Leaderboard

Popular Content

Showing content with the highest reputation on 11/21/23 in all areas

-

None, correct Neither the mass of the balance nor the gravitational force will vary as a function of rotational speed, and as weight (gravity effect) is a function of those two parameters it won't vary either. A simple experiment to demonstrate this is to use one of those spinning gyroscope toys and weigh it stationary and spinning, there will be no change. A spinning gyroscope will resist changes in the orientation of its axis, but it can't defy gravity.2 points

-

2 points

-

Ray Welcome from across the pond. Tool set, regret? No such thing. I have been using my £13.50p set I purchased 23 month ago. Still using all the tools at some time. I make sure my screwdrivers and tweezers are always dressed (filed). I was less than at your state then. Apart from owning a watch I had never done anything other than wind. Really did start from scratch. I've listened, been advised, cajoled by the wonderful members of this forum. Many are experts, some professional. All have taken the time to offer help and assistance. Can't fault them. Two pieces of advice I offer. Do a distance course. Practice, practice, practice and then, practice some more. Can't fault this hobby either.2 points

-

See this video. You have to adjust the tail of the anchour in a manner that the clock is level and in the same time the beat is even. This has nothing to do with leveling the movement, as it can stay tilted in the case and this is not important.1 point

-

Hi. The escapement is out of beat . Untill the movement is level it won’t run. Tilt thr clock from either side untill you get an even tick…tock. Now the hard part, the escapement bridge will have to be adjusted until it locks the pallet/anchor correctly. First remove the movement from the case and make a stand to fit it on. Next check the movement is level (spirit level). You can get little ones. Now we have the movement mounted level. Move the pendulum left to right can you see it releasing the escape wheel in not move the bridge up or down on which ever side does not lock properly, once done a couple of turns on the spring fit pendulum and re try running the clock, if not go through the adjustments again. It can be a fiddly job but requires patience. Come back to us with the results good or bad for more information. At this point do NOT bend anything.1 point

-

Hi beat movements have over lo beat movements only when they are moving. When the movement stays still, the frequency doesn't affect timekeeping at all. See, the balance is in contact with escapement only when it is within the lift angle. When it is turnetd more than half lift angle left or right from the zero position, it oscillates free. So, the biger amplitude, the more time of free oscillation. But, the frequency has nothing to do with it, as the 'free' time is the same percent of the whole time, if the amplitude is not changed. I will advice to look at the rate 9 hours after full wind, or time error, measured every morning, as like it is random quantity. It actually is, and has it's expectation (average value) and dispresion. And, the good quality and well adjustet movements show small dispersion, the cheap and not well adjusted usually show big dispersion. That is all1 point

-

For the staff or the stem you can always check those with balancestaff.com. you may get some help from the smithswatches site if you drop them an email.1 point

-

1 point

-

It's useful to know which screws are common. For instance I need some dial screws for a cal 0104 which must be common. Also the Deluxe models were upgraded movements (e.g. 27CS) with better balances - timing screws and overcoil hairspring. But is the balance staff the same?1 point

-

1 point

-

Hello Ray and welcome to the forum. No introduction is boring we like to know our people and their skills.1 point

-

Ray, Welcome to the addiction! When you say "build 2 distinct watches" can you explain what you mean by that, for example do you mean buy an complete vintage ETA 2824 watch, then strip it down to the last screw and then rebuild it, or do you mean buy the major new/working parts i.e. movement/case/strap etc. and simply assemble it. This choice will have a big impact on what tools and knowledge you need. If you let us know, the floodgates of advice will open I am sure1 point

-

1 point

-

1 point

-

Thank you all for the great responses! If I want to restore to the original technique used I believe the engravers wax is probably the way to go. I have an electric pallet warming plate that I might try to use as my heat source rather than an alcohol lamp. I am sure the enamel paint/putty option is faster, but not sure how it will stand up in watch cleaning solution. I see some experiments in my near future. Thank you all once again! Waggy/Scott, wanted to thank you for the advice you provided as well. I have some painted bezels to restore and was wondering how to approach them. Now I have a plan of attack for that project thanks to your suggestions. Cheers!1 point

-

I managed to find a setting lever so gave up trying to make one. The first one I made, using a feeler gauge, took me two attempts to anneal, but it somehow worked, and was so and easy to saw and file. The second time, using the same set of feeler gauges, I just didn't manage to get it soft enough to work. I now have some powdered charcoal, and a cut down box spanner to use as a cylinder, for the next time I try annealing. I hope to get it all red hot with a hand held butane torch, and it cools slowly enough.1 point

