Leaderboard

Popular Content

Showing content with the highest reputation on 11/17/23 in all areas

-

5 points

-

I usually use 400 grit wet and dry (used dry). For straight grain, this is my cheapo set up. It works really well. I stick the case back to the bracket with some Rodico. Running along the wood means I can run it up and down and keep the grain straight. If the case back is not absolutely flat, I put a very thin layer of something spongy under the paper (I use some thin packing foam). For circular grain, I use 400 grit on a stick, and pull it from the centre out. I don't have space for a bench polisher so have to use a Dremel type tool. With practice I can get a good finish.4 points

-

3 points

-

2 points

-

2 points

-

Lovely watch. Have a look here https://www.watchprosite.com/girard-perregaux/mimo-wwii-dienstuhr--a-closer-look/6.1004143.7068013/ Are there faint markings on the back? Could it be German military and the marks have been erased? Looks like the radium is flaking.2 points

-

2 points

-

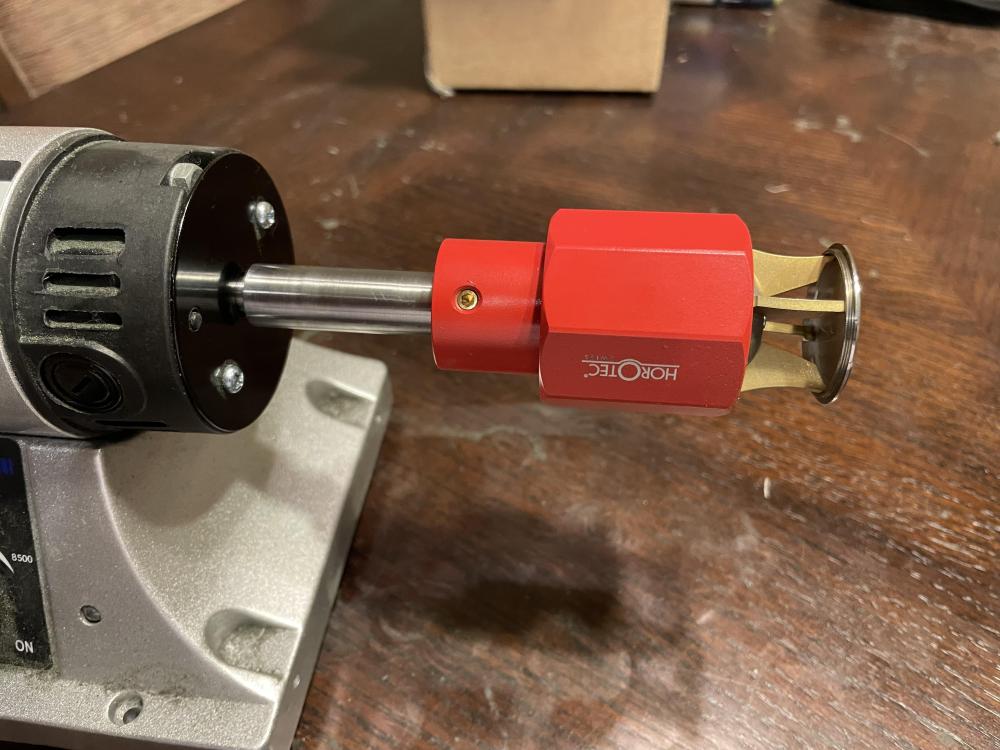

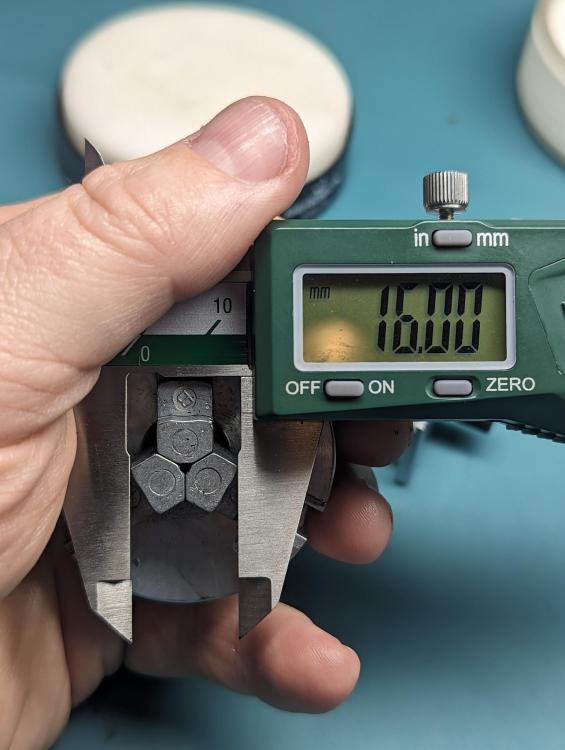

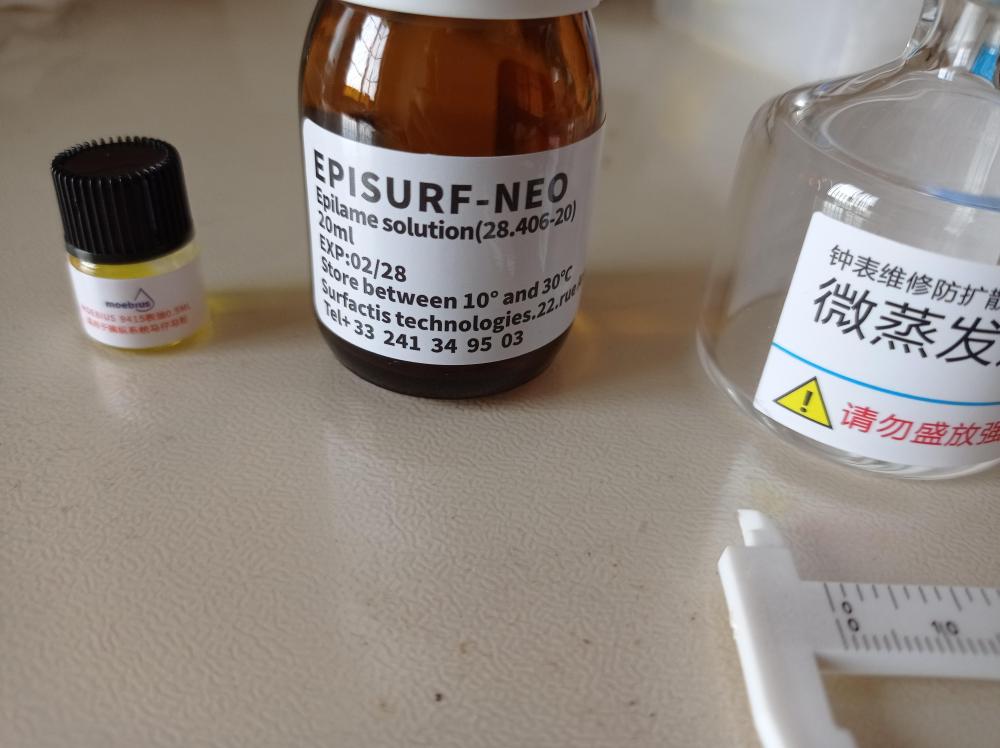

