Leaderboard

Popular Content

Showing content with the highest reputation on 01/11/24 in all areas

-

I bought it!!! Phew, what a journey this has been and I've not even started yet Thanks everyone for your help and opinions, what a great forum, so nice to see such an active community, happy to have stumbled upon this. @tomh207 I'll try not to destroy this beauty, it would have 100% been better off in your hands5 points

-

This is the way. Make a new bridge for an existing movement, see how that goes, and continue or not. Making a whole new movement from scratch is very daunting and few manage from that starting point. I've done it, and it probably shortened my lifespan, haha.3 points

-

I've got a couple of Accutrons tucked away somewhere, but I've never serviced or repaired one, so it's good to know there are some proficient servicers here that I might be asking for help in the near future.3 points

-

If it's a complete wristwatch you want to work on, you could do a lot worse than something with a working ST/FHF96 movement in it. There are a lot of them about, as it was a popular budget movement back in the day. That makes them reasonably priced, spares are available, they were made to be serviced so they are relatively easy to work on, and what you learn there will transfer to a lot of other movements. Avoid anything coming out of India though3 points

-

fortunately when I post things I usually put them in a particular folder so I can find them for uploading so conveniently they were together. oh and yes you really would need the stem thing if you are installing this for the first time. If it's already in an existing watch it by theory should be much easier to do unless you change the back gasket. In other words on a 214 the location of the crown versus the back gaskets and the movement the back casket will of course move things around. then while I was remembering this that's why I uploaded this to some other group somebody was having a running issue on a 214 with a hack although unless you disassemble you won't actually know if you have a hack or not sort of. So I uploaded to comment on if it has a hack it could be an issue in these would be the issues why. In other words the crown is on the back if dirt gets under the crowd that changes spacing if the back gasket thickness should change. Which unfortunately will occur today as you may not really get original 214 gaskets and they have replacements and of the thickness is different it can be an issue. Oh and then if you are installing this for the first time you'd need the thing on the stems because you would have to change those to get one of the right length. I very distinctly remember when I installed one of these I was a student in school which was quite a while ago and I do not remember being a pleasant experience. Because as you can see with the instructions you have to set everything up and put it all together and if not right then you have to yes they can be a fun experience. I don't think I've ever done a 214 after that that had a hack though Accutron 214 hack.PDF Accutron 214 stems.PDF3 points

-

3 points

-

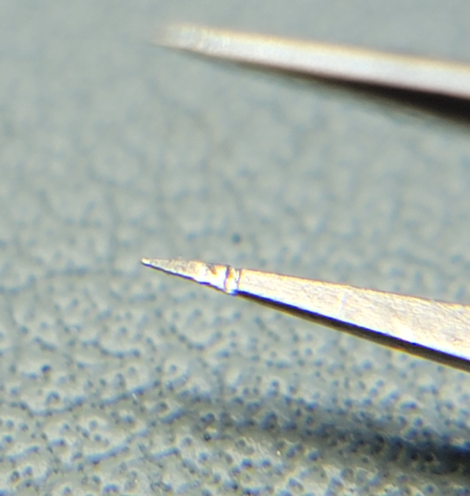

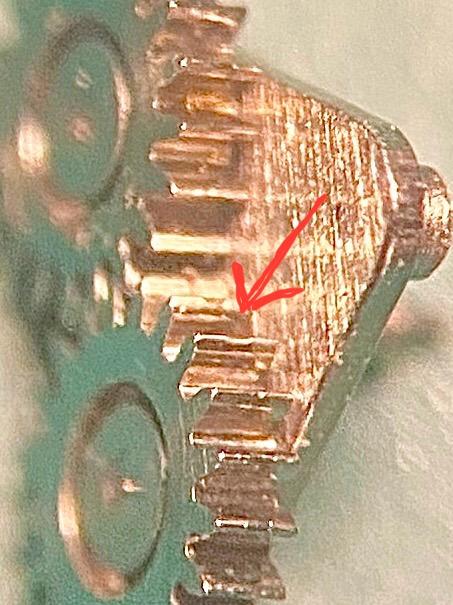

When I clean the index wheel I put it in the Accutron index wheel holder. What have found is that while holding the arbor, the wheel flops around because the tweezer will not hold it in a fixed orientation. Well, I fixed that!!! I modified a set of 3C tweezers by adding a notch so that the index wheel arbor is held orthogonal to the length of the tweezer and will not wobble. The notch is on both legs of the tweezer but only one is shown.2 points

