Leaderboard

Popular Content

Showing content with the highest reputation on 11/25/23 in all areas

-

So the house we live in has a dedicated spa room. (as in the water filled one) Liz and I hardly use used it and it has been empty for a while now as the circulation pump shaft seal died and all the water that was meant to be inside the spa decided it would be better off being adventurous on the outside of the spa. So out with a bit of garden hose and siphoned it all out. We have also bought ourselves a very nice free standing induction stove and oven. The catch with it is that it needs a 40A supply. The spa was 32A so the sparkle is going to disconnect the spa completely, upgrade the circuit breaker in the board inside the house. I am not sure if this will also involve upgrading the external board as well. New wiring has to be run to the stove. Not the easiest of jobs in a 2 storey house. We have some things in our favour so we will see how we go. The upside is that we have a friend who wants a spa so I'll be getting a new pump, fitting that and then selling the spa on. So now I will have an empty room with a very handy door to the house which has a much higher than usual door handle. Pool rules. So that will keep out nosy grandchildren unless Poppy is with them. It will be turned into a watch and clock workshop and I will be moving all of my gear from a dusty garage into a lockable, closed part of the house. Wife's idea. Go figure. I'm quite chuffed about it, to be honest.8 points

-

I can tell you no matter how big you have your workshop it will never be big enough. Good luck with it and don't forget to post some photos.4 points

-

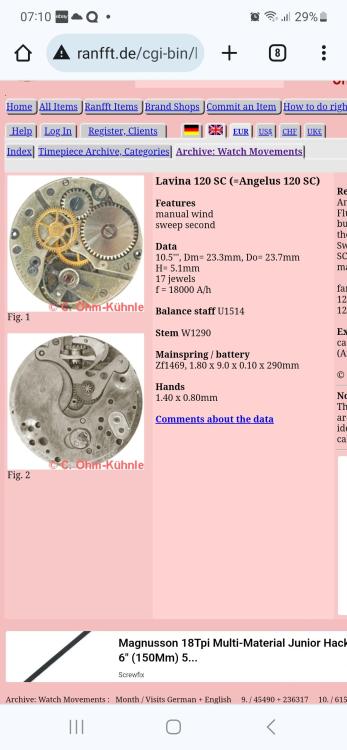

I assume you go to strip off the old paint and whatever before you spray-painted? Maybe a better approach should be just to get a different dial altogether leave this one alone. As you know what the caliber the watches you just get a replacement dial and make it up the way you would like. Often times people frown on modifying a watch in the restoration of it but it is your watch so you can do what you want I'm curious as to how you work this out? Yes the UT part is right but was the caliber number under the balance wheel for instance? The history of Swiss watch making is interesting. In a lot of countries what they're doing would be frowned upon. From time to time and they done this in the past they form groups and they tend the function as one company even if they appear to be separate companies. Like you UT is found inside a shield their oh whole bunch of companies under this grouping and then they excluded companies that were not part of their grouping. Swatch group is just the latest evolution in how they function. Simplistically they function as one company with agreements not to compete in various markets which is why if you travel you'll see them brands that you've never seen before because they have agreements. All of which would be frowned upon in a normal country as anti-trade practices.3 points

-

The link works just fine for me. You haven't actually described how it is messed up, what the problem is...... Two things worth mentioning, with the ETA 2824 you should have the keyless works in time setting position when you remove the stem otherwise some of the component parts get out of sync and you have to reassemble them from the dial side. It's possibly the same with the 2893. Secondly, you should only push the button a tiny amount. If you notice the button is set in a rectangular slot. This is so that if you use a 1mm screw driver to push it, it can only push in the right amount and no further. If you use some kind of a pin then it is likely you will go too far.3 points

-

That wife of yours is definitely a keeper! I'm lucky too, whenever I shoot a part across the room (bedroom so far) I call my wife and she searches, often without my help, because she thinks I'm in the way. She has hawk eyes. So, definitely a keeper too! "Beside every great man is a great woman" I wouldn't say I'm great, but my wife sure is!3 points

-

Hi personally I would clean it up with a little distilled water carefully and leave it , it’s part of its history. But as John said it’s your watch so you do what you think fit. Good luvk2 points

-

Hi use your thumb nails. They break before the teeth and are easier to repair.2 points

-

2 points

-

Never tried it on a Seiko movement but I have successfully used the diluted 9010 on Swiss movements many times over the years. I have only recently encountered issues with a 7.75''' ETA 2651 which wasn't happy so I bought some V105 and solved the problem.2 points

