Leaderboard

Popular Content

Showing content with the highest reputation on 01/18/24 in all areas

-

11 points

-

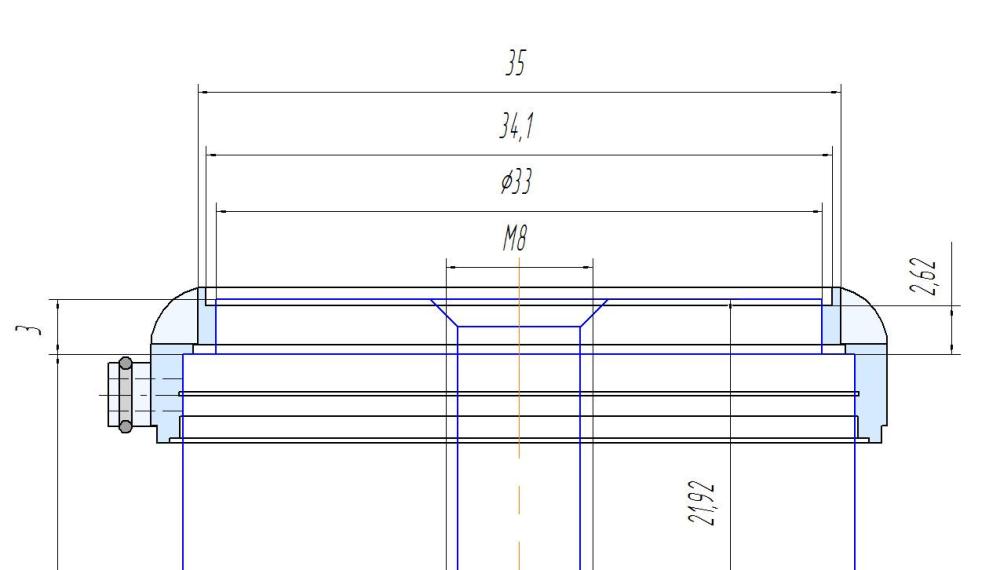

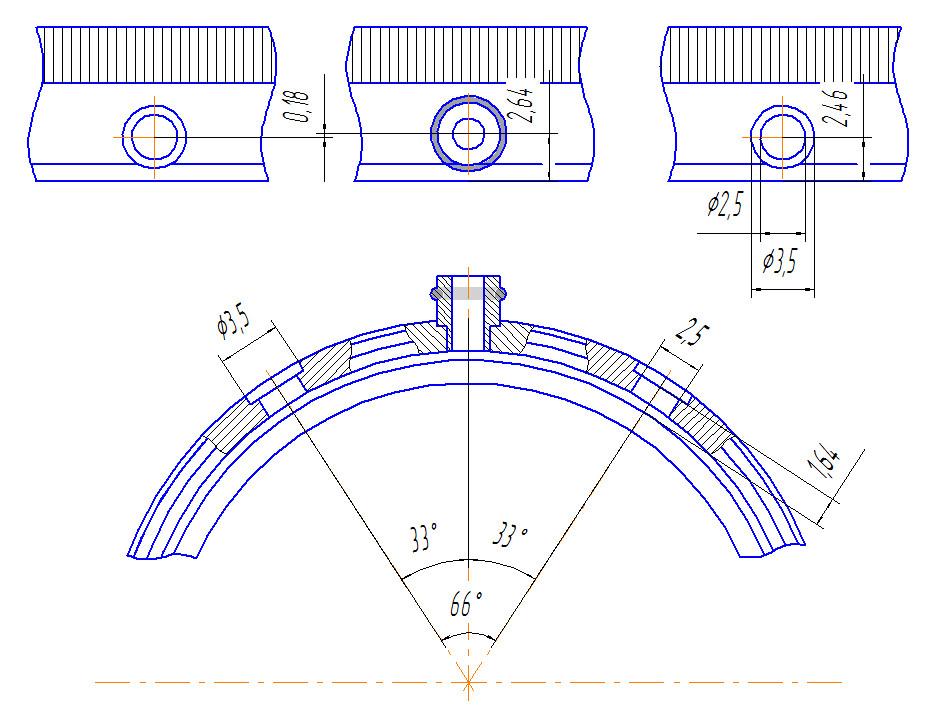

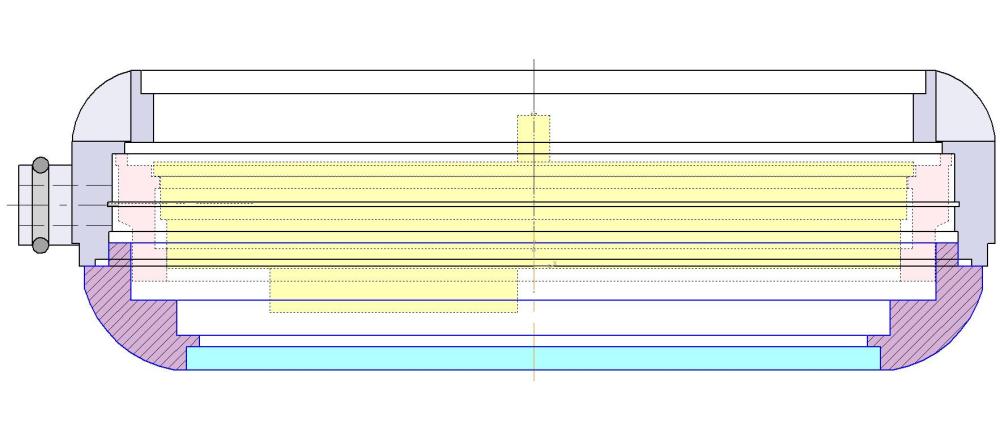

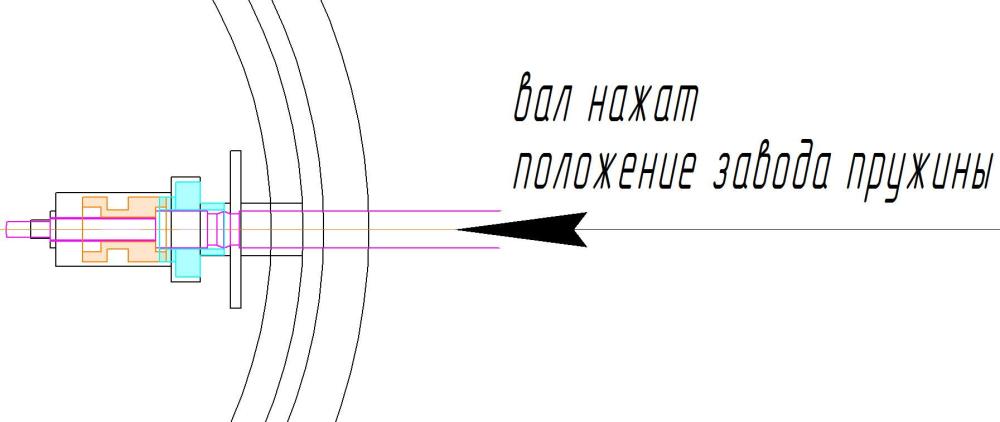

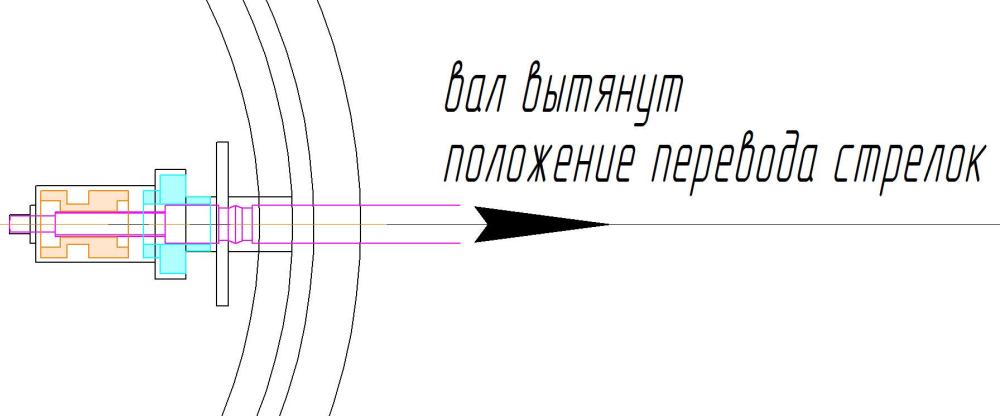

