Leaderboard

Popular Content

Showing content with the highest reputation on 01/26/24 in all areas

-

...when you buy a specialized tool costing five times as much as the watch you're working on and that you will likely never have any use for again.4 points

-

.... your YouTube homepage suggestions all have pictures of watches ... your wife calls you out for thinking about "why that click spring won't fit under the ratchet wheel" when she is in the middle of a conversation with you about her sisters new curtains ... you see something in a store that you immediately think how to repurpose it for using it in watchmaking ... you find yourself shaking your head and rolling your eyes when you friend expounds on their great new smart watch, and they are confused when you don't share their enthusiasm as they thought you 'like watches' ... you get in trouble for all those little bits of rodico bunging up the washing machine, vacuum cleaner etc... ... your family don't find it unusual to find you on your hands and knees with a magnet swearing at the floor and mumbling about springs/screws ... your family know better than to use those 'little screw drivers' to change the plug on the kettle ... your family know exactly what they are getting for every birthday/christmas gift ... you don't have any idea what time it is, or that 5 hours have elapsed since you started that 30 min quick fix despite being surrounded by watches and clocks ... your family start a conversation with the words "it's ok you don't have to look up..." I'm sure I will think of more as the day goes on!3 points

-

Always best to use a piece of brass wire to fit into the cannon pinion to stop it from being crushed. Put the wire on a hardwood block with a groove scored into it with the edge of a file and file the brass wire with a slight taper until it fits snuggly into the cannon pinion. The same wood block can be used to polish arbors with a lolly stick and some Autosol then Brasso like in the pic2 points

-

The natural lume is seen on the dial and it has green color. It doesn't seem to have radium, also they stopped using radium in the 50's and this clock is made later. Do the dots on the dial still shine for some time in the dark right after ehposed to bright light? Good work with the hands! The factory existed untill mid 90's and then was closed. In the 80's they started to put plastic wheels under dial and plastic barrel for the alarm spring. When the factory was closed, the movement looked like this and only 2 jewejs left from 11 in the original2 points

-

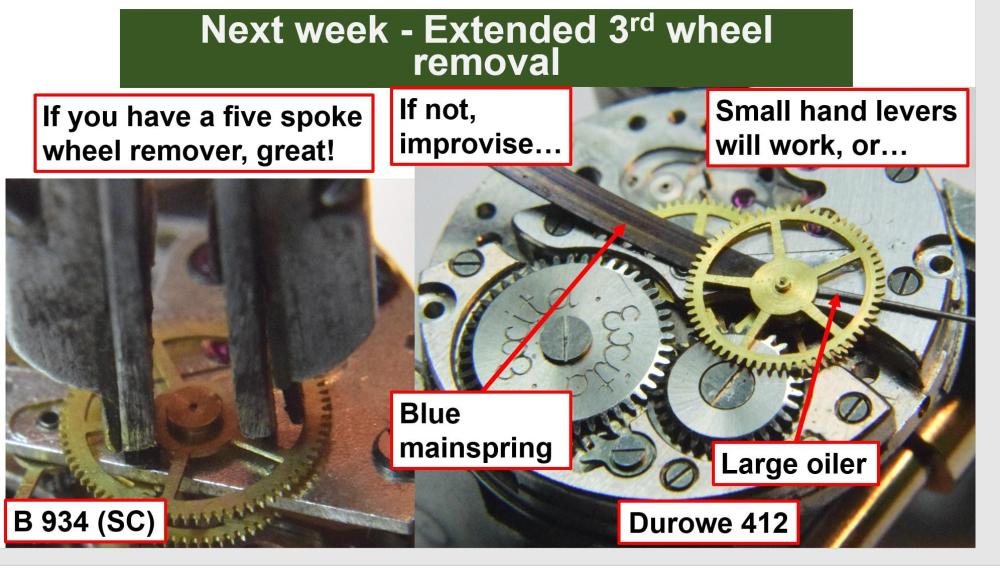

No worries Ross! When I eventually find it I'll link it. In the meantime here's a video section where Kalle demonstrates the Bergeon 5-spoke wheel lift tool (only 50.35 excl. tax and shipping from Cousins ).2 points

