Leaderboard

Popular Content

Showing content with the highest reputation on 11/15/23 in Posts

-

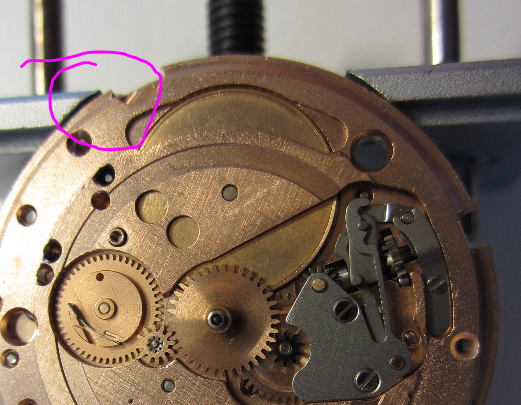

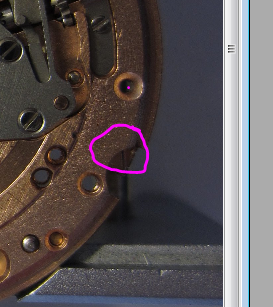

I've been learning for a while. Loving every moment of if. Ish... But for a while I have been defeated by one watch. It is a Seiko Bellmatic 4006a. It has put my confidence in a little trough. I've followed the routine of my mentors. If in doubt, remove an item and replace the screw so you know where it comes from to stop problems arising. I had two problems. The alarm bolt yoke spring keeps popping out. Every time I have put on the calendar plate, the setting wheel rocker has popped out from under the plate. I redo everything again, done many times. Getting fed up. The spring and the rocker are held by screws. The spring is against the screw that holds the setting lever spring. The rocker is held by the alarm setting lever screw. It has taken me some time to figure out the the screws placed in those holes were obviously not the original. I have removed both screws, gone to my ebay spares drawer and obtained 2 screws with larger head heights. Bingo! Both items are now secure. I can proceed. ish... Waiting for the next problem5 points

-

4 points

-

3 points

-

3 points

-

Yes. Needed to close a lose pinion. No stump. Made one with a groove to hold the pinion. Hammer time. Done. Good this hobby innit?2 points

-

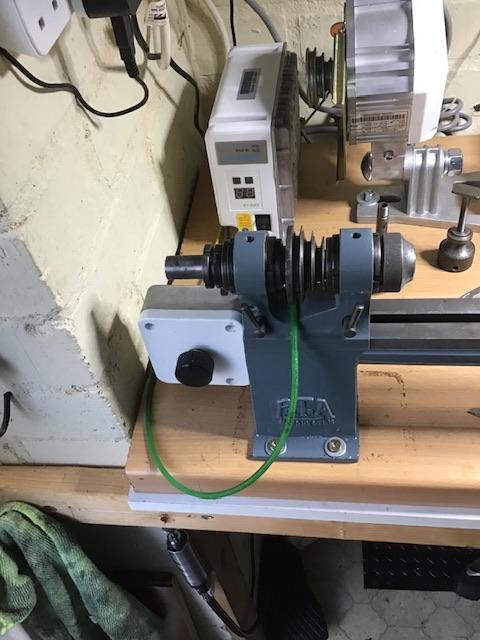

Hi Neverenough i don’t know if you know but if you’re having trouble finding collets to suit your new lathe but depending upon how things fit the spindle you may be able to get or certainly make an ER collet chuck for it and get some good quality ER collets, I have made one for my Pultra 17/70 although at the Birmingham watch & clock fair I purchased a very complete Pultra P type 10mm lathe it takes the same collets and accessories as the 17/70 but has a smaller foot print and as my workshop is very small I am going to use it , just in the process of restoring it and it was nice to find that all serial numbers match. i have added a picture of the collet chuck practice pieces I made just to give you an idea Dell2 points

-

This is the sort that I used. https://www.hswalsh.com/product/bergeon-bushing-wire2 points

-

Interesting thread. A little cold, but I came to it just last night. If interesting, I can share my experience, which is generally turning pre-hardened and tempered to blue steel in a big lathe wit cross-slide support, using carbide cutters. In the distant past I have used T-rest and hand-held cutters too, and still use this technic when needed, but not often.2 points

-

Can you please send a picture, this will help us advise. Also if you list what tools you have available, we could maybe recommend the best one and how to best use it We'll crack that nut!2 points