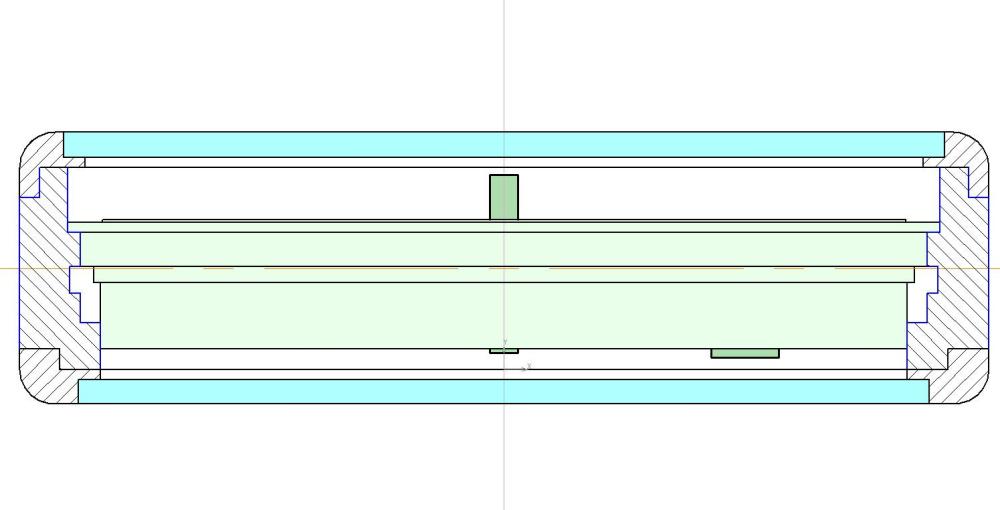

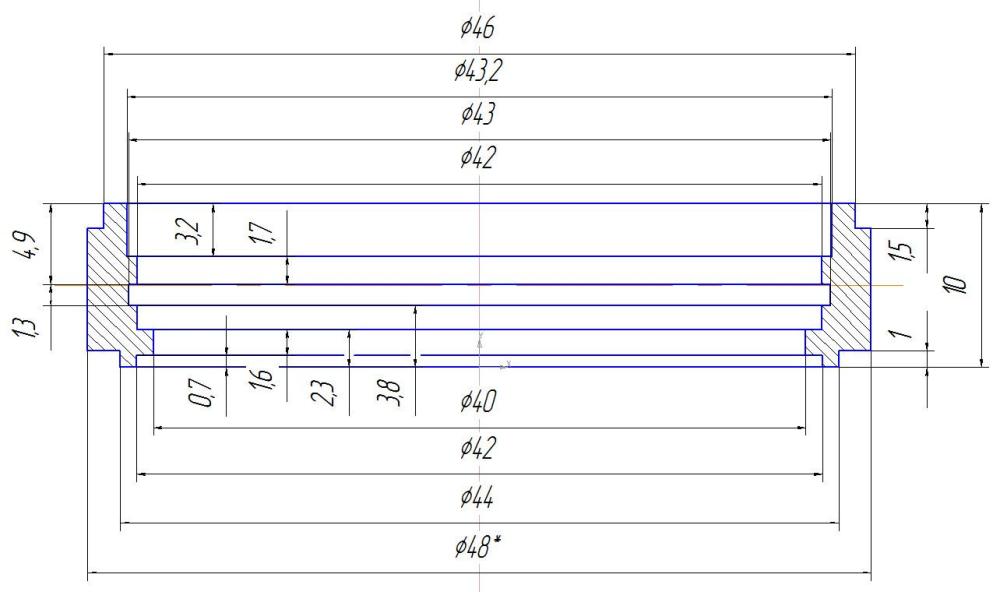

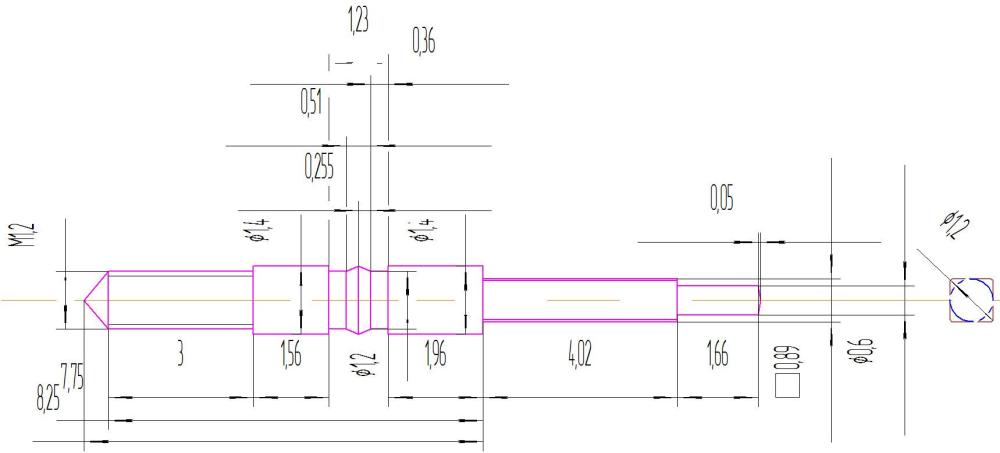

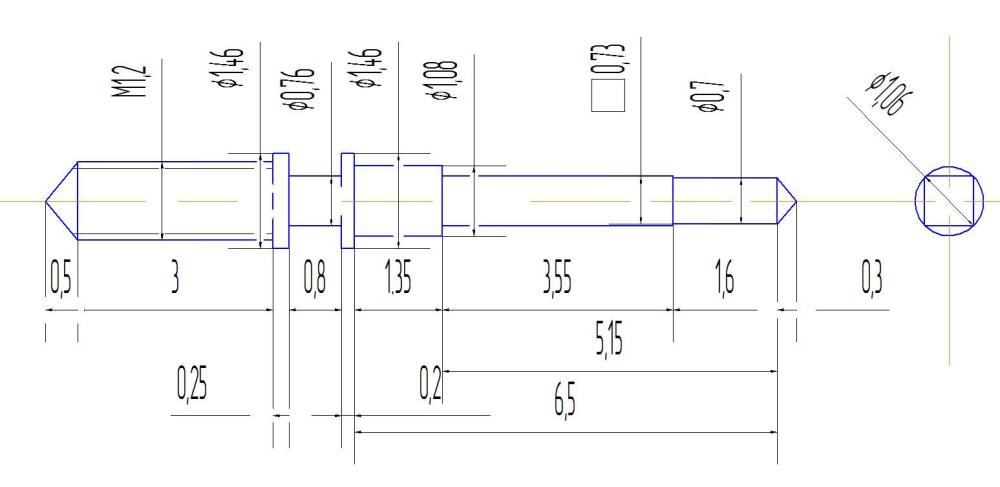

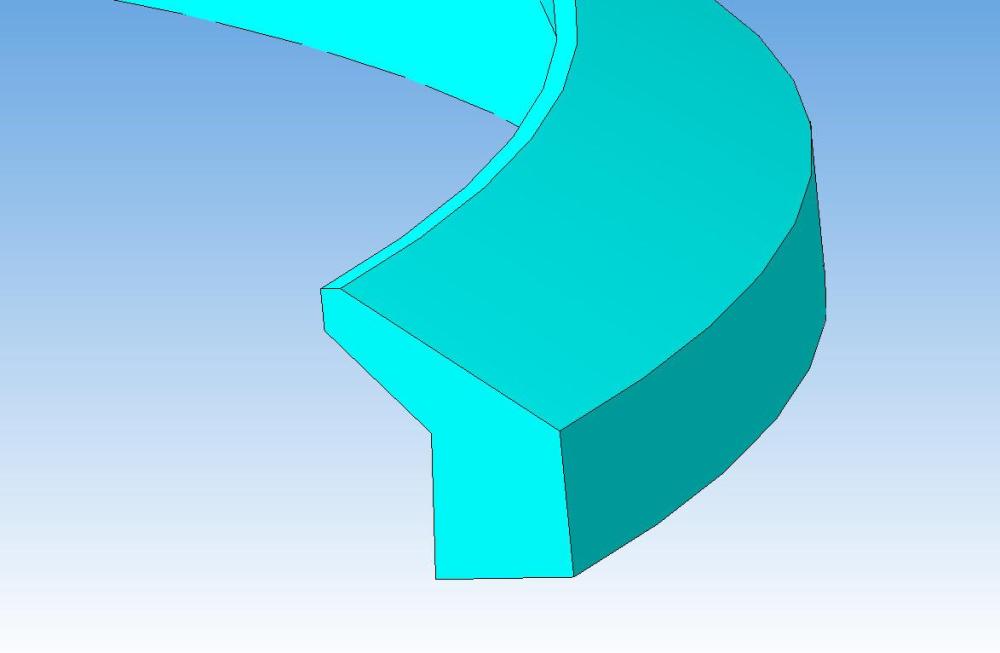

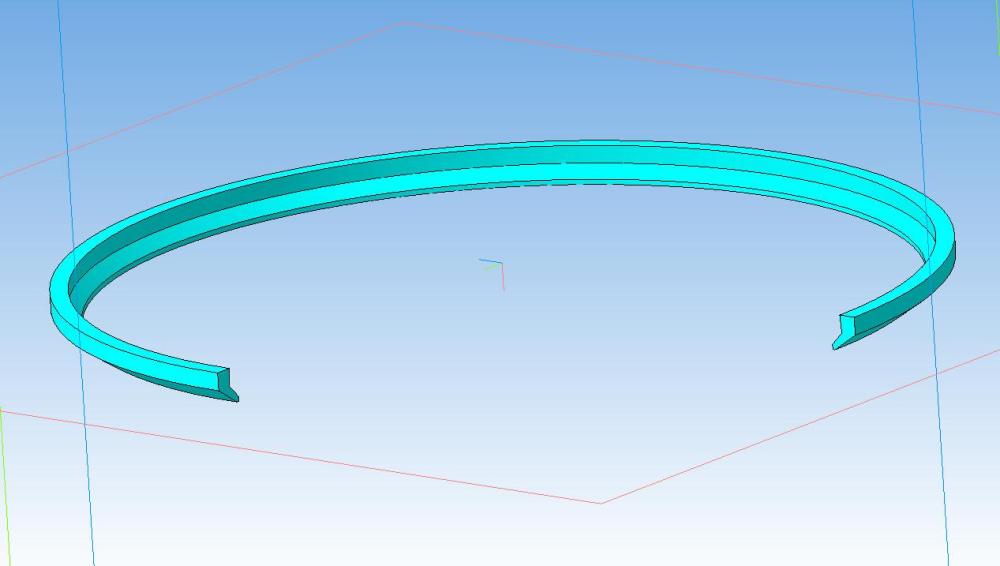

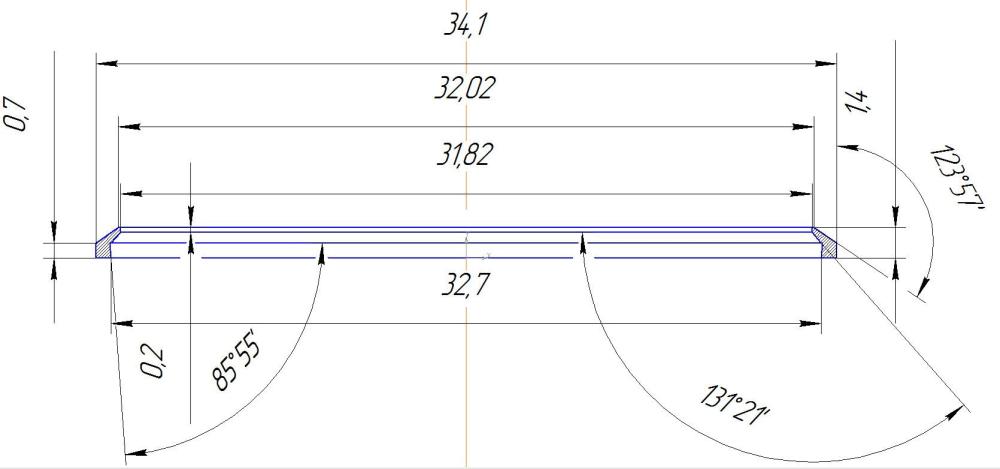

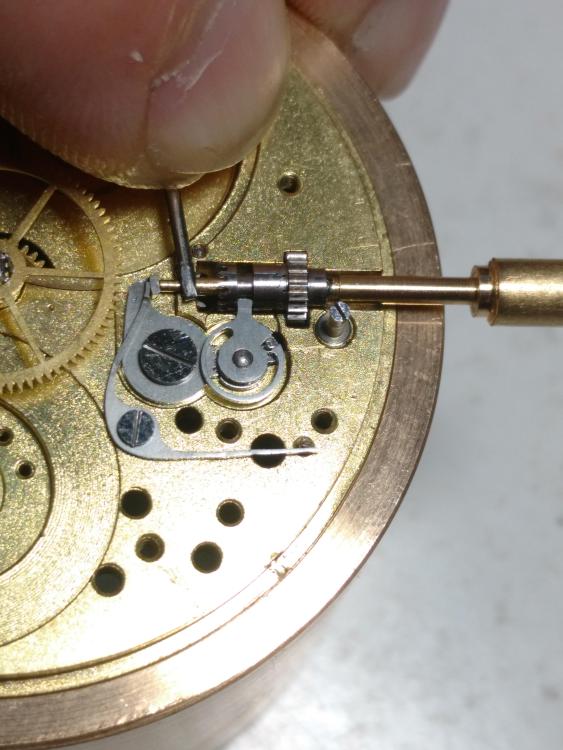

