Leaderboard

Popular Content

Showing content with the highest reputation on 11/18/23 in Posts

-

Well, that's good to know! If it was some other body part telling us perhaps we'd use our left foot4 points

-

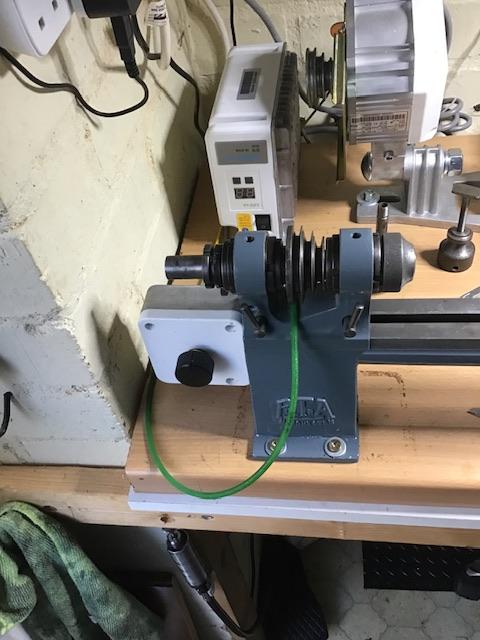

A lot of people seem to ask what motor to use to run a watchmaker or small instrument lathe so I thought I would post my observations on the motor that I use , because I only service, repair and restore torsion clocks I use a Pultra 10mm instrument lathe but the motor I use will work just as well for a watchmaker lathe, it is made by Jack and it is an industrial sewing machine motor although I have removed the foot pedal and replaced it with a potentiometer because I have trouble with my leg twitching, the motor is very quiet and smooth and the torque is very good even at slow speed and I have added a video of me making a replacement disc pendulum adjustment rod just to show how good it is, I tend to run the lathe a lot slower that most when using a graver the video is when I had my original Pultra 17/70 although I no longer have it because I needed a larger lathe for some work and as I am very short of space I sold it when I got the Myford something I regretted almost immediately ( benefit of hindsight) , anyway I have now found a Pultra P type in very good original condition apart from a broken knob on the drawbar and at a price I couldn’t turn down so after stripping, cleaning and repainting it is setup on a piece of kitchen worktop with a Jack motor , I have checked runout and it is half an increment on a 0.001mm dti so very pleased, I have made a replacement knob for it on the Myford and I have made very small screws on the Myford IE 12BA but find it a lot easier on a small lathe using a graver, I hope this is of els to anyone looking towards a small lathe. Dell3 points

-

If you are not practicing as well then you are limiting yourself. I keep a small pot of screws and shock settings and spending 5 mins of twisting, twirling and releasing springs before i start to work on anything, kind of a warm up that stems from my weight training days. If i dont work then maybe 10 mins just so i have at least done something.2 points

-

Got my microscope today. Shipping was faster than I expected. Still waiting on the camera, though. Went together no problem. One difference I notice is that to tighten down the head (fore/aft tilt) on the Eakins it is a just an Allen head screw, not the silver handled knob like for the (left/right tilt), unlike the AmScope. Not as convenient to change that tilt. I imagine once set though, I probably will not be futzing with that. I really had to crank down on that screw to keep the head from tilting. The AmScope has 3 of those silver handled knobs. The Eakins just has one, with a plastic knob to lock the boom in place. The dust cover for it is rather useless. Too small to cover the whole stand and too big to cover just the head. The instructions that came with it is for the SZM series microscopes (much smaller stand), which makes me wonder if the dust cover was intended for a smaller microscope. The stand is quite heavy. Wife brought in the box from the porch and asked if I bought a box of bricks. lol Though, the microscope can be tippy if the boom arm is fully extended, so a bit more heft would have been nice. Overall, I'm quite happy with the microscope. I think it will be so much nicer to use this when servicing a watch. Next up is the camera and monitor setup. I was thinking of getting a VESA mount to put on the back of my hutch, so as not to take up any desktop space.2 points

-

Can't wait for you to post some of your work with this new lathe!! I am addicted to lathes and have way too many WW lathes. Now and then, I run into a situation where I need to handle larger stock, so I have had my eye on a Sherline. If I already own six lathes, adding one more is only 17% increase. I can get that by the accountant, or maybe I just hide it from her!!2 points