-

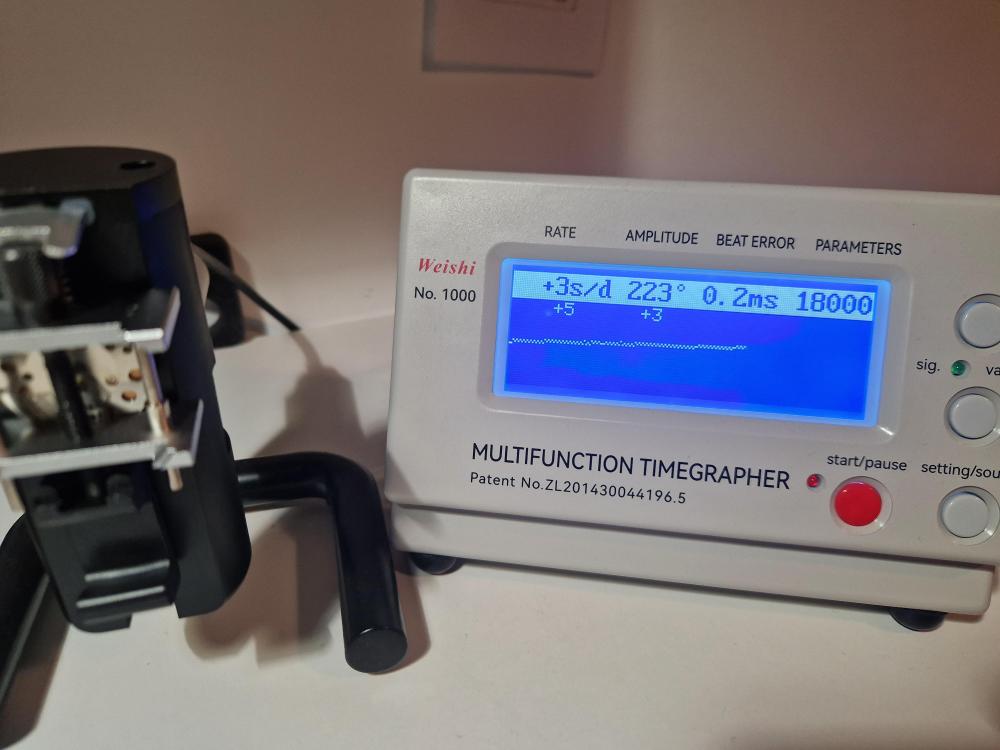

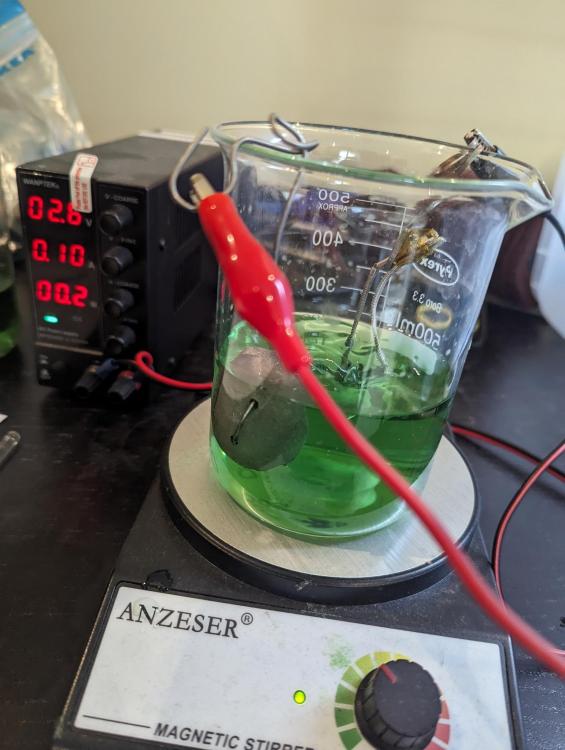

So.. good news!! New ratchet wheel arrived and everything works just fine. While it now definitively confirms where the problem was, we will probably never know how the ratchet wheel ended up with such a bizarre off-center hole. I'm also very happy that the hole-closing on the bridge and barrel arbor holes seemed to have worked well. Sure, I'll only know in a few years if the repair was long-lasting, but at least for now it doesn't seem to cause any increase in friction - quite the opposite: Amplitude is very high with nice, stable traces. Here a picture at full wind and dial up: And before you say anything, dear @JohnR725, here are pictures after 24h in dial up and vertical crown down positions: Dial up at 24h: Crown down at 24h:2 points