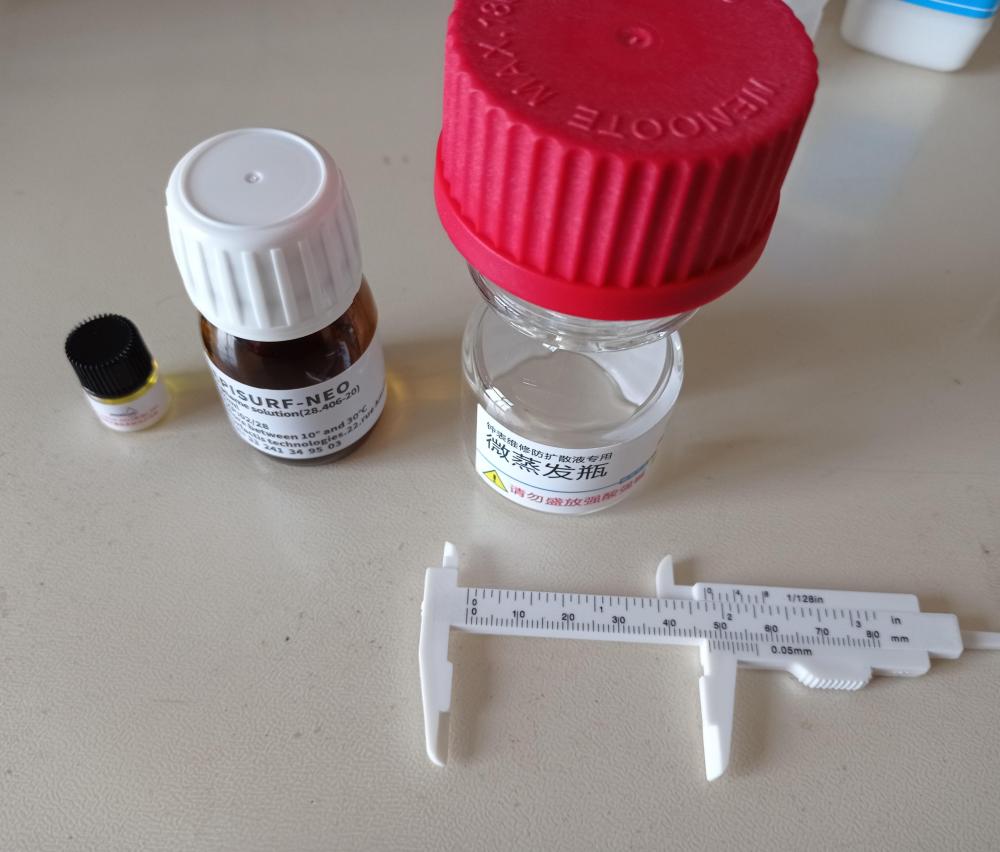

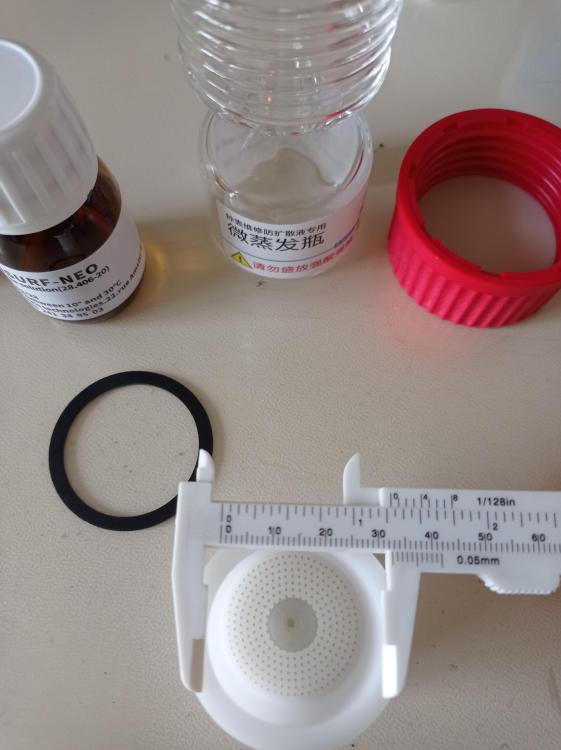

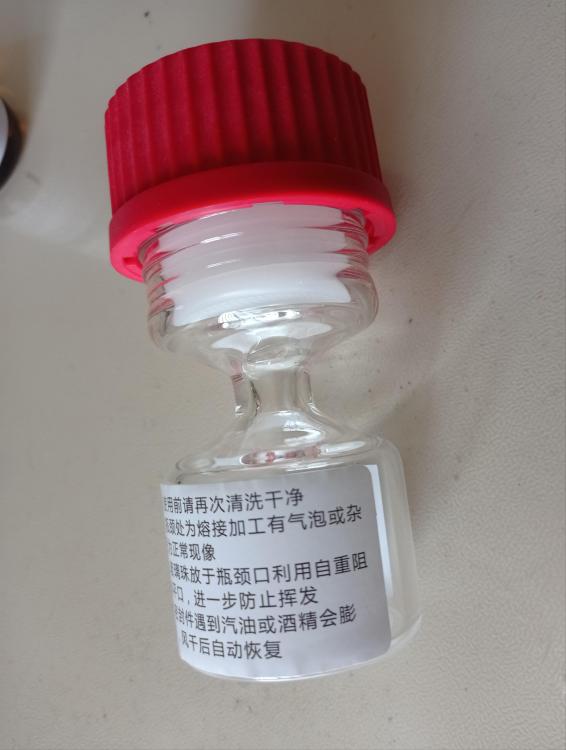

Well I happen to score a Horotec polishing vice for a song on eBay. I was able to call up a friend with a lathe and got an adapter machined so I could mount it to my motor arbor. Horotec sells a reduction die, but the size wasn't compatible with the arbor on my motor. I got this little part made, then drilled and tapped a few set screw holes for the arbor side. I can't wait to destroy a few junk case backs & bezels while I learn how to use it properly!2 points

