Leaderboard

Popular Content

Showing content with the highest reputation on 01/09/24 in all areas

-

4 points

-

3 points

-

@Rixy towards the end of last year I acquired the remnants of a watch/clock makers estate which included a reasonable stock (upwards of 50 or so) convex clock glasses of a variety of sizes. If you let me know what size you actually need I can go and have a rummage in the shed and see if I can find something for you. I won't go into detail about what else there was other than to say that I now have over 60 clocks in my shed and I can't actually get in there to do anything. This is what I brought back, unloaded into the living room prior to sorting and relocating to more appropriate places. Any way, let me know what size you're after.2 points

-

I don't want to burst your bubble but to make your own watch you are going to need a lot more then just a lathe. You will need a wheel cutter to start and they are not cheap. The lathe will have to be a high end precision which I hope you won't take offence unless you have worked of high end precision you will find it impossible to make your own.2 points

-

I think you should purchase a used Levin, Moseley, Webster or any other watchmaker lathe, you will find the other attachments for those lathes more easily and be ready to do the things you want, you will spend too much time making a lathe and attachments, I have seen several on places like eBay and auctions in you price range....2 points

-

Just made a program to download all issues I could find of the AWCI Horological Times to my OneDrive. I hope I didn't do anything illegal, but I'd be happy to remove the files in case I did. Enjoy! https://1drv.ms/f/s!AnVrKJ9agkNWkfFk72cqE5ISkNJ78A?e=mYbidJ1 point

-

Hello to all from a new member. Am relatively new to watch repair/modding, with modest experience and skill level. I hope to learn from other's experiences in watch restoration and repair, and perhaps make some useful contributions to the community along the way. Will be posting some pics soon of a 1976 Timex Viscount project that I have started.1 point

-

You beat me to in one way. So this is my go. There are many useless tools in the UK (people in government) but not watch related.1 point

-

Hi can you post pic5ures of the watches front and movement please1 point

-

haha, brilliant. when just seeing the title of the thread, I was already laughing about "Found a tool I Don't want". That sounded like a joke already. But seeing the tool, I'm floored.1 point

-

1 point

-

Try this company https://glassrepairslondon.co.uk/horological-glass-replacement/1 point

-

If I were you who ever you pick to service the clock make sure they do the repairs on their promises, only these days many farm repairs out and you will not know where its at, who repaired it, make sure they guarantee their work and for how long it should be at least a year and how long it will take. Good luck.1 point

-

1 point

-

I had to do a little googling to make sure that was real. Maybe if you're working at a high volume manufacturer?1 point

-

I honestly think you would be better buying one. How much of the watch do you intend to make ?1 point

-

To add to CYCLOPS comments. You would be much better off buying a watchmaker lathe, even if abused a little it will be much more accurate than the build you propose, new parts or not. Tom1 point

-

I think he was hinting without saying Yes. The balance needed changing because I ruined the original beyond what I could fix. I started on this watch a year ago when I had developed less experience and dexterity. A relative gave it to me - it had been sitting in a drawer for decades and no one remembered who had owned it. Its initial condition was to run for a few minutes and stop. Yes again. I don't remember why I initially tried to remove the balance from the balance cock but there must have been a reason. Having only worked on pocket watches before this, or simple clean & oil where the balance didn't need disassembling, this had been the first time I dealt with a wristwatch balance and regulator boot. If I recall, I bent the terminal curve removing it, but was actually able to fix it. Then when reinstalling it, I slipped and totally mangled it. Along the way, there were other problems, loss of Antichoc springs, cap jewels, usual new hobbyist mistakes. I put it aside until I had more experience, leading to today. The main identifying difference between P72 and P72A listed on Ranfft's archive was a movable stud carrier on the "A" variants. Both my original and donor movement have that movable stud carrier, so I wrongly assumed these were "A" variants (despite the stamp on the plate saying "P72"). On ebay, a few listings for balance completes were labeled as P62/P62A, P72/P72A. This I now know is probably incorrect, unless the 72A had an 18000 variant. But it led me to believe they were just interchangeable. Mistake. I bought one from Italy, a NOS Renata balance complete labeled for "P62A/P72A 21". Installed that balance and once running I found out that the watch was stopping after a few minutes not because it needed service, but because the pallet fork horns were bent and eventually it would overbank. I managed to fix that fork (surprising right?) and now have it beating away smoothly at the wrong oscillation for its train. If I choose to fix this, my options are to try again to find and buy the correct 18000 balance complete, or to get another parts movement that is for sure a 72A and swap the necessary train wheels resulting in a hybrid 72/72A with 21 jewels at 21,600bph. Lessons learned: Read ALL details of Dr Ranfft's pages, not just the ones that seem most obviously relevant (that stud carrier) The "21" printed on my NOS Renata balance complete probably was an indicator this was a 21,600 beater and not that the movement was 21J as mine is. Watch for that next time The caliber stamp under the balance probably tells the truth, despite other identifying details. Look there first and do not attempt to mix parts from movements that seem "similar enough" Some ebay sellers may not know what they're really selling (not a new discovery) plus a bunch of useful technical lessons as this watch has come together1 point