-

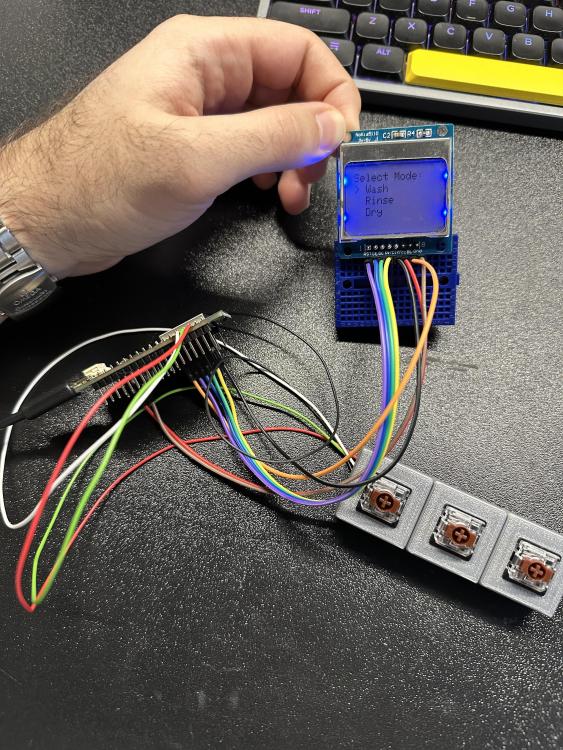

Everything aside from the frame is on its way. The frame is the big mystery at the moment. I really like Gert's implementation, would be nice if the jars would also change automatically. The bad side is that it's quite chunky, I don't have that much space. The Kiwi Watch Cleaning machine project is a bit simpler and just works. The good part is that its smaller. At this point I started from the software, as I already have the components. I took a board that have Bluetooth and Wi-Fi... meaning you can get a notification when the job is done. Maybe a bigger display would be nicer, will see... The plan is to keep the menu simple, just 3 functions that one could select by going up an down with the buttons. Probably I need one more button to act as a cancel/emergency cancel button, for when any of the jobs is running.2 points

-

oh for servicing this when you get around to it would give you the sheet on setting up the hack for it. The railroad approved to Ford teams have a hacking mechanism and the only way you get the instructions would've been if you had purchased the hacking upgrade kit. Otherwise the specifications do not seem to exist anywhere in the universe fortunately I PDF that.2 points

-

Howdy. Been awhile since I posted here. Serviced all my watches and then got involved in other things hence the absence. Now that i've done about 7 day/date three hand watch services on seikos that all seem to have only gotten better with age I decided it was time to step my game up to something a bit more complicated and a golden opportunity came my way. Got this beauty in one of those lucky "I was given my dead grandfather's old seikos thats just sitting in a drawer for 20 years." finds from a friend who needed some cash. He never knew the guy and he doesn't wear watches so I got the thing off him for 150 bucks. It's in fantastic shape, crystal needs a sanding and polish and there's a few dings on the case but the movement, case and bracelet look beautiful outside of that. Two service dates scratched into the caseback, one in 1974 and one that's illegible thanks to being scratched over with some strange code, it's like X3-AX-AG or something, I already forgot what it says but something like that. Not a speck of rust on it, it ticks and the alarm worked when i got it but has since stopped. There's no tension on the winder for the alarm winding anymore so I got a feeling the bell mainspring broke. I got a feeling this will be a straight forward cleaning and service job and i'll give her some new mainsprings. I know some folks here have spent some time in these things so tips as i go through this are as always appreciated. The tech sheet for these things isn't near as easy to follow as modern ones and I found a lubrication guide to it from the time but there's only two lubricants listed so I might have some questions here and there of the best modern thing to use on various parts. Only current questions I got are: 1. Anybody ever heard of a company called techswiss? There's a guy selling aftermarket mainsprings for the thing for pretty cheap, swiss made and made by this company. He's a reputable vendor i've used before I think. 2. If anybody offhand knows the size of an aftermarket mainspring i could get for the bell on cousins that might save me some cash. There are plenty of NOS ones floating around but I'm weary of buying stuff from Thailand and the Philippines, especially since the only pics i see of them don't appear to be in any seiko packaging despite saying NOS in the description. From what i've gathered there's good fits for the alarm mainspring aftermarket/generic but not for the main-mainspring.1 point