-

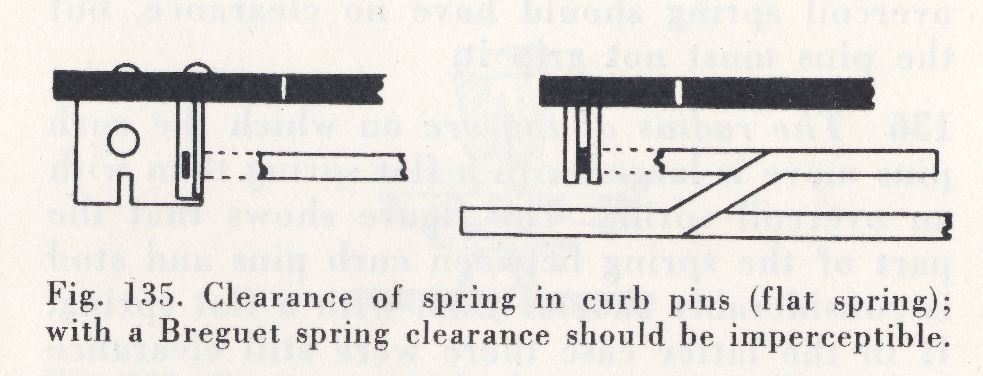

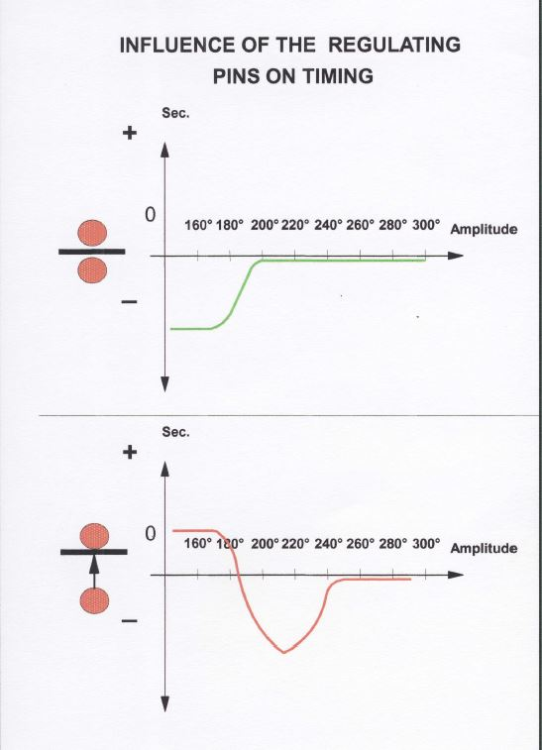

Here's a very good reference and a review of the reference. But minor problem with reference material like this and he even brings this up but he doesn't pointed out as a problem. Reference books like this cover a lot of stuff from manufacturing point of view. So he talks about using it to make hairsprings. You have an existing watch is not going to redesign the watch so it's going to have design flaws. Even if the watch does keep really good time. https://youtu.be/op68gwVvsCo?si=7-jq6k3mRsgTqUeZ Interesting wording let's look at what Wikipedia says https://en.wikipedia.org/wiki/Isochronous_timing Let's see what Wikipedia has to say watch is isochronous if it runs at the same rate regardless of changes in its drive force Notice the reference to drive force the watch should keep the same time regardless of amplitude unfortunately amplitude does affect timekeeping. Another Wikipedia entry let's look at mainsprings https://en.wikipedia.org/wiki/Mainspring Notice the pictures the mainspring is like the top right out of the package and then the lower left the Elgin Springs. Reference to the interesting curvatures designed to produce more even force as the mainspring unwinds. Unfortunately if you take mainsprings out of the ring you find that they don't always have this really nice curvature like they're supposed to. I find a lot of times with modern pocket watch Springs the most amusing was one that basically had the center curve and went straight out and had basically no curve at all that is going to produce very uneven power. Other Springs look almost set but the brand-new and some of the later generation both Hamilton Elgin tend to be some of the nicest looking mainsprings because they do have the proper curves versus the modern Springs which often don't so if you don't have a mainspring of the right shape you're going to have an even power so if there is manufacturing inconsistencies that can be an issue especially when we want to be super nitpicky on timekeeping down to the second. Did you notice this question why do you think I ask this? If you looked at your watch dial down which most people is the only position they looked at the regulate the watch and then move it to crown down what happens for timekeeping? Often times people love to have amplitude and if you around the end your pivots you'll get lots of amplitude but ill have a problem as soon as you go to the crown positions is more friction you lose your amplitude. It's why typically the ends the pivots are flattened to make their amplitude more even with the pendant positions. Basically looking at the watch in more than one position can show the effect of amplitude changes from dial positions the pendant positions and then 24 hours later with the timekeeping look like you also find related the mainspring is our watches that will run 48 hours and 56 hours another attempt to get a more even powered mainspring. So usually not necessarily at the extremes at least at the extremes of running out of energy like you would be of it had a watch that only ran for 30 hours for instance then those pesky hairspring regulator pins it would be nice if we just break them off and not deal with them at all as timekeeping would be so much nicer. Regulator pins spacing depends upon type of hairspring you have. Here's an interesting image obviously a flat hairspring. So we can see the effect of the hairspring bouncing off the regulator pins as long as it's doing that it should keep relatively linear time. But as the amplitude drops basically the regulation point moves and the watch slows down. Opening the pins up will make this worse and closing has issues because flat hairsprings are supposed to have some spacing. Basically if you took the thickness of the hairspring multiplied it by two that's the spacing between the pins. But like everything else that can be some minor variations here Then what happens if you're not centered between the pins. This will also depend upon how strongly are pushing the hairspring out of between the pins. For instance I once worked at a shop where we were instructed to bend a hairspring so it always touched one of the pins. Which would work fine as long as they hairspring never got enough amplitude the liftoff.1 point

-

1 point

-

I wonder if you couldn't contact Eakins (or even Amscope) and request parts. Maybe you got that scope "used" for AmScope purposes. Alternatively, there's always McGuckings up in Boulder! Or McMaster. That's definitely a worthwhile note for the non-AmScope alternatives. There are ways to spec a cheaper scope from those factories in China, and hardware substitutions like this are definitely one of them. You might find you want to adjust the tilt if you're using the full power (180X), as the result of keeping the slight angle is a very thin band of usable focus AND a corner of the light is almost touching the work surface. Also, the AmScope dust cover is big enough to cover the whole thing. Another cost saving substitution. That said, the plastic cover isn't anything to write home over. It keeps dust off the eyepieces, and I keep mine in place for that reason (our house is old, super drafty, and incredibly dusty due to all the mica coming out of the canyon walls). I need to get my wife to make me up something a bit more... more.1 point

