Leaderboard

Popular Content

Showing content with the highest reputation on 01/15/24 in all areas

-

7 points

-

It gets you in the ballpark, and in some cases excellent timing. A funny thing, I worked for some years doing work as an "external" for a big old brand who made a lot of really tiny watches. They still wanted pretty tight deltas on these tiny 60-80 year old pieces... so sometimes many hours were spent chasing down the last seconds. On this tiny stuff, often, dynamic poise was a real pain, as it would seem to effectively reverse. It could be hard to detect since already seemingly micro adjustments could throw things the opposite way, but on some pieces it was simply reversed. I've spoken about it with some serious timing experts, who've also seen it, but no explanation can be found. Bottom line was the hairspring collet is disproportionately large, throwing the center of the spring further out, pivots a disproportionately large (even at a whopping 0.06mm), etc. I did a staff for a colleague for a LeCoultre 104 he was working on. This is rectangular movement is about 1mm bigger than the 101, the "smallest watch". It timed suuuuper bad. He begged me to poise it, so I put it on the static tool, got it very close to spot on on that. Dang thing had a 30s delta in 6 positions which is unheard of on these... it was a good bit of luck, but he still thinks I'm some sort of wizard, haha.6 points

-

Well, this is big amount of writing... Statical poising is for the balance wheel and the roller as a assembly. If balance well poised statically, the movement should have performance within 1min/day for the vertical positions, and if we need beter performance, dynamical poising should be done. Why statical poising does not give perfect results? Well, it is done without the hairspring. Adding the hairspring changes the things... The hairspring has a mass and it affects the poising, especially when not correctly centered. Centered means the imaginable center of the spring, which does't exist, to be in the middle of the hole of the collet. But, as we know, the hairspring is attached to the periphery of the collet, not in the middle. No mater, the spring can be centered as if the missing center of it would be in the center of the collet, but it is true only in static position. When the balance is rotated, the spring gets deformed (shrinked or enlarged), and together with this, the effective center of the spring moves, it shifts from the static position. Thus, the hairspring constantly brings error to the balance poising when balance rotates and thus affects the position errors. The dynamical poising helps to compensate this error from the hairspring by adding or removing material on the rim. The compensation is possible for certain amplitude, not for all amplitudes, but still it gives beter results than only static poising. The dynamical poising can be done by modifying the internal hairspring end too, by making changes to hairspring centering.5 points

-

Number one thing to keep in mind with dynamic poising, is it should be done on a fully serviced piece that is running perfectly. It's counterproductive to attempt it on something that's not 100%. That said, it's extremely useful. If I restaff a watch, I rarely even check it on the static poising tool. A danger of the static poising tool is you might detect a poise error, correct it, only to find that you now have positional errors related to- the poise. Since dynamic poise takes into account the hairspring and how it affects the balance, you can get something that's COSC level with dynamic, but the balance seems out of poise on the poising tool. The best writeup I've seen is at the amazing site Vintagewatchstraps (such a funny name). Great info.5 points

-

One should be careful not to confuse the "unvarnished truth" with simple opinion based on an individuals personal experience (which can be base on as little as just 1 watch), preferences, and prejudices. I like Russian watches (and I have serviced and repaired many) but they do have their faults. Movement wise the designs range from direct copies, licensed or otherwise, of Swiss movements, to some highly innovative in house designs. Build quality can be somewhat variable, if you get a good one then fine, but if you're up for a bit of fettling then even the less that fantastic can be brought to acceptable levels of performance. The quality of finish ranges from quite acceptable to what can only be described as "agricultural", so the Massey Ferguson references have some grounding. A lot of the 1970's and 1980's watches came in cases that had absolutely no water resistance, or even dust protection what so ever, so the movements often suffered from corrosion issues. The cases were generally chrome or gold plated base metal, and would wear through to the brass quite quickly. However the full stainless steel cases with a screw down back and a water proof crown were not too bad, and the Amphibia divers are pretty good. This is of course a completely pointless comparison, you're not going to get high end Swiss watch levels of performance or finish from any budget watch where ever it comes from, but so long as you keep in mind that that is what most Russian watches are (budget), you shouldn't be disappointed. I don't know about current prices but it was only a handful of years ago that Vostok Amphibias could be had brand new for as little as £75 including shipping, find me an AP at that price point... As @HectorLooi says and it's a nice clean example, looks like a late '70's or early '80's vintage with a fairly well finished movement. The case is chrome plated brass rather than stainless steel but the chrome is in good order.The case back gasket appears to be missing but get that sorted and it should have reasonable water resistance. At the right price (I wouldn't pay more than £40) it should be a fun introduction to Russian watches, and of course provides you with the the opportunity to start to formulate your own "unvarnished truth" about them. It also opens up a whole world of customisation should you wish to personalise it. Well worth reading if you're interested in these... https://www.linkedin.com/pulse/vostok-watches-history-explained-muhammed-amjad https://www.hodinkee.com/articles/vostok-amphibia4 points