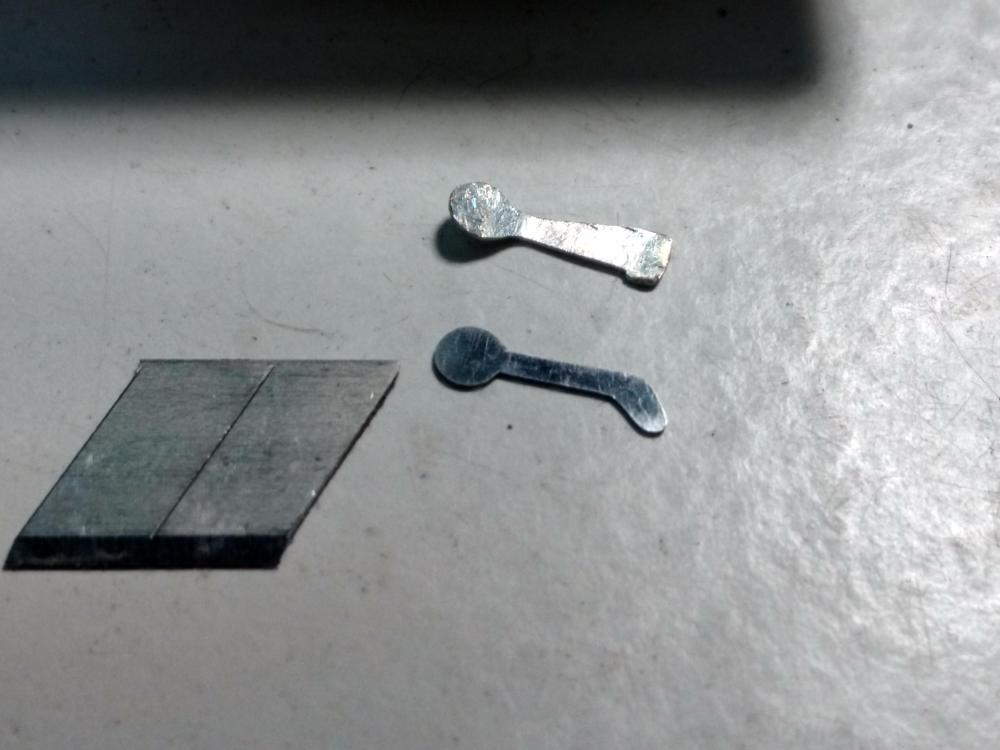

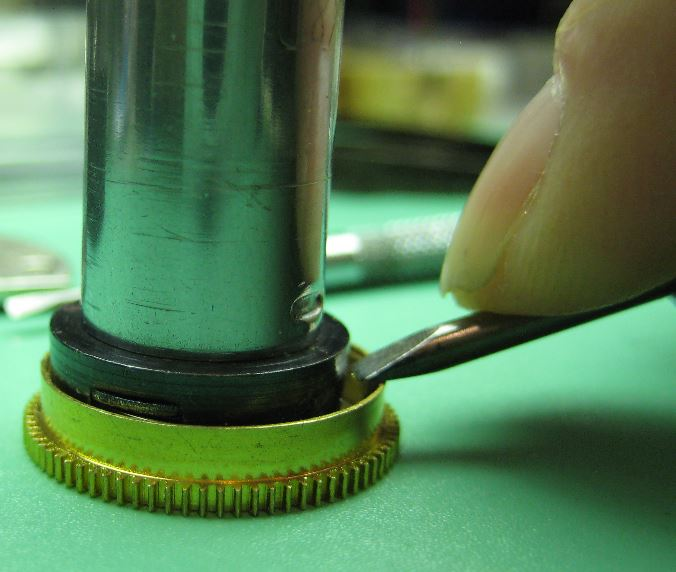

Here are some pics of my nail-clipper mods, for those hobbyists who do not have lots of cash!! Only cost would be for a suitable drill for the setting screw hole (tungsten carbide needed as material of arms is very tough), the rest from the 'bits