-

So, I have some news about the ECS jacot tool from a French watchmaker: "This E.C.S tower is 2nd generation, certainly manufactured by Houriet & Cie in Tramelan (Switzerland) in the years 1940/1955. The company was bought in 1989 and became Horia Steiner Company. See this link: https://www.horia.ch/fr/L-entreprise/Historique/Historique-HORIA-SA.html E.C.S lathes are beautifully made pivoting lathes, identical in their use and precision to the latest generation Horia/Steiner lathes. Another advantage is that they have the same spindle diameter and are therefore interchangeable."2 points

-

No, You can use alum only if the screw is in brass plate. All the steel parts have to be removed from the plate, othervise they will dissolve too. Arbour will be damaged for sure.2 points

-

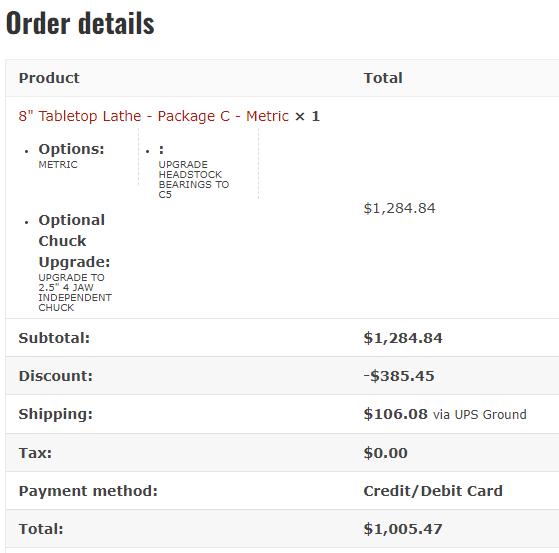

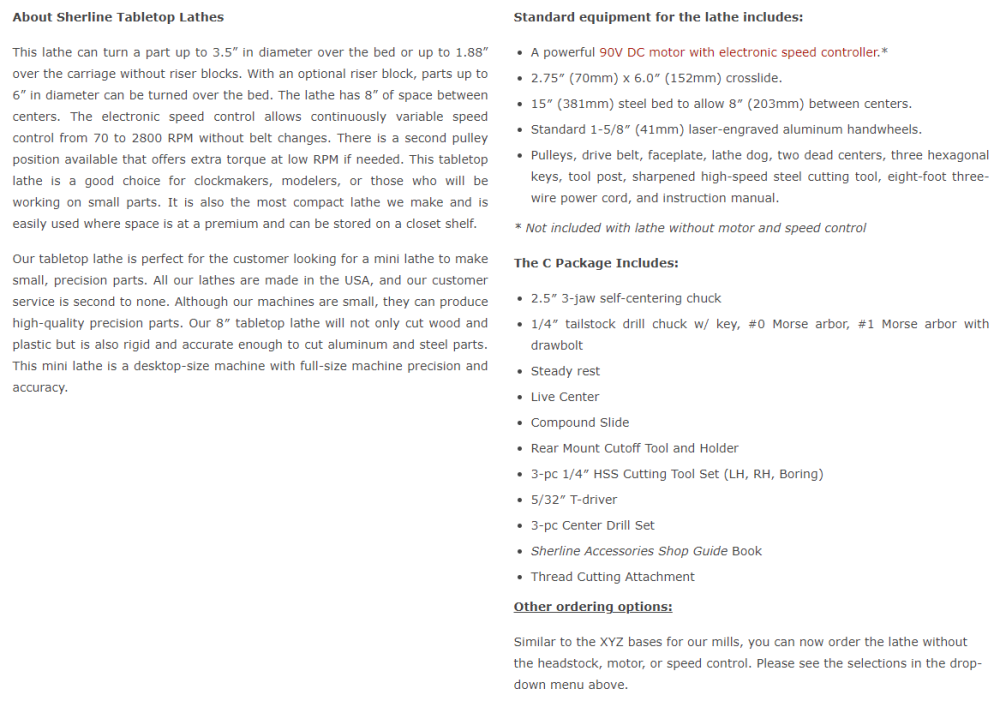

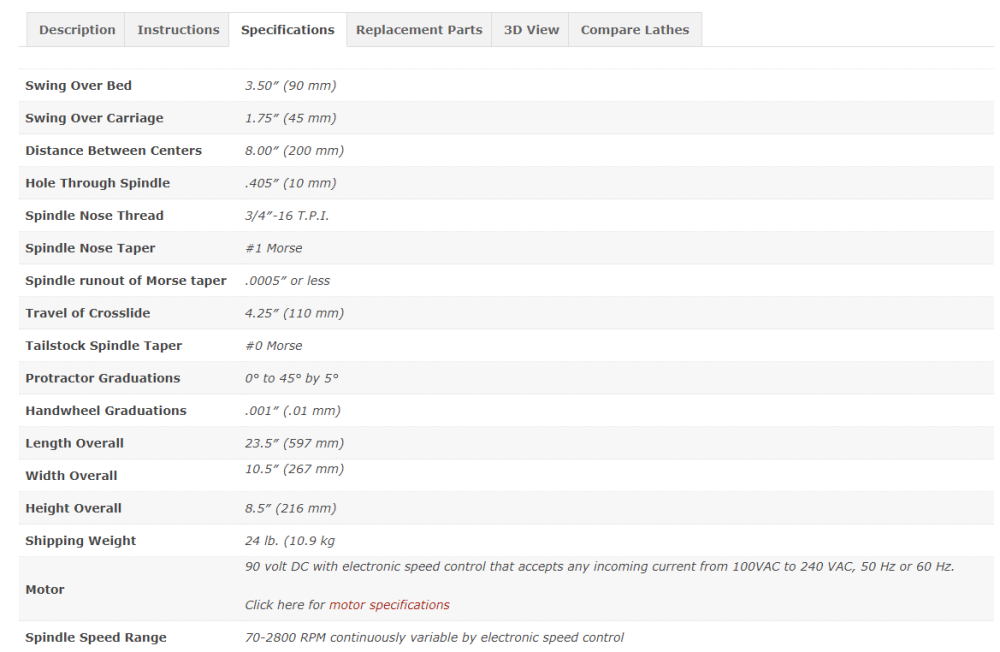

Apologies for re-raising this issue, but I would like to put my own spin on it (pun intended), I would like help on getting started in the world of lathes. I have reached the point where not having the ability to make parts on a lathe is starting to hamper my watch making development. However, I have never owned or used a lathe and have no practical knowledge of them, quite an admission from a 25 year Chartered Mechanical Engineer who is also a Fellow of the Institution of Mechanical Engineers.... but there you go! I can design in 3D CAD and program for a 6 axis CNC machine, but stand me in front of a manual lathe and I wouldn't have a clue. Anyway, back on topic.... I am a great believer