Leaderboard

Popular Content

Showing content with the highest reputation on 01/17/24 in all areas

-

5 points

-

4 points

-

Purchased this watch as needing case, strap and clasp refinish (very scratched) plus movement not running. I wish I had taken pictures when I first opened the caseback re: the movement was literally swimming in oil. I had to clear a space on my bench to clean it since every part i pulled out of the movement left a pool of oil.....I just don't understand how even a casual hobbyist would think submegining a movement in oil could work? Even the hairpspring was soaked....luckily while the dial and hands were also soaked in oil, they cleaned up fine without loss of detail. Anyhow following a full cleaning (hand cleaning first in naptha then ultrasonic), reassembly and basic timing went smoothly. Case, caseback and bracelet where refinished using my new (inexpensive) buffing set up. Am pleased with how I was able to get decent graining on the braclet, case top and caseback while maintaining polished finish on the case sides.3 points

-

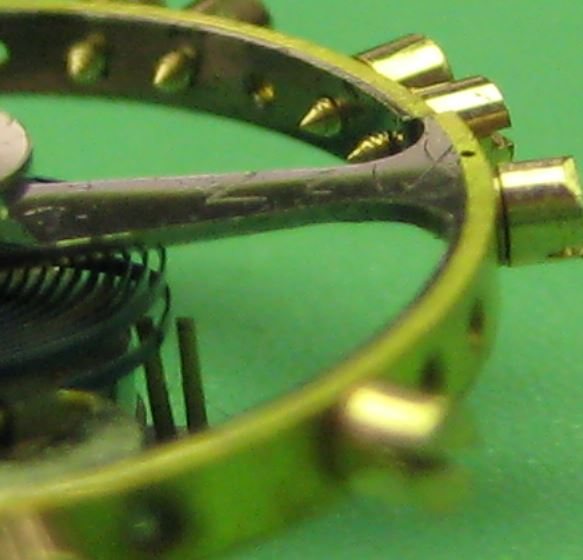

Maybe a better question would be how many watch people we will expand that to anybody who touches the inside of the watch actually poise is the balance wheel correctly? We regularly see Rolex watches that have poising issues because people were playing with the timing screws and never bothered to look at the watch in any other position other than flat. In case you think perhaps I was joking about one position timekeeping we used to send watches out to shop when we were shortstaffed and then we gave up on the individual. One day when the person came in I cautiously asked well basically I wanted to know if he actually knew what a timing machine was. He reassured me that he had one of the Chinese machines and I also asked at the same time more or less of we noticed oil on the pallet fork pivots. Apparently somebody told him that something he should do I didn't bother to inquire if he knew that his timing machine microphone rotated because we knew that he never did. One position timekeeping only who cares if it's a Rolex of course he was terminated because my boss gets obsessed with the nifty automatic microphone and six position timekeeping at all watches should keep perfect time in six positions etc. etc. Although I get annoyed because I think he forgets that pocket watches for instance run over 24 hours and maybe they'd look spectacular on the timing machine but are they going to look spectacular tomorrow? Oh and I was thinking about you today so I got you some images. This is an incoming watch I doubt it was done by a watch enthusiast I suspect it was done by somebody claiming that they repair watches. I looked at it I did take the balance out and fortunately there's a whole bunch of other things in front of it to do I seem to be backlogged probably for the next century right now When the watch came in I noticed on the paperwork there was a reference to something wrong with the balance arms. So we have a more or less straight down image where maybe there's something wrong with the balance arms I wonder if this watch is poised for instance? I was really curious about what it would look on the timing machine but it's running so poorly at least right now that I can't even tell. Then we can see in a close-up it does seem to be a little bit of a discrepancy with the lining up of the arm with the rest of the balance wheel The other side was even more interesting yes you thought this was interesting not compared to the other side we get a bonus amusement. So as we could see carrying on the theme the arms do not appear to be where there supposed to be and they don't even appear to be symmetrical. Plus the bonus regulator pins and know the hairspring doesn't even appear to be touching any of them right now I doubt this was done by the owner of the watch so was done by exactly? That's why was curious if it would run well enough as to whether it keep time at least dial down the consequences of one position timekeeping. Plus the consequences of who repairs the watch and they're not always hobbyists that are the problem unfortunately just people that don't really have the proper skill sets and knowledge even if they claim that's what they do for a living etc. etc. Back to your original question of how many enthusiast poise their balance wheel? You find a lot of the hobbyist don't like to change balance staffs that limits how many people were probably play with their balance wheel. Another question to ask is just how many hobbyist or enthusiasts actually exist in the world versus the quality of watches. Versus the quantity of so-called professional watchmaker's. I know I've seen it somewhere it might've even roughly explained why but the problem of accumulation of too much documentation and trying to remember all of the obscure things becomes a problem. First off English is such a peculiar language. I'm guessing it came about before the people who generated standards and specifications for things? Kind of joking about that out of the way because those people who perceive there in a country that speaks English should go to another country that also perceives it speaks English and then discover that they're not exactly on the same page of things. For those people who never left their country or never watched television from another country or it sometimes comes as quite a surprise of English isn't always universal and doesn't always have the exact same meaning for everything. Then for instance the shop I work in the owner's wife came from Iran although she likes to tell people occasionally she is Persian because I guess it sounds better. So yes we run into that quiet up yet of things that we say that lead to confusion. Then unfortunately I can't remember she was doing a conference meeting with a group of people she works with and somebody said something and she responded to it and everybody was bewildered for exactly what you're saying it was something that everyone in the group knew exactly what the person said but somebody that didn't grasp that particular version of English would be very bewildered by what was said and know I can't really remember what it was. So yes languages can become quite interesting and in the case of horology the definition of things have changed with time. To basically for horology location and time can change the meaning of quite a few things.3 points