-

We have success! I was able to service the shock setting finally and the watch went from running at +100 s/day to only -9! The tolerances are significantly tighter than in incabloc springs and it was difficult to see even if the spring was unseated or not. I'm still curious about what this shock setting is called but for now I'm willing to just accept this small victory.4 points

-

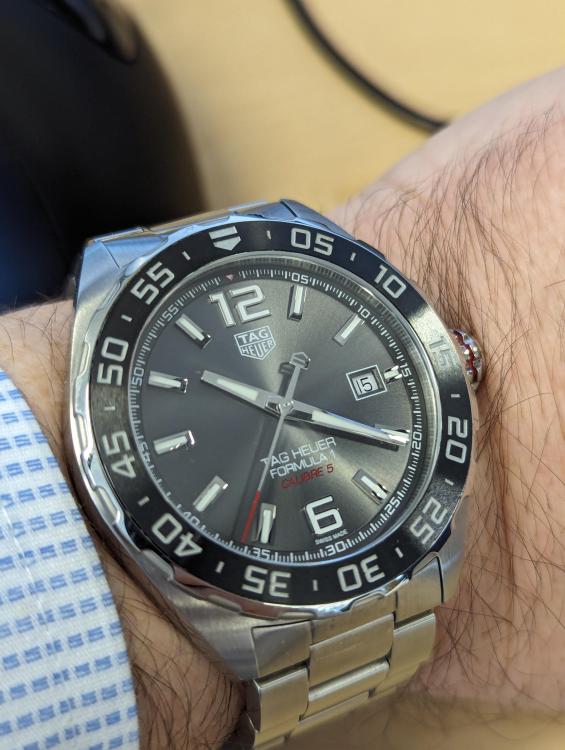

Before rushing to purchase a new movement? The word tag bothers me end that often times they modify the watch. Plus you're missing one other little piece of information you need anyway. Somewhere there is a height number that you need to make sure you get the right height in other words will account for the various thicknesses of dials etc. So oftentimes that's what tag will change that. This kind of thing comes up for a work where they have to sometimes swap components from one watch to another to get the right height components because you may not build actually purchase the right height movement. So just something to pay attention to.3 points