-

I really can't remember. May be even more than 2 month. I know it was and upmarket watch. For me anything over £30 is up market, sorry. However it was in discussion about the removing of a press fit wheel. He actually used the Bergeon tool, but discussed how his original tutor dealt with the issue, and that the tutor, even though he had the Bergeon tool, always used the pegwood. I think he demonstrated the use of the pegwood, but for time constraint of the evening, used the Bergeon tool. I have used this pegwood method 4 times since. NO problems. Just took time. Up to to 4 minutes one one occasion. Stuck screws have taken infinitely longer.2 points

-

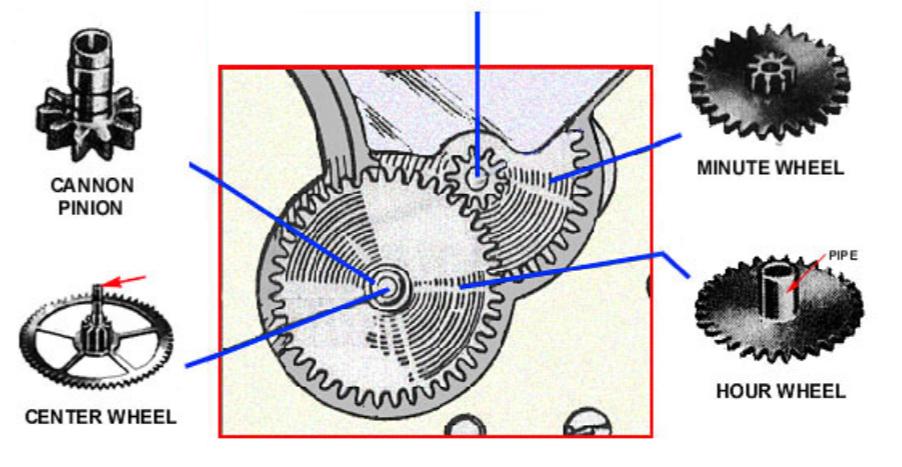

To clarify, the barrel drives the center pinion, which extends through the mainplate and carries the cannon pinion, The center wheel drives the 3rd pinion, the third wheel drives the 4th pinion, and the 4th wheel drives the escape pinion. The center pinion does indeed extend through the mainplate and carries the cannon pinion. The long pivot on the 4th pinion, which is part of the 4th wheel, extends all the way through the center pinion, to carry the seconds hand. And as Kalang's excellent drawing shows, the hour wheel rides on the cannon pinion, driven from the cannon pinion through the minute wheel to get the 12:1 reduction necessary.2 points

-

Don't you just love the people on this forum. Just made a tool for closing a cannon pinon that is loose. I had tried to close a cannon pinion by using my Staking set, but applied to much 'hammer'. Actually pierced the pinion Saw this DIY on this forum, made by a member. I have now converted a nail clipper. Taken out the plunger. Inserted a bolt, made it solid with a filed down nut and then put another on the top. I now have the facility to do what he did. Using the flat edge as a gauge I can apply pressure to about 1/1000" depth. Need to file the cutting edge a little. But it looks ok.2 points

-

...it's New Year's Eve and you're sitting reading and writing on WRT. ...you start your timing machine before you start the coffee maker. I guess there are many other ways to know, so please fill in with more signs that you are stuck in the repair quagmire1 point

-

See, understanding is needed, not blind following what they do in videos. If the cannon pinion is loose, the watch will not stop, but the hands will. The seconds hannd will run, but the minute and hour hand will stop. Is it the case? If the spring is weak, then the amplitude will be to lo and timekeeping bad. The spring is not likely to be that weak, but it is possible that it is not wound enough by the autowinding or the outer end slips and thus the spring unwinds. In such case, the power reserve will be to small. Is it the case? The problem can be in calendare itself. To check the watch without calendare, take out the day wheel and if the watch will start to work correctly (without calendare function), this is the case...1 point

-

You are disappointed that the non-running watch you purchased on Ebay is running out of the box.1 point

-

There is also this tool from Bergeon : https://www.cousinsuk.com/product/wheel-hand-roller-remover-bergeon It looks tricky to use.1 point