box'. The original pin for the lever was 5mm diam hence the crimp screw diam, this could be different for other clippers. Any epoxy would do but JB weld sets very hard. The setting screw can be any size provided it does not compromise the integrity of the arm (ie weakening it across the arm) and the locking nut fit re fouling the crimp screw head. The crimp screw could be in the other way but thought easier to have both screw heads on same side.5 points

-

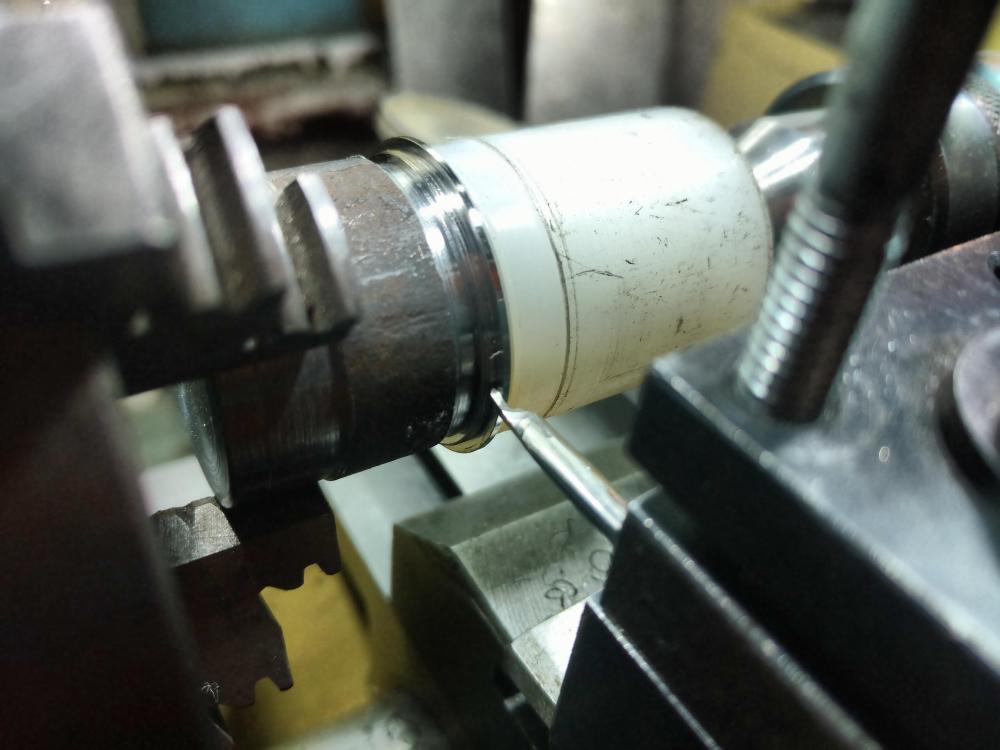

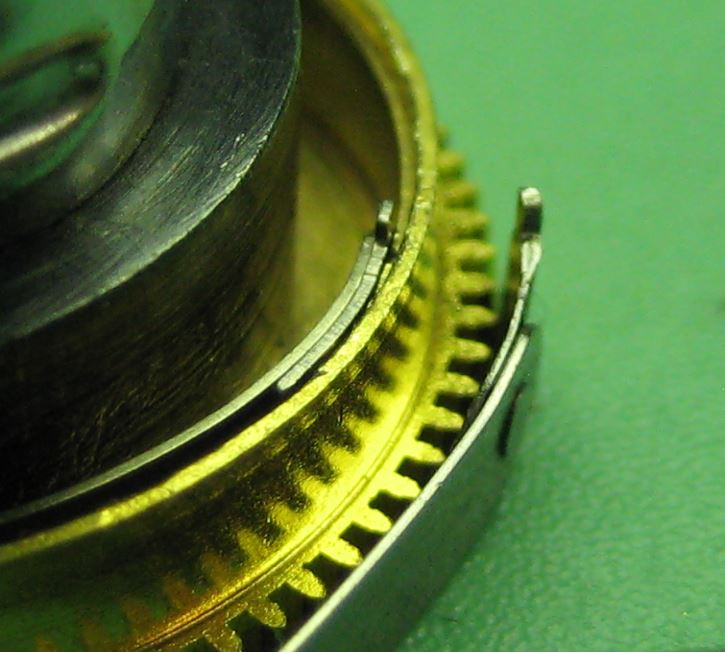

Since the metal wants to deform, but can't go "in" it goes out, once the pressure is off. Works great!4 points