-

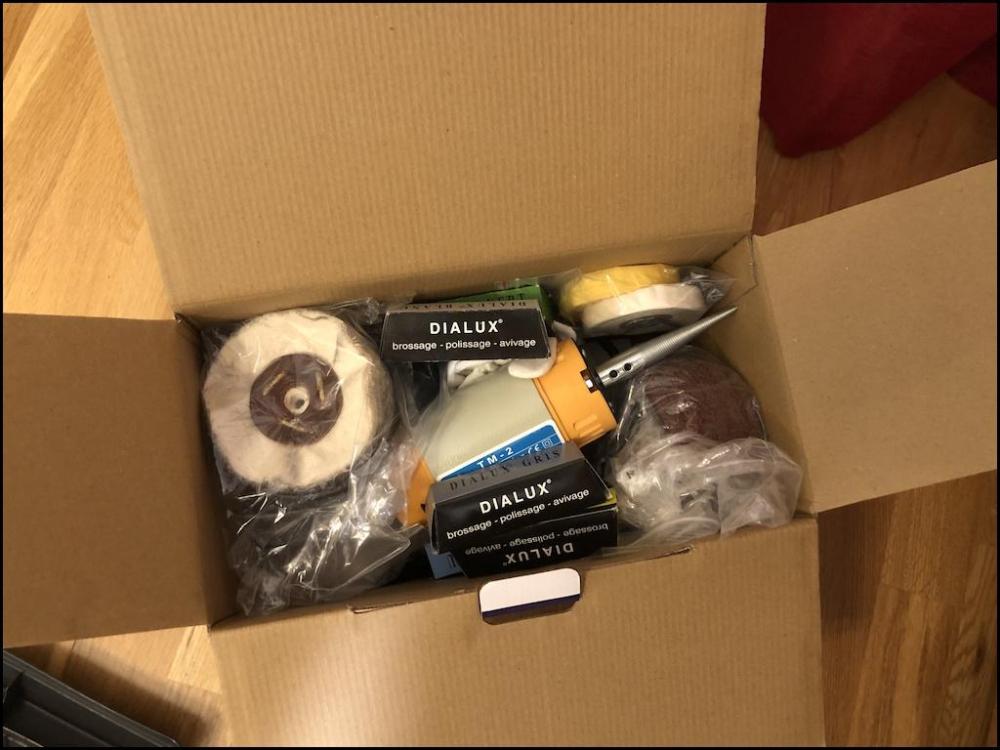

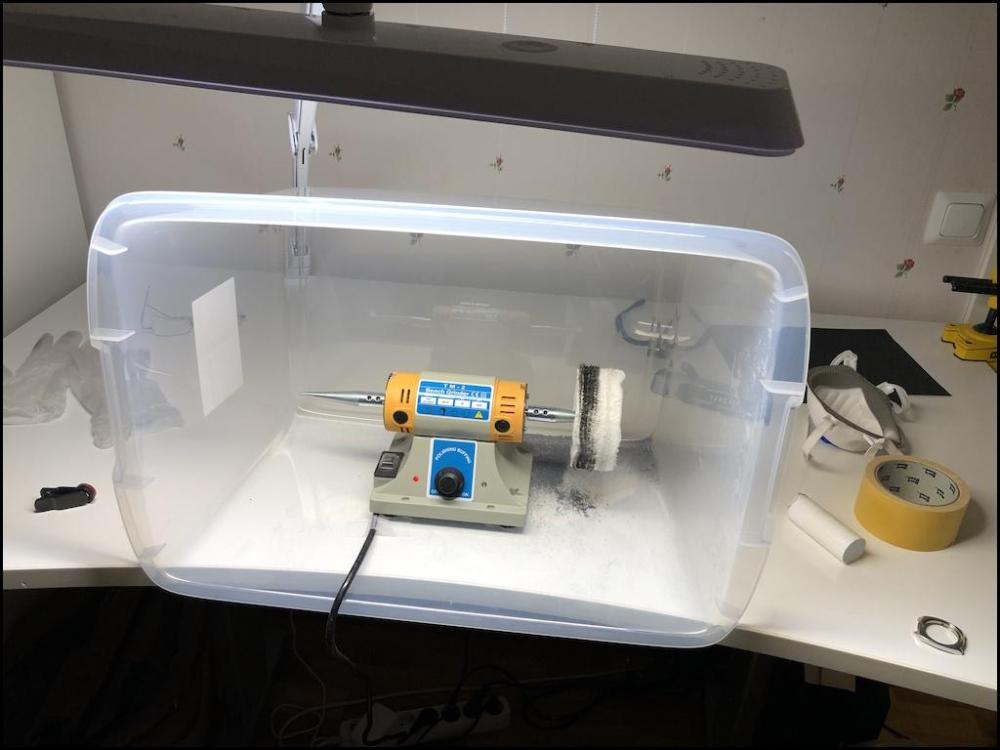

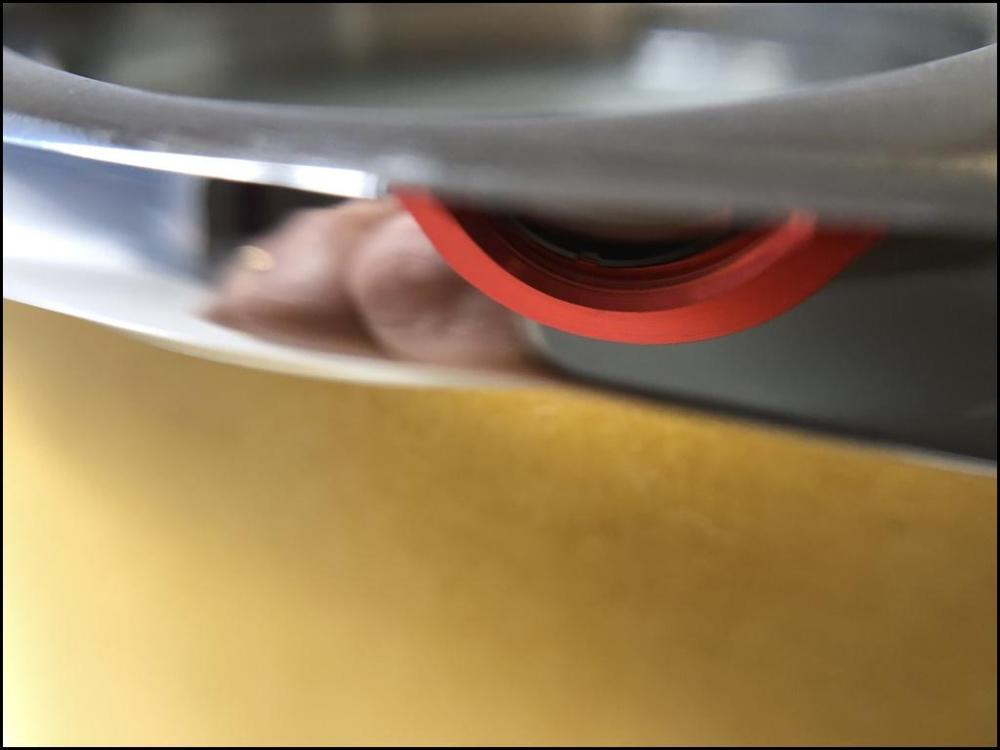

I have now received most of what I ordered from Cousins to start polishing. I'm still missing Kapton tape to mask off already high-polished sections, but it's been ordered and will probably arrive in a few days. As a first attempt, I only tried to polish the left side of the case which should be mirror-polished. I ordered three polishing wheels: One from the 2nd stage (4" x 2" Aurelia (Calico) 112 fold), one from the 3rd stage (4" x 2" Madapolam, 120 fold, UK), and one from the 4th stage (4" x 2" Felpato, 60 fold). I started with grey Dialux along with the wheel from the 2nd stage and got exactly the result advertised on Cousins' site, i.e. all superficial scratch marks were quickly buffed away. However, deeper pits cannot be counted on to disappear. I tried for a long time to polish off some small deep pits but it was hopeless. In the end, I had to get out my wet sandpapers and my mini sanding block, which meant a lot of work. There was so much work that I finally started cramping my fingers. Maybe orange Dialux along with a 1st stage wheel could work to remove some potholes, but I doubt it. Unfortunately, I don't think you can eliminate wet sandpaper from the process. I have ordered a sanding file and a square sandpaper holder from Cousins. Hopefully, that will ease the process. When I had finished sanding, I polished again with grey Dialux and the same 2nd stage wheel. In the next step, I switched to the 3rd stage wheel along with blue Dialux and got an even nicer finish but not perfect. Still, I think most people would be happy with this finish. Finally, I switched to the 4th stage wheel along with Polinoxx polishing compound and I think I got a more than acceptable result if not perfect. I don't think my result would be approved by Jaeger-LeCoultre but at least my wife thought it looked very nice, and that's always something! I have to say that I benefited