-

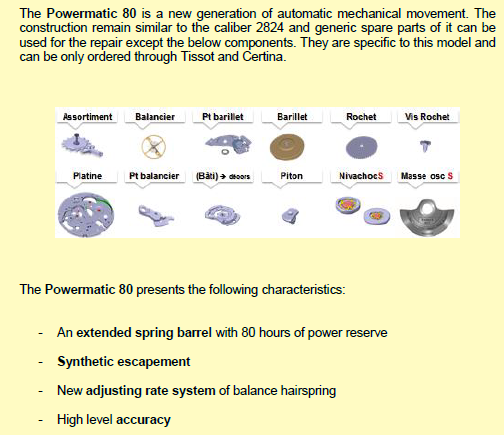

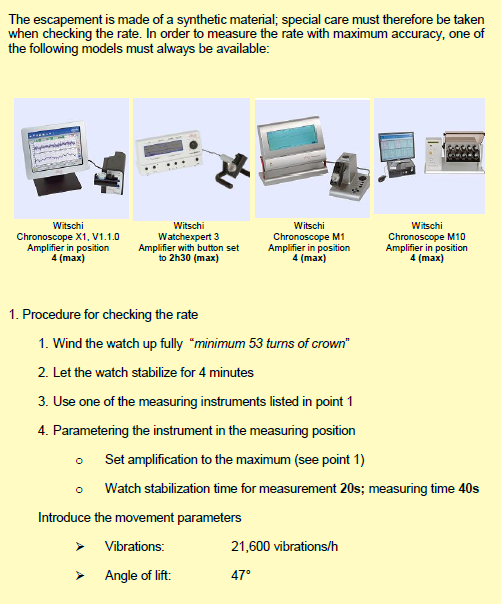

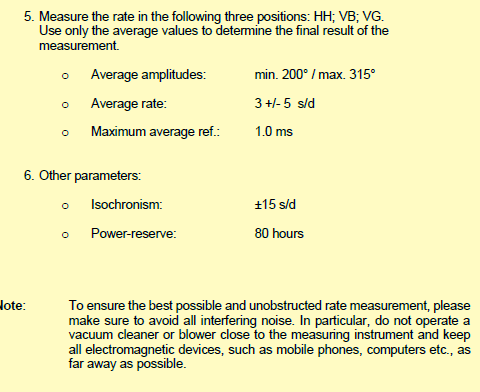

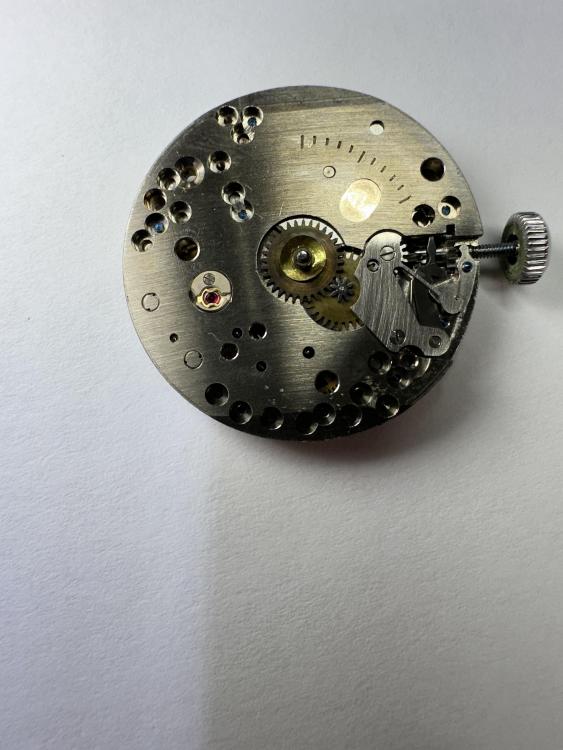

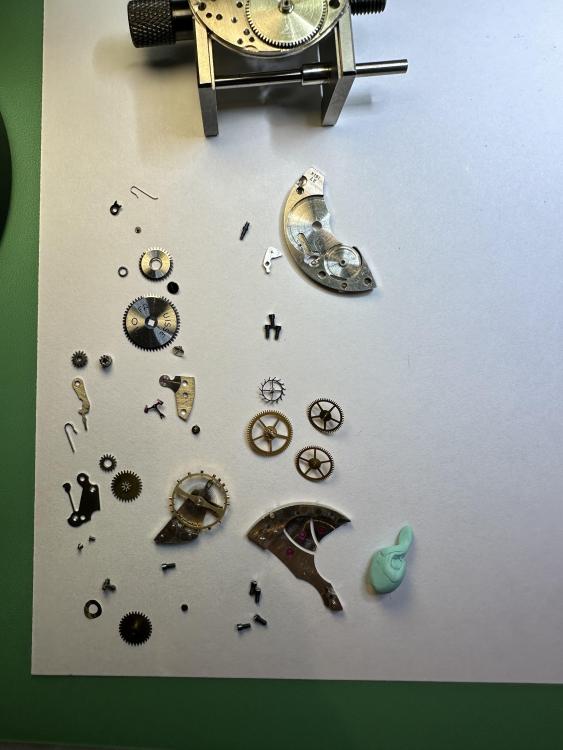

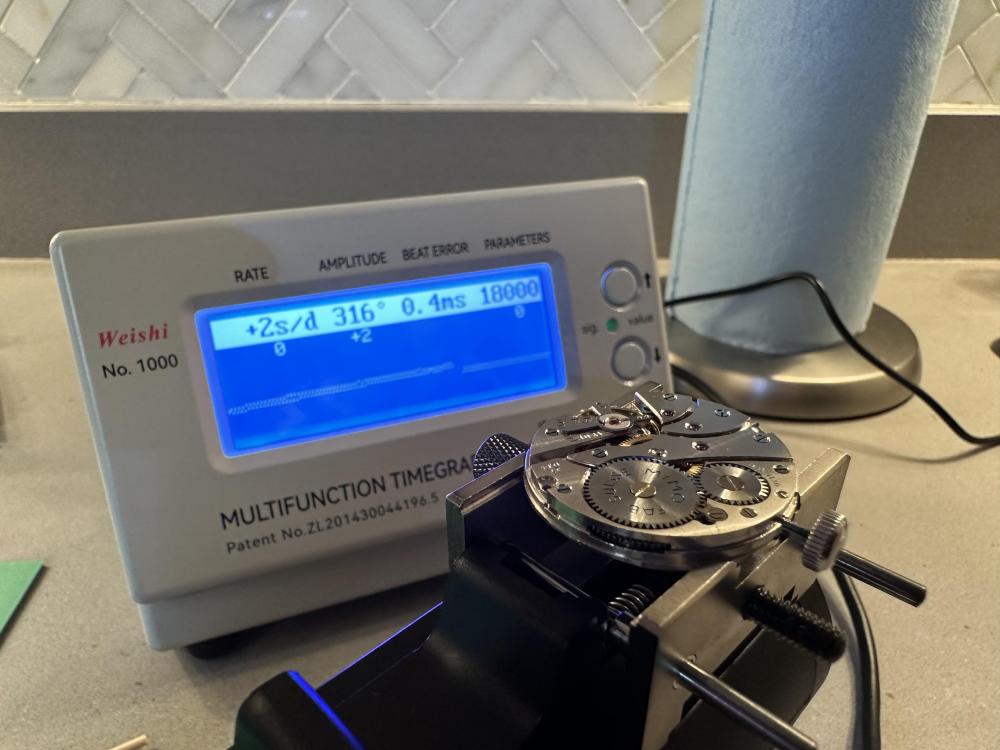

Let's do a little googling because I need a model number. Googling gives us this https://calibercorner.com/tissot-caliber-powermatic-80/ So if I guessed correctly why don't you try a lift angle of 47°. Let's quote something from the website Base Caliber ETA C07.111 (based on the ETA 2824-2) From the website that I quoted this from if we look at the specs for the 2824-2 for instance we find that It has a running time of approximately 38 hours. One of the problems that people often make is the assumption that the base caliber is the caliber with just some minor little modification. Except it usually is not and that will result in issues like availability of parts. So for instance what been changed on this watch well we know that it runs for 80 hours not 38 that's going to be a gear change and a new mainspring barrel. It has a synthetic escapement which by the way requires a special lubrication for the escapement. Plus a few other things have been updated and/or changed. Think of the base caliber as the base that something was built upon not something that had a minor tweak done to it. Then I find