-

I wouldn't argue with that and i bought some old winders very quickly, i really shouldn't have bothered, i think I've used the set of 9 winders maybe half a dozen times now. I learnt to hand wind and also made a little jig to help me do it better and safer. I have more winders now and use them for ease but occasionally they dont fit so i get a little refresher course in hand winding. After a good amount of practice I dont bend, kink or twist them inappropriately when i do one. What may happen is the spring will take on a helix shape, but that can happen with the removal of it as well. There is the possibility that the spring will rub on the barrel inside if its has a helix form and I'm sure it happens, thing is you dont know if it is or not until you remove it again and find evidence of rubbing. So that kind of leaves me on the fence with the whole handwinding thing. But if its already formed a helix shape on removal, coiling it up in a winder doesnt remove the helix, ive tried it and it doesn't . I have managed to remove some by pulling it through itself but only from the inner coils or on an old spiral only spring. Flat diamond steel plates are ideal and can be cheap. In fact i just had a 3000 4" diamond disk delivered it was a fiver from china, intended to put on top of a grinding wheel to go in a bench grinder to sharpen gravers. I was expecting a poor quality generic grade of grit that could have been anything from 400 to 2000. It was i guess bang on 3000 as its so much finer that a well graded 2000 plate i have. Disks like these are perfect for making micro diamond files from and as we discuss here an 1" x 3" sharpening plate for tweezers and drivers, the sharpening plate doesn't need to be a big 8x3 . You can even make up your own sharpening stone from a lollypop stick or metal stick and emery cloths. They dont last forever but just an example of what its possible to manage with.2 points

-

2 points

-

The dial on the Hamilton 974 I just serviced has markings in red at the outside edge of the dial. I guess there were many variations and the other may be a railroad style dial. Interesting that my dial also has the name of the shop "The Watch Shop" instead of Hamilton. I love the gold details in the movement.2 points

-

When I was in school (in the U.S.) I worked evenings for a "trade shop", this is a workshop that does work for other watchmakers or jewelry stores. It was a one-man shop, plus me. His prices were like 21 bucks for a mens manual wind, 23 for an automatic, and I think a dollar more if there was date. Ladies watches were like 18 dollars. And I got half of that . But I could do 3-4 watches in an evening, 3 nights a week, say 10pcs/week, that was like 400 bucks extra a month which really made a difference 25 years ago! Sounds like the work was similar to John's outside guy. His method was: dial and hands off, date ring off. Disassemble far enough to get the barrel out, open barrel (spring stayed in). In the cleaning machine it goes. After, balance comes out with its cock. Into cleaning machine #2, which had a final bath that was supposed to lubricate the whole watch. Back together it goes, hit the accessible jewels with a little oil just to be sure (haha), on the Vibrograf dial down long enough to get a fairly straight line, dial and hands on, back in the case. We would clean the case. I deviated from his method though. I would disassemble the balance jewels, whether shock (easy) or non-shock (entails removing balance from cock, two tiny screws, usually one tiny screw to get the cap jewel off the plate). I would also remove the cannon pinion, and the fork. I did leave the spring in the barrel, but would at least oil it. In several cases I was able to detect blockages in the train post-cleaning since I would check the train freedom as the fork was out. And I knew at least the balance jewels were clean and oiled correctly. I don't think I had any "comebacks", maybe one? Which I pointed out to him when he finally noticed how far I was digging into the pieces- he was furious! I told him I would continue that way as it saved me time in the end- he said ok, but any lost parts would come out of my pay. Hahaha. I do really appreciate the time I spent there though, as I learned a lot about a lot of different calibers in a short time. And learned what not to do too! He also figured out I was good at replacing staffs, so I got all of those, which was an extra 10 bucks, whoohoo! The funniest thing of all - he insisted that we wire-brush the backside of every dial. No exceptions.2 points