-

1 point

-

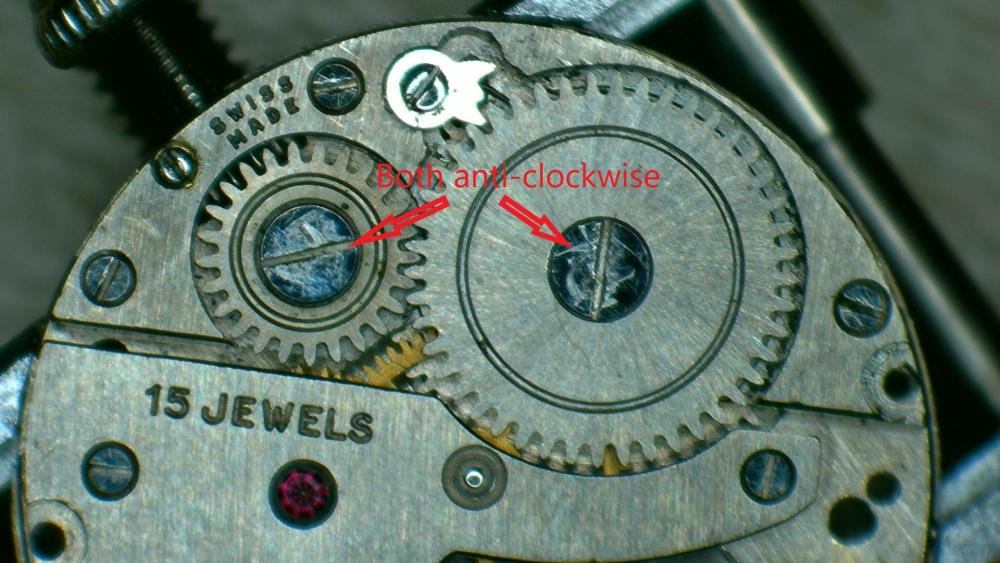

The crown wheel screws are always (?) reverse threaded (if it's only one screw in the centre), or they would tend to unscrew as the crown turns. The Barrel screw is almost always a normal thread, though a few are reverse. You can try them either way if you turn the screwdriver a tiny amount. I've just finished working on a tiny one too. You get used to it1 point

-

I believe it’s like anything else we do, practice enables flexibility in approach. Like @RichardHarris123 I’m not truly ambidextrous but have fine motor skills with my non-dominant hand. Tom1 point