the description cheapo quite interesting considering the Chinese 1000 and 1900 and my viewer outstanding purchase versus purchasing a witschi machine that will cost quite a bit more. Although it is quite a bit nicer timing machine but doesn't really matter which one you use if you're clueless over what you're trying to do for instance. Then the problem was Swatch group is they don't like sharing their documentation. It is almost basically not available typically unless you try really hard to know the right people. So for instance This is a older document as witschi has newer machines that I know would be a little time this. So think of this is a sampling which is telling us something all of the machines have the again sent to the maximum because this is a quiet escapement. Ideally I would recommend not trying to regulate this watch. You're supposed to have some special tools something that goes under the balance rim so when you're rotating the timing weights you don't screw things up by pushing down on the arms.2 points

-

..because everyone likes visuals here- just off the bench- Mimo AS cal 1130. It was an country auction house purchase nobody paid any attention. It took all of a day to fix up start to finish. I only needed to remove the gummy oil and the wrist Rauchkäse. My obligatory new mainspring though there was alloy inside. Hand rubbed the old crystal... I was quite impressed with the movement and the case here. Hefty and the way the screwback slides open...high quality. ...Is it from a military batch? No markings on the case back so dunno....and I don't know too much else other than prices for these things are all over the place. I paid less than 100 quid to get it to the states from UK. Imma wear it!1 point

-

1 point

-

1 point

-

1 point

-

For the most part. When oiling a cap stone i'll hold the tweezers in my right hand and the oiler in my left, but when setting hands, I'll position and steady the hand with tweezers in my left hand and press them on with my right. Bum wiping shall remain unanswered.1 point

-

...when loading old crap I like to keep my dominant hand free of old crap. Any crap, really...1 point

-

Sometimes the simplest solutions are the best - consider this copied1 point

-

1 point

-

Concurring with the people who hang out here is not necessarily an ironclad sanity check. I will wear finger cots on my right hand and use it to hold the movement while tools go in my left hand, but then again, I am left-handed. Do what feels most comfortable.1 point

-

I used a 320 grit wet and dry and it seemed to work OK1 point

-

OK, just wanted to make sure I wasn't crazy. I can't even find that advise now but it sure looked like hooey. Thanks guys.1 point