-

OK, I have recently services four Accutron 218s and disassembled another (my first) which is now a parts watch...lol. Feeling really good about my results and my methodology. Accutron recommends OL-207 for all but jewel settings. OK, if these watches I have serviced were lubricated in this way...I am not a fan! It appears to dry and then flakes everywhere. When confined (e.g., center wheel) it seems to gum up and freeze. I determined not to use it--NO. I am using Molykote for those lube points instead. Shields up--prepared for incoming!1 point

-

Fair comment I just don't want anyone to get into trouble.1 point

-

I haven't published these magazines on WRT but on my site, so in that sense, Mark has nothing to do with it. In my OP I said I would be happy to remove the files but that was a typo. What I meant was I would be happy to stop the sharing via the published link and if @Mark or a moderator want to remove this thread I wouldn't mind, and it would be the right of WRT, of course! I'm an IT teacher (ASP .NET Core MVC) and I always tell my students that any page that isn't authorized (requires a login) is up for grabs, so make sure to properly protect anything sensitive. AWCI has not, and I consider it their responsibility.1 point

-

I suppose if you like the other PDF may be of like this one. it's not a complete PDF it only has 214 and 218 stuff. Bulova had parts kits a box with a large card that when in the lid and all the envelopes corresponding to the parts and I think they would add empty envelopes. So if you were servicing these at one time it would be smart to have these although I'm pretty sure they were expensive. So somebody kindly scanned them into a nice PDF I had scanned a couple of the cards but this is much nicer it's all in one place. So then were missing all the other watches but typically the majority of the tuning fork of Bulova would be 214 and 218 and the others while popular not as much and I don't think every single other one had a parts kit that was probably at 230 kit and a 221 kit don't think there was a 219 kit may be. Bulova Accutron Parts.pdf1 point

-

Don’t bet on it, I’m one of the folks who needs the knowledge before I jump in to get the experience, then I am in my happy place. I have done some minor repairs and such but not a full service or revision yet. It will come and for me and the way I learn and approach things it usually works out. Tom1 point

-

1 point

-

Would this be a good start: https://www.ebay.co.uk/itm/225879500437?hash=item349777a695:g:gIwAAOSwJRNlWzfZ I was looking for some FHF96 models as proposed by Klassiker.1 point

-

Its a swiss bal. shock spring. Stabil, it should operate like a lyre spring. If you can post a clearer closer photo.1 point

-

it's one of my amusements when I started watch repair in school a very long time ago. I remember looking in the phone book yes we didn't test smart phones back then how sad. In a case a member looking in the phone book and they didn't seem to exist. I remember asking one of the material houses and they basically said if you don't know they exist without they don't really care about you you have to know the wholesale businesses even though some of them were retail they didn't care about you. Then as we move on to this newfangled electronic Internet age quite a few of the material houses are still operating without fully grasping that. Some of them like cousins switch to 100% Internet and rumor has it there are no physical people there at all at least trying to physically talk to one could be an issue. Others are partially online like a lot of the ones in the US 90% of what they have as far as watch material goes you will have to reach out by telephoning or emailing or some other communication. The used to be really big with fax machines I briefly worked in a material house learning the cut glass crystals and they used to get the phone ringing and then a fax would spit out of the machine. So yes unfortunately material houses like the hide and they were scattered across the planet so it is always conceivable that you may have physical material somewhere around you that conceivably might do business with you. Otherwise you have to look for them online and yes there hiding they like to hide.1 point