-

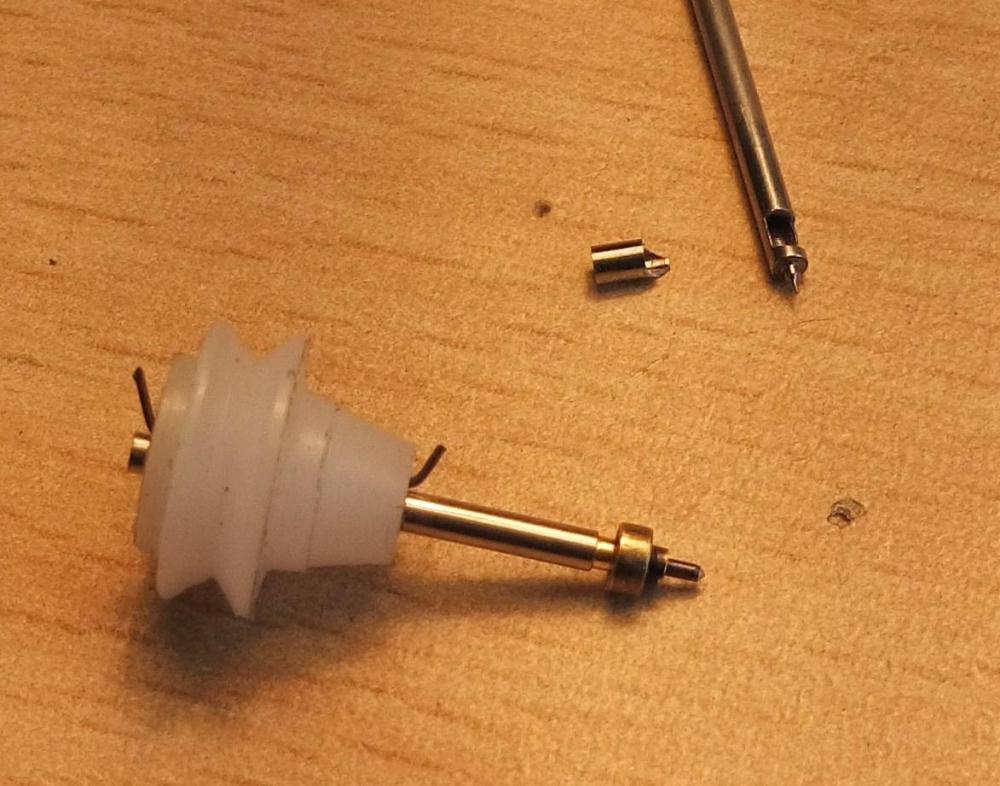

OK, The safety roller is separate, and it came off really, really easily. I don't think I pushed the staff more than .2 mm before the safety roller came loose. I machined off the swaged staff material and then pushed out the staff. Looks like I also machined a bit of brass from the balance wheel too dang it. Not easy to do perfect. Still learning big time, but enjoying it very much. Bill2 points