-

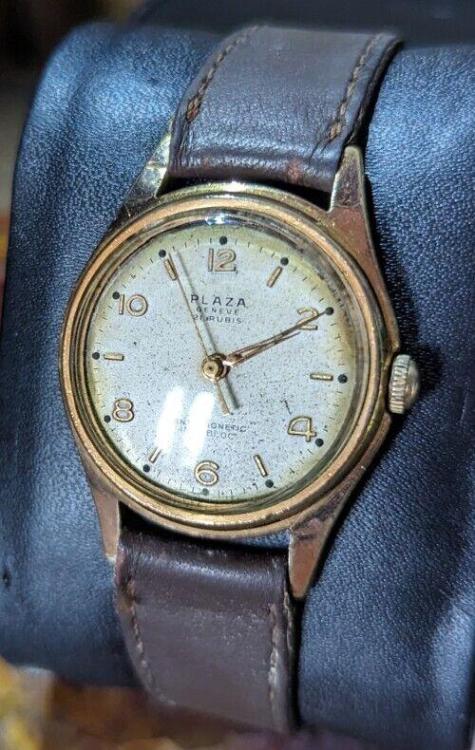

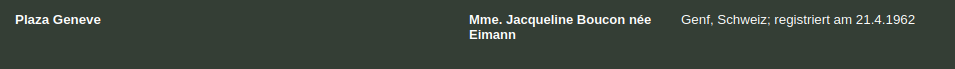

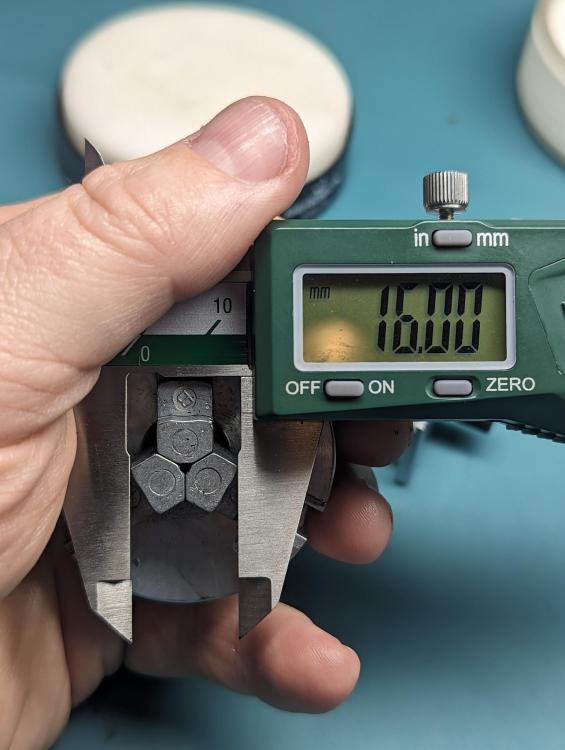

A slightly scruffy Plaza Geneve 21 Rubis "shockprotected" caught my eye in the bargain bins on fleabay. This has a distinctly 1950s early 1960s vibe to it. I'm also a bit of a fan of this size of watch, as to my mind it has much more refined engineering and design aesthetics than the over sized frying pans and so called "smart" watches of today. The listing pictures showed the second hand moving between images, so it kinda works I presume. The case and strap are filthy, and the hands probably need a bit of work, but it has an elegance about it, and a gentle patina on the dial, so with a little work I think it will look pretty good. I have no idea what is in this 404 club candidate, but if the only other similar example I could find is anything to go by, then the movement looks to be well finished. This might be what awaits me inside. EDIT: I looked for a maker on www.mikrolisk.de and it seems it may be from some time around 19621 point

-

I think you naturally head that way, i have definitely noticed over the course of two years i am using my left hand much nore than i ever used to. I often hold a pair of tweezer in each hand at the same time. Position the part with my right pair, pop the screw in from the left, then switch the right hand for a driver. The more you practice the easier it becomes.1 point

-

I do the opposite, but it brings up the point that one needs to develop some skill with the non-dominant hand. Oiling cap jewels is a perfect case for that.1 point

-

For the most part. When oiling a cap stone i'll hold the tweezers in my right hand and the oiler in my left, but when setting hands, I'll position and steady the hand with tweezers in my left hand and press them on with my right. Bum wiping shall remain unanswered.1 point

-

1 point

-

I usually use 400 grit wet and dry (used dry). For straight grain, this is my cheapo set up. It works really well. I stick the case back to the bracket with some Rodico. Running along the wood means I can run it up and down and keep the grain straight. If the case back is not absolutely flat, I put a very thin layer of something spongy under the paper (I use some thin packing foam). For circular grain, I use 400 grit on a stick, and pull it from the centre out. I don't have space for a bench polisher so have to use a Dremel type tool. With practice I can get a good finish.1 point

-

1 point

-

Try peeling an apple with the apple in your dominant hand, and the peeler in the other.1 point

-

1 point

-

If buying a manual lathe i would also suggest something micro in the watch makers arena. Due diligence is very important when buying used lathes as many of them are not fit for machining micro components and holding tolerances. I myself as an engineer with 30 years precision engineering and machine building background have come across some nice looking used lathes however on closer inspection they were not up to the job for precision or micro machining. It would be a good investment to buy a used machine and over all it by converting it to a CNC controller. If i can be of any help please fire a message, I just picked up a used Boxford Lathe and starting stripping it down to be updated with new CNC controller and motors.1 point

-

1 point

-

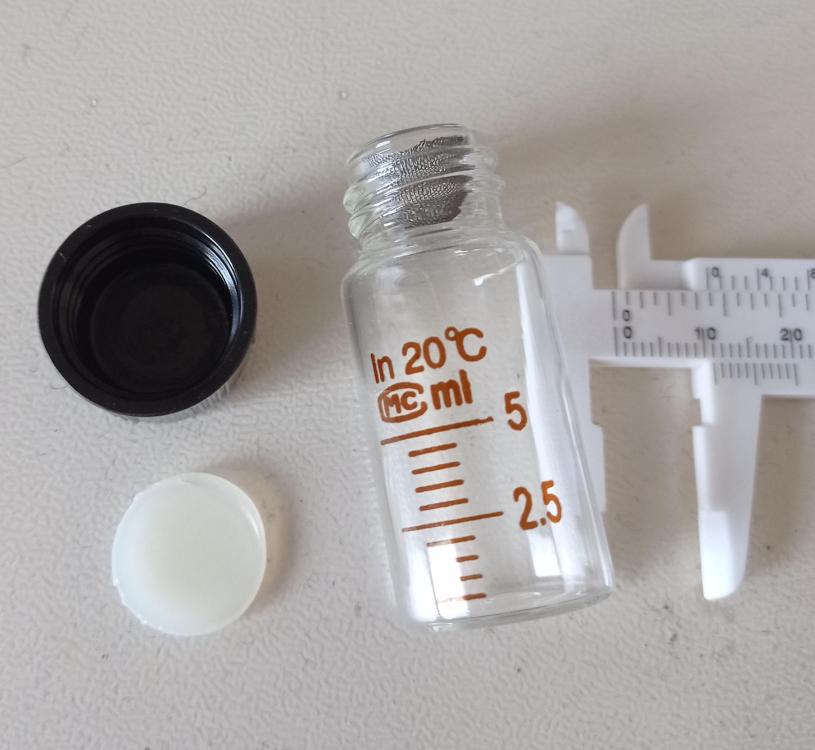

A similar discussion the other day on a thread about "one dip" as I recall. As an amateur, I do the following when working on shockproof watches (more or less). - Remove the balance assembly and put it in one-dip - Disassemble the rest of the watch - Put the disassembled parts in the L&R basket for cleaning - Run the basket through the clean-rinse-rinse-dry cycle (actually, I do three rinses to get longer life by swapping jars) - Remove the cap jewel from the main plate-clean-oil-install - Take the balance assembly out of the one-dip to dry - Put the balance cock on a balance cock holder (balance tack--that pointy thing) - Remove the cap jewel from the cock-clean-oil-install - Assemble the watch and finally the balance assembly I have never run the balance assembly through the cleaning machine. Seems a little scary. However, I am open to the idea and may try that on a non-critical watch. There was some discussion about how well the one-dip cleaned the balance. Fair question. I have noticed that after a cleaning, there is clearly residue in the jar, so something has been removed. In the steps above, when I work on a Seiko (diashock, diafix) or an MT-antichoc system, I add a couple of extra steps for cussing, yelling at the wife, and kicking the dog.1 point