a lot from Kalle Slaap's video "How to polish your vintage watches - Part 4 Practical Tips". Here are some pictures: Fortunately, the polisher is so small that it fits together with most of the accessories in the same box as it was delivered. Good for me as I don't have a workshop and have to pack the stuff away when I'm done. When I first unpacked the machine, I was sceptical that such a small machine would really work efficiently enough, but that concern was completely put to shame. I have to say it works amazingly well and seems very strong, quiet and efficient, so I'm very happy with my choice of machine. Many thanks for the tip @Waggy As you can see, it's a set inspired by Waggy's set (again, many thanks!) It would have been handy if my plastic box had been 15 centimetres wider, but I was impatient and didn't go to IKEA, but instead found this plastic box in a store (Jula) nearby for just £4, so it will do for now. I'm also very happy that I chose the wider two-inch wheels so I can work the way Kalle Slaap suggests in the video I linked. Here is a picture of the final result, as I said, it is only the left side of the housing that I polished. The rest remains. Another picture of the final result that better shows the mirror shine. If you look at the right side lug, I missed a particularly deep pit. However, it is now so small that I don't want to start sanding again. When you work with sandpaper, the initial rough scratches from the sandpaper hide many pits that you then don't discover until you get to the finer sandpaper and then you just have to start over. So it's worth noting where the pits are before you start so you have a chance to inspect these places extra carefully before you go ahead with the sanding. I'm only including this picture because I think it's funny to the extent that you can see part of the red macro lens. Many thanks to all of you for your input, your pictures and your tips! Incredibly valuable for me and hopefully for many others now and in the future.3 points