-

2 points

-

These mesh baskets are really good. Much better quality than the cheap ones you can buy from Cousins and very similar to Bergeon or Elma ones for three times the price. I use these for all my small parts and screws the escape wheel teeth don't get stuck in the mesh either. The 10 I bought some months ago aren't for sale anymore, but these look the same. The top doesn't screw on or has a tight fit, but that doesn't matter when used in a rotary cleaner where the top tray keeps the lids in place. https://www.aliexpress.com/item/1005006192329408.html?spm=a2g0o.productlist.main.59.2399715egHxh7H&algo_pvid=19494d80-aaf6-4dfb-a4bb-fb4a5ad410bc&algo_exp_id=19494d80-aaf6-4dfb-a4bb-fb4a5ad410bc-29&pdp_npi=4%40dis!GBP!8.15!8.15!!!72.24!72.24!%4021038e7717054389218812584eb60c!12000036207516935!sea!UK!2256404187!&curPageLogUid=8QbW0xCZafcu&utparam-url=scene%3Asearch|query_from%3A Here are some more at a discounted price: https://www.aliexpress.com/item/1005005546766070.html?spm=a2g0o.detail.0.0.76411b0990nco7&gps-id=pcDetailTopMoreOtherSeller&scm=1007.40050.354490.0&scm_id=1007.40050.354490.0&scm-url=1007.40050.354490.0&pvid=6481242d-aa57-445e-8520-9342c7591c84&_t=gps-id:pcDetailTopMoreOtherSeller,scm-url:1007.40050.354490.0,pvid:6481242d-aa57-445e-8520-9342c7591c84,tpp_buckets:668%232846%238111%231996&pdp_npi=4%40dis!GBP!8.63!4.83!!!10.64!5.96!%40211b801917054393081287742e93c3!12000033489630855!rec!UK!2256404187!&utparam-url=scene%3ApcDetailTopMoreOtherSeller|query_from%3A#nav-review2 points

-

2 points

-

No problem instead I've been looking for an excuse to pop next door and fill in my neighbour , he does my bloody head in,1 point

-

1 point

-

Geeze, That was a pain. I ordered the fat spring pins on January 1st from Uncle Quality Watch Straps which is in southern California. They shipped them fairly quickly and then they went for a 10+ day USPS driven trip around Virginia. The pins arrived yesterday, some 15 days after being put in the mail.. Anywho, everything got reassembled, which included straightening the links I had to open to cut the original fat pins out and voila! here it is: Thanks for the moral support!1 point

-

By nature, I think we are all alike. We ignore the things we have done correctly and focus on tiny mistakes. Maybe we should stop?1 point

-

1 point

-

This is what I use for sharpening screwdrivers. https://www.amazon.com/DMT-D3EFC-Dia-Sharp-Extra-Fine-Diamond/dp/B00006IIO3/ref=sr_1_5?crid=1DCBME1CROYFN&keywords=dmt+diasharp&qid=1705510223&sprefix=dmt+diasharp%2Caps%2C112&sr=8-51 point

-

I am going to reinforce @Neverenoughwatches suggestion of sharpening stones. Especially if you buy less expensive screwdrivers and tweezers, it is essential to keep the sharp and properly dressed. If you don't you'll be pinging, dropping, bending, scratching, gouging and every other -ing that's detrimental to small delicate parts. You don't need a specialty sharpener, just some good flat stones of coarse, medium and fine grades. And I'd suggest a holder for sharpening, too. https://www.esslinger.com/watchmakers-screwdriver-holder-for-sharpener/?gclid=CjwKCAiAkp6tBhB5EiwANTCx1JajexWqvKIjFQrsuO2OMvee9an0JvvIYyKhq39izoZeFhkvA7AKoxoCMDwQAvD_BwE1 point

-

Thanks for the good words, Yes, the mouth of the cylindre is shaped with files by hand, the needle is not hard material. Now I use tungsten carbide flying cutters and make cylindres of blued steel.The needle sizes as I remember are with step 0.1mm, so there is 0.8, but no 0.85. Thanks Rich, Who needs workshop full of complicated expencive machines and devices, if the work actually needs only simpe tools and decisions? I guess You have seen all my equipment and it is all I need to make pracically all watch parts when needed.1 point

-

Do you think that some folk get an idea into their heads or they hear something from someone with supposed knowing or a general rumour going around that something should be done a certain way. BUT they dont actually decide for themselves if its right or wrong or what the consequences might be. " oh it must be right because so-and-so does it this way " or " well its always been done like this " . The biggest and most dangerous example of this is the demonising of foods that have high fat content in the 70s ( Lets supply ultra processed foods instead, fricking idiots ) 50 years on and most folk still think the same way. " Fat is bad, you shouldn't eat it " . Really !!!.1 point

-

This type of obsession with destructive oddities seems to be making a comeback in many trades in my part of the US. Plumbing, masonry, housekeeping, gardening… It’s strange1 point