-

one of the problems with watches that haven't been worn for long time is an indication that they might actually need to be serviced. then there's the other problem when you change the capacitor/battery of complicated watches they usually lose track of all their settings. this usually requires a reset procedure and setting everything by very exact procedure the watch knows where everything is again. I'm not sure it's actually in the users manual it took a quick look if it's not there it would be in the service manual which is normally one document but due to the fact that this is a rather complicated watch there is actually four separate PDFs. So somewhere in there should be the setting instructions if you change the capacitor/battery. 7D46A,7D48A_1.pdf 7D46A,7D48A_2.pdf 7D46A,7D48A_3.pdf 7D46A,7D48A_4.pdf Seiko setting instructions 7D48.pdf1 point

-

if you are going to do a lot of re-pivoting this will be your go to, nice tool....1 point

-

I appreciate being part of this group. I started with this hobby two years ago , and is an amazing journey, learning something new every single day! Thanks!1 point

-

1 point

-

try a thin metal disk or some other material to cover the dial damage, the movement nut will hold it in place,I have seen things like that for hanging ceiling lights too...1 point

-

Just wondering about copyright. I think you should let Mark know.1 point

-

Great! Thanks for clarifying and sorry for being a bit of PITA! Oh BTW, when I've finished my stash of Polywatch I'll get myself a tube of Autosol acrylic polish. Excellent tip!1 point

-

Hi all, I'm new here this morning I'm a watch enthusiast with a small but growing collection. My father has been a watchmaker for 65 years or so, still in business today. I grew up doing my Saturday job in his shop, fixing clocks, stripping and cleaning clock movements etc. Only recently have I dipped my toe into watches. Same principles but much smaller obviously! I started on a cheap Ingersol pocket watch with a Cattin 66 movement, and I'm just working my way through a BFG866 movement. Luckily I have the advantage that my father has literally hundreds, possibly thousands, of spare movements to play with. I'm hoping to learn plenty from the forum. Nice to meet you all. Mike1 point

-

1 point

-

Same issue another interesting series started called: Common Sense Escapement Checking1 point

-

Thank you for letting me join as I'm up for retirement soon ive have given a lot of what to do besides my carp fishing so I'm going to hopefully learn to repair/service watches so at some point I will definitely need you help. William1 point

-

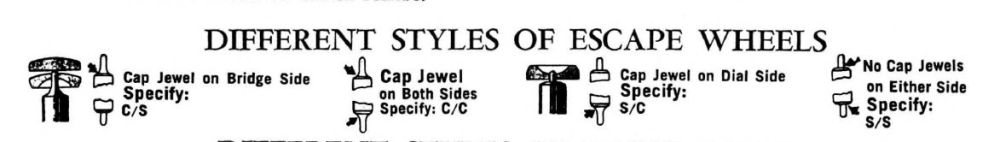

it's always interesting what watch companies will do to enhance the quality of their watch by enhancing the jewel count. Even though we might question whether those jewels actually do enhance other than how much they charge. For instance in the bestfit book there's a image of a warning basically when you're purchasing escape wheels. But I do think sometimes the same morning could apply to pallet fork pivots. But their example is escape wheel.1 point

-

@RichardHarris123, @nevenbekriev, @CYCLOPS Thank you - sorry just saw these responses. my push notifications must have been turned off. I'm pretty sure the case might be stainless. I ordered a reagent testing liquid to confirm.1 point