-

1 point

-

So the hour hand fits onto that pipe on the hour wheel? That must mean that it (the pipe) fits on the outside of the cannon pinion? Is it just above the bottom gear on the cannon pinion and below the bulge? And so the minute hand fits directly on the cannon pinion above the bulge? Now that I know what to look for I can see plainly in The Watch Repair video I linked to above at 29:27 the hour wheel with its pipe being slid onto the cannon pinion with some space above the pipe for the minute hand to go on.1 point

-

Your day revolves around # wondering what the lads on WRT are discussing # When your first thought of the day as you wake up is # where the bloody hell did that spring go ? #1 point

-

1 point

-

Thanks, Ross! Any clues as to what type or brand of watch it was? Thinking it could facilitate in finding the video.1 point

-

1 point

-

I've been asked about the location of this comment before. However it was within one of the Tuesday evening tutorials within the last two months, I think. Each is the display of the disassembly of a watch and last usually 1 1/2 hrs. I've been watching and learning for over 12 month now. Great to learn about disassembly and what to look for. Wonderful explanations on the causes of damage, and good practices for disassembly. There are over 200 videos which cover many specialised aspects. Chrionoglide includes many pocket watch disassembly's. Chronoglied has also started to do information videos abut the watch industry. These are mainly on a Thursday evening. I learn assembly from other videos on YouTube Hope this helps1 point

-

Ah. That I had not done. Lack of experience and too excited to just 'hammer'. I will try the Staking Set again next time. At least I will have my new back up trusty clipper. Take your point about the 5 spoke wheel lifter. I think that would be the correct thing to do and I would love to own one. However, for me, not an option. I am never going to be repairing at a level where it would be cost effective. Services are just for me. Would not like the pressure of doing it for others. Fun and experience is the name of my game. Think you are right in retrospect. Good to dream though1 point

-

After bending a pivot beyond the point of recovery i went and bought the Bergeon tool from Otto Frei. I figure it would pay for itself in replacement wheels or donor movements I wouldn't have to order.1 point

-

something that seemed like such a brilliant idea to allow everything to be adjustable and unfortunately all get adjusted at the same time sometimes. So basically can be a big pain to adjust because you have to move one then move the other one back and basically continuously going back and forth until everything is in the right place if you're lucky.1 point

-

1 point

-

Specially when barrel lid to be rebushed, I make the bush with smaller internal diameter. Then, put the lid in place on the barrel correctly according position mark, if thhere is no position mark - then make one. Next I turn a step on the face of a bar to enter the barrel hole and then fix the barrel on the face of the bar with shellac. Then I turn the internal diameter of the bush to size. This guarantees perfect true barrel rotation on the arbor1 point

-

Often (usually?) step chucks are soft enough to turn. They have a through-hole of a given diameter, chuck on a piece of bar there, then you can retouch the step/s. Make sure there aren't any bumps or burrs on the cylindrical and tapered portion that fit in the lathe first! If the bushing needs to be flush on the inside, I like to cut a small step (can be very small, like 0.2mm deep and bigger on diameter), and make the bushing with a corresponding lip, so when all pressed together it's almost impossible for the bushing to accidentally push out.1 point

-

Welcome to the forum! Sounds like a fun retirement I started out with a soviet watch. It's possible but not necessarily the easiest. Just make sure you start with a watch that already runs. You could also buy two identical watches (or a spare movement) right away to have spare parts ready to go -- an additional movement won't break the bank and probably save you some frustration when the first shock spring disappears into the "kosmos". Cheers and good luck1 point

-

I can see both sides of the argument (sort of) in the debate about lubricating the pallet fork pivot jewels, if we need to do it for the other wheels in the power train to increase amplitude and reduce pivot wear, then why not for the pallet fork also as it is moving the fastest out of all the wheels. On the other hand, I believe the reason for not oiling it is to reduce the likelihood of the oil finding its way to the balance spring - please correct me if I am wrong. If this is the reason, then how do we explain oiling the cap jewels on the balance, they are closer to the balance spring so more likelihood of the oil finding its way to the balance spring from there, and there are 2 of them so twice the risk? I would be genuinely interested in the real reason with some logical reasoning, hopefully it's not just a 'we just do it that way because we always did it that way'1 point

