Leaderboard

Popular Content

Showing content with the highest reputation on 11/22/23 in all areas

-

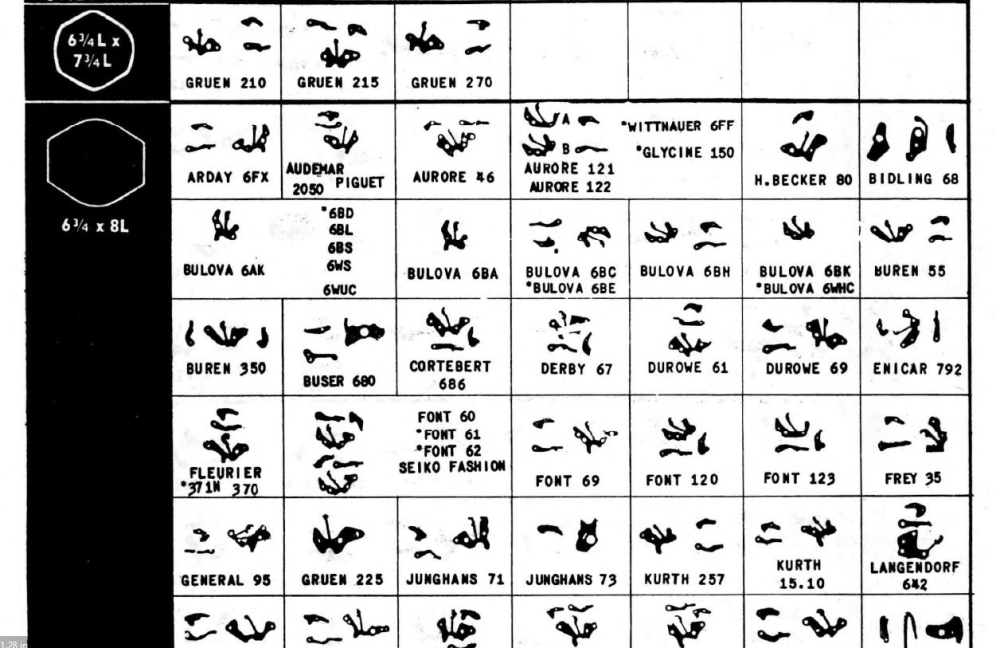

I don't suppose we can get a diameter? With a diameter in ligne as that's how we measure watches or in metric I've attached a PDF see you can convert it. The reason for this is material books printed from the venture when it started exactly the 50s through the mid 70's perhaps during that time range material books what have what's called the fingerprint system. So you look in your book and if you know the size I just gave you a sample below to see what it looks like. But with the size and a clear picture the setting parts you did attempt to figure out what your watches. Without a size that I have to guess and that takes way more time which I'm not going to. So a nice picture of the setting parts and the size of the watch I can look at my book and see what it is. watch-ligne-size-chart.pdf2 points

-

2 points

-

Haha. I would think the questions about compatible balance screws, canon pinion tightness or detent finishes would give the game away…2 points

-

I've looked, Excelsior mainly made chronographs. I could only find a couple of non chronographs , neither looked like yours. PS. It says Brevet , patent in English.1 point