-

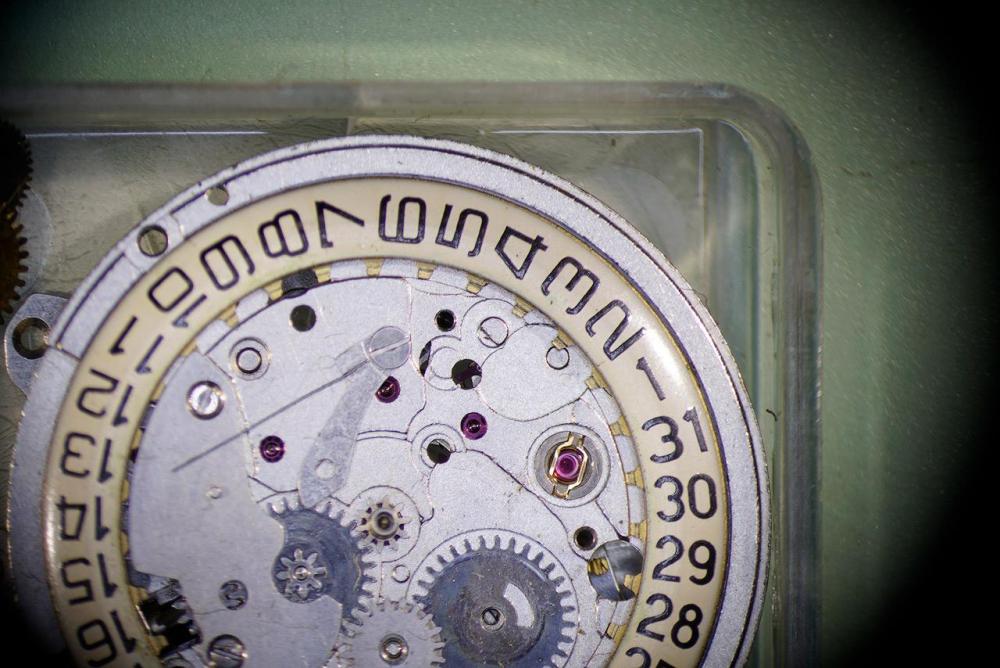

Russian vintage if you mean from the 60's or 70's leave them alone they are not well made, can be fiddle getting the wheels between plates, threads on the screws are poor. Certainly not recommended by me. There calendar works are a nightmare with an abundance of very fine springs that will not sit in their designated spot and would sooner fly to the moon then stay in the movement.1 point

-

1 point

-

1 point

-

Hello there, When this summer my son Jules was born, I was looking for something to celebrate his birth. Quite coincidentally, YouTube suggested a watch video which I looked at and now I'm here I really fell in love with those small but big feats of engineering and would love to try some servicing/repair out as a hobby. I'm a big fan of stuff that requires full focus like chess or assembling and painting my Warhammer miniatures. Time to roll up my sleeves and see what this rabbit hole has to offer! See you on the forum, Louis1 point

-

Hi guys. I am a Norwegian, just turned 60 last December, situated in Thailand and have learning this trade for the last 3 years. Working mostly with Seiko but do other brands as well. Just wanted to say hallo :) Rune1 point

-

and everyone is looking at the new guy. I'm Jeff, I live in NV. I'm a former auto mechanic and retired Marine Engineer, I like machinery and working with my hands. My main hobby is working on my vehicles and motorcycles. I've been interested in watches for quit a while, I recently decided to look into working on them as a hobby. I watched a few videos and thought assembling a watch would let me try it out without buying all the tools. I have my parts, I have what tools I think I'll need, and now I need help, so I joined the forum.1 point

-

If you are looking at wristwatch then where you are https://speedtimerkollektion.com is worth a look. A lot of different watches and parts at not terrible prices with a good reputation too. Tom1 point

-

one of the problems and watch repair is newbies confusion over model numbers. Companies will purchase basic OEM models and they will case them up in their own watch and label them with a model number. Service manuals usually go back to whoever made the OEM movement. This is why it's always nice to give us a picture so we can see what you have and we might actually figure out who made the watch possibly a manual probably not though. One of the problems are not all watches have service manuals in fact only a fraction of all the watches ever made have service manuals. But we might get lucky for manual otherwise we could probably tell you how to put the wheels back in if we had a picture of what were dealing with1 point

-

That is what I always recommend start with pocket watches but not the fusse type they are so different. The next stage a gents watch with a basic movement, then gents with date, then day and date, you can progress up to a basic auto then the same with date and so on. Next ladies watches in the same way. When you have reached that you go to the high end movements. The last is chronograph/split timers. Reading through you should see how it works. With high end movements make sure you have the correct case opening tools. When all this has been achieved in being able to clean all these types of movements which includes replacing mainsprings, buttons and stems, you can start replacing balance staffs.1 point