-

For the time when these were introduced, the technology was truly leading edge. The 218 movement seems solid...not difficult to service. But...and this is a BIG but, Accutron (really Bulova) fails at the non-tech stuff. While I like the two-piece back, the case quality is generally poor. The dials seem fine enough, but the hands are low quality compared to a nice swiss watch. I have one case where the crown interface appears to have been milled incorrectly. Not sure...still investigating.2 points

-

Hi @nevenbekriev Iam sure there are members who would appreciate your methods of how to produce a cylinder for a clock or watch as its not a common skill required these days unless by enthusiasts. thanks.1 point

-

OK, this is cheap movement and pritty small. No worth making cylinder for it. Making a cylinder is possible and even normal routine task, but when the movement is valuable. It is beter to start practicing it with cylinder for carriage clock, which are much bigger than this one. There are different ways for making cylinder described in books, i have my own way too. Will expain when needed.1 point

-

I understand that making the hairspring more symmetrical ( symmetrical being something that is impossible) by having the collet and stud pinning opposite each other will have some small improved effect on the poise of the hairspring as it breaths. Something that the overcoil overcomes.1 point

-

Not an expert by any means, the way I see it static poising will show you how well you have restaffed the wheel, not so much how it will work. Dynamic poising though for me is more about how to get the best out of the watch once it’s working to its best mechanical level. Tom1 point

-

In 1991 I bought a brand new Russian wrist alarm watch „Corsar“ for just 50DM (€25) from a department store in Stuttgart. My initial excitement vanished immediately when I found, that the alarm spring could not be wound correctly. After opening the watch I found a ratchetwheel with the squared hole stamped about 0,5mm off center. So the ratchet wheel lost engagement with the crown wheel every turn. Hard to be fixed… Unfortunately this was the one and only Russian alarm watch in the store. The movement was a SU 2612,1 which is a copy of the AS 1930.1 point

-

Yes, there are different versions. One is 200w and another 500w. The one in my link is the 500w version.1 point

-

I can only report I didn't find the results to be unsatisfactory but YMMV. One particular Breitling was caked with that gray mix of old oil and old debris, so I did this: during disassembly screws got a dunk in ronsonol with the blower, peg the holes, then screws back on the plate. Time consuming but not more time and less risk than photos and cataloging all the screws, at least for me. I also use a Pearl machine with L&R for parts, not ultrasonic. I didn't see unusual hygiene issues under the microscope during pre/ assembly but what do I know? Do watch screws in their threaded plate holes make a waterprooof seal? If so I need to rethink my plumbing strategy...1 point

-

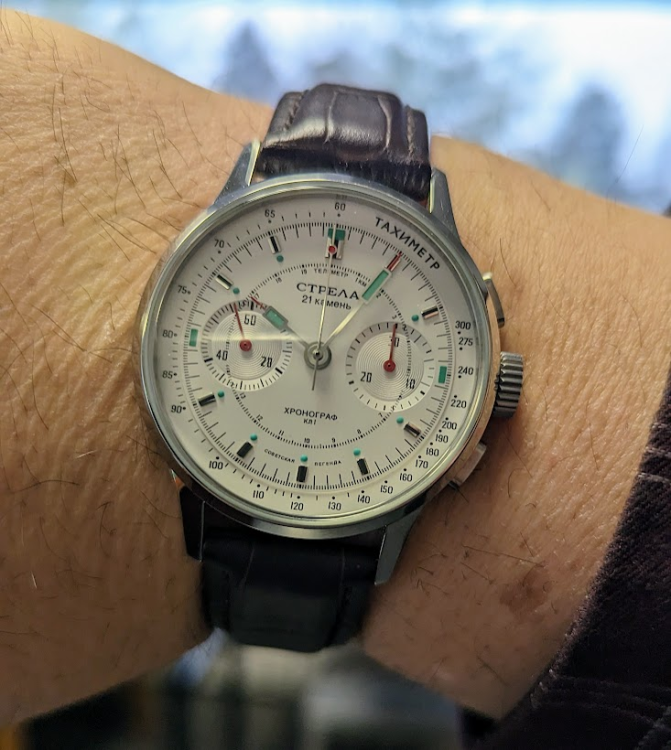

I think of Vostok as the Timex of Russian watches. They take a licking ... you know the rest. They also produce some incredibly "budget minded" (aka cheap) watches, as well as some very decent timepieces with a long interesting horological history. I have three Russian watches in my collection. A Vostok "scuba dude" just because it's cheap, quirky and fun. It's the VW Beetle of watches. A made-for-the-western-market Amfibia (spelled with a f instead of ph) that's a typical Vostok calibre with a bit more finish on the case and dial. And a reissue of the Strela chronograph, the Russian version of the Omega moon watch. Watches are like wine -- you can get good wine cheaply and some expensive bottles are pure vinegar. Don't let anyone tell you you're wrong for liking bulk wine in a box. And, that doesn't mean you can't appreciate a good vintage bottle from a well known cellar. My opinion + $5 will get you a small regular coffee at Starbucks if you have a coupon.1 point

