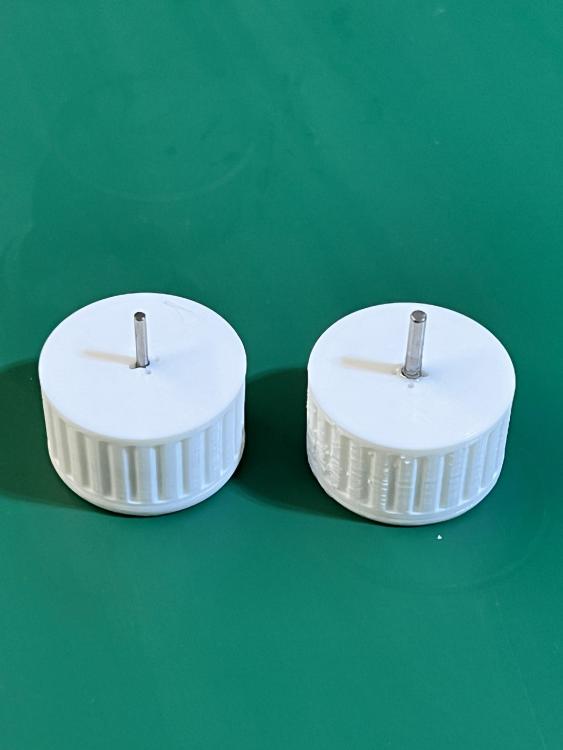

rehajm, Mikepilk. Making one as we post. The down stake is made. Making the bottom post. I have the Fried book as a Christmas present from my bride. She had put it away to wrap. No amount of pleading will allow vision before Christmas. Update. Just made the stump. Top is flat. I will do the groove for the canon pinion tomorrow. Hopefully it will look like Fig. 3. Not sure if I will use a stake like suggested by rehajm, I think I will, or the 'pin point' as suggested by the same fig. 3.1 point

-

I think it's a sort of chronograph, but not with constant running time. The clue is the word "stop" on the dial,and if you look at the movement you can see the hack lever that stops the balance wheel. If you leave it running it works as a watch to tell the time but the pushers allow you to stop and start it for timing purposes. These have always puzzled me because it means that you have to find a reliable time reference to reset your watch once you have finished using it as a stop watch.1 point

-

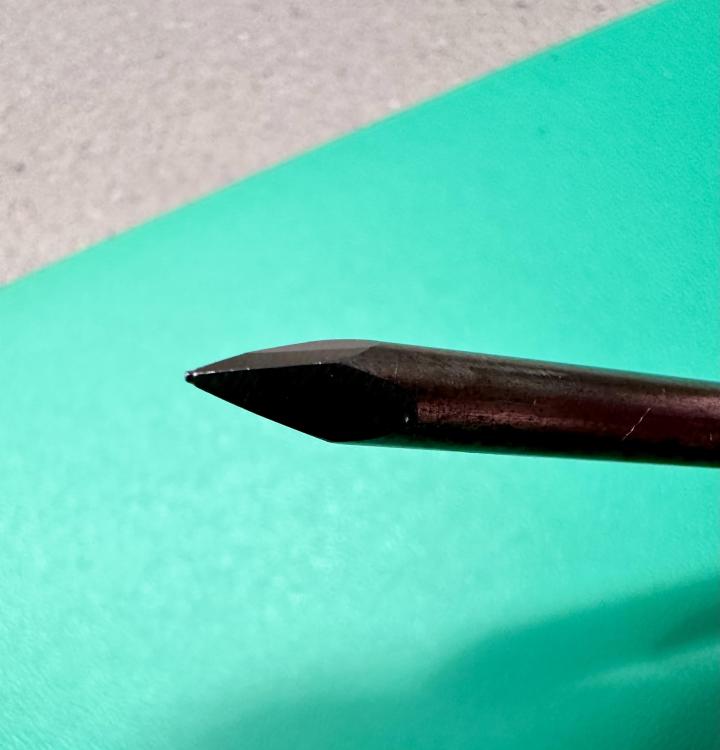

I find the dent tools to be too much stress and after having overdone and had to open a couple pinions back up I tried that spikey broad-arrow stake that I keep snagging my hand on. A couple little taps on the bottom of the pinion gives four little notches in the pipe for the end of the pinion to grip the base of the center wheel near the plate… …I don’t know when each technique is more appropriate but after 2-3 with the spike I haven’t had to adjust yet…1 point