-

The play looks acceptable to me. A design fault of this movement seems to be the rocker mechanism of the automatic works. The wheels are both riveted to the rocker plate, so the pivots can not be cleaned and lubed properly. Furthermore the teeth of the wheels are prone to wear. That’s most likely the reason why JLC changed the design of this movement from bidirectional to unidirectional winding. Here is the unidirectional redesign:1 point

-

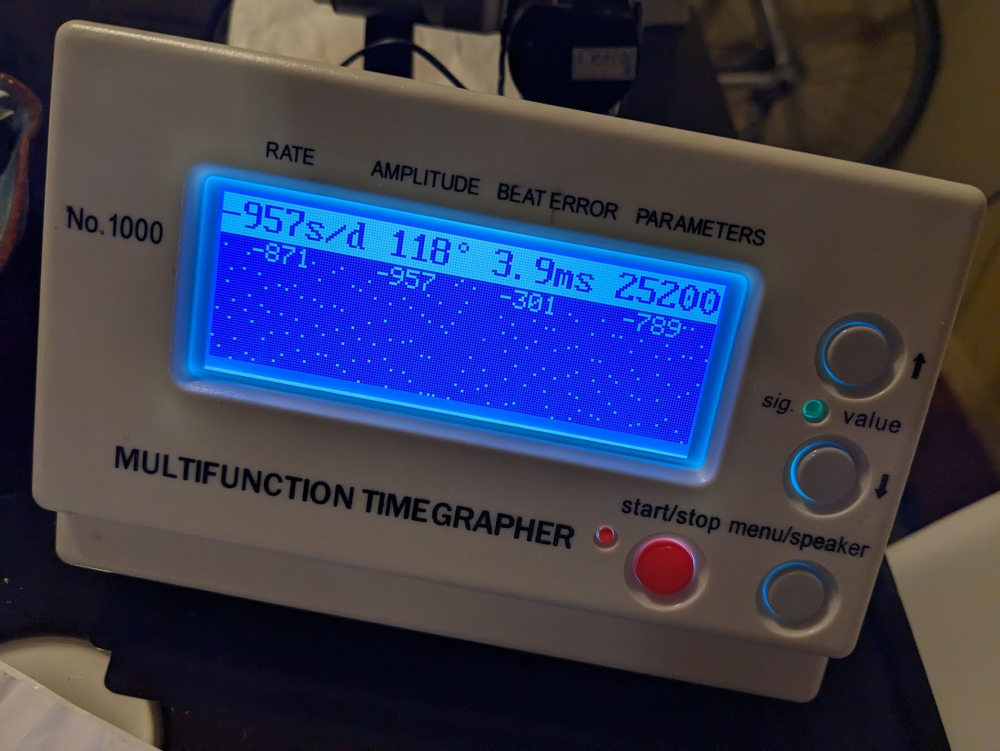

Lovegrapher shows smooth run, perhaps bus load of kids.1 point

-

I stopped working on that movement. Instead I started working on a Seiko 6309a and thankfully that movement is running. The tip of the escape wheel was already broken in the Ricoh movement. So, it was dangling around and when it engaged it sat around the center wheel thus stopping the mainspring barrel...1 point