-

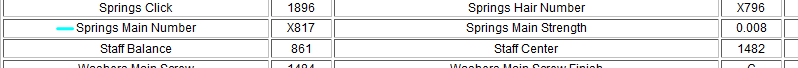

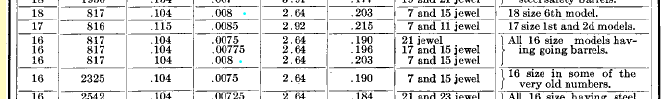

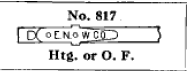

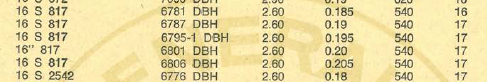

For mainspring the thickness a micrometer would work better. They're not exactly outdated. Sometimes they're the only thing you can get. The problem typically with blued steel or carbon Springs is they set and then there not quite worthless but just about worthless. In other words your watch will not run overnight. Then one of the concerns is with the modern Springs for the same thickness there supposed to have more strength or power to them. But they also have interesting amusing problems. For instance both Elgin and Hamilton made outstanding alloy Springs that are still good to this day brand-new typically they come out of the package and out of the ring they'll have a beautiful back curve to them. The back curve to the mainspring is designed to supply even power to the watch. But modern springiness when you push them out of the ring and they can be all sorts of interesting shapes none of which necessarily as nice as what the original watch companies have. I had one spring words basically straight with no curve at all. So much for modern quality control. The ring size is only really important if you're shoving the mainspring out of the package into the barrel which is not going to work for this watch at all so that number is irrelevant of no importance oh and before I get to that have attached a PDF it shows a lot of American pocket watch springs and O get you close to what you need next time plus the ends and other stuff now insertion of mainsprings with protruding T type ends? Typically you cannot shove them out of the ring because the T part needs to go into a hole or slot and is not enough to be on in alignment because as soon as you push the spring it's going to jump it has to actually be into the hole and/or slot. So is basically two ways to do this I would prefer to use a mainspring winder and if you don't have one yet you'll get stuck winding it in by hand. But make sure that the T is in place no matter what because it will move around if it's not and forcing it around after the fact is not desirable. The preferred way or at least my preferred way is with a mainspring barrel winder. We've covered this somewhere before on the group including nice pretty pictures. But that means you have to do a search so let's see if I can find a folder on my computer where I have pictures Okay here's what your end looks like or should look like There's an image of the winder with the spring sticking out yes it really does have to stick out for the salt to work. Plus the barrel has to be small enough to fit into your barrel. Here is an example of the different ends so once the spring winders in the barrel he rotated around until it appears to be in the right location and then you have to Push it in the place. Then I like to turn it over and verify it will look something like this Then with it back on the bench before you can push it out you have to hold the T end in place either with a really big screwdriver the backside your tweezers. Then you can push the spring out and if you're successful it will stay in place. Mainsprings Cas-Kar Catalog 2018.pdf4 points

-

3 points

-

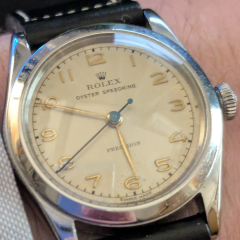

Geeze, That was a pain. I ordered the fat spring pins on January 1st from Uncle Quality Watch Straps which is in southern California. They shipped them fairly quickly and then they went for a 10+ day USPS driven trip around Virginia. The pins arrived yesterday, some 15 days after being put in the mail.. Anywho, everything got reassembled, which included straightening the links I had to open to cut the original fat pins out and voila! here it is: Thanks for the moral support!3 points

-

2 points

-

You need a key or a vice to hold the key end and inside the barrel the arbor should unscrew. Be very careful some are so tight they wont budge.2 points