-

It's a AKA3 MO CCCP. Initially only for sale for the military or Westerners with US$. Seems a nice and clean watch. There is nothing wrong with these watches, provided they are not already tinkered to death. But this one seems in good & nice condition. I've always said, and will say it again; especially the Vostok Amphibia is the best value for money (or for the US: "the most bang for the buck") you can buy on this planet. Nothing comes even remotely close. Go for it Please note, this is the Amphibia 200mtr diver, not a Komandirskie. The Swiss could learn a thing or two from the Soviets / Russians.1 point

-

1 point

-

Yes I would agree that's why have two of them. Although my reason was actually that one of these surplus electronics stores a very long time ago when actually existed in physical forms locally. His liquidating one of the watch companies with the LCD modules and I got the press for practically nothing but nothing to push just the press. The other thing they were selling it was interesting day I managed to pick up the waterproof case opener similar type constructions is probably the same manufacture. The store was just swamped with people because the electronics people didn't grasp the value of the watch repair tools. Then it won't be for several years until I met a nawcc regional meeting where I see one for $20 but none of the accessories how sad? So I walk away but I walked back and ask and all of them were in the box underneath. Always important to ask if you don't see something is maybe it's lurking. In the old days where the regional meetings people and have stuff and eBay hasn't influenced the prices yet. The same seller had the plastic box with the meter and all of the tuning fork accessories for Bulova I'll skip over the price of that it was really good at. It's amazing all the wonderful tools that I purchased at the regional meeting over the years at least until eBay came. But the asses always nice to have more than one just in case something undesirable happens. Which probably never will a few have two of them will only happen if you have one of them.1 point

-

If anyone is interested, i found the first buffer in the original post for $169. https://www.walmart.com/ip/597117275 At least if you redide in the USA.1 point

-

It unscrews from the front and seeing circlips and not pins it is not that old. it looks like the barrels can be removed with out taking the whole movement apart. I would like to see the movement out of its case showing front and back plates and between the plates before I say anymore.1 point

-

I repaired a 955.112 awhile back. The pcb was dead but the mechanical movement seemed ok, so I tried a Chinese replacement pcb from AliExpress. Cost me around $5.1 point

-

I'm afraid I can't be of help to your direct questions, but I thought I'd mentioned that this calibre is the only quartz I've ever serviced and made a service walkthrough when I did.1 point

-

1 point

-

@Neverenoughwatches - I FOUND IT!!! - Sorry if I'm late to this one, but I finally located the business site which has complete cylinders in different sizes, from common pocket watch sizes on up. I have worked on cylinder escapements, often enough that I bought the special Bergeon punches and staking anvil. But I hadn't worked on one in a few months and I thought I'd bookmarked the site. Well, NOW I have. This is where: https://watchparts24.com/Cylinder-wrist-watch-21560 That said, if you have a lathe and are handy with it, you can turn a tampon. Funny story: first time I tried turning one, I got most of the way done, then accidentally jabbed myself with the graver... and I got blood on my tampon. Guys don't usually have that problem, I hear.1 point

-

I love my Russian watches. The Vostok Amphibia and Komandirskie... maybe not so much. They are rough but robust. Can take a lot of abuse, unlike my Swiss Army watch which uses a quartz movement and just dies sitting on the shelf. It's like an AK47 compared to a M16.1 point

-

Sometimes, I worry that I will not get the unvarnished truth on this forum.1 point

-

The case isn't English silver no English hallmark. The movement is probably French or Swiss. It is a cylinder movement, hands are in the style called Spade and the decorative dial is typical of French/Swiss the same goes for the case decoration. Date around 1880's to 1890's1 point

-

If I get one like that, I break it up into subsystems, and clean in multiple batches. I.e., for a chronograph, the actuating levers all get cleaned with their associated screws, then the chrono bridges/wheels and their screws, etc. As the movement comes apart, I put everything into little aluminum canisters with glass lids (the lids keep desk bumps from being catastrophic, the glass is occasionally nice to have as a known flat and clean surface), and clean as many or few canisters at a time as I feel my feeble brain can handle. A chronograph with lots of different screws would likely take up a couple of trays, and with 3X 5 minute US sessions, take quite a while.1 point