-

That's great @Waggy. Small enough for most watch backs. It's exactly what I've been looking for, and they are on ebay UK for just £18 (just ordered) I just had my latest watch delivered today, a Smiths Everest 19J, and the back happens to have radial brushing.1 point

-

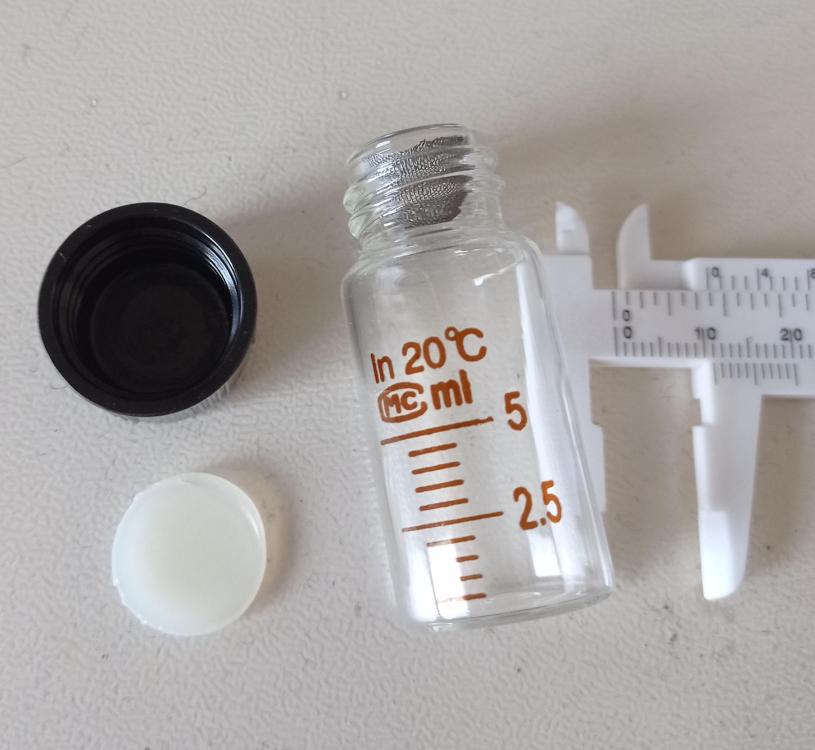

I think there are two types of cleaning machines: 1) rotating, 2) ultrasonic "Moderately priced" only has meaning to you. New cleaning machines are expensive. A new Elma rotating machine on the JulesBorel site is about $3k. You can buy an ultrasonic cleaning machine (single bath) from $50 to $1000 depending on many variables. Some people put the cleaning solution into a jar and parts, then put the jar in an ultrasonic. Then same with the rinsing solution. A tedious process but probably works. Using this method, you could have a cleaning setup for well under $200. I have chosen to go the rotating route for the most part (I do have several ultrasonics). I just bought a vintage L&R machine in non-working condition for $300 (shipping included). I am refurbishing it now and will have to add a basket which is about $50. Cost of paint, etc. I will have $400 into it. I have seen units go upwards of $800 on ebay. If you are a scrounger (as I am), you can happen on to super deals. So, in summary, if you are willing to go vintage, you can have a rotating machine for less than $1000...maybe less than $500 if you perch on ebay and wait for the right deal. It helps to have some electrical skill (I am an EE) because these machines can come with motor issues. Sorry if I am rambling. There is a BUY IT NOW unit on ebay for $550 with free shipping (I am not the seller).1 point

-

1 point

-

Try peeling an apple with the apple in your dominant hand, and the peeler in the other.1 point

-

1 point

-

1 point

-

1 point

-

NC and UNC are effectively the same. But, even if you made an adapter to the highest level of precision, i.e. in a larger lathe that can cut threads, and it was "perfect", you would still see concentricity issues, and also rigidity issues from spacing out the chuck that much further from the spindle bearings (plus just having an additional coupling between the chuck and spindle). Even at 220 bucks with shipping it's a ridiculously low price for the quality of the Sherline chucks.1 point