-

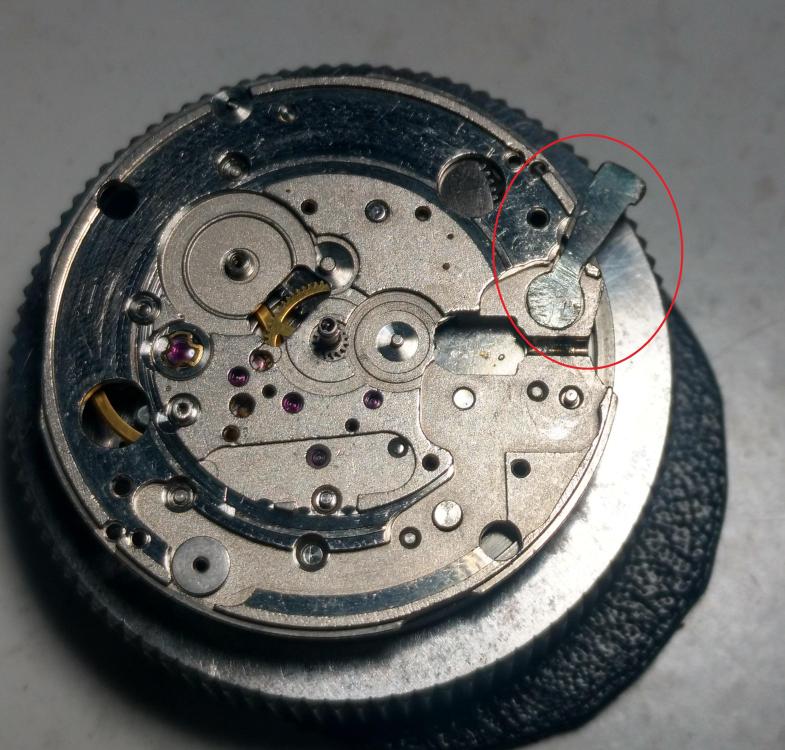

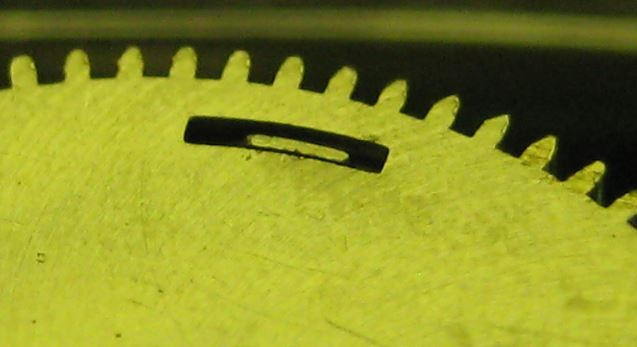

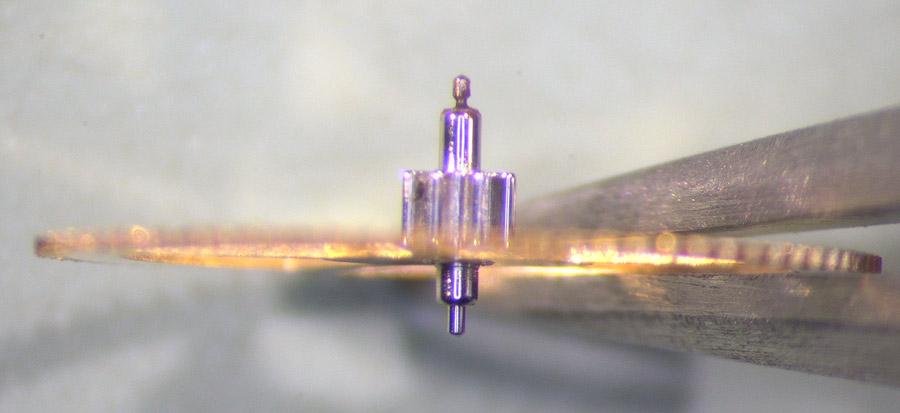

If you find that a cannon pinion is too tight, the easy fix is to give it a squeeze right on the indents with it installed. This actually causes it to open a tiny bit.2 points

-

http://www.elginwatchparts.com/ Interesting I didn't know the Elgin Springs came with different lengths? Then don't know if you took your spring out but it doesn't have your usual End supposed to have a end like this which is a standard for an Elgin mainspring Then cousins is going to be using one of the mainsprings from this Catalog. Looks like based on the strength which is basically the heaviest spring they made 6806 would work fine but unfortunately reality with American pocket watch mainsprings whenever you get will unfortunately also have to work fine as you may not be able to find any of these. Looks like cousins has the spring Then as you can see from the little exercise I did there is more to the mainspring of then the dimensions. Typically with American pocket watch springs you really do need the right end in other words you ideally need the right mainspring.2 points

-

Добро пожаловать Владислав! Thank you for all your images. Very beautiful and impressive work and watches!2 points

-

I know but " Shitinerand " was that the best they could come up with Haha close but not close enough. I could change my name to Bradley Armpitt for fun but i still wouldn't do it better than a shit in er and2 points

-

Hi, If the only difference is the lenght, ten no point to wary, it is OK. You typed 'the spring inside is 2.50mm x .1 and it's 21.5 inches', which I guess is mistyping, as '.1 ' is not pocket watch spring dimension. But, if there is difference in the thicknesses, it will be a mistake. What is the reason for changing the spring? Is it because all people do so when servicing watches? Please, if so, when everything is done, do test with the old spring too, and say here what is the difference in amplitudes with the new and with the old spring, will be interesting.2 points

-

Hi everyone, I would love to know your opinions on which movements and corresponding watches are suited for beginners. A lot of people recommend starting out on a Seagull ST36, but actually having a real watch to work on is where I would really love to start. I did a ton of research, scrolled through eBay and Catawiki a gazillion times but analysis paralysis got the best of me. Brought to my knees by the sheer amount of information I now turn my attention to you, hoping I can pry off some knowledge. What kind of watch was I thinking of? Time only Preferably 0 - 75 euros Manual wound Commonly found online Please share your opinions on this matter!1 point

-

Hello All, I found this forum when searching for watch repair information. I watched a few too many of those "get into watch repair" videos on YouTube and got it into my head that I, too, can do it. My motto is Move slowly and don't break things. Nice to meet everyone1 point

-

1 point

-

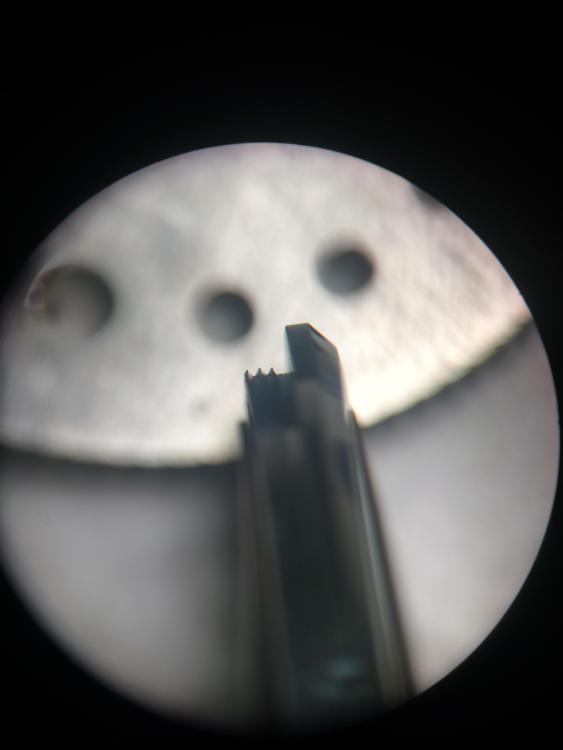

I've tried one but the thing I like more with the Horia is that I can put the hand tube between the "jaws", flip the tool on its side under the microscope and see the tube compress just a bit while I turn the micrometer.1 point

-

1 point

-

I have these as well and have used them on my Seitz. I have a Horia clone now and might revisit using it for this purpose. Precision is nice.1 point

-

This is a wonderful tool but I cannot let pass an opportunity to comment on the pleasant aesthetic of this presentation, like some kind of ‘retro-technical’ comic book style. I find it quite amazing- well done! …on topic, one of the classic books demonstrated using the pointy four sided punch to tighten the canon pinion. The punch creates the small pattern of raised edges in the base. It isn’t obvious to me why this alternative method is not preferred? I find the pinch method risky and despite great care have damaged a pinion this way…1 point

-

See, the thickness is the most important spring dimention. It is also called 'strenght', as the force it creates is proportional to 3th degree of the thicknes, so verry little difference in thickness changes the force dramatically. If You got 2.5 insted 2.6, and 520 instead of 540, that's OK. There are 3 different strenghts in the table, and You bought the weaker one, so may as result get lower amplitude with the new spring than with the old one, if it is correct for the movement. The end is important, but it can be changed if needed.1 point