-

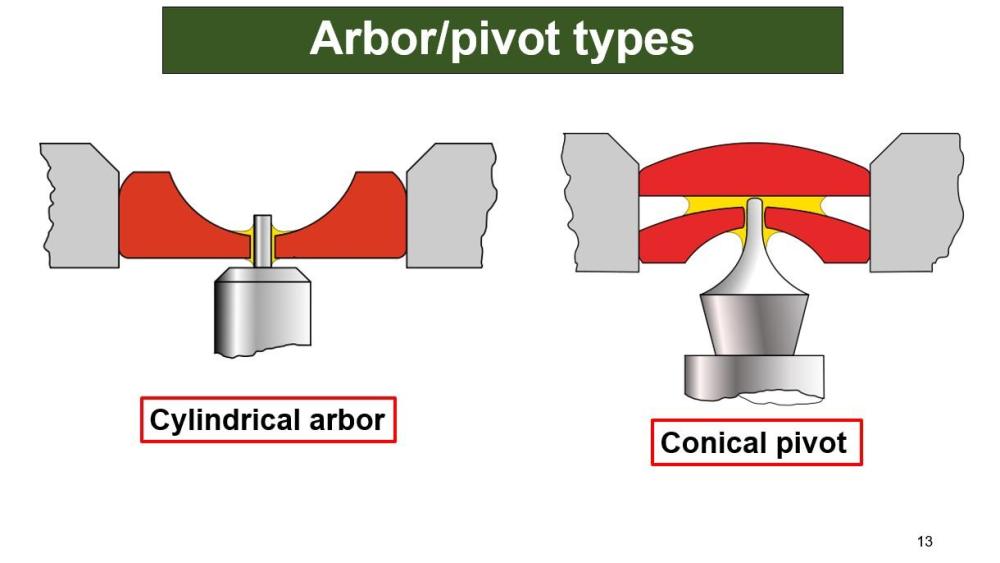

Sometimes manufacturers would make a base model with 15 or 17 jewels and then they would also make a model with a higher jewel count, so it made no sense to make the main plate any different from the base model. The higher jewel count version would have a cap and the jewel would be convexed (olive jewel) with no oil sink and invariably the wheel that sat in the capped jewel would be a conical pivot/arbor rather than a cylindrical pivot/arbor with an oil sink1 point

-

The shape of the jewel hole would determine if the hole was designed to have a cap jewel or not. If the jewel hole is convex on the side facing the supposed cap jewel, then there should be a cap jewel. But if the jewel hole has an oil sink instead, then it means that the manufacturer decided to leave out the cap jewel in the final production.1 point

-

Thanks. After a bit of research within this & other Forums, I thought the K&D Inverto facility was a key feature along with the reasonable availability of stakes & stumps, K&D's reputation and, as you say, the available documentation (e.g https://archive.org/details/KDStakingTools/page/n17/mode/2up & at https://kanddinverto.weebly.com/junior-inverto-600.html). With no real idea about value for money (although I know there are other watch repairs I'll be using it for) but assuming it might be an appreciating asset in the long term, I paid £268 (inc P&P) for a set with 76 (out of 100, judging by the 'holes') stakes and 15 (out of 20) Stumps with a box albeit missing 2 handles & original latch but otherwise in apparently good condition. I could have bought a new, Indian-made boxed set for £375 with 120/20 items or waited for a complete K&D set to turn up but I feel, as you imply, that I've made the right decision- as they used to say of a Rolls Royce purchase: "the Quality remains long after the Price has been forgotten".1 point

-

1 point

-

You sure like to make life hard. Why don't you buy them already sharpened.1 point

-

1 point

-

Just keep watching. I lucked out today and scored one off craigslist an hour away from me. Complete lathe (head, tail, bed, and motor. Came with a good selection of collets, and a stand. I'm stoked. I need grabbers but I can get those a piece at a time. I'll use a file until then. Lol1 point

-

Hi all i have just finished restoring my recently purchased Pultra P type and am gobsmacked at how little runout there isn’t, I used my Verdict finger dti that has just come back from Verdict after being serviced and regulated so I know it’s working fine, I had to do a video of it so I could check it on a big screen because I couldn’t see any movement on the needle with my old eyes, I set the finger against the internal spindle taper and run the lathe very slowly and as can be seen in the video I adjusted the arm of the holder a couple of times just to make sure the finger was touching properly I am well impressed. Dell1 point

-

1 point

-

1 point

-

1 point

-

Pretty much all the lathe makers offered collet holding tailstocks. And there were a bunch- Levin, Derbyshire, Marshall/Peerless in the U.S. (there were others, but they were the big ones), Boley-Leinen, G. Boley, Lorch, Wolf-Jahn in Germany, Pultra in England, Favorite and Star in Switzerland, easily a dozen more. But yes, having the ability to hold the same collets in the tailstock as the headstock is a very, very, nice feature.1 point

-

1 point

-

One of my Peerless 8mm lathes came with the tailstock accepting 8mm collets for drilling. It's really great to have1 point

-

Great tip. Bergeon has dedicated tweezers for this purpose but as usual the price is, shall we say, a bit steep?! How do you get the chamois leather to stick to the tweezer tips? Where can you get chamois leather? I want to make my own. A grease frequently used as a braking grease we haven't talked about is Kluber Chronogrease P125. I'm pretty sure @nickelsilver mentioned using it for all types of barrels. It's the grease I use. And mind you, it is only £23,000.00/Kg (including VAT) You need to elaborate if we are going to have a chance to understand it and comment.0 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)