in the 80:20 rule, so looking for a set up that will allow me to cover most of what I need (when starting out anyway) without breaking the bank on getting all the bells and whistles that would sit on the shelf for 99% of their lives - I can work on those over time. I am also looking for a setup that isn't some obscure brand or setup/size, as I want to be able to look up instructional videos etc. Not having any experience I need a volunteer(s) to "lead me by the hand"....."Scott, buy this and this and this..... there you are done!" kind of thing, also, any recommendations on YouTube/videos and other resources on using a lathe for watch making would also be great. Confession over... and thanks in advance for the help and advice.1 point

-

1 point

-

1 point

-

Bloody brilliant Ross, you owe him a pint. Haha and i have one of those "men in sheds" Its in a sports pavilion on a field at the end of my road , its never occurred to me to give them a visit1 point

-

1 point

-

That’s great Ross- have you used it in battle yet? …and I have a honeydo list for the shed for men . Are they fueled by pints?1 point

-

The pierced wire OH linked is far better for bushings than regular 360 brass rod; it's been drawn which makes it significantly harder and the difference in wear (lack of) in use is also significant. Still very nice to machine.1 point

-

1 point

-

Welcome Jaime, I'm not a pocket watch guy but when you said some ? WOW. you just have to give us the story behind this please.1 point

-

Be care its starting to look like a slinky toy. https://youtu.be/SCi_5KpQfUU?si=VhzJFql_cC6OyaQq1 point