-

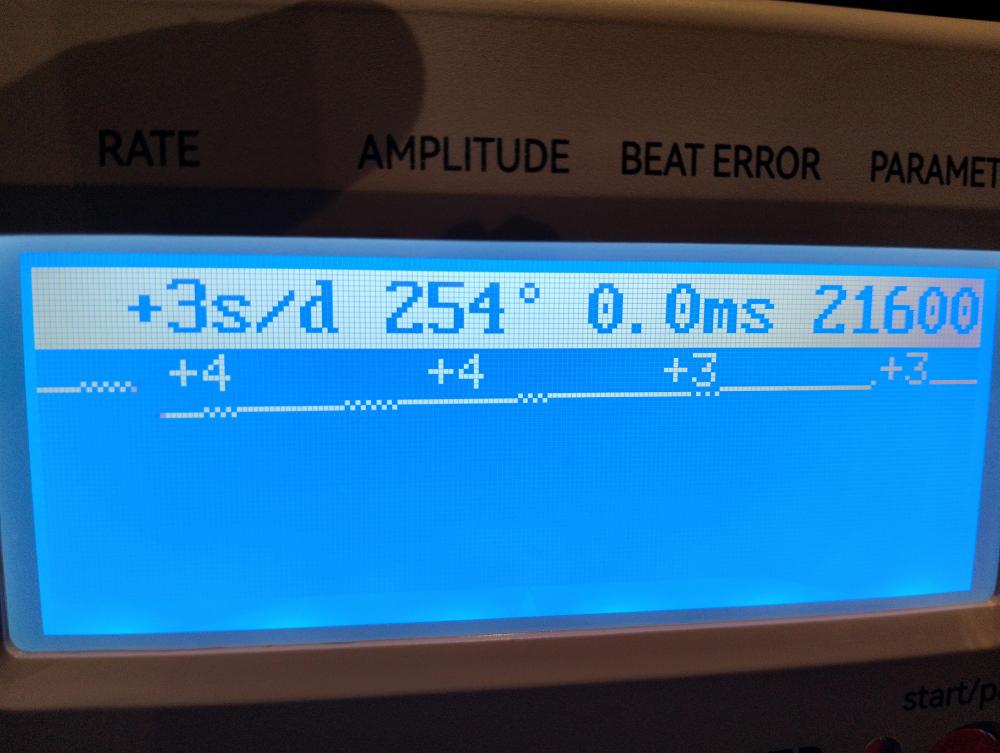

Ray, Well putting together a watch is quite straightforward. You get your movement, iso for you a 2824. Then you look for a face for that movement that you like, likewise with hands. Then select a case for that movement and at the right size for the face. Then buy a few winding stems. Put the face on, put on the hands. Put the movement in the case. You cut the winding stem to the right length so that when you push the crown in, it goes in the correct amount. The you put the crown (that probably came with the case) onto that stem, with a bit of threadlock. Then you put the back on the watch, put a strap on it. Then sit back and admire your work. I've done just that with a Seiko 5, putting in a different movement (NH36) to what it came with. It now handwinds, hacks and I've regulated it to around +4 s/day. The biggest difficulty I found was cutting the winding stem to the correct length. Oh, and putting on the second hand was really tricky! Have a go. It's very achievable and incredibly rewarding. So this course is my next step. Trystan1 point

-

1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

1 point

-

Thanks for the advice, I'll give this a go in the coming week when I get a chance and update with the results. So far it has been running for a couple of days with what sounds like an even tick, I don't have the hands on it at present, I'm running it to see if it keeps going consistently before I put it all together.1 point

-

On these clocks the pallets are mounted on their arbor with a friction fit, and beat error is adjusted by carefully rotating the pallets around the arbor against the friction. To do this place the clock on a level surface and set it running. Observe the pendulum and listen to the ticking. If it's out of beat then the tick on one side of the swing will be longer than the tick on the other, this is because the pallet is engaging too deeply with the escape wheel on that side. Once you have determined which side of the swing has the longer tick, gently push the pendulum across to that side until you feel a stop. This is when the pallet is fully engaged in the escape wheel and can't go any deeper. Now gently but firmly push a little more. This causes the pallet arbor to rotate slightly in the anchor so that when the pendulum is released it will have slightly less engagement on that side than before. Test the pendulum again and you should find that the ticking is less uneven. You may need to do this several times, pushing the pendulum against the stop on the longer tick side of its swing until you get it right and the ticks are even. It's very easy to go slightly too far so you may have to adjust in the other direction as well. If the clock is intended to live on a surface that isn't level then all you need to do is set the beat up on a test surface that has the same slope as the intended location for the clock. That way even though the clock isn't level it will still be in beat. Obviously the severity of the slope that you can accommodate with this procedure is limited by how much free swing the pendulum has. I first got this procedure from instructions on a factory printed label stuck on the inside of the door of a Smiths clock, so at one time it was part of the set up instructions Smiths provided for their clocks, and I have used it on many Smiths clocks since. I can't comment on how it applies to other makes. Also I would say that, as with most things horology, if it requires anything more that gentle force there is probably something else amiss and further investigation is needed to prevent inadvertent damage.1 point

-

Actually quite a handy little gadget for around 25 quid. The best use of it as WW mentions is the pulse test, an audible click that can be heard from it as the chip emits its signal to send an electrical impulse to the coils. The cmos can be tested independently , the one i have can also test for a dead or working quartz crystal.1 point

-

Ah, I think I have seen this on a youtube, fortunately quartz movements is something that I have yet to work on... so can resist buying the tool....for now! Thanks for the explanation1 point

-

Hi there, sorry I'm late to the party, I have done a few 7009s and always take the mainspring out and give it a clean. like @JohnR725 says, the philosophy of changing a mainspring varies. However, I think just blanket changing it regardless of its condition is wasteful and an unnecessary cost to you or your customer. I look at the condition after cleaning and if in doubt I change it, otherwise if it is in good shape I will re-use, which I think is what most of the guys do here. Seikos use the thick black graphite grease in the mainspring barrels which looks a lot worse than it is, the springs can be difficult to reinstall without kinking (due to the reverse bridal) and sometimes jump out, due to the shallow barrel, but once a good spring is reinstalled they seem to perform well even with swiss oils lubricants.1 point

-

Not sure I know what this is, can you explain? Hopefully not another tool I have to try and resist buying!1 point

