Leaderboard

Popular Content

Showing content with the highest reputation on 01/10/24 in Posts

-

Hi Murks, The watches you have problems with are the ones that need more specialist knowledge for example the one you had with the jewel problem. Unless some one like John 725 picks it up or some one who has been there and done it your responses will be low or not at all. John725 is the knowledge base on vintage watches as that is what he does professionally so the information is always good. The essence is Murks please be patient and if your post gets lost then re post . What we do here is to help people over problems as best we can, so rest assured we are here to do just that. Try as we might we don’t know all the answers but collectively we come pretty close. Good luck with your present project.4 points

-

3 points

-

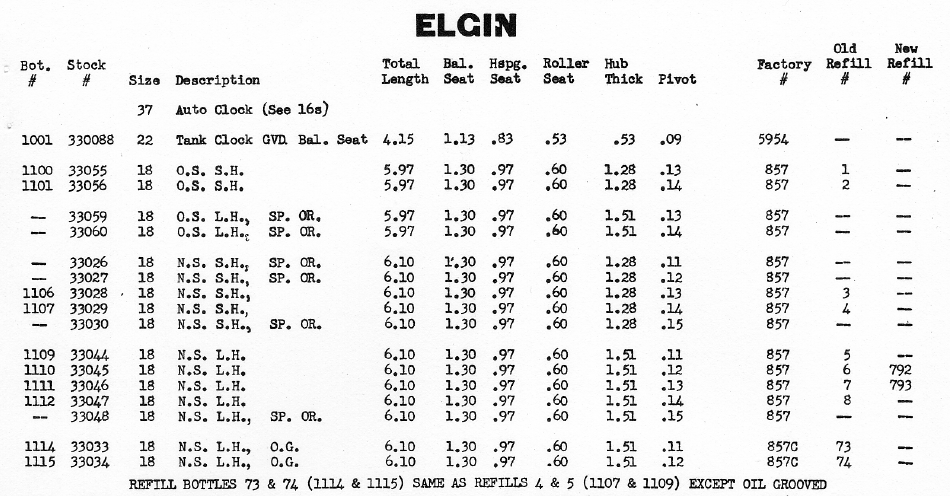

my comments on this is watchmakers are learning like doctors or basically we are practicing. Every single watch we practice and hopefully we get better. Unfortunately when working on vintage sometimes it is several steps backwards before you can go forward again. in other words vintage is a specialty and even with specialty knowledge they can be quite annoying. one of the problems with the message board being fragmented in the so many sections is I've changed how I do things. t used to be I just go into the main folder I go down the list I'm looking for anything that hadn't been answered or anything that looked interesting. Now that were fragmented in the thousands of categories I just ask for all the unread messages in other words have I read it or not. Then I look at the titles to see if it looks interesting. But of course this means I'm not going to see everything. So things will fall through the cracks. Oh and just a reminder for vintage especially vintage American which has parts books we can look up your parts we can see what they are it's an exact science of insanity. Yes you probably weren't expecting to see the word insanity? This is because there tends to be lots of variations. for instance I know someone who did a project where they needed a whole bunch of identical 12 size watches that were affordable. So they picked a particular 12 size Illinois watch because according to the parts book all the parts are identical in other words there are no variations over its life span. Except the parts book was printed before they finished the run and there were variations lots of variations. I was looking for a balance jewel and had to cannibalize quite a few movements to find the balance jewels for the particular movement I was trying to fix for instance here's an example of part number problems. Or why part numbers are not necessarily an exact science or why is it I ordered by a part number and I didn't get what I expected. This comes out a book that lists American balance staffs printed long after all the American watch companies quit making pocket watches. So were looking at the 18 size Elgin 857 balance staff. One balance staff number but how many separate balance staffs you see? Four different types or sizes for variations and then a course a whole bunch of different pivots sizes. in other words here's the problem of vintage they can be really beautiful and spectacular when the watches running but getting it back to running condition be quite a challenge with variations of parts that may or may not be listed in the books. People before you than a plate with the watch who decided for whatever reason to change things because I guess they could or adjust things because they could or all sorts of bad things. Which is another reason why vintage is a challenge.3 points