-

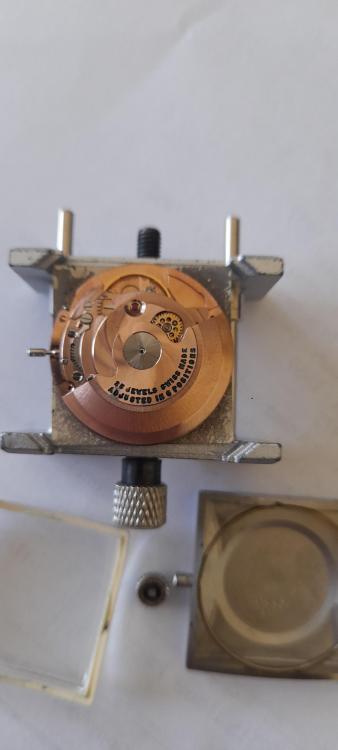

I will definitely post photos @oldhippy The room gas a tiled floor which should make anything that 'pings' off into the wild blue yonder just a littlwe bit easier to find. I am going to have a good look at it to make sure that I have a decent workflow set up in there. The little Unimat will be coming in there. The 3D printer as well. The stereo as well so I have something to listen to. Also made myself a test stand for movements with long pendulums. I have already worked out that I need to modify it and cut some holes in the upright sections so that some large pendulums will have unrestricted movement. I will be building a new bench or getting flat pack stuff as the bench that I have now is a bit to deep, so getting to stuff at the back is a bit of a stretch. Not sure what a good depth would be, but what I have at the moment is too much. I have an offer in my email about Marks course and I am trying to work out how to tell Liz the I want to spend some more money to do this. Definitely cheaper then the BHI course which would need me to travel to England at some stage as well. Ok. So Mark's course is for watches. I would like to think that the principles still apply to clocks. I have to do something as I have been thinking about this for years and haven't done a bloody thing about it. Bought some tools. Whoop de do. If I'm not doing anything with them, I may as well have just set fire to the money and kept warm for about 2 minutes. Need to make a big commitment and turn all of this thought into something. Speaking to a clock repairer in Melbourne and he said Geelong really needs one as there is no=one here at all. Watches as well. So clocks I have are the one that I bought from a store in Daylesford. There's photos somewhere on the forum of it. I really like it. The Hettich mantle clock that was my grandmothers that I am restoring. Cuckoo clock that my dad (RIP) bought when he went to Germany on a training course. Some people would say to just replace the movement, but I am determined to not go down the route unless the Darwin weather has played havoc with everything for the amount of time that the clock lived in the Northern Territory. The Urgos Grandmother clock. The mantle clock that I bought for $20 dollars which I think is worth much more then that. The 'learner' as I call it that I got from Darwin. Our Grandfather clock that Liz won't let me touch as she is not sure that I know what I am doing. Another very old clock that was her great grandfathers which is desperately in need of being serviced. Another clock that Liz is reluctant to have me look at as yet. Watches that I have. My Seiko which just needs some work doene to the band. I t has been serviced by a company in Sydney and looks great. My Tissot quartz which needs a new battery, but I am not sure hw ti get the back off yet. I would say it a snap on back, but I can't find any are ain the back that would accept any type of knife to open it. One fo the Tissot's that I have coming is the women's versions of my mans watch. Really happy about that. I have the Rotherham pocket watch tat I need to work on to get going again. Fully wound but does not run. Catch has gone on the dial cover so it stays open and won't lock closed. Then they'll be the other 2 automatic Tissots that are coming as well. The neighbour across the road has just moved away after losing her husband to a stroke one morning. Kylie has a beautiful Jahrensfabrik Anniversary clock that I would have bought from her in a heartbeat. It is an heirloom that has been passed down by Bills' (RIP) parents to him so it was not for sale obviously. I can say that I have seen one now. I really need to get one. Thing was just beautiful. Never know, maybe I will pick one up here that has flaking paint etc and just remove all the paint except for the dial and turn it into a brass clock. Up to me I suppose. I just looked back at this post. Didn't mean to write that much. Isn't in funny what a bit of alcohol does for you. If there any spelling mistakes , I apologise.2 points

-

I was told off for doing that on the first day i joined the forum by whom shall remain anonymous . I just use my fingernails to press down on the teeth now, Its a good idea to check that the lid is straight when you put it back on especially if some force was needed to pop it off.2 points

-

You sure you don't have my bride? Sounds like her.2 points

-

Billy Fury applies. Jealousy. Your bride is like mine. Pure gold.2 points

-

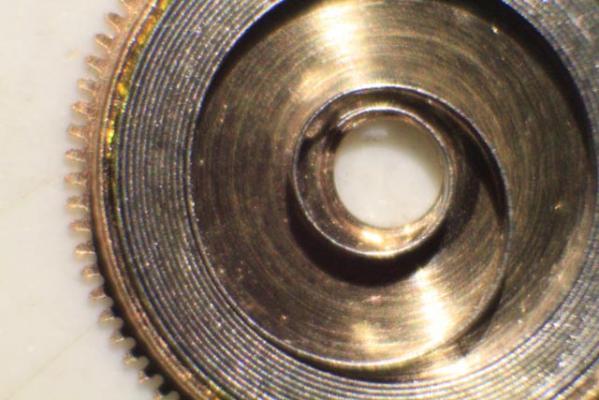

No matter whether you have the best tool for this or handwinding there is a risk of it all going terribly wrong. At this stage of your education it is probably good to do the hand wind for the experience, you learn what to do and what not to do and the bonus is it doesn’t cost you lots of money. Tom2 points