-

One way of cleaning the screws is by hand. While the movement is being cleaned in the watch cleaning machine. If you have made a note of what goes where, clean the screws in some Ronsonol lighter fluid, you need a small pot with a screw lid, fiberglass scratch brush a pair of tweezers some tissue paper and your bench blower. Its time consuming but you can't go wrong, you can even take a photo or two to help you, You will find after repairing a few complicated movements you will soon learn about the screws. My master told me to learn it this way but without a camera. Hope it helps.1 point

-

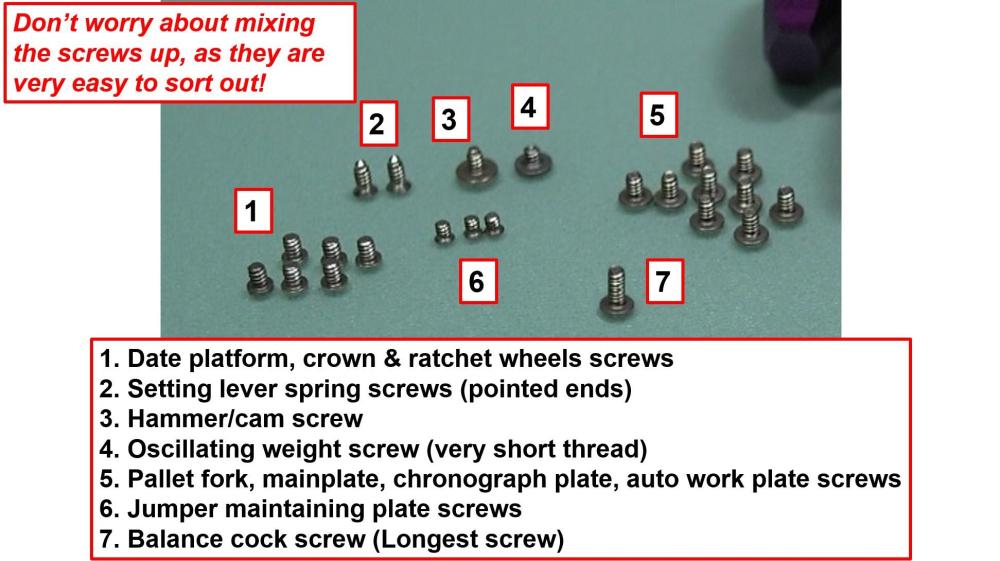

If I'm unfamiliar with a particular movement I will do as others have suggested and take photos of those screws with their respective parts. I always clean screws through the cleaning machine, as this gives the screws and the holes in the bridges and main-plate a really good clean as well. It also makes sure any brass fillings and crud are removed in the process. You can save some time sorting the screws out by putting all the keyless work smaller parts in a mini basket together with the screws. All the bridge screws go together in another mini basket and maybe the pallet bridge screws in with them, as they will be very different to bridge screws. barrel bridge furniture and screws are all kept together (crown, ratchet and click screws) They are all different lengths. The crown screw will always be shorter than the ratchet screw, as well as being a left-hand thread, and generally, but not always the click will be the smallest. I use four or five mini baskets and keep the screws in one of the baskets with the respective parts where the screws are from, so it isn't a crap shoot when removing them. Even working on a Rolex automatic this method works very well. Working on a 7750 is even easier, as the screws are so different and most are the same type as I have shown in this slide from one of my lessons. With the 7750 all the screws can go in just one basket. Once this discipline has been done several times, it becomes quite natural to know what goes where. You may get the odd one out of place, but not often. Cleaning the screws and the bridges and main-plate and bridges is important for the reason I have already stated, although some may not think so. Watchmaking teaching discipline, rather than the easier softer option, but that only comes with practice, knowledge, and then wisdom from the previous two.1 point

-

For a calibre I haven't worked on before I take macro images of the screws together with the parts they are holding. Once out of the cleaning machine, I sort them by appearance into the parts tray as illustrated in the image. For a normal automatic or manually wound movement with only a date complication, there are only about 4 or 5 different types of screws, so no big deal, but perhaps not very practical for a chronograph!? Not cleaning and inspecting the screws I would personally consider to be a service error.1 point