-

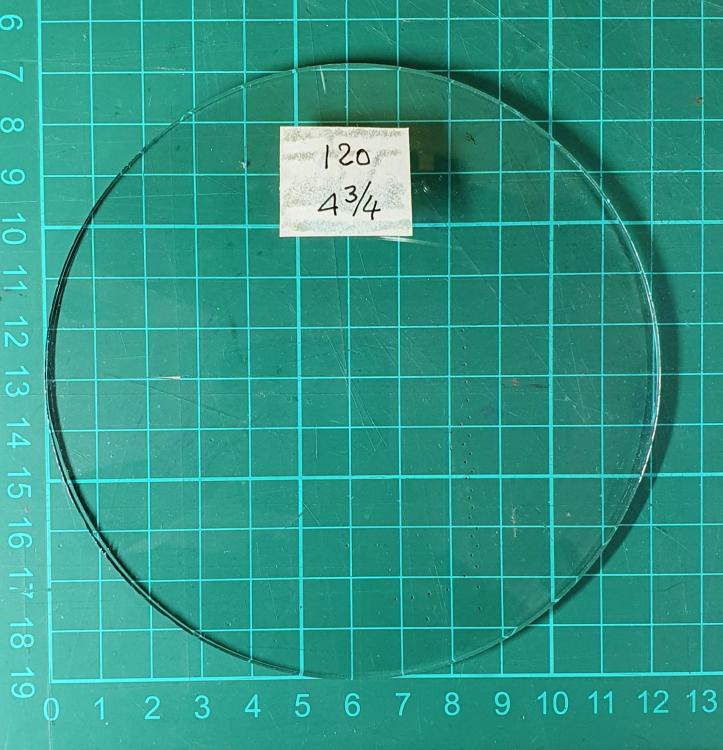

@Rixy let me know if the attached is any use. It is domed although that doesn't show up very well in the pic. Also what appear to be scratches are in the cutting mat underneath, the glass is actually pretty clean. If will do the job then pm me with your address and I will try and get it in the post at the weekend.3 points

-

Minute recording wheel Venus 150. One NOS on eBay: https://www.ebay.de/itm/225163116133?hash=item346cc47e65:g:oAcAAOSwfrljIbEt&amdata=enc%3AAQAIAAAA8BbDkNJE4lOk28DTZK2An92pCJU26es9hbA0ytT4b7aWpA6u%2BYnLP0xlA3QN0rxKMbDjs33lGBVUouYM%2Fl3KX3SwPFS%2FTeOwWEw7lnSiYXS5jyntNuPYNM8syZrc560tewai%2B83qIo3yzqShCwqr7P0C0gDf5MkuP3FOfJoJb9HGUCY%2FVTL6DZ%2BBQOheC5BVEnllgr8%2B4%2BEWIkJdIvPgDt54289NAOlqM1EcDl46heJLF9yElTIeEw99TMtVTEQOOPwnEugglkCVCqdOCL0Rb0Z0nzciZvfbOwA6jlp5bCI4o0p3WDHedGbxZHrL9WlEPQ%3D%3D|tkp%3ABFBMksDwrZ5j I once wrote a "reverse pulling" technique. No guarantees, but another option in your toolkit; https://www.watchuseek.com/threads/reducing-the-risk-when-pulling-poljot-3133-chronograph-hands-my-best-so-far.5139739/?post_id=51140455&nested_view=1#post-51140455 Click the "see more".3 points

-

The only thing that would be on the end of the minute recording wheel would be the minute recording hand. It might be the tube that the hand was riveted to.3 points