-

Oh I should have mentioned that it’s a pocket watch, not a wristwatch. The length of the mainspring I got from the American Watch Movements manual but perhaps I was looking at the wrong movement.1 point

-

The strength of the new mainspring will be much higher than the one you removed which is more like a wristwatch strength, are you sure you measured the old one correctly ? As the length also seems too long for a wristwatch1 point

-

If you look closely at spring bar types and the holes in the lugs of watch cases, you will come to realize that you need the right type of spring bar for the type of hole. For blind end holes, like that of your Seiko, a double flanged spring bar is needed. Don't ever use a single shoulder or double shoulder type because once the pins go into the holes, it very difficult or in the case of the single shoulder type, impossible to get it out. Single shoulder types are meant for the adjustable section of bracelets, where the pins protrude out from the holes and can be pushed in to release it. Double shoulder types are for watch lugs with through-and-through holes, where again, a tool can be inserted to push the pin out. It could be possible that a novice watchmaker disassembled the bracelet for cleaning and mixed up the spring bars during assembly. If you come across a single shoulder spring bar used in blind hole lugs, the only way to remove it is to cut it. I have come across a few and I used my dental highspeed drill with a tungsten carbide bur to cut it. But now that I've retired, that would be a difficult task. Looks like I've to setup my compressor and highspeed drills in my workshop just in case.1 point

-

Hi once the balance is removed check both the escape wheel pivots and the pallet pivots, and that the pallet stones are not loose.1 point

-

Remove the balance and check that the impulse jewel is present and not broken. Then check that there is power at the pallet fork by moving it with a pegwood.1 point

-

Hi Rich, I clame to use ancient techniques, but, as a modern man, I use electricity. I never tried to learn using bow to power the turns... The nylon pullley - it has been long time ago (2015, when I se the names of the picture files), but probably I have made the pulley to fit the needle, or have used pulley that have made before for something else, with proper size. Such puleys I make for different small electric motors that I use for powering the turns, or my milling attachments for the lathe. I am not sure if I get the question for the pivot supporting, but it is center of this kind, that is used to turn a pivot when You have the stock with cone shaped tip only1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

A staking set is a good step up for a beginner and no doubt the first watches that are encountered would have need of one. But for me, I'm next to hopeless when i use a loupe, i can inspect with one but little else, maybe some disassembly. Clear use of both my eyes which permits better depth perception than when using a loupe is mega important to me. I started with big magnifying glasses and that soon evolved to a binocular microscope before i even knew they where used in watch repair. If i was starting again and know what i know now i would change many things, but getting a microscope quickly is one thing i wouldn't change. When searching inside a movement i constantly strive to get the best light and the best magnification in there with me, its a healthy threesome1 point

-

I wouldn't argue with that and i bought some old winders very quickly, i really shouldn't have bothered, i think I've used the set of 9 winders maybe half a dozen times now. I learnt to hand wind and also made a little jig to help me do it better and safer. I have more winders now and use them for ease but occasionally they dont fit so i get a little refresher course in hand winding. After a good amount of practice I dont bend, kink or twist them inappropriately when i do one. What may happen is the spring will take on a helix shape, but that can happen with the removal of it as well. There is the possibility that the spring will rub on the barrel inside if its has a helix form and I'm sure it happens, thing is you dont know if it is or not until you remove it again and find evidence of rubbing. So that kind of leaves me on the fence with the whole handwinding thing. But if its already formed a helix shape on removal, coiling it up in a winder doesnt remove the helix, ive tried it and it doesn't . I have managed to remove some by pulling it through itself but only from the inner coils or on an old spiral only spring. Flat diamond steel plates are ideal and can be cheap. In fact i just had a 3000 4" diamond disk delivered it was a fiver from china, intended to put on top of a grinding wheel to go in a bench grinder to sharpen gravers. I was expecting a poor quality generic grade of grit that could have been anything from 400 to 2000. It was i guess bang on 3000 as its so much finer that a well graded 2000 plate i have. Disks like these are perfect for making micro diamond files from and as we discuss here an 1" x 3" sharpening plate for tweezers and drivers, the sharpening plate doesn't need to be a big 8x3 . You can even make up your own sharpening stone from a lollypop stick or metal stick and emery cloths. They dont last forever but just an example of what its possible to manage with.1 point

-

I am going to reinforce @Neverenoughwatches suggestion of sharpening stones. Especially if you buy less expensive screwdrivers and tweezers, it is essential to keep the sharp and properly dressed. If you don't you'll be pinging, dropping, bending, scratching, gouging and every other -ing that's detrimental to small delicate parts. You don't need a specialty sharpener, just some good flat stones of coarse, medium and fine grades. And I'd suggest a holder for sharpening, too. https://www.esslinger.com/watchmakers-screwdriver-holder-for-sharpener/?gclid=CjwKCAiAkp6tBhB5EiwANTCx1JajexWqvKIjFQrsuO2OMvee9an0JvvIYyKhq39izoZeFhkvA7AKoxoCMDwQAvD_BwE1 point

-

The dial on the Hamilton 974 I just serviced has markings in red at the outside edge of the dial. I guess there were many variations and the other may be a railroad style dial. Interesting that my dial also has the name of the shop "The Watch Shop" instead of Hamilton. I love the gold details in the movement.1 point

-

1 point

-

Probably not in this case. That'll be a world full of pain! I suppose if you do that particular movement several times, you will get used to what goes where. What I always say to my students is, 'Don't always assume what you find is meant to be there', so sometimes you'll find a screw has been replaced with a thread that fits, but a profile unlike anything else because it is a replacement for what was lost, which makes identifying the screw from a profile pic nigh on impossible!1 point

-

I'm not sure what's going wrong. As long as you have the spigot in the hole in the date corrector, it should work. Have a look at the attached document, It explains how it works OMEGA Calibes 551-751.pdf1 point

-

Thanks for your responses. I will keep an eye on the bay for a proper tool. In the meantime I have some old nail clippers and have flattened the cutting edges on it. I might try and drill a hole and fit and adjustable/locking screw for better control (not sure if the material might be too hard to do this. If not I'll give it a go without.1 point