-

1 point

-

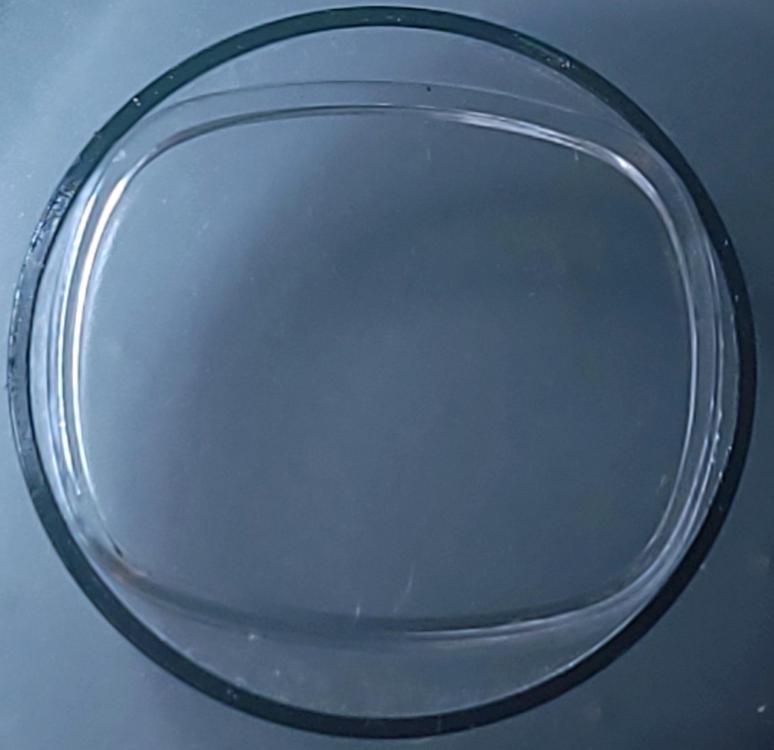

Well, I got the original gaskets, and I can't get the crystal gasket to fit properly. There's a little ridge around the crystal, but it's not deep enough to hold the o-ring in place, which seems to need a little stretching to fit properly. I'm dying to wear this guy, so I put the flat gasket that came out back on, and it's a perfect fit. And after an embarrassing time assembling the crystal, gasket, and retaining ring in the wrong order, It's back together and running again. What a handsome watch! You know what...I think I got the caseback and crystal gaskets reversed. That would make so much more sense and I'm an idiot. Back soon.1 point

-

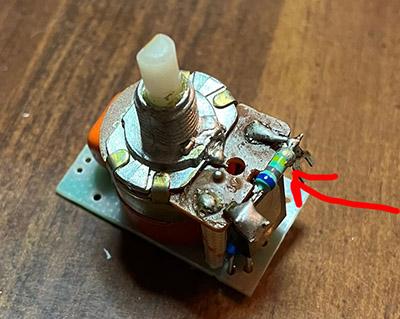

I've been working on just that problem. This solution works better than the current rheostat. The problem is this resistor in parallel with the potentiometer. It's 680k ohms. On 120vac power, it needs to be somewhere between 100k and 150k. I wound up going with 122k ohms. If you're in a 220/240vac country and don't like how your rheostat works, experiment with the resistor. You don't need to take the pot off the machine. But here are all the parts. I wound up replacing the frayed wires with silicone insulated wires. You can just pry out the dial on the timer by a little bit and wedge the wires between the dial and the case to hold it for soldering. Here I put 100k and 22k in series (122k total; series adds the values together). And the result? I marked my switch for OFF at 10:00. Just ON is at 12:00. You can see the motor is running with the rheostat at 3:00. Full ON is at 8:00. I will say, the motor doesn't change speed a lot for much of the arc. It comes on and runs slow, then jumps in speed in a few spots, but at the end of the arc, it really changes speed a lot up to the full speed. Sort of an exponential curve. It's easier to use, but the quality of the motor has its limitations. The real secret is putting the warranty sticker back on!1 point

-

1 point

-

Always good idea to take pictures as you disassemble, bucz datasheet might not be available for the caliber you work on. I did google for image of 65WLGSS04 to no avail, is this the caliber? in case your not sure, best to find a picture of your movement on internet and give us the link. Image of the actual piece is not neccessary for calib identification. Rgds1 point

-

1 point

-

Same here. I'm also a bit of an electronics nerd, so I very much enjoyed an excuse to buy a new micro soldering setup to replace the capacitors and resistors that seem to be common points of failure. I'm gearing up to do my first 218 replacement this weekend.1 point

-

@natanaelfh i have similar ideas about doing things with movements. I am looking at the idea of making custom bridges first then maybe rotors and decorating them. There are quite a few quality Swiss brands that seem to do this and call them their own. another interesting avenue to look at which would go a lot further is the openmovement initiative, this is mainly a group of Swiss independent watchmakers designing a movement that you can buy parts for or make yourself with no royalties, licenses etc. https://openmovement.org Tom1 point

-

I will second this. I also use 9504 in my Accutrons (and just bought 9020 for the pivots). I don't have nearly as much experience as @JohnR725, but I've serviced a few so far with excellent results.1 point