-

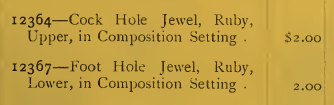

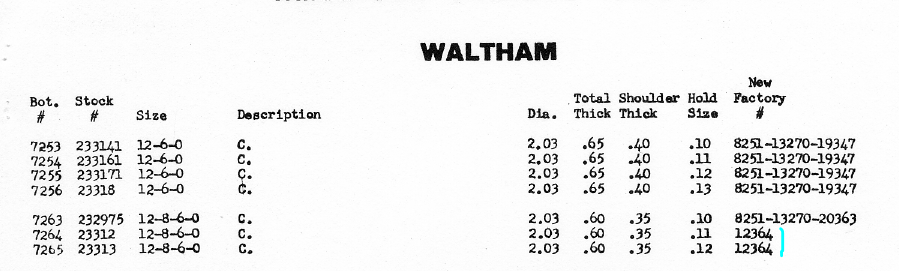

the run into several problems with some of your questions like people answering the questions are all across the planet. So while your question is burning in your mind that this particular second some of us might be asleep. Then there's the other problem this group is based in the UK where you're located and that appears to be an American pocket watch? Although both Waltham and Elgin exported quite a few watches to the UK and other parts of the world. But still American pocket watches is not exactly the thing of this group so getting clear answers is problematic at times https://pocketwatchdatabase.com/search/result/waltham/2125977 yes you did get the model but I do like the look at the pocketwatch database unfortunately it sucks for Waltham parts CF to go to a physical book. Or in this case a PDF. oh I'm a bit confused by your pictures because you can remove the jewels. Two screws on each plate and in the jewels will push out usually their frictions in but they will push out as you can see your hole jewel and what you're dealing with. If there is enough brass in the hole jewel assembly you can smash the old jewel or get it out of your way and put a modern jewel in its place. Sometimes frowned upon by obsessed people that think you should burnish the jewel back in but nobody's going to see it works fine just to put a modern jewel in. But often times there isn't enough brass because of the way it was originally put in with the setting I suppose you to try to put a modern jewel in but the diameter is going to be so huge. The other way to do this is if you had a watchmaker's lathe you would just make an entirely new setting for your new jewel. then looking in the parts catalog we get parts numbers sort of I don't suppose you know what hole size you need? then my usual reference for balance jewels only shows one of them? Although it does look like a eight size is odd which brings up a course a problem of finding parts for watches that were made a very long time ago and not necessarily huge quantities but this does bring up and shows a problem of if you try to bypass the setting you would need a jewel of at least 2.03 mm in diameter and balance jewels I don't know how big the tools go but that's a really big jewel. So the best would be to see if you can you replace the tool itself for the modern jewel with the brass setting you already have somewhere in the US they used it company that's all the balance jewels but I can't remember who were aware that is and the other place to try is Dave's watch parts you might have which you need if you want to buy the original jewel to be the best but for now to get a better idea of things why don't you take your balance jewels out there a little hard to see when they're in the watch with the end stones in place then I found the company that was making the balance jewel assemblies they don't seem to have yours but you can email an inquiry https://www.ebay.com/sch/i.html?_ssn=qbstuff&store_name=americanpocketwatchjewels3 points

-

I use M56-b (AKA LGN) for pivots (surprise surprise!). It has a lower viscosity than 9020. Of course there is this craziness from the Accutron service manual. I am taking a shine to servicing these things. Each one gets easier. Still a little tricky getting the index and pawl fingers just right. My cleaning methodology is pretty refined now, using the ultrasonic for the clean and an L&R Master to spin dry between each step as well as dry in the last step. Found the right jars for the job and printed a lifter to lift the basket out of the jars.2 points

-

oh man this makes so much sense. I never considered it because this was a ebay find for repair and the hands were broken off or missing and I never saw it. I was so worried. Already bough the replacement wheel. Thank you very very much!2 points

-

Bearing in mind your comment, on firing up my Adonstar magnifier I found that there was a 'castellated' flange at the end of the cogged pinion of the smaller part although the flange length wasn't long enough to be folded over on the far side of the big wheel once inserted. However, your comment caused me to push out the flange from its slightly folded-in state - which I did using a round nose hollow stake (K&D #80) - press the piece into the larger wheel & then re-tighten the connection with the #80 stake. The compound wheel is now re-installed in the music box mechanism which is now working !2 points

-

Hi a pair of crossover tweezers would do the trick as they have to be pressesd to open, naturally in the closed position or an anglers heamostat used for removing hooks as these have a lock on the handle. To solder fine components like coil wires etc, get some copper wire and wrap round the soldering iron bit and file to shape and tin. The iron will transfer the heat to the copper wire. Also how about solder paste which contains both solder and flux.2 points

-

2 points

-

Are you sure it's soldered? I've worked on Accutrons that were spot welded and no amount of heat will be able to release that. But if it's soldered, flood the area with flux first. It helps to transfer heat to the joint and prevents oxidation. I prefer solders with lead. Lead free solder is a real pain to use. Put a dab of fresh solder on the joint, it will help to melt the old solder.2 points

-

Reading this makes me feel how lucky I was when I started it was so well stocked with spares both in clock and watch all I had to do was go through our stock and find one. It must be very hard these days when stock is poor or in some cases non existent. Well done Marc for helping out I'm sure Rixy will be well pleased1 point