-

Russian vintage if you mean from the 60's or 70's leave them alone they are not well made, can be fiddle getting the wheels between plates, threads on the screws are poor. Certainly not recommended by me. There calendar works are a nightmare with an abundance of very fine springs that will not sit in their designated spot and would sooner fly to the moon then stay in the movement.1 point

-

1 point

-

That is what I always recommend start with pocket watches but not the fusse type they are so different. The next stage a gents watch with a basic movement, then gents with date, then day and date, you can progress up to a basic auto then the same with date and so on. Next ladies watches in the same way. When you have reached that you go to the high end movements. The last is chronograph/split timers. Reading through you should see how it works. With high end movements make sure you have the correct case opening tools. When all this has been achieved in being able to clean all these types of movements which includes replacing mainsprings, buttons and stems, you can start replacing balance staffs.1 point

-

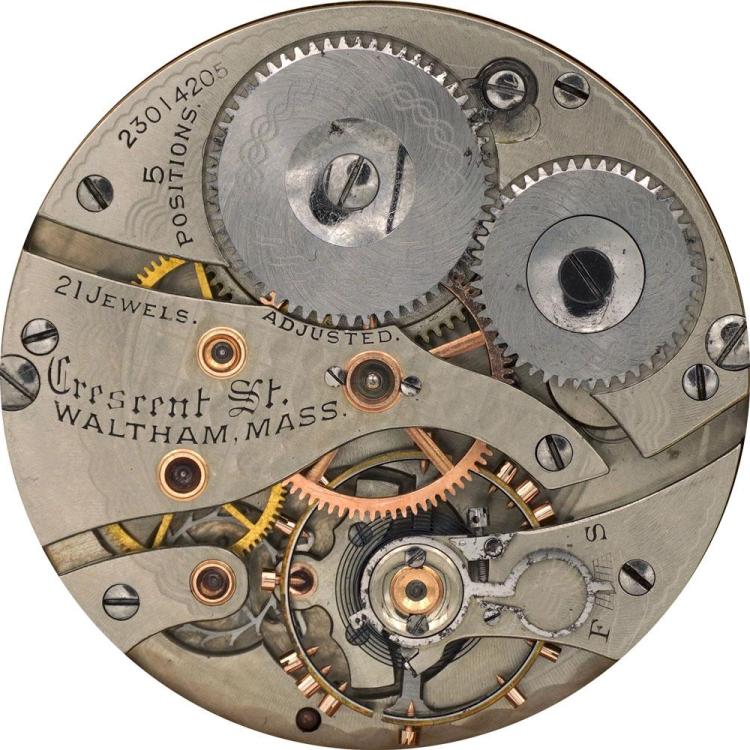

I started with pocket watches as the parts are so much bigger. You could just buy one cheap movement and practice taking it apart, putting it back together to get used to handling small parts. It doesn't matter if you trash it. With wrist watches, If you want a chance of it running well, I always suggest don't buy a manual wind with less than 15 jewels. There's plenty of suitable cheap watches on ebay <£30, you could even buy a job lot to practice on. Try to find what the movement is before buying, then you can check the availability of parts should you need them. There's hundreds of makers, but if you go for the bigger manufacturers like ETA, A Schild, FHF etc, parts are usually easy to find (and cheap).1 point

-

parts listing at the link below. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=STA_412 in the absence of a balance complete a roller table except is listed as our stock but at least was available http://cgi.julesborel.com/cgi-bin/matcgi2?ref=\^}DZD\g1 point

-

1 point

-

1973 Bulova Sea King HH. Before and after pictures. The bracelet was not original but a Hong Kong special with lots of wear and DNA. Could use a new crystal but the old one cleaned up okay and I plan to work on it more. Added a blue leather rally band. The dial is almost perfect as are the hands except for a loss of some lume. This would be a good case and crystal to practice polishing on as well. The case was difficult to open but the gasket did it job and the movement is clean. definately needs a service with the low amplitude.1 point

-

1 point

-

Yes just found it documented elsewhere. One the two registered rebberg calibres known as Aegler rebbergs. I'm pretty sure i have the other calibre stashed somewhere train bridge looks rough as does the balance pivot bearing.1 point

-

Rebberg did indeed make movements for early Rolex watches. As to being repairable, probably but it is in really bad condition. Missing jewels, probably broken balance staff etc.1 point

-

In case somebody stumbles on this old thread, I've managed to 3D-print a replacement. Here's the video of it in action:1 point

-

1 point

-

1 point