-

I've seen that mentions in the AWCI horological times magazine then explain how to make the or modify the tip on mechanic compressed air to do that. Here's something amusing I thought it was removing the lid but it looks like it's removing the mainspring with compressed air or removing something I don't feel like reading the entire thing it just looks amusing. Then the bottom of the pages interesting yes I skipped over all the details other than as a can of air in the mainspring. So he does not recommend that you do this instead recommends sending your watch to certified Watch repair shop. Then if you click on the link you get to his shop where he doesn't explain how is shop became certified or why we should care about a certified shop I'd be more concerned about a certified watchmaker but what do I know about the things they case it was good for a laugh. Oh and then basically from what I'm seeing it have to make one of these for each this different sizes of mainsprings are doing and it seems well amusing https://www.bobswatches.com/watch-resources/rolex-mainspring-barrel Then I'd be really curious if the method you using in this discussion is what you would use to remove a pocket watch mainspring lid as they usually have way more force to come off. I was going to describe it but I found a nice video and even though it's 4 o'clock basically on pocket watches all of what he says applies especially if it's an 18 size pocket watch. This is where you want to pay attention to which way the arbor goes in often times it doesn't have a screw I could find on the newer watch for the ratchet wheel usually on 18 size the UN backwards the mainspring so you always do want to pay attention pocket watch. The only difference from the video is I use a small brass hammer. Then yes sharp whack and 90 some percent of the time the lid is free if it's not free then you do not want to continue to whack then you get stuck trying to pry it up which is not a big fan of doing consumer markup the edge of the barrel. I don't think I've seen those advertisements although I tend to stay clear of Ukrainian watches especially if there a bargain price. I once purchased a Russian watch very cheap I'm reasonably sure it said it was working and wasn't working when I got it. To me it looked like it was a ball of rust but it was super super cheap not worth the time and effort to send it back unfortunately. Which is probably what the seller was counting on. Then expanding master watchmaker to serve wristwatch on eBay I always find that amusing. Always have to wonder how well the watch was serviced of its being sold on eBay at a bargain price. Occasionally people even show a timing machine results of luck I service to see how nice it looks and a lot of times the timing machine does not look that nice.1 point

-

1 point

-

Typically on a street quartz watch with no complications reset is not required. Then hopefully M not reading that the way I am which is shorting the positive the minus which is shorting the battery out which is not recommended on watch batteries as they just don't have enough power to withstand. The problem with brand-new watches are there brand-new to you but how long has it been sitting in the store the warehouse the factory etc. if the battery is dead well it's been several years and it also depends upon temperatures like it was a jewelry store under bright lights getting nice and toasty warm for several years that would be a bad thing for the battery and lubrication Sounds like no warranty issue except you already opened up the watch. Companies usually get nervous about warranty issues if others have been playing with the watch. Interesting wording of somewhat serviced? That is a standard Seiko service guide implies that it can be serviced. But it's still a brand-new watch covered by some sort of warranty I would go that route first. Then maybe don't want to service the watch may be the just replace the movement https://www.esslinger.com/genuine-seiko-2-hand-quartz-watch-movement-6g28-small-second-at-6-00-overall-height-5-0mm/1 point

-

Sorry to hear that @watchweasol. Praying for your speedy and complete recovery.1 point

-

Yes, those must be the Master Watchmakers mentioned in most Ukrainian listings on eBay. So, when the thumbnails break, what is plan B? B as in Brass tweezers?1 point

-

1 point

-

WW so sorry to hear of your predicament, I wish you a speedy recovery to full health.1 point

-

That doesn't sound too good. Page 7 shows where that goes. It needs to fit in such a way that when you pull the stem out to setting position the hack lever (or stop lever) pivots so that the hook end makes contact with the rim of the balance wheel and stops it.1 point

-

Page 8 gives you the exploded keyless works. The set lever (443/1) has a long post on it that fits into a hole on the main plate and around which the lever can pivot. The button is actually the end of that post as seen from the other side of the main plate. Take plenty of good sharp close up pics as you disassemble the keyless works. They seem a bit daunting if you haven't tackled them before so plenty of pics (take a new pic each time you take something off) will help you to see how everything goes back together. Also make sure that you know which screw goes where because they all look very similar, but getting the wrong screw in the wrong hole can cause you a whole new world of pain...1 point

-

I was using the sides of the tweezers straddled over the barrel so resting across a few teeth on each side. I still got told off and have never done it since1 point

-

I've just read that if you push too far it can jam up and you'll need to strip the keyless works.1 point

-

Hi give it a little jump with the line release tool, (cheap enough on eBay). It may be Down to sticky oil and being dimmed up. Thr line release tool will spin the mechanism round slowley a n free the train. Do this without the battery in then re fit battery and try again. It sometimes helps if you put a little oil or spirit in the train pivots before hand.. if it all starts up ok , that’s good but be aware the movement will needs a clean and oil. Service.1 point