-

Correct size crown gaskets don't exist. I had to order mine from Spencer Klein. Changing one is tricky but surely doable, I managed to do it on the first try. Which is nice because I didn't have a spare crown.1 point

-

Hi another source of parts is Esslingers and Otto Frie in the US or Cousins uk or speedtimerkollection.com in Europe1 point

-

Yes, this is the tube from the hand. The wheel will need to be repivoted or replaced.1 point

-

Welcome to the forum, enjoy.. A picture or better still a vid would be helpful to analyse the fault also it’s caliber is useful1 point

-

Thanks alot it worked with the way you should me appreciate I am starting to understand most things now not doing the same mistakes thank you.1 point

-

shields up and haven't you built your fallout shelter yet? Nothing like a good fallout shelter. I don't worry about the recommendation so I use 9504 modern and it works really well. Plus it does at that pesky really short shelf life to upset you in as a shelflife twice as long and then I'll just disregard that because it's synthetic it should last forever. then yes back in your center wheel discussion didn't I point out that you do not want to use the manufactures recommendation because their retirement plan was based on selling a lot center wheels when they get disintegrated due to poor lubrication choices.1 point

-

a useful place for looking for watch part numbers is this website http://cgi.julesborel.com/ a notice of the top of the page you can enter in case numbers and get your casing components one of the problems with the vintage watches is availability of parts can be interesting but at least you get part numbers and yes the parts are all really discontinued it's a vintage watch but still you got numbers there may be substitutes or eBay http://cgi.julesborel.com/cgi-bin/matcgi2?ref=SEK+CS%236105-8110&submit=Search http://cgi.julesborel.com/cgi-bin/matcgi2?ref=SEK+CS%236105-8009&submit=Search that's the same link you can look up movement parts and get their numbers which of course of all but discontinued. But still get the numbers and might be better to purchase a used watch off of eBay. I've attached the relevant parts lists just in case you don't have those the reason for the 6106 apparently that's the base caliber for the 6105 6105A.pdf 6105B.pdf 6106A-2.pdf1 point

-

I would mount it back on the movement and solder. But make sure you prime the tab and capacitor lead with fresh solder first, to minimize contact time with the hot iron.1 point

-

don't see any crystal gasket listed and a lot of times yes there glued in. The UV glue works really nice but you could use five-minute epoxy. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=SEK+CS%237T32-6G40&submit=Search oh here's a website that talks about putting crystals in https://blog.esslinger.com/how-to-replace-a-watch-crystal/1 point

-

Hi Nath, My answer will differ from the others. As one who has built several lathes (not complicatet ones, but well working), I think i have this right. Making own lathe is possible, at least I did my first one when I was 15 years old. Watchmaking was different before 150 years, one aprentice would never be proclamed 'watchmaker' untill he built by himself several different size and style clock and watch movements. And, learning the craft always started by lesons for filing, cutting, heat treatment, building simple tools, then more complicated ones... At that time the watch parts were not interchangeable at all and even repairing watches ment making parts when needed to replace. Yes, buying lathe is easier and faster, but making one will make You eyes and mind much more open and You will obtain skills that others will only dream for. There is a Bulgarian fairy tail with wisdom inside that says about the Fox - She was hungry and tried to reach the grapes in a vineyard, but the grapes were too high for her to reach, so the Fox said they are too sour for her and went away... Now, for making own movement... I will quote a Bulgarian Writer, one of his heroes said: ‘One is to WANT, another is to CAN, and 3th and 4th is to DO IT’. I will continue this thought with my own experience. When one is young, he WANTS, but he CAN'T. Then, when growing older, he gradually gathers experience and abilities, but when he is already experienced and able enough and he has proved that he CAN, he would probably has forgotten what he WANTed when he was young... See, making movement is different if one will copy existing movement, or even only the escapement, than if he will design everything by himself. Designing will need many knowledge and experience... Now, for the lathe design: You will need one more bearing for the spindle. One on front, and one on the back. Single bearing, even if it is with two rows of balls, will not support the spindle stable enough. What are this rails? What is planned to move on them? What is this thing on the front rail? Is it rail bearing? Unless I will know the answers, I will be not able to say if it will work well or not.1 point

-

everything on the schematic is low-power so typically would use 1/4 watt but if you're really worried about it you could have 1/2 but that would kinda be overkill perhaps1 point