-

Thats some pretty clever work nev. It amazes me how little amount of tools you use and their basic design. George Daniels used the term " cork and nail work " he heard that from one of his mentors David Torrens. It basically means a high level of skill attained to enable just the use of the simplest of tools yet still produce perfect work. Negates the need for an all singing all dancing workshop.1 point

-

Sorry, late to the party, I guess it's a little like balancing a tyre. When something rotates a centripetal acceleration (acceleration towards the center of the spinning thing) is created which causes a centrifugal force (thanks to Newton, every force has an equal and opposite reaction). If you balance statically, you omit to take into account the centrifugal forces and therefore cannot account for them when trying to balance your new tyre, or balance in this case. So you can balance something perfectly statically, but then it will shake itself to death once it starts to rotate.1 point

-

Technically I suppose it's not exactly the correct wording. When we were shortstaffed I have no idea how he was found his shop existed a clock repair shop. So he would come and pick up work taken away bring it back. Of course they would go on the timing machine the nifty incredibly expensive witschi machine at times everything and six positions. So termination of giving him watches occurred at some point in time because were spending too much time regulating the watch which should've been regulated in the first place. So technically he was never an employee so that means he Be fired.1 point

-

What impresses me is when you look at what people do not just here but all kinds of fields where no one ever told them they can't do whatever it is they doing. So often times people can do phenomenal stuff because they didn't realize they're not supposed to bill would do it with either the tools of the knowledge they have. Depending upon how you do this making your own watch will require more tools than A lathe. If you're looking for precision then sometimes you abandon the modern watchmakers Lathe and go with something traditional like turning between centers. Here's an interesting link on how to make one although somewhat amusing because the turns itself is a very simple device and hear a heck of a lot of equipment was required to make his. https://watchmaking.weebly.com/the-turns.html1 point

-

Thanks, but this is done 200 year before me exactly the same way, so no my ideas.1 point

-

I had to go look at the picture and I usually associate the 18 with 6 o'clock for those of us that had a 24 hour dial at one time. Then yes it is interesting how the 18 seems to be all by itself until all this they realize oh look there's the rest of the numbers. Then it's interesting how the numbers on either side got trimmed off or just work printed with the dial is made which of course adds to the mystery of the 18 floating around all by itself. Oh and then regarding the movement yes always nice to see a picture of a beautiful railroad grade Hamilton pocket watch. But that would assume that the original posting person comes back to us and? It'd be interesting to see statistics on the message board of how many people post a question and never come back at all. On the other hand if the person would come back and post a picture of the moment we get a serial number and find out approximately when it was made and information on the movement and of course the case which is probably not solid gold it's probably a gold filled case which is basically very heavy gold but not solid.1 point

-

@Jon Thanks for the tip Same as with the IOSS, when living in the reincarnation of the Soviet-Union, it's the AliExpress fine-print that warns you already: "For items delivered from outside the European Union, you may be subject to additional charges for VAT and, when applicable, customs duties in your country" That's in Denmark already, by definition, US$ 23.50 "handling fee" + 25% VAT. I'll search inside the SU1 point

-

Wonder if it would be possible to punch a small dimple(s) in the lid or cage to make a friction fit?1 point

-

OK, the balance looks undamaged, but next time do it the right way. See this video, it is not to long:1 point

-

I hear you, one trick I picked up is to lay an old crystal on top of the parts inside the basket, the weight of the crystal will keep them horizontal and unable to stand up and get stuck in the mesh. Also works for wire springs etc. I'll be getting some of those fancy baskets @Jon recommended.1 point

-

One of the things to remember with quartz watches are there very very intolerant to well anything affecting the gear train I remember when the quartz watches came out initially there was an assessment of no lubrication needed because there is no friction. But the early metal on metal bearing watches would have issues. Then people try to oil their watch but that would have issues because that whales are all too heavy. I had one particular Seiko watch that with oil didn't work without oil didn't work and I think it even had jewels it was a small line Seiko watch that they would put insurance case. And then the Swiss came out with oil for quartz watches which is a very light weight oil and the watch worked perfectly. So I do find that the Swiss quartz oil works really well but if a quartz watches so sensitive the lubrication that would also imply anything with the gear train is going to be an issue then typically with quartz timing machines they use basically a capacitive pickup. So basically they're not putting a load on the oscillator because of course that's a really tiny micro-powered oscillator and everything is going to be a load. Unless you can figure out how to tap into one of the outputs like the stepping motor.1 point