-

Inheritance such an interesting word you recently acquired a heckuva lot of pocket watches. Did the pocket watches come from a business that went out of business or an individual it collected watches what to know about the person who collected them if that is the case? Are these European pocket watches American pocket watches? For the most part it looks like at least their intact pocket watches. Often times we acquire stuff from former watchmakers for instance they will be in pieces and you never know what pieces are missing but yours at least look like their intact that's the good news. Watch repair tends to frustrating if you make assumptions of how easy watch repair is and you don't know the direction you're going in. Plus if you look at the YouTube video is that's very bad without understanding because they tend to make watch repair looked really easy. Then yes disassembling reassembling a watch without any prior knowledge is going to be challenging. Then you don't need proper training kind of you need to practice. Watch repair as I often will say is similar to learning to become a doctor. You need some education like from this group to get you started and then you need the practice. Just like everyone on this group is currently practicing all practicing to be better. So obviously when you begin with no prior knowledge and lack of practice well you should practice on something that you don't care about as the patient will probably die. Which is why they typically don't let doctors practice on live patients until they can handle them. You really have two separate problems here you would like to learn watch repair and you of a nightmare of a collection because at least from what you've said all we know is there pocket watches. So and choice a pocket watch the start learning on is a big factor there are some watches that nobody in their right mind should ever start on. Maybe we can start by categorizing like who made your watches what country did they come from how do they all come together to be in this big collection?1 point

-

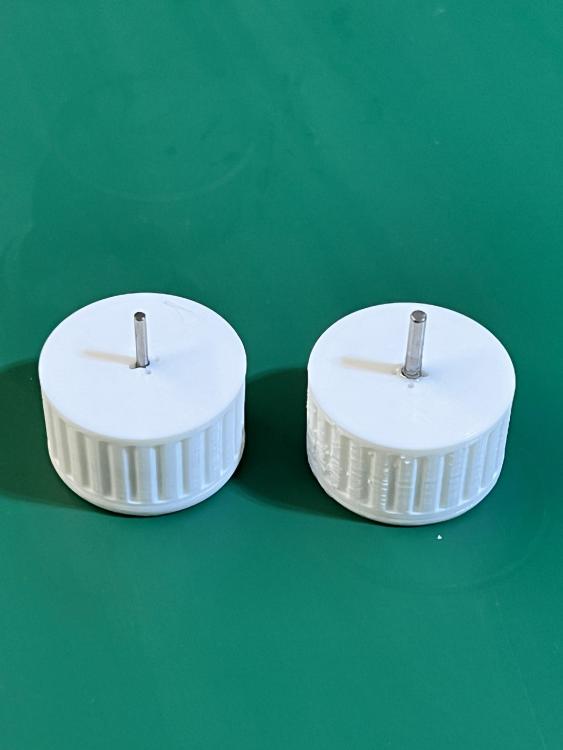

I have been using the 3D printed winders designed by zero and I am coming to believe they are an excellent option. Even with less than optimally printed parts from my local library, I achieved success after some practice. I have not used traditional metal winders but my suspicion is that it would take a similar period of trial and error before becoming proficient in their use also. I recently purchased two bases, from Andyshap who sells sets on eBay, as the bases with the small holes designed to accept the staple ‘hook’ is the most critical part from a printing accuracy standpoint. Andy’s parts are well printed (photo below), prices are reasonable, and he is a pleasure to deal with. The barrel, plunger and setting base that the library printed were easily good enough to work as designed. The greatest difficulty I’m having with the 3D printed winder is the initial setting of the spring into the drum such that the tail of the unwound spring exits through the appropriate aperture. The wall on the 3D winder being so much thicker than the thin metal wall of a traditional winder makes this initial alignment more difficult. For the price, and ease of procurement (not having to trawl eBay waiting for a good vintage set to turn up) they are tough to beat!1 point