-

Wow, servicing that lot will take you years. Welcome to the forum enjoy.1 point

-

Just a wonky part Rich, a wonky part. Something I've always had bother with.1 point

-

1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. You need to go through them all with extreme care take down the makers names on the really old ones the name will be on the back plate of the watch. Sort out silver cases from the gold case ones. If you don't have very much knowledge of pocket watches its a job to advise you on where to start. How about you start with those in trays post good photos of those first and we can help you.1 point

-

Wow that's a lifetime of work, by the time you finish the last one, the first will be ready for a service.1 point

-

1 point

-

The unfortunate enthusiasm of watch repair versus watch repair. What YouTube is not filled with God's? The gods of watch repair. Somebody probably on this group once did a whole little ranting and raving of how The YouTube gods Okay perhaps didn't actually say the God's but YouTube's gods did more to promote hobbyist and watch repair them all the watchmakers all throughout history or something. So there are some good and some helpful channels out there and there's a heck of a lot of well undesirable things they skip a heck of a lot of steps or Basically produce almost worthless garbage but it's entertaining the clueless. My absolute favorite so far as somebody who disassembled a cylinder watch with the power still on. Then yes it was obvious what kind of watch it was if you understand the person didn't understand and didn't really grasp the dangers. Perhaps think about YouTube watch repair videos like let's take up a new hobby of bomb disposal. Yes there still a lot of misplaced explosive things in Europe you can help your community by watching a video and disarming one of those things. After all what could go wrong? One of the favorite sayings that my first instructor and watch repair school had don't please the timing machine. Of course that was one of those old-fashioned timing machines that just spit it out paper. He wasn't discussing these new timing machines that have microprocessors so obviously they have intelligence they have a program. Unfortunately the program is interesting. It's interesting when you compare a witschi to the Chinese to the reality of the situation of what they can and cannot do. The unfortunate reality of a timing machine is it requires intelligence in the form of the user because the machine does not actually have any intelligence at all even if it does have a processor. Then even if someday someone made an artificially intelligent timing machine it's still is going to have a problem if it cannot do with the human being can do. In other words you have to be able to make visual observations of what the watch is doing. The timing machine points you and directions gives you clues to what to look at but somebody still has to make a visual observation which requires experience typically lacking a newbie's. This is why made the reference of quick pleasing the timing machine you're probably making things worse much worse. Oh other minor problems with timing machines especially the Chinese it lacks audio. It's amazing in addition to your eyes what listening to a watch can tell you I assume you're following of the standard procedure of learning watch repair by learning as you go? Perhaps a picture so we can see what you're using and we could help you to use it better.1 point

-

I know I may be stating the obvious, but you do know that both screws are a left-handed thread? Also, alum is a bit crap, unless you have lots of time on your hands. the best thing to use if you do need to dissolve screws in Bergeon Visson which takes less than ten minutes when whatever you need dissolving is put in a crucible and heated with a spirit lamp. make sure there is nothing like a minute wheel post in the crucible which is usually made of steel. Also Incbloc setting will dissolve, so be very wary what you are doing https://www.hswalsh.com/product/screw-loosening-extractor-fluid-vissin-bergeon-4503-0050-hv401 point

-

The wheel actually made me very confused when disassembling the watch. I tried to take it out but it wouldn't move, so I found a youtube video of someone taking the same movement apart and they didn't remove it either. I guess that the real mistake was to assume that video was "correct" instead of doing more research. I will start over and clean it properly! Thank you very much1 point

-

...after a ham-handed week of peril that left a wake of parts in trays here's a victory- Fontainemelon ATP with some lovely dial patina- the photos do not do it justice. New Spring and crystal is all- this one wasn't harassed much over it's life. T'was stuck up tight with dried lubricants but cleaned up beautifully excepting a bit of finish on the lower barrel. Some fiddling this morning has it back in beat and the hairspring a bit more on the level- runs flat as a pancake up/down and three- amazing. Was deserving of a new strap so I ordered one of the military reproductions, though if you like old leather with cheese I kept the old one, likely the first and only other for this watch... ....hopefully this doesn't start an ATP kick. I'll try to temper meself...1 point