-

For a while, AliExpress convinced itself to present one of my browsers only with Arabic, and I could not change the language on any page until nuking cookies.1 point

-

1 point

-

1 point

-

Not going to do that. I'm trying to work out how to tell Liz about Mark's course and that is cheaper than most things I can find on eBay1 point

-

Hehe. Going on ebay isn't a good idea after drinking either.1 point

-

1 point

-

I'm not sure (you can never be in this business) but I really don't think it matters whether we use our fingernails or brass tweezers. The lid seldom sits very hard, and the metal the barrel is made of is considerably harder than both fingernails and brass. Furthermore, when using tweezers we're really pressing on the base (not the tip) of the teeth closest to the barrel.1 point

-

@linux I'm not a pro but I have used the technique shown by Mark in course video C2.1.8 ever since saw the video some five years ago and it has worked flawlessly. So, what happens? Don't you get the lid off at all or does the spring and arbor fly out of the barrel? Mark is pressing on the teeth on both sides of the barrel, lid up, while the arbor rests on the staking block. That's exactly how I do it, although I use brass tweezers, and I never noticed any damage to the teeth. Perhaps I have just been lucky or it is the brass tweezers that have been key to avoid damage.1 point

-

Mainsprings can always be a problem no matter what. Hand winding tends to be frowned upon because of the risk of distortion of the mainspring. Also if your hand winding especially if it's a blued steel spring you risk getting things on the mainspring that shouldn't be there you probably should wear gloves. In other words blued steel Springs that have been handled by human hands have a much greater likelihood of breaking. Not that they won't break all by themselves just because they feel like it. On the other hand mainspring winders if you try to squeeze a spring in that should go into something that small gets distorted. But for limited quantity of mainsprings you can hand wind again if you have enough hands strength I usually just find it inconvenient so I use the winders because I have them. But I of people who will eagerly hand wind the spring in because I don't want to mess with the winders. So no matter what mainsprings can be an issue. Also a removing the arbor and the mainspring ideally it should be in something like a towel works as it helps to dissipate the energy of the mainspring. It's always an amusement in the shop when the other watchmaker occasionally has a barrel go flying away and usually it's a very expensive barrel. But don't worry in both cases they were found several days later. So it's always important to contain your mainspring after the lid is off and you removing either the spring or the arbor to prevent it from disappearing and never being seen again.1 point

-

Hi again - no problem removing the crystal with a thin blade and the crown split from the stem easily so I was able take movement out of the case. It is an ETA 2542 movement and is in very tidy condition and runs well. My next step is just a minor outside clean and put it back in my collection. Once again thanks for the good advice and I look forward to sharing my next project - a recently acquired TAG Formula 1. Bilo1 point

-

No need to source a whole 3-D printer besides a lot of 3-D printers aren't big enough for tall enough to do this anyway. It's amazing what you can find on eBay. From time to time companies I go out of business liquidate their stuff on eBay and then you can pick up stepping motors and all sorts of bits and pieces were very good prices. Plus just the usual yet the woman him all kinds of things off of eBay then rather than convert a 3-D printer maybe just take all the bits and pieces and build something like the cleaning machine. For instance 3-D printers have XY and Z we don't need all those accesses for the cleaning machine. You obviously need the Z to raise and lower the basket but you really only need something to either move the jars or move the basket. If you are really clever you can figure out how to put the jars in a circle and rotate the entire assembly like they do on a regular cleaning machines. OR have a central column in a short arm for the cleaning basket z-axis. As you don't really have to go all the way across with two stepping motors necessarily and then just move the jars back and forth all sorts of ways of doing this but still an interesting idea and it has people talking. Either this or the or the combined altogether CNC unit where their integrated together those are available relatively inexpensively.1 point

-

Interesting point and correct but all we can do, is try to help and hope that they will learn and stay on the site to help others in the future. I'm still an amateur and always will be, but thanks to this site, I've learnt enough to of at least help newbies from time to time. Thanks to all, my knowledge is still lacking but I started not knowing what a crown was , let alone a stem etc. Being of help is good enough for me.1 point

-

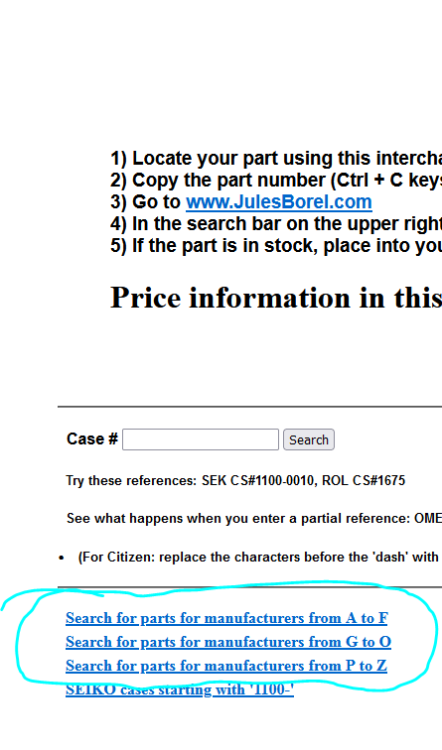

You're not going to find anything on your case back as the database won't have anything. In order to use the case back search you have to have a watch that you actually know who manufactured at it has to company that had parts listed for their cases like Seiko Rolex Omega and others yours does not fall under that category I snipped out an image for you notice I circled something that's where you want to go click on one of those links see where that takes you1 point