-

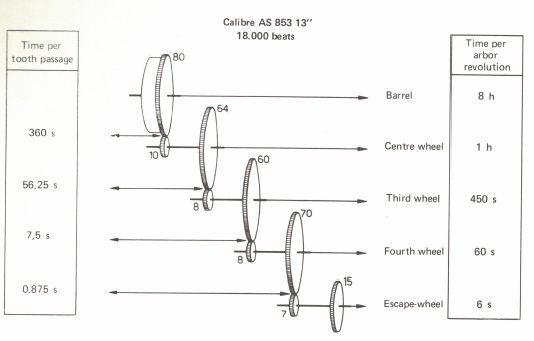

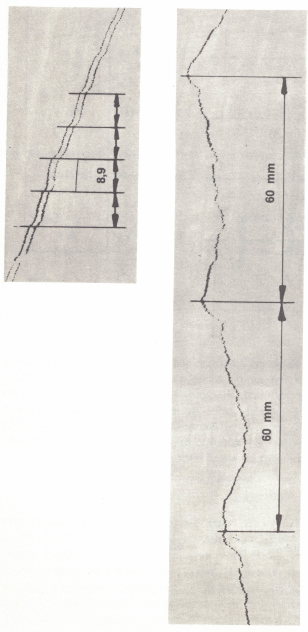

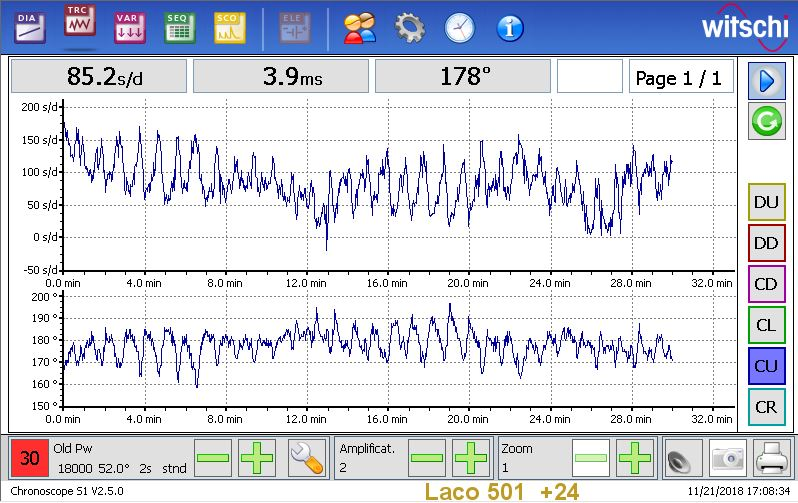

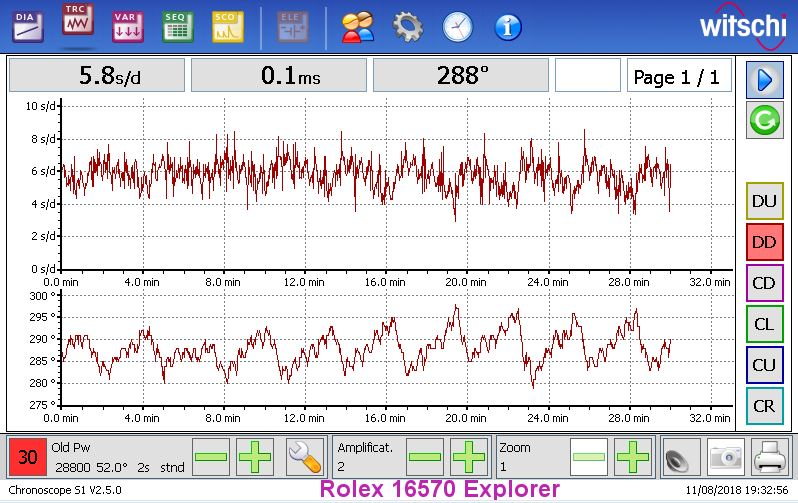

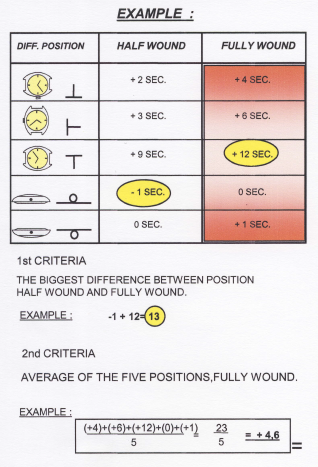

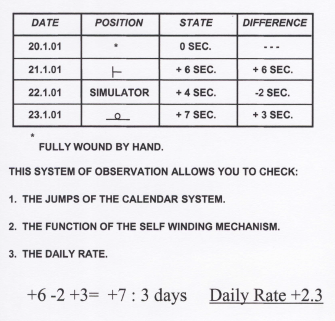

I'm not 100% clear on something here? So what we're seeing is the watch was set exactly to time and nine hours later over a variety of days that's how fast the watch was running? We've already established that we don't know how wound up the watch was. It's always assumed that are automatic watches always fully wound up but it depends upon how much motions somebody has so unless it's actually wound up at the time we don't actually know so that will be a cause of variation. So what can cause a change of rate? We've already established amplitude what can cause amplitude changes beyond the mainspring? What about the gear train could that be a source of problem or if the watch has a calendar that the calendar changing have anything to do with this where even the gear train related to the calendar? Could any of this cause an amplitude variation? For instance I a timing machine I've ever noticed how the numbers seem to fluctuate? Now remember here were needing to look at really attempt of a second one second is a good enough for the timekeeping were looking at. Which I do think on the 1900 I think you may build a change it to measure tenths of a second. But in a case have you ever noticed your numbers slowly going up and down? What if you regulate the watch on one of those swings with the swinging up and down is over a five minutes for instance and you regulate of the watch during one of those up and down how would that affect the actual running time of the watch? So for instance what about this image What if one of those wheels was slightly out of round or what if the pivot was slightly bent what would that do to our timekeeping? In other words if the gear train was less than perfect and producing a power fluctuations what would that do so the interesting features of paper tape machines you can look for patterns for instance much harder to see on the LCD screen where the relatively short. With modern software and some modern timing machines for software to make a computer and a timing machine you can run time plots another way to look at the timing machine output. Makes it much easier to look for issues like this. So for instance here is a example of a cheaper watch. Ideally with time plots you're always going to see an up down gear trains will always produce pulsate's and the power but they should be relatively random. You never want to see a pattern on the time plot. Here's an interesting time plot notice how nice the numbers really look even though graphically they look bad. We can definitely see a pattern but the timing is really really good And because this is