-

If buying a manual lathe i would also suggest something micro in the watch makers arena. Due diligence is very important when buying used lathes as many of them are not fit for machining micro components and holding tolerances. I myself as an engineer with 30 years precision engineering and machine building background have come across some nice looking used lathes however on closer inspection they were not up to the job for precision or micro machining. It would be a good investment to buy a used machine and over all it by converting it to a CNC controller. If i can be of any help please fire a message, I just picked up a used Boxford Lathe and starting stripping it down to be updated with new CNC controller and motors.1 point

-

I doubt your repairman would get your watch to run as well as when the piece left the company . The level of excellence your watch was regulated to, matches King Seiko. Its a six year old watch so you shouldn't expect to run like new. Enjoy your watch in good health. Rgds1 point

-

Don't take it to the place you went to last time. Do it yourself if you want the practice and are curious to see what improvement you can make. Otherwise, come back to it in a year. I bet it's keeping excellent time when worn.1 point

-

OK, I usually make balance staffs for big pocket watches out of rollers from roller bearings. This are rollers from car driveshafts bearings. I know people with car services and thus have unlimited source for material. The rollers are size 1.8-2.4mm diam. X 10-15mm, usually made of good steel and are hardened, need only tempering to deep blue. Actually, the tempering slightly depends on the steel sort, and there is a rule by G. Daniels that says 0.1mm test pivot should bent to 30 degr. before it breaks. I also check if the test pivot is normally strong, as in some cases it will break much easier than a normal pivot, and then this lot of rollers (or steel) is not good for staffs. For wrist and small pocket movements, where the pivots are thinner than 11, I usually use 115CrV3, this steel is superior to everything else that I have ever test, but I have limited quantity, it is soft and needs hardening and tempering. Working with this steel is a pleasure. I also have and use soft У10А, which is Russian analog to O1. Usually make of it screws, stems, etc. It needs very careful heating when hardening, as overheating is easy and it ruins the steel, developing big grains structure and parts break easy. Here is my main lathe, as You see it is really big and actually nothing to do with watchmakers lathe, just regular general purpose 70 cm lathe. But, I am able to make staffs for the smallest wrist calibers on it. I also make threaded parts on it, directly from blue steel, but with milling attachment instead of cutter. The interesting here is this set of cutters, which are accepted on the place of the tool post. They are pre adjusted in high and ready to use. Changing the cutter takes minimal time. The cutters are tungsten carbide and are made of CNC router bits, which are cheap and easy to source. I use this kind of diamond disks to sharpen cutters. The smaller disks are cut from a bigger one, the disks also easy to source, grit 600 or 800. I sharpen the main cutter every time when start new staff turning. If the cutter needs re-sharpening during the turning, this usually means that the steel is to-hard. If it is possible to turn 2-3 staffs without re-sharpening, then the steel is softer than needed. I have developed technic for easy maintaining the sizes in high and making one staff usually takes me about 30 min.1 point

-

Any jewel with a shock setting should be removable and should be removed and cleaned as part of a service. The ST36 only has shock jewels on the balance, so for that movement all the others are pressed in and not removed for service, just pegged. Right now, I'd just keep the balance complete all together and just practice removing it and placing it back. Removing the shock jewels can come later as it is a little intimidating initially.1 point

-

Here it is. Photograph taken outside on the front step as light too poor inside. It has taken me a while, and I have learned so much. Still so much to learn. Special thanks to YouTube videos. Adam (Weekend Watch Repair), and our leader Mark Lovick (WatchFix - Watch Repair channel).Their presentations on the Bellmatic 4006a have been my bible.1 point

-

1 point

-

@VWatchie This is a truly remarkable walkthrough. So detailed, comprehensive, clear and fantastic photos. Congratulations and thanks!1 point

-

You could do like they did with the post WWII German watches in Eastern Europe, and just scratch the everliving hell out of the back until there's no engraving left.0 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)