-

Have you serviced this watch movement after fully disassembling everything? Have you checked for any chips or damage on the pallet jewels and they have a good depth of 'lock' with escape wheel teeth? Have you checked that the impulse jewel isn't loose or not straight or chipped? Have you checked that the notch of the pallet fork isn't damaged or badly worn? Have you replaced the mainspring with a new one? Trying to diagnose why a movement has a low amplitude when the mainspring hasn't been replaced is a pointless exercise! Did you check the chaton jewel isn't badly damaged or chipped, because you said there was a broken balance? I'm assuming it was a broken staff? The breaking of the staff sometimes damages the chaton it was spinning in. Did you remove the wheel over third? That's the wheel that is staked onto the extended third wheel arbor and when you checked the freedom of the wheel train with the wheel over third removed, did you look from the side at that extended third wheel arbor to ensure it was spinning without any wobble? Have you checked after replacing the movement with another balance that the balance end-shake is good? For this movement, it should be about 0.02 mm to 0.04 mm. Is the hairspring touching the boot? Does the hairspring have room to breathe between the curb pin and boot?1 point

-

I think you should stop trying to please the timing machine. I don't suppose you have a model number? One of the interesting problems with timing machines is if the amplitude is too low a timing machine will often read the wrong part of the waveform and give you a really nice happy number. If the amplitude is too low everything gets magnified like beat error becomes extremely bad when it may be isn't. You have to be careful when you're interpreting the timing machine graphical display has to look somewhat decent. The numbers should agree with the graphical display and visually that should agree with what you're seeing on the timing machine then the timing machine becomes reliable. When you have a seemingly random dots bizarre patterns and other stuff the timing machine numbers tend to be worthless. So basically the timing machine is telling you it's having a problem your watch is having a problem as opposed to it's an exact science of my watches doing exactly this the timing machine is just telling you you have a problem. If you're concerned about the beat error but the power down and visually look at it looks like give a movable stud you should build put it exactly where it's supposed to be? Also out of curiosity how did you lubricate the escapement and the rest of the watch .1 point

-

As it is your personal watch, I would say not to worry too much about what you see on the timing machine. As @nickelsilver hints, TMs aren't all that reliable. I've had situations where my Chinese Weishi 1900 indicated 240 degrees amplitude when in fact it was 300 degrees. For more details you can check this and this post of mine. I suggest that you put your timing machine on the shelf for the time being and instead investigate how the watch fares in the real world. I have been surprised several times by how well watches worked in real life, showing somewhat frightening results on the timing machine. Wear and use the watch consistently for a few weeks and read how much the precision deviates per day. If the watch consistently goes a certain number of seconds too fast or too slow per day (give or take a few seconds), you know it's working as it should and then it's probably just a matter of you needing to regulate the rate.1 point

-

Just forget about hairspring magnetization. In this movement there is much that can get magnetized, but not the hairspring. Hairsprings that can get magnetized, made of steel, were used long time ago, with bimetallic compensating balances for example. But not after WW2. Something else: You best timegrapher reading is actually the one with 286 degr. amplitude. That’s why I said I doubt that the balance/hairspring are couple, as there the timing error was more than 700 s/day. What You need to do is find how and where the hairspring now touches/rubs. This could be the balance arms or the cock, the hairspring may be not in plane that is parallel to the movement. May be in rest position it doesn’t touch anything, but when balance turned to 90 degr. for example. Please, do the free oscillations test – remove the lever and with the balance in place, turn the balance to 180 degr. and release it, then count the number of free oscillations to the full stop. Here, as with the amplitude, one oscillation is swing to the left +swing to the right, so You must count only swinging to the one direction, or just the expandings of the hairspring. The good result is about 100 – then we will know the balance, bearings/pivots, hairspring – all OK.1 point

-

Hi all, just thought it had been a while since I posted any projects. I've actually been quite busy preparing for a local market where I plan to sell some watches for the first time. Here is one of the watches I worked on, a Seiko 7S26, it actually needed quite a lot replaced on the automatic works, but I got there in the end. Before front and back And the finished watch: Here is another Seiko I worked on, this time a 7S36 from my friendly supplier in the Philippines, this one with a sport style case. And the after shot, I ditched the bracelet that came with it to use on a future project, it was a Seiko bracelet but wasn't original to the watch. Thoughts, comments and suggestions greatly appreciated.1 point