-

In watchmaking no bad thing comes from thought.1 point

-

1 point

-

Hi Waggy. Ihave a custom made desk built from redundant kitchen units with drawers and a cupboard, not pretty but practical. I also made a desk top one with a drawer again from bits to use in the house in winter as the workshop has minimal heat and the fingers suffer. So it is quite possible a lot of members have the skills to do the same, it’s not rocket science by any means. Do you have a picture of your bench so others who may be interested can get an idea. Thanks1 point

-

strange sort of chap, lots of ideas, fingers in pies, bravado and bull tbh lol. I think i had a little dig once when things didn't add up and he never came back , oops sorry about that gramham some things i cant tolerate.1 point

-

I have a height adjustable desk, and it made a world of difference. My wife insisted I get one about 2 years ago as I was constantly complaining about neck ache. Should always listen to the wife! Gone are 99% of all watch related aches and pains. I also found that using a scope for most of my work instead of a loupe or visor also forced me to sit upright with good posture instead of hunching and causing neck/back strain. The desks aren't too much more than an ordinary one, I was surprised at how little the cost difference was +25% (ish) In short I would highly recommend.1 point

-

Hi @urqjolt I've ordered from Perrin and Gesswein and they've been both good so far! Gesswein seems more focused on jewellers but they carry some things that Perrin does not :-) There's also Somal Canada, but I believe that they are more of a business supplier so I haven't tried to set up with them -- I want to know what I'm doing before I make any pretensions of having a 'business' of this! I've also come across Lacy West Supplies though, like Somal, I haven't attempted to use them for anything yet. Beyond that, I'd go with a UK supplier before a USA one, it's just more affordable.1 point

-

Here's one: why bother with the fake $h!t, when you can get the Real Poo right here - https://www.ebay.com/itm/364687541987?mkpid=0&emsid=e11021.m43.l1120&ch=osgood&euid=3cae395826ce4ba1bd75307b02bbba42&bu=45336855555&ut=RU&osub=-1~1&crd=20240119054242&segname=110211 point

-

Russian vintage if you mean from the 60's or 70's leave them alone they are not well made, can be fiddle getting the wheels between plates, threads on the screws are poor. Certainly not recommended by me. There calendar works are a nightmare with an abundance of very fine springs that will not sit in their designated spot and would sooner fly to the moon then stay in the movement.1 point

-

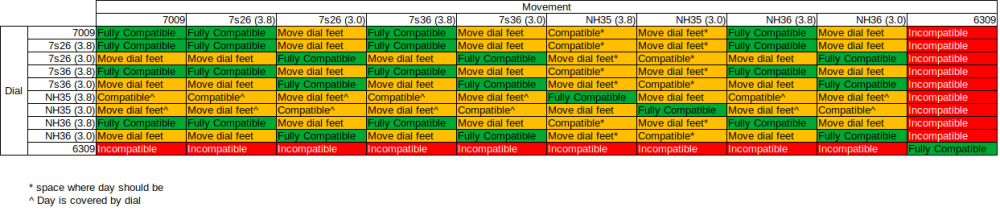

OK so here is what I figured out by switching and swapping my dials and movements at home: 7009, 7Sx6 (3.8 stem location) and NH36 (3.8 stem location) are fully interchangeable So is the NH35, but you would have a blank/cover-up where the day should be depending on which way around 7Sx6 (3.0 stem location) and NH36 (3.0 stem location) are fully interchangeable So is the NH35, but you would have a blank/cover-up where the day should be depending on which way around The 7009, 7Sx6 (3.8 stem location) and NH36 (3.8 stem location) movements can use a 3.0 dial, but the dial feet will need to be moved, and visa versa So is the NH35, but you would have a blank/cover-up where the day should be depending on which way around The 6309 movement and dials are incompatable with all versions of the 7009, 7Sx6, NH36 and NH35 Note, the spacer rings on the above movements are cal. specific but each will accept a dial from another movement type, for example, a 7S26 (3.8) movement with a 7S26 spacer ring (Black) will take; 7009, 7S26 (3.8), 7S36 (3.8), NH36 (3.8) and a NH35 (3.8) dials without any modification (but you would cover up the day ring on a NH35 dial) Clear as mud? Maybe this helps?1 point

-

Cleaned up this thread out of respect for the OP1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)