-

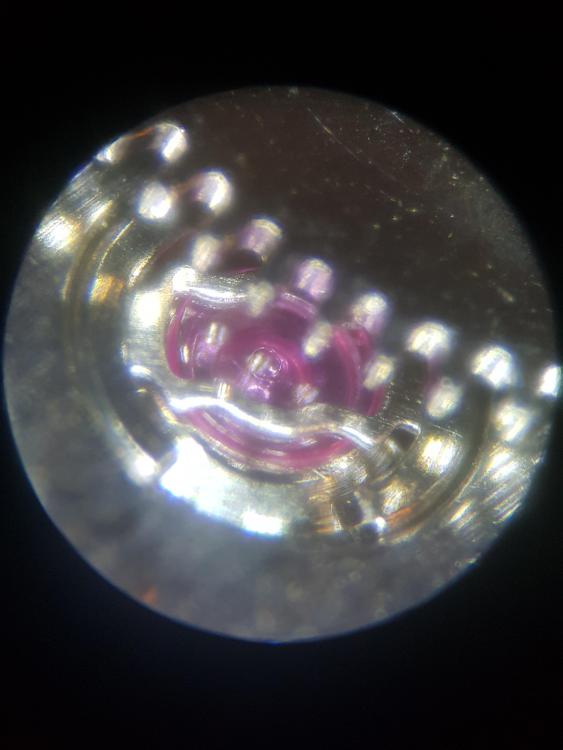

Hi. Just serviced a very slim Mappin and Webb 1970s gold dress watch. This is a 25 years service presentation watch which jeweller's used to supply back in the day. To my delight it had a Favre Leuba twin barrel 255 hiding inside - my favourite movment. A deeply clever design and a joy to work on. Despite clear evidence of at least two services, it ran at very poor amplitude. However the trace was clean so after a good scrub and lubrication the mainsprings were extracted. I've done three of these over the years and every time old mainsprings had been left by servicing watchmakers. This is unfortunate since the layout allows the two barrels to be removed in seconds. Jeweled barrel bridge - posh eh ? The barrel design is unusual because the winding ratchet wheel forms the top cover and arbor thus saving height and complication - see pic. A different approach is needed to replace them which seems to deter servicing watchmakers. The replacements should be 1.50 * 0.07 * 285 at 7.0 mm diameter - GR 4052 will do. The excellent Gleaves & Co supplied mine. The fun starts when you find the central coil is too large for the arbor hook to engage. I use two methods. The strong cheap flat tweezers fit inside the small barrel and careful squeezing will allow you to tighten that curve enough. The internal post in the barrel will help prevent snapping the spring - be gentle. Plan B is to temper the spring fixing point to a brown colour using a temperature controlled soldering iron and then bend it around a drill shank slightly smaller than the desired end loop size. Both work with patience. Hope that helps guys.1 point

-

As almost all watchmaker lathe makers are now defunct, it's good to get a brand where you will run into accessories and parts without too much trouble. I strongly recommend going with an "American" style lathe, with what's called a Webster Whitcomb bed. Here some quality makers are Derbyshire, Levin, G. Boley, Boley Leinen, Wolf Jahn, and Lorch. Of those, my absolute favorite is Boley Leinen. One of the main reasons being that the tailstocks always line up, from one machine to the other, mixing and matching*. They also accept commonly found 8mm collets from Schaublin, Boley, Leinen, Levin, and others, in my experience. Some of these machines are made to take 10mm collets- you definitely want to stick with 8mm, far more available second hand. I would go for a machine that comes with a collet holding tailstock as it opens up so much the utility of the tailstock. A lot can be done freehand turning (well, all, if you really want to), but having a slide rest is incredibly useful. Unfortunately most made for this type of lathe leave a lot to be desired. After all my years doing this, I have never found anything close to the quality and utility of the slide rests from Levin. They don't come up for sale everyday, but are worth what they go for. Watch out- they came in both metric and inch versions, metric being the preferred one. You can find boxed sets with loads of accessories, but most of the little bits and bobs will sit in the box unused as they have done already for decades. A good basic lathe, a good slide rest, and a good set of collets is enough to have you making parts. I use my lathe daily and it's rare to need anything other than that. I do have some scroll chucks and such with are handy for certain work. Some info on Webster Whitcomb *On the Boley Leinen- there were two "eras" older and newer. Older ones had a very slightly different bed size, and wont mix with the newer ones. Newer ones always have straight black locking levers for the head and tailstock, older have more bulbous fancy ones. You want the newer style. The machines were made with both plain bearing and ball bearing headstocks, either is fine, the latter tending to be more expensive. And finally, I've read on other forums (check out Jerry Kieffer's posts here) where some folks have been super happy with Sherline lathes even for doing tiny watch parts. As an adapter is required to use 8mm collets, I have a hard time imagining that you can chuck up a small part and get it to run truly true, and there are some other limitations. But those machines are very affordable brand new, and can do some stuff that is very difficult on a watchmaker lathe, like cutting screw threads. For new machines, the only one I can see as being worth any investment is the apparently very high quality Chinese made CZ-50. It appears to be a sort of homage to the ball bearing head Leinen machines, and they have a lot of very happy customers. I think the base price is around 6k dollars for the lathe with collet holding tailstock and cross slide, so not something one would buy as a first machine necessarily unless that sum is palatable.1 point

-

1 point

-

You want the pins straight, and parallel, with a gap approximately equal to two spring thicknesses. The gap is a guide, you might want it closer, for example an overcoil would like a very small gap (just free) as OH said. Depending on how the pins are installed and their spacing. One some older pieces they are spaced a bit, so you have to bend them toward each other, then straighten. I just use fine tweezers for this, like #5. Sometimes to widen the gap a little those are still too big, then I will use a broken oiler that has been stoned to a very fine wedge shape (like a microscopic screwdriver). That will fit in the smallest gap and allow some tweaking.1 point