a Rolex I believe this watch has no regulator pins One of the interesting things with mechanical timepieces are they will average their mistakes over time. This is why if you look at Rolex timing specifications once they verify the watch pleases the timing machine then they run the watch for several days and average those numbers together to come up with an average rate per day. So on a instantaneous day your watch may appear to be outside of specifications but there timekeeping specifications is an average over time. One of the interesting problems here is if I interpret correctly the watches set exactly to time and nine hours later it's look that and we see random timing but normally watch companies average an average over 24 hours would that change anything? Plus they do a little more averaging would that change anything Here's something Rolex has half wound is 24 hours later fully wound up with courses fully wound up. Notice how in one position its 12 seconds fast how horrible. Except their criteria system so the first criteria is basically the isochronism the difference between a fully wound up and 24 hours later. The second criteria is averaging. Now this is where most watches are going to fall down this example is pleasing a timing machine. Then what about real-world timekeeping? Notice once again they average their numbers so on a instantaneous particular day at might look bad but the overall average is good. Oh and of course all of this assumes that whatever you using the time your watch is more accurate than the watch itself. Oh and while were here discussing precision timekeeping a little light reading in case you think your watch that pleases the timing machine or overnight keeps time maybe you could please a standard? But you will note that the standards and Rolex all base their timing on 24 hours. ISO-3159-2009 chronometer certification standard in English.pdf1 point

-

Preface: this isn't to be a nitpicker, just for future reference and the benefit of all On a forum like this, using a topic title that is descriptive is really important. For two reasons: -it aids when searching the forum for similar issues down the road -it aids other forum members who maybe have insightful info to click it and help, and other members who aren't the least bit interested from reading about something where they have no input to give. I realize as a newcomer it would be hard to know how to title something, but in this case, for example, instead of "QUESTION", which most posts are, you could say,"Unkown battery operated watch need help". Everyone with zero knowledge of electric/electronic watches will avoid (unless curious), those with a proclivity will check it out.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. You need to provide good clear photos of what you have. We should be able to advise you.1 point