-

1 point

-

1 point

-

Waggy quote" I assume it is something to do with the cannon pinion?" Exactly the same problem. I realised when I replayed Mark's course material Level 3: Fault Finding c3.1.0 The Initial Inspection c3.1.1 Check The Motion Work. Described the exact symptom. Same as you. Back to a complete rebuild. Disassembly, clean and off I go to apply a fix to the canon pinion. So pleased I've got the right tool on my DIY additions in my staking set. Good this hobby innit?1 point

-

1 point

-

This all probably sounds like a time consuming and tedious process but I assure you it is much quicker to do than to write out a description, and I can complete the whole process in a minute. I find the most fiddly element is the inserting and removing of the staple hook into the spring eye and I suspect a smaller staple would be more suitable for this particular spring. I think this spring winder excels for a number of reasons: 1. it’s very cheap 2. it’s very easy to print different size barrels to cover any watch size 3. I see in these forums people saying that regular winder are subject to the arbor hook wearing. This is not an issue for the 3D winder. 4. I believe that springs of different thicknesses may not align with the arbor hook of standard winders. For the 3D winder the shank of the staple hook is free to ride up and down and thus position itself as required for the spring thickness. 5. Springs can be wound left hand or right hand in the same winder. All in all, a great option for hobbyists. Well done To Zero for his excellent creation.1 point