-

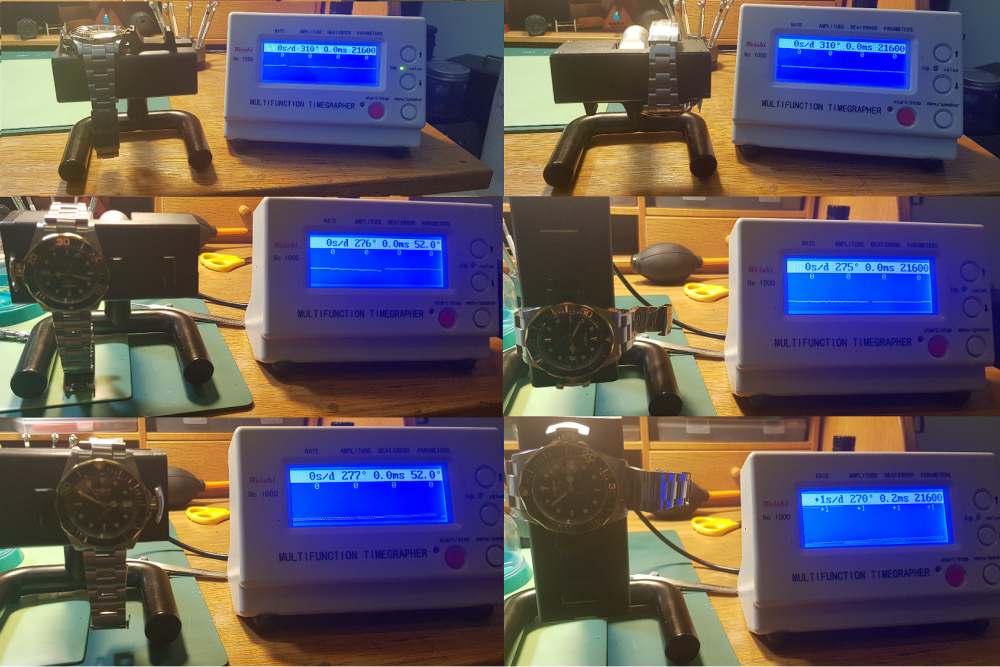

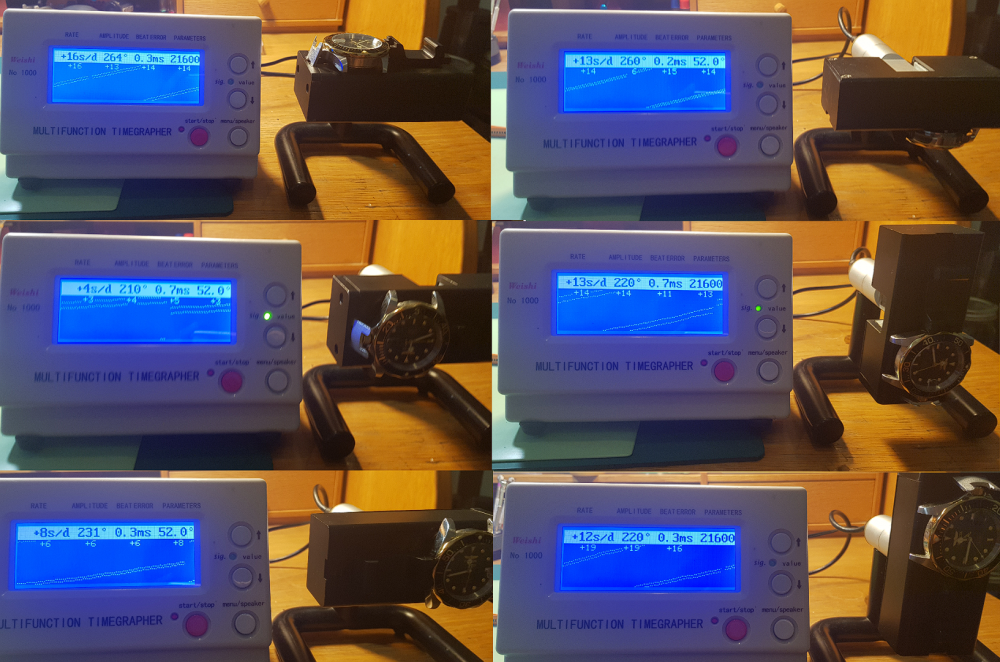

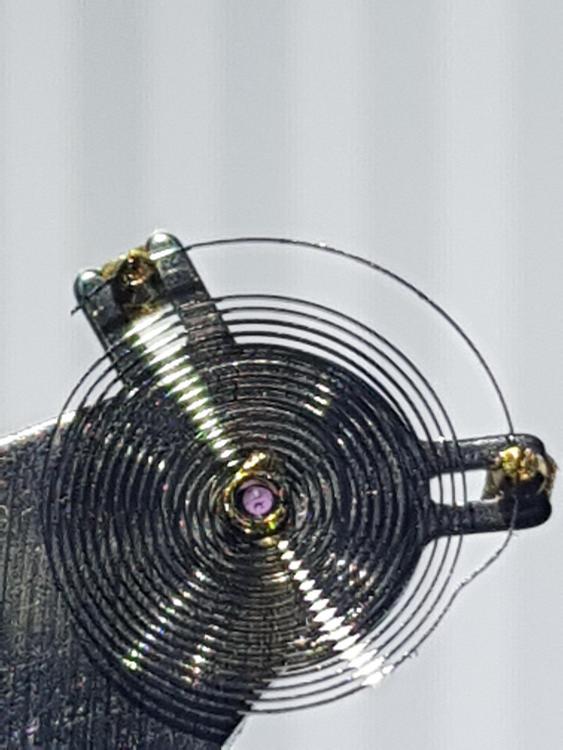

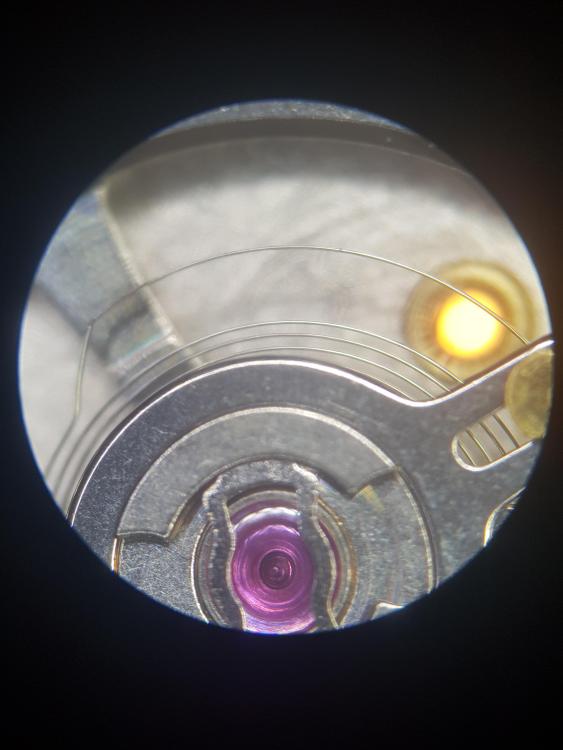

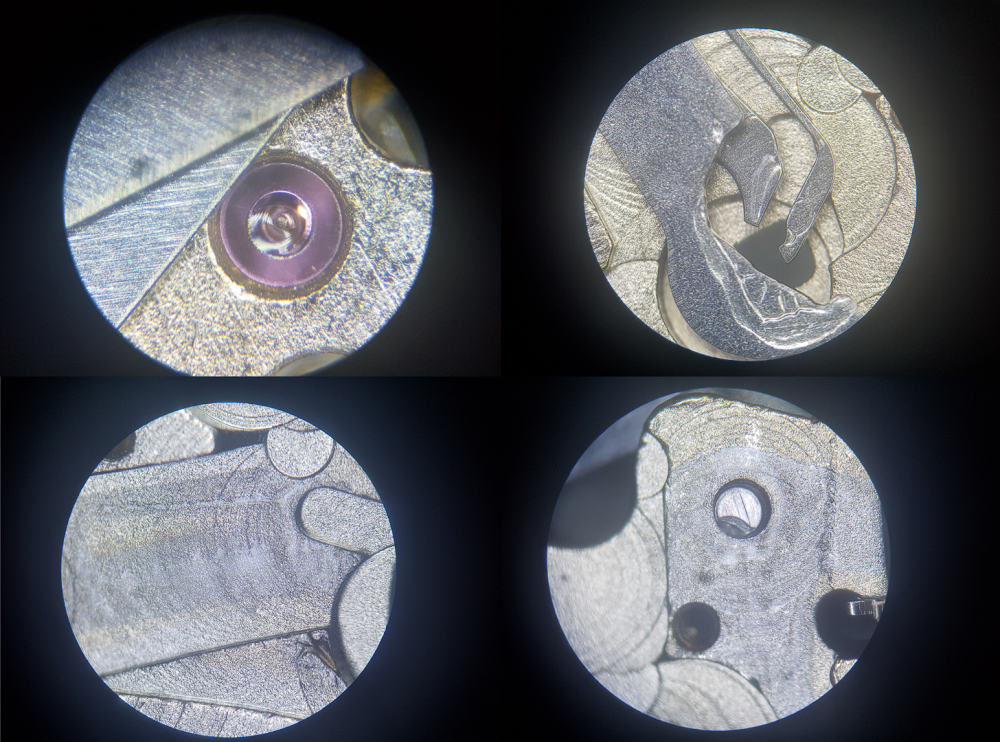

Today I show off what is probably the most accurate Seiko NH35 in existence. Let's see what this brand spankin' new Invicta does on the timegrapher: Oof. Ya hate ta see it. I know these numbers aren't anything to cry over for an 80 dollar automatic, but considering how these days microbrands stick this movement in watches costing hundreds more, and Seiko themselves with the equivalent 4R in watches costing even more, it's just not great. The rate itself to me is a trivial matter as nudging on the regulator is a trivial task. But what speaks to the quality of a movement in my eyes is the consistency of that rate in different positions. With 12 seconds per day difference across positions, middling amplitude, and fluctuating rate while static, albeit slight, is all just a bit "meh" to me. Let's crack it open and see what we can do. . Hairspring seems to be pulling towards stud. Hairspring removed from balance and mounted on cock and we can see the full extent of the malformity. That collet is a good ways off from the jewel. Few hours of sweat later: Much better! Regulator now runs the full length of the terminal curve without disturbance and collet is centered on jewel. Let's check out what else I saw: Some places are absolutely flooded. While others just barely got any. A good thing I intervened. This thing needed to be redone top to bottom. Stripped apart, ready to get rid of the crappy factory lube job, and get a real, proper lube job. All put together, lubed, and few rounds of dynamic poising later: Massive boost in amplitude, runs on rails and a measly 1 second difference across all positions. Wasn't lying when I said "probably the most accurate Seiko NH35 in existence." See for yourself. Isn't it at the moment a bit of a waste that this souped up NH35 is being trapped inside its Invicta skin? What do you think?1 point

-

1 point