-

Hi all watch people, hope you are all doing well. Here is my first attempt at using the Star crown taps. The crown on grandfather's watch was very worn with virtually no grip left and quite undersize i thought for my chunky digits. So i decided to find something more suitable, finding the right thread on the assortment of crowns i had was proving tedious. So it seemed the perfect opportunity test out this little gadget, i must say I'm rather impressed. The drilling out of a smaller crown thread and re- tapping to the size i needed 0.95 was a complete doddle. A little oil required for both the drill and tap and with John's help discovering the depth stop on the crown vice saved me potentially drilling too far or breaking the tap. This is probably the first time I've managed to give the watch a full wind and bizarrely enough the amplitude has jumped by around 50° and the tg trace is vastly improved from the last time i checked. How crazy is that ?1 point

-

Very nice watchie, I've noticed of late you have a strict fascination with accurate timekeeping .1 point

-

It's arrived! Along with the bits and pieces I bought for a refurb. Here it is next to the last one I did, which is my daily driver. It's actually keeping decent time from the looks, although I'll still do a complete service, but good to know it doesn't look like there are any immediate issues. The rubber strap is absolutely awful to wear, incredibly stiff. The case looks to have been polished, I think it should be more matte, but it's in okay condition. The rotating bezel is a bit loose, will be interesting to see what's under it. Also keen to see if that dial is original or aftermarket. It's pretty old and whilst it doesn't look like it has reference numbers I can tell they used to be there, and the Suwa Seikosha logo looks correct.. At any rate, that dial is going to be replaced, but it will stay with the watch along with the old hands and bezel for posterity.1 point

-

It's not exactly the same as a 7001, though I'm sure they share a lot of parts and function equally well. It begs the question why Peseux (and AS, and many others) made so many different, yet almost identical calibers. It's part of why there was already a government ordered consolidation of certain manufacturers earlier in the 20th century (post Depression)- when each company came with their hands out for subsidies to develop a new caliber, they were like, "there's not only no room for more of the same calibers, there's no room for all of you!". Obviously it's a long complex story, ending in the formation of ASSUAG (mandated by the gov and banks) and SSIH (more of a volontary merger of Omega and Tissot), but that's the gist. Eventually with the quartz crisis many makers went bust, and a lot of what was left got absorbed by SMH, founded by Hayek in the early 80s, and that became Swatch Group.1 point

-

With clocks it depends on the dial. Long case brass dials a black wax is used. White dial clocks paint is used. Colouring sticks can be used. The sticks are also used in furniture restoration for touching up. Marc has hit the nail on the head with Black shellac or engravers shellac.1 point

-

I have a link to the history of the New York standard below. https://pocketwatchdatabase.com/guide/companies/new-york-standard-watch-co Here's a site that claims to have the most up-to-date listing Notice how they've excluded American watch companies? https://watchguy.co.uk/cgi-bin/lift_angles The reason why these lists came into existence was timing machines that could measure amplitude came into existence. Because without a timing machine the measure amplitude there would be no need for the list which is why typically will never find vintage watches almost. Somewhere out there is my pocket watch listing when for variety of reasons I was enthusiastic and figured out the lift angle. But I don't recall ever working on a six size New York standard. Fortunately if you really want your left angle there is a simple procedure. So the procedure is quite simple put a Mark on the balance wheel you can see. Slowly wind the watch up until you get a 180° Then adjust the lift angle in the timing machine until it reads 180°. Then you can report back to the group Just in case anyone else's curious.1 point

-

I would approach it the same way I do with bezels, I use model enamel paint (se below) and overfill the engraving with enamel paint then quickly wipe over with my thumb. You are unlikely to get an exact colour match and painting new paint on top of old paint may not be a great idea. So when I do bezels I sit the part in acetone for 20-30 mins to remove the old paint and then paint fresh. Acrylic paint tends to be water based and would most likely wash off the next time the watch was serviced, but the enamel is oil based and 'weather proof' so would be much more resilient. I also saw a youtube video where (I think it was the Nekkid Watchmaker, but I can't remember the episode, link) used coloured epoxy putty on a bezel in much the same way as myself and @RichardHarris123 mentioned about the paint, ie rubbed into the engraving and then rubbed off. I did get some of the milliput (see below) but I haven't used it as the enamel paint method has always worked for me, maybe I should give it a go with the putty next time. Epoxy Putty: Paint:1 point

-

Black shellac or engravers shellac is what is used, you can find it at the link below. https://www.cousinsuk.com/product/engravers-wax-elephant-black?code=E0494 And this is quite a good video on how to use it.1 point