-

Going against the trend here as I do tend to clean the screws etc along with the rest of the components, but not for any particular reason, just hadn't given it much thought. I segregate my components in my parts tray as I am disassembling the watch much the same as discussed above. Then I place all large components (eg main plate) in the main wash baskets of the watch cleaning machine. However, I put any small parts in those little mesh baskets, sometimes up to 6-7 small baskets, some with only 2 screws in. So I know which basket goes with each slot on the parts tray I make sure I place in a 'clue part' for example the escape wheel, instead of putting it in the main wash basket i include it in the small parts basket, then I know all the small screws and doodads in that basket are part of the escape mechanism. Similarly I may use the sliding pinion as my 'clue part' to flag the small parts in that basket as being part of the keyless works etc. Not sure where I got this from, just something I started doing and it seems to work.1 point

-

I just found this forum earlier today and I'm already finding some incredibly valuable discussions. I can't wait to learn more and get to know you. I've been a lurker to this hobby/skill for a while, taken apart some movements and watched a ton of YouTube videos, but maybe one day I'll reassemble something and it will work. I'm originally from Texas but currently live in the Atlanta, GA (USA) metro area. Thanks for letting me join such a cool community! -Philip (OldMarine)1 point

-

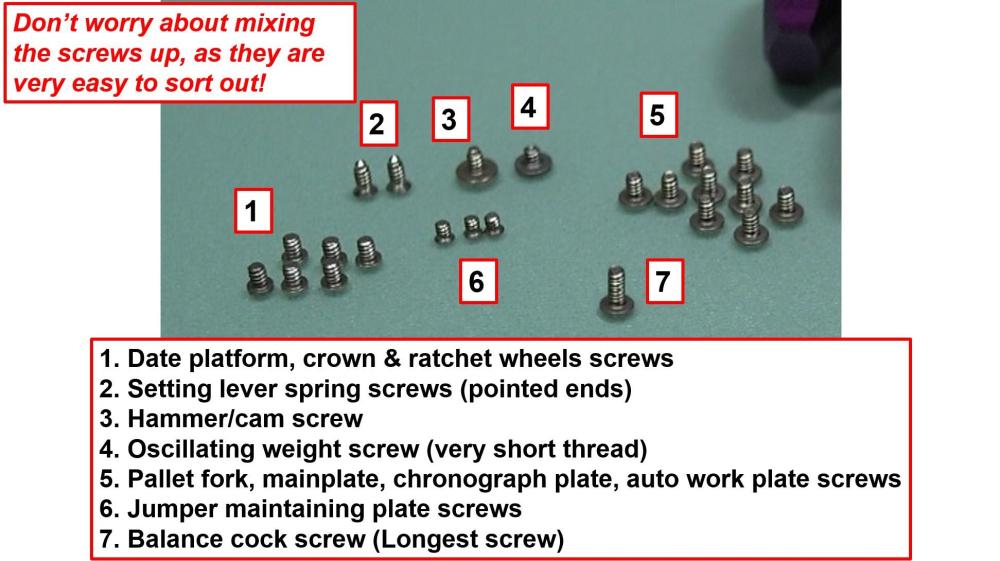

If I'm unfamiliar with a particular movement I will do as others have suggested and take photos of those screws with their respective parts. I always clean screws through the cleaning machine, as this gives the screws and the holes in the bridges and main-plate a really good clean as well. It also makes sure any brass fillings and crud are removed in the process. You can save some time sorting the screws out by putting all the keyless work smaller parts in a mini basket together with the screws. All the bridge screws go together in another mini basket and maybe the pallet bridge screws in with them, as they will be very different to bridge screws. barrel bridge furniture and screws are all kept together (crown, ratchet and click screws) They are all different lengths. The crown screw will always be shorter than the ratchet screw, as well as being a left-hand thread, and generally, but not always the click will be the smallest. I use four or five mini baskets and keep the screws in one of the baskets with the respective parts where the screws are from, so it isn't a crap shoot when removing them. Even working on a Rolex automatic this method works very well. Working on a 7750 is even easier, as the screws are so different and most are the same type as I have shown in this slide from one of my lessons. With the 7750 all the screws can go in just one basket. Once this discipline has been done several times, it becomes quite natural to know what goes where. You may get the odd one out of place, but not often. Cleaning the screws and the bridges and main-plate and bridges is important for the reason I have already stated, although some may not think so. Watchmaking teaching discipline, rather than the easier softer option, but that only comes with practice, knowledge, and then wisdom from the previous two.1 point