-

You will likely need a staking set at some point if you will be working on vintage watches. Finding a good set can get expensive (vintage or new). However, if you are just starting out in watchmaking, I'd place getting a microscope ahead of a staking set. I just got one and am kicking myself that I wasted time and money by not biting the bullet and getting one early on. So much nicer to use for servicing a watch than loupes, visors, or digital microscopes.1 point

-

Who wants good health, should enjoy good things not to much. Funny. Tell that to the guys with APs, Rolexs and so on... just kidding))) Cool sets btw! Thank you for sharing. Understood. Thank you1 point

-

I dont have the skills to rebuild a movement........yet. I want to get a working 2824, select the case, dial hands and face to put it all together. I am sure its a pretty simple procedure for the likes of this group, but my skill set so far is blowing a mean blues harp! The short version- I used to work on Harley's and play 11 string instruments. Proficient in martial arts and could be found on a stream side with a fly rod most days off. Then.......open heart rebuild. It took about 80% of my right arm, neck and hand. (yeah, they messed up) so now I have to approch everything with extreme caution in both physical and budget. So ANY direction (and ways to save a buck) is very welcome! For my former biker friend, you are going to hate my russian cranky old gal!1 point

-

1 point

-

1 point

-

1 point

-

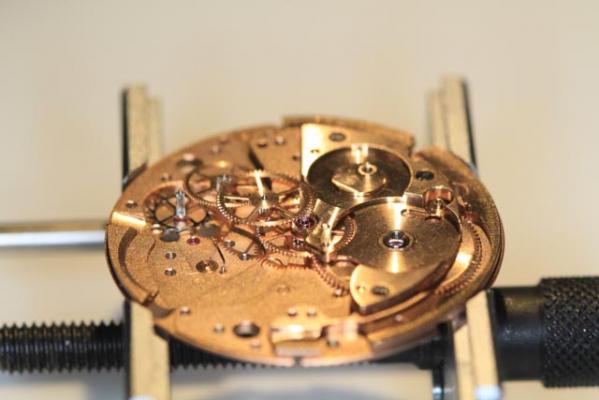

Hi all, been a while since I posted a 404, so decided to tackle this non-runner today. The balance spring was mangled so I decided to put on my "big boy pants" and stop avoiding balance hair spring issues and take it on as part of my learning journey. The watch movement is very poor quality, it looks like they machined the parts with a knife and fork, but I was pleased I got it working and it has now become an exam gift for my son who loves the retro corny appeal of the watch, especially the waving hand which is attached to and elongated pivot on the pallet fork. All original parts except the strap and crystal (the old one shattered when I removed it). This watch was bought as part of a job lot so works out to be a whopping £1.62. So here are the before and after shots, starting with the front: Here is the movement, with closeup of the hairspring: And here is the finished watch: Let me know what you think1 point

-

1 point

-

Yeah you'll never close the hole 0.1mm, 0.01 is hard enough. I'll have a look what I have when I get in the shop. Otherwise, you can ream to 1.40, or, take a smaller jewel and make a thin walled bushing to fit the original hole. I do this frequently, no harm to "originality" and 100% functional.1 point