-

1 point

-

Now that we have the correct movement number which we do know has dial screws here's what he's referring to so one of the dial screws is found. Unfortunately these gifts over the other one but still now we know where it is So yes a lot of the time style screws are found in notches and go in at a angle especially with dials that have calendar mechanisms or the dial feet have to be on the very edge as there's no place else to put them with calendar discs etc. Then somebody else servicing a watch unfortunately skips over things like the dial...But we can also look at his movement pictures and based on the video image above we can make a wild guess of this is where one of the dial feet screw is. So once you grasp where that one is the other one should be easy to find.. https://watchguy.co.uk/service-omega-constellation-calibre-564/ Okay I will make a wild guess if you look at where the dial screwed those then you can see the whole look dial foot was into and it has a little bit of a taper so the flick will go in versus having just a straight hole as there's quite a few holes on the plate. So my guess is this is where the other dial foot is and unfortunately at all the pictures above were looking at the wrong angle we really can't see this1 point

-

1 point

-

1 point

-

Is it a knot ? Or is it not a knot ? Ive had coils jump inside each other, you can work it up to one end, the cock stud end with a fine needle. Fried was a bloody master of hairspring untanglement. If i can find the video, i once counted the number of times he said tangled and untangle, it was a lot, yes I'm a very sad and strange individual . Hairspring 101 i think it was, let me find it and come back. No it wasn't 101 I'm talking out my arse, but this is Henry the hairspring wizard performing his mystical art . https://youtu.be/egCwtMMoOCU?si=4LDRlpfqWVXKUHET1 point

-

Just arrived today. Tissot Seastar automatic with a 2481. I really like the cushion case and this may be my daily wearer for quite a while. Some very minor adjustments only. Added a Barton silicone band that is extremely comfortable on the wrist. I need to look up the serial number but must be early to mid 70s.1 point

-

As almost all watchmaker lathe makers are now defunct, it's good to get a brand where you will run into accessories and parts without too much trouble. I strongly recommend going with an "American" style lathe, with what's called a Webster Whitcomb bed. Here some quality makers are Derbyshire, Levin, G. Boley, Boley Leinen, Wolf Jahn, and Lorch. Of those, my absolute favorite is Boley Leinen. One of the main reasons being that the tailstocks always line up, from one machine to the other, mixing and matching*. They also accept commonly found 8mm collets from Schaublin, Boley, Leinen, Levin, and others, in my experience. Some of these machines are made to take 10mm collets- you definitely want to stick with 8mm, far more available second hand. I would go for a machine that comes with a collet holding tailstock as it opens up so much the utility of the tailstock. A lot can be done freehand turning (well, all, if you really want to), but having a slide rest is incredibly useful. Unfortunately most made for this type of lathe leave a lot to be desired. After all my years doing this, I have never found anything close to the quality and utility of the slide rests from Levin. They don't come up for sale everyday, but are worth what they go for. Watch out- they came in both metric and inch versions, metric being the preferred one. You can find boxed sets with loads of accessories, but most of the little bits and bobs will sit in the box unused as they have done already for decades. A good basic lathe, a good slide rest, and a good set of collets is enough to have you making parts. I use my lathe daily and it's rare to need anything other than that. I do have some scroll chucks and such with are handy for certain work. Some info on Webster Whitcomb *On the Boley Leinen- there were two "eras" older and newer. Older ones had a very slightly different bed size, and wont mix with the newer ones. Newer ones always have straight black locking levers for the head and tailstock, older have more bulbous fancy ones. You want the newer style. The machines were made with both plain bearing and ball bearing headstocks, either is fine, the latter tending to be more expensive. And finally, I've read on other forums (check out Jerry Kieffer's posts here) where some folks have been super happy with Sherline lathes even for doing tiny watch parts. As an adapter is required to use 8mm collets, I have a hard time imagining that you can chuck up a small part and get it to run truly true, and there are some other limitations. But those machines are very affordable brand new, and can do some stuff that is very difficult on a watchmaker lathe, like cutting screw threads. For new machines, the only one I can see as being worth any investment is the apparently very high quality Chinese made CZ-50. It appears to be a sort of homage to the ball bearing head Leinen machines, and they have a lot of very happy customers. I think the base price is around 6k dollars for the lathe with collet holding tailstock and cross slide, so not something one would buy as a first machine necessarily unless that sum is palatable.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)