-

What I do is keep screws with the parts they were attached to in the trays. When disassembly is completed I take a picture of the trays before cleaning. Something like this 7750 I'm working on now. I'll put the parts but not the screws through the cleaner and then put the clean parts back in the same slot in the tray, with their original screws. Those little orange triangles help me keep everything indexed. Finally, as I am reassembling, I'll clean the screws manually if needed. The shouldered screws or reverse threaded screws are obvious, and plate screws are usually all the same size/thread, but you have to be careful with levers and springs which might have similar heads and/or threads, but be different lengths. Those I make sure are in separate trays.1 point

-

@Rixy towards the end of last year I acquired the remnants of a watch/clock makers estate which included a reasonable stock (upwards of 50 or so) convex clock glasses of a variety of sizes. If you let me know what size you actually need I can go and have a rummage in the shed and see if I can find something for you. I won't go into detail about what else there was other than to say that I now have over 60 clocks in my shed and I can't actually get in there to do anything. This is what I brought back, unloaded into the living room prior to sorting and relocating to more appropriate places. Any way, let me know what size you're after.1 point

-

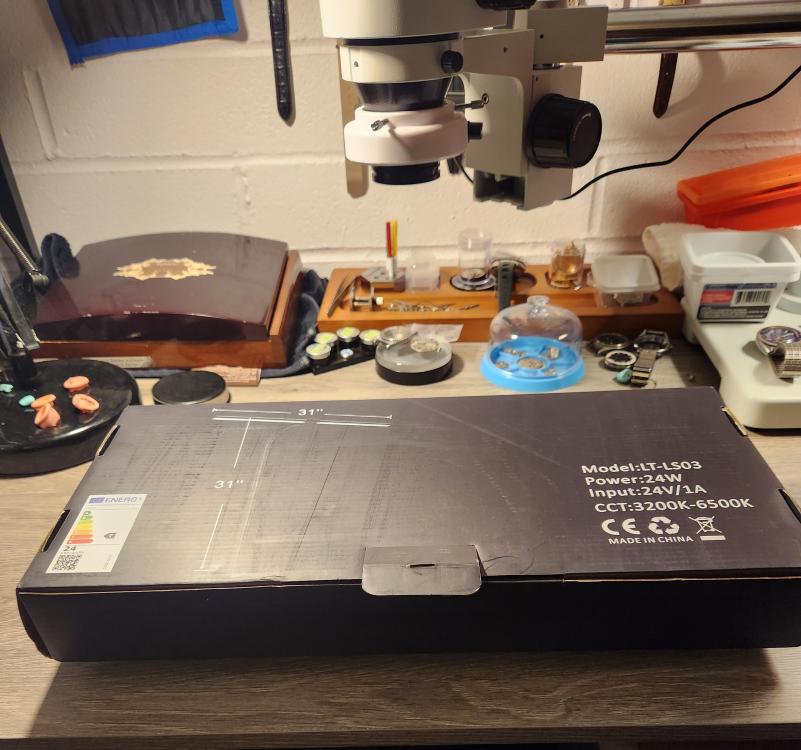

Very informative thread! After reading through, I ordered a lamp from Amazon. Under $49 US (£39) tax shipping and delivered in 6 hours, yep! This one has 5 intensity levels and 5 color settings from 3200 to 6500. I use a binocular microscope and have the gooseneck lamp in case I need directional light. Don't mind the clutter of watches, those are usually moved off the bench when working on a watch. This really lights up the area nicely. The ring of leds on the binoculars is fairly cool when compared to the new lamp. I like it because once set it returns back to the setting when turned off and back on again.1 point

-

My wife took these pictures today. Not sure if there is a message that I am supposed to get The first bench is the one from my Dad. The second is the one I bought from Maine. The third I bought from someone in Wyoming. The last watch bench came from Dallas. The other bench is just a converted office desk. The last picture captures a portion of the room. This was not staged...and I am a little embarrassed about how it looks. That's me and Cromwell.1 point

.thumb.jpg.cd3ece6ce8c054131f98a89039d8dd34.jpg)

.thumb.jpg.ef81f0dc2fb2ce4f3f9e5dd22868422d.jpg)

.thumb.jpg.2b347800663eee281d06715cda026563.jpg)