-

You can find stem sizes information for a lot of movements here. But, the reverse ingeneering is the comon way when You can trust Youself and no information is easy to source.1 point

-

Mainsprings and lubrication are interesting. Depending upon whose service information you look at and depending upon the type of watch. So for instance if you look at modern mainspring this do they need to be lubricated at all? If you go to a modern school and ask the instructor why are we being taught how to lubricate mainsprings when they don't need to be lubricated quite honest I really don't remember the answer to that question but in schools are taught the lubricate mainsprings. Omega has an interesting document on recycling mainspring barrels. Interesting because in their service centers they just replace the whole thing because they have an endless supply of them. But in the case of recycling the mainspring is just wiped off with a lint free cloth no lubrication. For instance there is an image of a lecture I once gave where I had a whole bunch of packages of mainsprings a few of them actually do say permanent layer self lubricating no explaining as to how or why. Others don't say it all and notice that at least all the modern ones are guaranteed for life and they never break which is interesting because they do break and they don't last forever. But the companies are no longer around to honor the warranties so life of the company One of the problems with a mainspring barrel is its typically sealed. Sell you can look at it and ignore it because you can't see the contents. If it really was not lubricated with anything like a lot of them are you might actually be fine to leave them alone. But if they been lubricated the lubrication can go bad with time and get sticky as you found out. Plus Accorsi of the barrel arbor which needs to be lubricated. Then in the case of anything that's a vintage blued steel it's probably sent. In the shop that I were The prior watchmakers wouldn't even think of touching a watch without a replacement mainspring. The current watchmakers will do a variety of things and I try not to pay attention to what they're doing. I do kind of like Omega's approach of looking at the spring and seeing if it looks like it's still usable it looks like it's still going to work and of course when you put her in the watch it does seem to work than it is probably fine. Even on vintage pocket watches what I take the spring out of its white it looks right and the watch seems to work right I will use the old spring.1 point

-

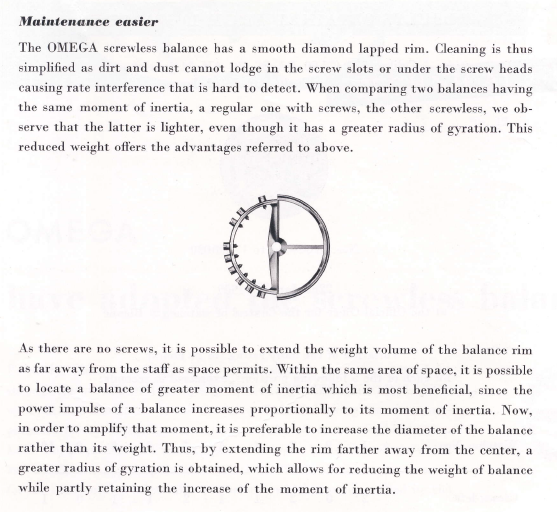

I was concerned we were hijacking your discussion into something possibly related or possibly not Air resistance what a strange idea that is plus you didn't clarify something? The clarifications would be what about the balance wheel construction is there anything we could do to make air resistant less? Plus what about air resistance at sea level versus the mountains or how much humidity is in the air? By the way I really hate scanning things to PDFs tedious and time-consuming but if it's a PDF it makes it easier to find in the future. First thing the scan is only four pages From Omega this get us started then who would later today possibly tomorrow a section I will book which I did recommend everybody read but apparently you haven't taken the time to read it so I'll extract out some sections of that later this will get you started. The attached PDF talks about switching from the bimetallic balance wheel to the modern balance wheel no screws basically easier to manufacture but is there anything in here related to this conversation? I've only extracted out a couple of things you should look at the PDF. Omega technical guide number 12 June 1959 Omega have adopt the screwless balance.pdf1 point

-

1 point

-

Do you mean mass? The weight of the escapement, the whole watch and indeed yourself is constantly changing. An interesting thought, any watch undergoing radioactive decay, radium/ tritium etc will be slightly less massive for eternity.1 point

-

I dont have the skills to rebuild a movement........yet. I want to get a working 2824, select the case, dial hands and face to put it all together. I am sure its a pretty simple procedure for the likes of this group, but my skill set so far is blowing a mean blues harp! The short version- I used to work on Harley's and play 11 string instruments. Proficient in martial arts and could be found on a stream side with a fly rod most days off. Then.......open heart rebuild. It took about 80% of my right arm, neck and hand. (yeah, they messed up) so now I have to approch everything with extreme caution in both physical and budget. So ANY direction (and ways to save a buck) is very welcome! For my former biker friend, you are going to hate my russian cranky old gal!1 point