-

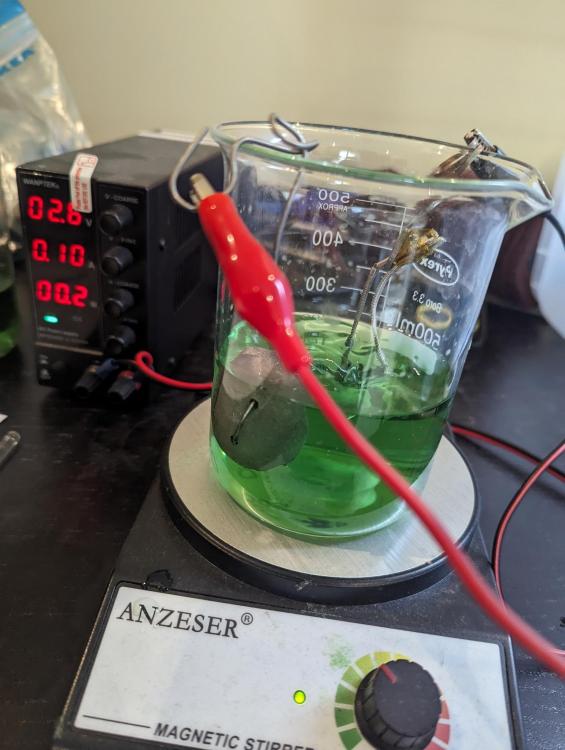

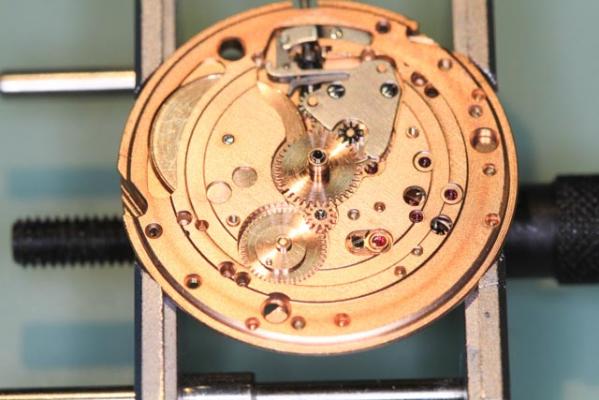

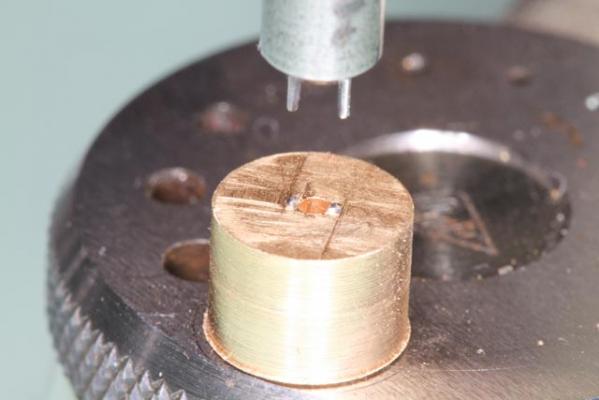

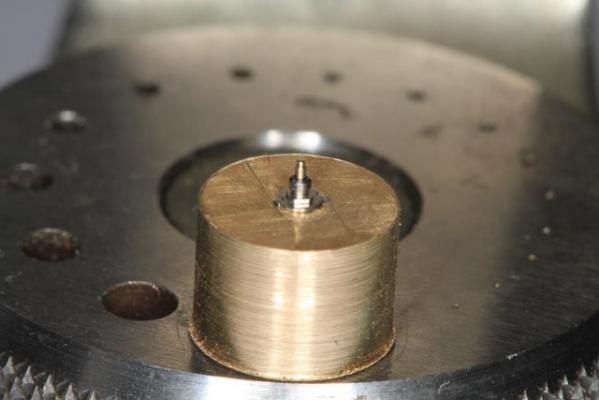

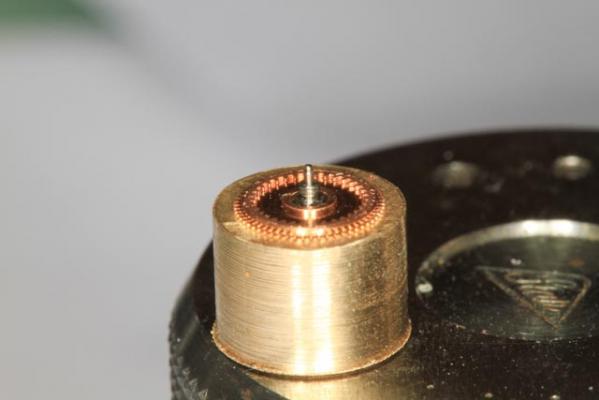

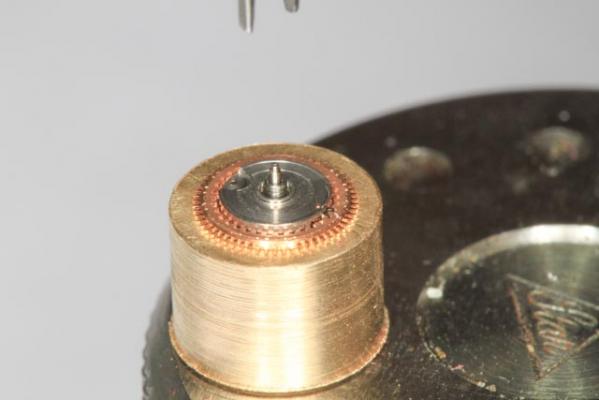

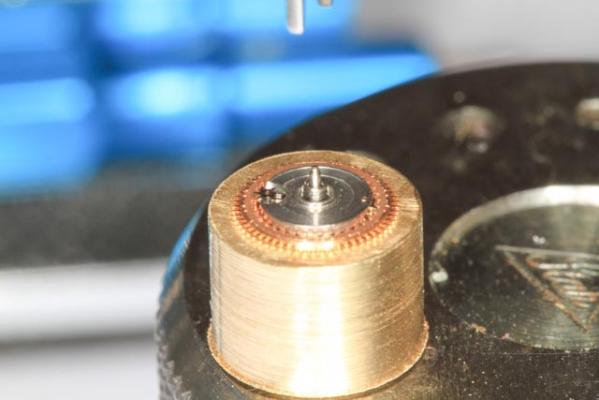

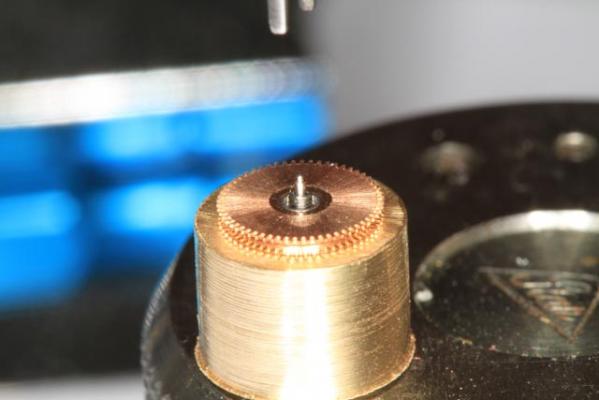

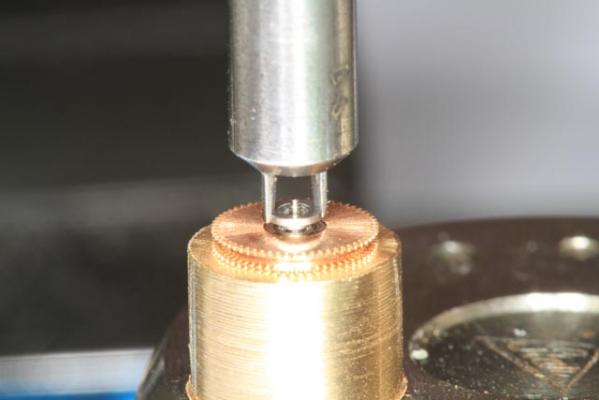

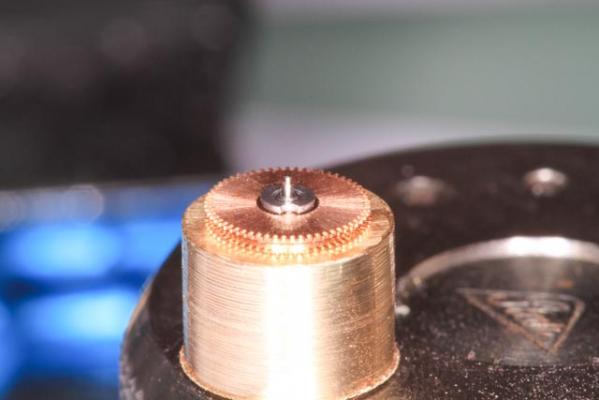

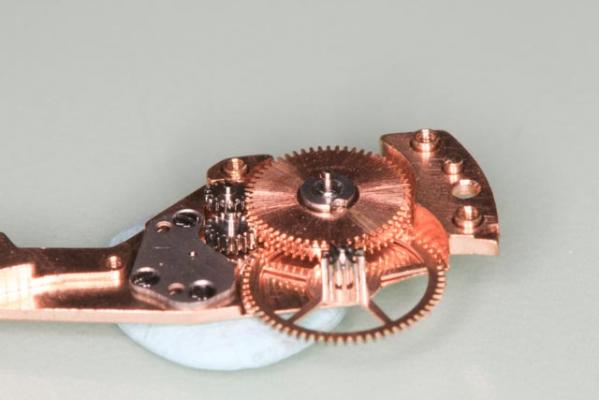

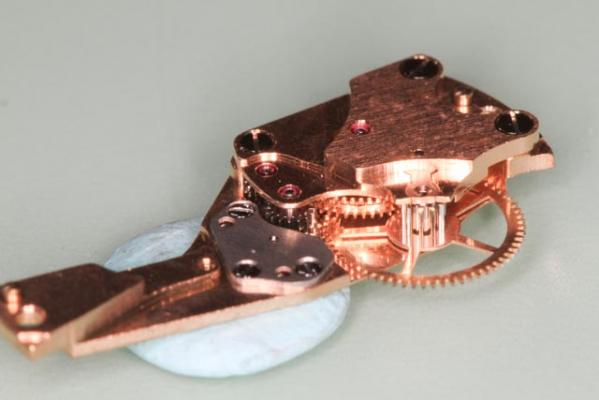

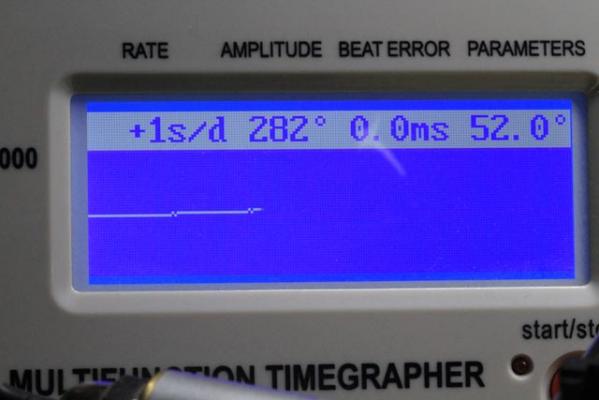

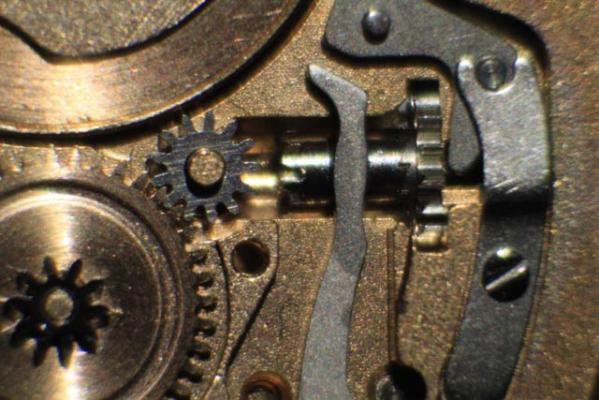

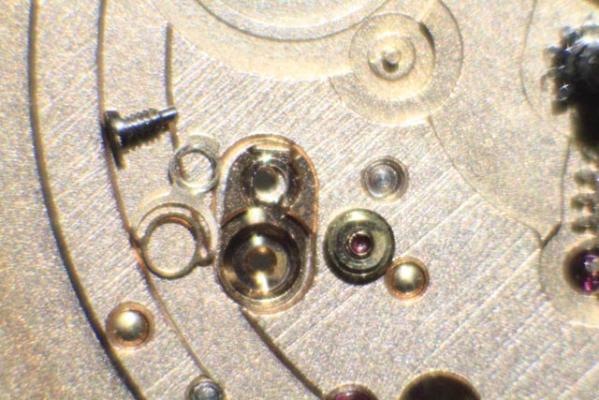

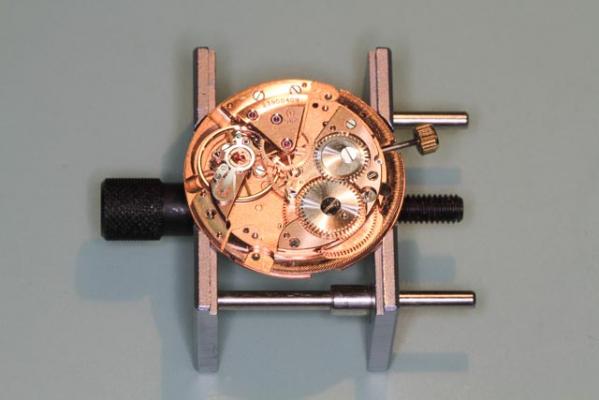

Here's a quick walkthrough of an Omega cal 562 I've just finished. Prior to the photos, I've stripped the movement down and cleaned it, experimentally, in Zippo fluid in an ultrasonic bath, which seems to be extremely effective and quick. I don't have a watch cleaning machine. Comments and criticism most welcome. First, I lubricate the barrel wall with braking grease 8213, and I add a dab of 8200 on