-

1 point

-

Minute recording wheel Venus 150. One NOS on eBay: https://www.ebay.de/itm/225163116133?hash=item346cc47e65:g:oAcAAOSwfrljIbEt&amdata=enc%3AAQAIAAAA8BbDkNJE4lOk28DTZK2An92pCJU26es9hbA0ytT4b7aWpA6u%2BYnLP0xlA3QN0rxKMbDjs33lGBVUouYM%2Fl3KX3SwPFS%2FTeOwWEw7lnSiYXS5jyntNuPYNM8syZrc560tewai%2B83qIo3yzqShCwqr7P0C0gDf5MkuP3FOfJoJb9HGUCY%2FVTL6DZ%2BBQOheC5BVEnllgr8%2B4%2BEWIkJdIvPgDt54289NAOlqM1EcDl46heJLF9yElTIeEw99TMtVTEQOOPwnEugglkCVCqdOCL0Rb0Z0nzciZvfbOwA6jlp5bCI4o0p3WDHedGbxZHrL9WlEPQ%3D%3D|tkp%3ABFBMksDwrZ5j I once wrote a "reverse pulling" technique. No guarantees, but another option in your toolkit; https://www.watchuseek.com/threads/reducing-the-risk-when-pulling-poljot-3133-chronograph-hands-my-best-so-far.5139739/?post_id=51140455&nested_view=1#post-51140455 Click the "see more".1 point

-

You will need a copy of George Daniels' Watchmaking. It shows all the steps to make all the parts, including jewels. And his designs are key-wound, so no need for a crown.1 point

-

Have done marks course the watch repair course all levels I'm now doing the chronograph course1 point

-

shields up and haven't you built your fallout shelter yet? Nothing like a good fallout shelter. I don't worry about the recommendation so I use 9504 modern and it works really well. Plus it does at that pesky really short shelf life to upset you in as a shelflife twice as long and then I'll just disregard that because it's synthetic it should last forever. then yes back in your center wheel discussion didn't I point out that you do not want to use the manufactures recommendation because their retirement plan was based on selling a lot center wheels when they get disintegrated due to poor lubrication choices.1 point

-

all very good lessons learned then maybe throw in look at a website that allows you to cross reference parts. From people who understand watch parts rather than as you've noticed on eBay if you seen one balance wheel you've seen them all and is it really important these little details obviously not. eBay sellers can be quite interesting in that often times that will sell stuff they might even specialize in certain items like I was looking for the oscilloscope once and I remember one seller was very clear that he knew nothing at all about our oscilloscope's yet that's all he ever sold which I was found quite interesting. But I suspect the reason for the claim was he would also claim they were unknown condition in that way if they were total rubbish he can't be blamed because he doesn't know what he selling. So a lot of people selling watches obviously are not watchmakers they just buy watches from wherever they do they sell them on eBay and let the buyer beware. Then it's always nice to use a site like this way can look up your parts and see what they cross reference to get a little more detail. http://cgi.julesborel.com/1 point

-

Did the old spring remove easily, normally they are left in place. incabloc springs can require the setting to be removed to fit them. Fitting the spring from the outside of the cut out.1 point

-

Questions are not always picked up first time murks, just keep posting till someone answers. But pictures are nearly always needed unless its just a general enquirly. One reason is your question might need someone advanced or watch specific to answer and they may not be available. As an example i never answer anything clock related as i have next to no knowledge in that area, also very rarely seiko questions or pocket watch questions. My knowledge lays mostly with vintage mechanical wristwatch era 30s -70s , Brand history, tool related , making tools, general all watch related issues and a little quartz knowledge. This is what interests me at this time, but sometimes you just need to be patient for the right person to answer.1 point

-

Hi. I use a water based ammoniated cleaner for clocks in the machine no problems. I think the most important part of the cleaning process is drying the parts well to avoid rust, warm air is the best and don’t skimp the process.1 point

-

Quick update, Last night I had a heavily corroded rotor with thick dark green scaling on it (looked like shiny bottle green glass), I tried to scratch some off with a finger nail, but it didn't budge so I dunked the whole rotor in regular store white vinegar for around 30 mins. When I looked after the 30 minutes I saw that the green corrosion was now more of a lighter matt jade green colour with white frosting (??) around it. Whilst still in the vinegar I used a bit of pegwood to poke at the corrosion (more out of curiosity than a serious attempt to clean) and to my surprise most of the corrosion crumbled away easily. A further 30 mins in the vinegar and the rotor was completely corrosion free. The exposed brass that had been lying under the corrosion was clean and shiny and the nickel (?) coating on the rest of the rotor was not damaged at all. Great result and my go-to solution from now on, much more sympathetic than using abrasive methods. Thanks to all that suggested this.1 point