-

Sorry for not being very active in this thread that I started. I've been meaning to get back to it but too many things have come in between. Anyway, not sure what it brings to the discussion but I would just like to remind you that an escape wheel of a hi-beat movement has more teeth (20) than a low-beat movement (15). Please keep the discussion going. It's very interesting Escape wheel of a low-beat movement (Vostok cal 2409) Escape wheel of hi-beat movement (ETA cal. 2824-2)1 point

-

Ray - you are already ahead of me, as I registered and joined Mark's course only this evening. I hope you enjoy the journey as much as I look forward to. My background is in soldering and making little electronic circuits as a hobby, so I'm hoping some techniques are in a way transferrable (dealing with small bits and making sure they don't fly off). On with the adventure! Trystan (Manchester, United Kingdom)1 point

-

That's because you weren't buying anything, your questioning should have been surrounded with the view to purchase . Information procurement 101 'potential exchange of currency '1 point

-

Hi all watch people, hope you are all doing well. Here is my first attempt at using the Star crown taps. The crown on grandfather's watch was very worn with virtually no grip left and quite undersize i thought for my chunky digits. So i decided to find something more suitable, finding the right thread on the assortment of crowns i had was proving tedious. So it seemed the perfect opportunity test out this little gadget, i must say I'm rather impressed. The drilling out of a smaller crown thread and re- tapping to the size i needed 0.95 was a complete doddle. A little oil required for both the drill and tap and with John's help discovering the depth stop on the crown vice saved me potentially drilling too far or breaking the tap. This is probably the first time I've managed to give the watch a full wind and bizarrely enough the amplitude has jumped by around 50° and the tg trace is vastly improved from the last time i checked. How crazy is that ?1 point

-

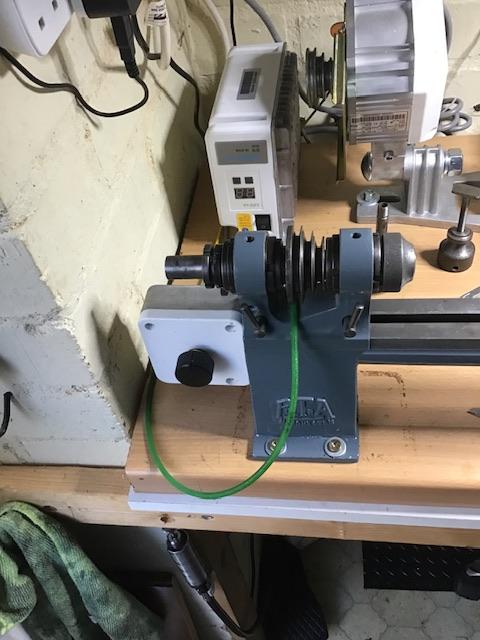

A lot of people seem to ask what motor to use to run a watchmaker or small instrument lathe so I thought I would post my observations on the motor that I use , because I only service, repair and restore torsion clocks I use a Pultra 10mm instrument lathe but the motor I use will work just as well for a watchmaker lathe, it is made by Jack and it is an industrial sewing machine motor although I have removed the foot pedal and replaced it with a potentiometer because I have trouble with my leg twitching, the motor is very quiet and smooth and the torque is very good even at slow speed and I have added a video of me making a replacement disc pendulum adjustment rod just to show how good it is, I tend to run the lathe a lot slower that most when using a graver the video is when I had my original Pultra 17/70 although I no longer have it because I needed a larger lathe for some work and as I am very short of space I sold it when I got the Myford something I regretted almost immediately ( benefit of hindsight) , anyway I have now found a Pultra P type in very good original condition apart from a broken knob on the drawbar and at a price I couldn’t turn down so after stripping, cleaning and repainting it is setup on a piece of kitchen worktop with a Jack motor , I have checked runout and it is half an increment on a 0.001mm dti so very pleased, I have made a replacement knob for it on the Myford and I have made very small screws on the Myford IE 12BA but find it a lot easier on a small lathe using a graver, I hope this is of els to anyone looking towards a small lathe. Dell1 point

-

I don't advise playing about like that, you are going to disturb the oils. Treat it as a new repair. Many years ago we would replace the complete barrel unit Seiko I think said every 7 years, because the shortage of parts and also they are obsolete it is normal practice to open the barrel remove the spring and clean it just like you would with any watch barrel. If the spring is tired and out of shape then replace it with new.1 point

-

Where are you based for future reference? I got the case back back, after letting a local jeweller loose on it. I wish I hadn't. She used gold solder to fill it, then tried to put keum boo on top. It didn't work and she re-flowed the solder. In cleaning up she has thinned the case. It still snaps on but it is noticeably thin. I am not sure whether anything can now be done - perhaps gold solder a disc on the back? I think the price would be uneconomic.0 points

.thumb.jpg.5bcbf283ad8d49ef2828ca90b38fbafb.jpg)