the spring itself (not sure if I need to or not) Fit the barrel bridge and centre wheel. Lubricated with HP1300 Adding the train wheels - these are fiddly (i think because the jewels are all olives) Fit the train bridge. Lubricated with 9020 Fit the centre-seconds spring. I lubricated the seconds arbor with a tiny dab of 9020. I left the spring dry (vaguely remember reading that somewhere) Separate the ratchet from the manual winding wheel to lubricate it (HP1300) ...and reassemble Winding gear all back in place. Rodico will clean this up... Pallet fork in place. Strictly no lube! Tiny dots of 9415 on the pallet jewel faces, and worked the escapement round until there was reasonable coverage. Fitting the keyless work. 1300 on the wheel arbors, 9501 grease on the yoke and castle pinion Disassemble the lower incabloc setting. Lubricated with 9100. Train all together And running quite nicely Time to fit the motion work and the date-setting stuff. Completely forgot to take any photos! Now the fun begins. Assembling and disassembling the reversing gear isn't trivial. I made a tool that sits in my staking tool to screw it all back together. Here are the components of the reversing gear ready for reassembly I sit the winding pinion on my homemade tool: Then add the superior winding wheel (tiny dot of 9020 in the hole) Fit the superior satellite pinion to the winding wheel core. A dot of 9020 keeps it in place... ..when you sit it in the winding wheel Then add the inferior satellite pinion (their name for it, not mine) And place the inferior winding wheel over the top Then screw the inferior nut onto the winding pinion using another home-made tool: ...and we're done. Putting it all together on the automatic bridge Lubricated with 9020 And fit the whole lot to the watch. The instructions tell me to dip the rotor gib in a piece of elder pith moistened with oil (9020 again) Finally, fit in to the case. This takes several attempts since every time I attached the case clamps, a new hair or dust spec would magically appear behind the glass. Job done. Hope that was informative.1 point

.thumb.jpg.5bcbf283ad8d49ef2828ca90b38fbafb.jpg)