-

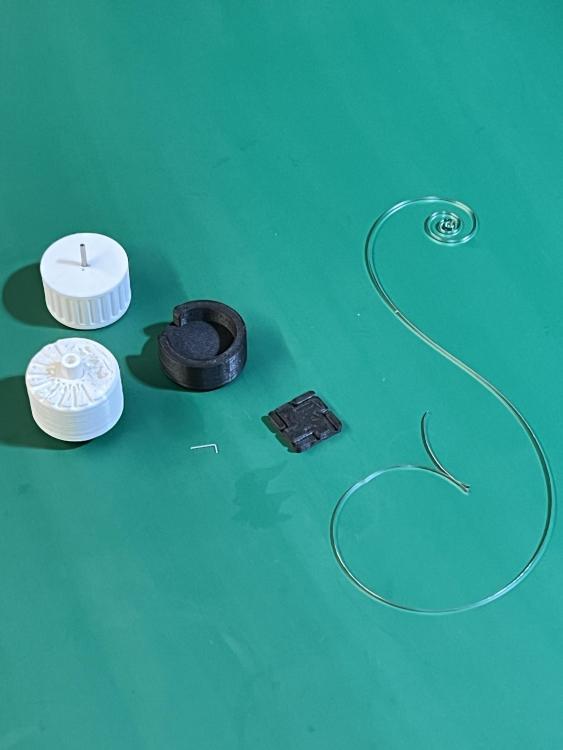

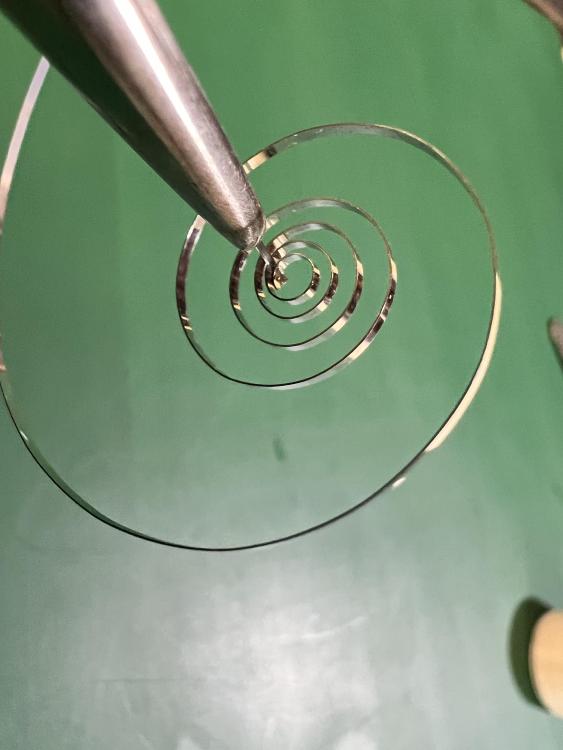

I have been practicing with the 3d printed mainspring winder and I have settled on a process that is giving me very good, repeatable results. What follows is a picture story board of my process that I hope may assist others considering this device as a primary spring winder. Firstly here are the collection of components that will get our spring back into the barrel: the winding barrel, the winding base, a plunger, a ‘setting’ bowl, a staple cut into the shape of a hook, and finally a clean spring from a seiko NH35. The square plastic piece is a jig for cutting the staple to size, however I am finding that I don’t really need it and can comfortably eyeball the correct size. Next, and perhaps it’s unorthodox but I use tweezers or small pliers to place the staple hook into the spring eye, going from outside in as suggested in the GitHub users guide: Next, instead of placing the spring on the shaft of the winding base, I place the spring into the barrel as I find this is the easiest and least frustrating way to ensure the spring tail exits from the correct winding aperture, and without any of the spring sitting on top of the barrel wall such that it would prevent the barrel and base closing together: Now take the winder barrel, with the spring in situ, and place it on top of the base. The shank of the hook will line up with an appropriate hole in the winder base, sometimes gentle guidance is required with fine tweezers: With the barrel and base snugged up and held together, I use slight finger pressure on the plunger which helps keep the spring in a flat plane as it feeds into the barrel this preventing any tangling: Now wind until the bridle approaches the winding aperture and help feed the initial bit in by hand before winding the remainder into the barrel: Note carefully allow the base to unwind and then lift the base off to reveal the wound spring with staple hook still in place: Carefully remove the staple with tweezers before placing the barrel into the setting bowl and pushing down with the plunger. The wound spring will sit proud of the barrel by about 1/3 mm: It is now the simplest matter to line the slightly protruding spring up with the metal barrel and plunge it home:1 point

-

This is an iconic movement from the heat of the chronometer trials of that period. They were made in small quantity, massive mainspring massive balance, tiny escapement. Rare. Numerous independent watchmakers have used this movement as a base for their work, which adds to its rarity and desirability. I don't know if this is a fair price, but given what some independent watches go for if I had the cash I'd buy this. Cooooool watch. (Very few were cased. Most were in "test" cases. The ones "found" by the independent guys were unfinished kits mostly, finished by them. No COSC certification, haha)1 point

-

I have been using the 3D printed winders designed by zero and I am coming to believe they are an excellent option. Even with less than optimally printed parts from my local library, I achieved success after some practice. I have not used traditional metal winders but my suspicion is that it would take a similar period of trial and error before becoming proficient in their use also. I recently purchased two bases, from Andyshap who sells sets on eBay, as the bases with the small holes designed to accept the staple ‘hook’ is the most critical part from a printing accuracy standpoint. Andy’s parts are well printed (photo below), prices are reasonable, and he is a pleasure to deal with. The barrel, plunger and setting base that the library printed were easily good enough to work as designed. The greatest difficulty I’m having with the 3D printed winder is the initial setting of the spring into the drum such that the tail of the unwound spring exits through the appropriate aperture. The wall on the 3D winder being so much thicker than the thin metal wall of a traditional winder makes this initial alignment more difficult. For the price, and ease of procurement (not having to trawl eBay waiting for a good vintage set to turn up) they are tough to beat!1 point

-

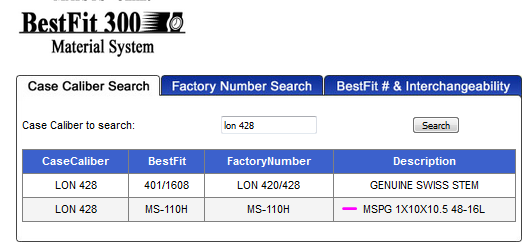

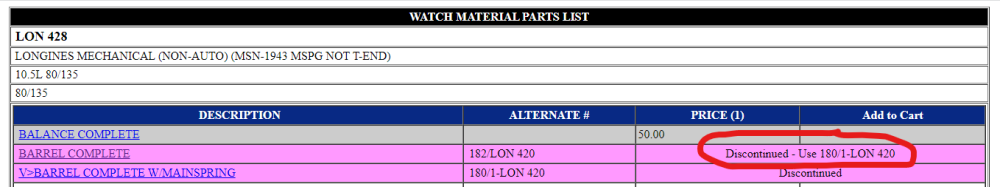

The PDF parts list is interesting because the barrel is sealed. You can see that in the picture but they also have a mainspring number. Which implies the mainspring can be changed. Also if you look at the link and scroll down the list a mainspring. Plus going to best fit online they don't have a lot of parts at all but they do a mainspring listed. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=LON_428 8343_Longines 428-1.pdf 8342_Longines 420.pdf1 point

-

1 point

-

Wish you well. Take your time. I've got this on follow Here is my free book. Please let your family read it. It has helped a lot of people Regards Ross No_Man_Has_The_Right.pdf1 point

-

1 point

-

I am attempting to remove the dial from an Omega Constellation with the Cal. 654 movement. I have worked on a few Cal. 650 series movements before, but they all had dial screws to remove the dial. This one appears to have a friction fit dial, but I can't seem to get it off. I've tried prying it and it seems to have moved a little, but I'm concerned that I might bend the dial if I keep going. Is there something I'm missing?0 points