-

all very good lessons learned then maybe throw in look at a website that allows you to cross reference parts. From people who understand watch parts rather than as you've noticed on eBay if you seen one balance wheel you've seen them all and is it really important these little details obviously not. eBay sellers can be quite interesting in that often times that will sell stuff they might even specialize in certain items like I was looking for the oscilloscope once and I remember one seller was very clear that he knew nothing at all about our oscilloscope's yet that's all he ever sold which I was found quite interesting. But I suspect the reason for the claim was he would also claim they were unknown condition in that way if they were total rubbish he can't be blamed because he doesn't know what he selling. So a lot of people selling watches obviously are not watchmakers they just buy watches from wherever they do they sell them on eBay and let the buyer beware. Then it's always nice to use a site like this way can look up your parts and see what they cross reference to get a little more detail. http://cgi.julesborel.com/1 point

-

Interesting. Yeah, Ranfft says the Durowe 7523/2 has the Rufa-Anti-Shock system. 17jewels says the 7255 also uses the Rufa-Anti-Shock system and the photo of it looks the same as yours. There seems to be a glitch in the matrix with the incorrect Incabloc information. It looks like that system isn't hinged, so I can see why it pinged off into the great beyond.1 point

-

Hello Ricktok, I've done a fair bit of soldering in my past. I'd say you've got a good iron there but I'd suspect the tip is going to be way too big. You'll need a fine tip, either buy one of the right size or file one down to suit. Being that it's from the 70's there's a good chance the solder contained lead, unlike today. Mixing old and new solder can be problematic, using flux and keeping it clean and grease free helps. Depending on your soldering skills you may be able to dab it back on using the solder already there, but you won't know until you try. Careful with the heat. An alternative way would be to use sliver conductive paint, but I don't think it'll help in your case, holding the component to the tag. I'd also practice on some scrap wire, components too especially at that scale, it may help in dialing in the temp and melting point of your solder, and how it flows. Good luck, let us know how you get on.1 point

-

Should be here this week, if its as good as I've been told i will be polishing and Repivoting every pivot that isn't nailed down.1 point

-

if you are going to do a lot of re-pivoting this will be your go to, nice tool....1 point

-

1 point

-

Looks like you are dealing with rubbed-in jewels or rubbed-into bushes and pressed in. Someone like JohnR725 or old hippy could answer your question. To be honest if you are looking for that buzz of a movement coming to life, you are choosing the wrong kind of watches. Too old , too broken and lack of replacements. These are difficult to work with murks, they are guys here with 5+ years experience that wouldn't attempt this kind of repair. I applaud your bravery indeed, i tried something equally as difficult last week. I wasn't expecting a good outcome and it wasn't but i wanted to test myelf and i did learn from the experience, so i do get where you are coming from if thats your reasoning to try this repair.1 point

-

Questions are not always picked up first time murks, just keep posting till someone answers. But pictures are nearly always needed unless its just a general enquirly. One reason is your question might need someone advanced or watch specific to answer and they may not be available. As an example i never answer anything clock related as i have next to no knowledge in that area, also very rarely seiko questions or pocket watch questions. My knowledge lays mostly with vintage mechanical wristwatch era 30s -70s , Brand history, tool related , making tools, general all watch related issues and a little quartz knowledge. This is what interests me at this time, but sometimes you just need to be patient for the right person to answer.1 point

-

I'll inform the seller that more orders are coming his way when i leave feedback for him. You never know, i wonder how tasty Hungarian chocolates are1 point

-

1 point

-

1 point

-

Hi John, Thanks for the input. The watch does run despite all the abuse it has received before it came to me. It has lots of broken bits though and had been well over oiled. Battery cover was missing and the movement had filled with fluff. Pretty sure I can get it close as I have an electronics background and access to an oscilloscope. I'm going to adjust the main oscillator first so that it peaks at exactly 32768 Hz as shown by the graph. It should run at that frequency at a certain temperature and then raising or lowering the temperature should cause the frequency to fall (at no temperature should it go higher than 32768 Hz). Then I will adjust the aux oscillator so that it gives 32768 Hz when the main oscillator is running at 32768 Hz (again as indicated by the graph). That should only happen at a certain temperature. A hairdryer will be used to change crystal temperatures up and down. I will post any progress.1 point

-

Thanks John, thats really good to know, the guy posted it first thing this morning. He must have been asked about the wheels before as they now come with both rough and fine finish.1 point