Leaderboard

Popular Content

Showing content with the highest reputation on 01/27/24 in all areas

-

I have mixed emotions about that one, initial elation, "yey bonus i got a runner" then disappointment " boo now i have nothing to work on " then curiosity " lets fix what ain't broke " lastly anger " grrrr i broke what didnt need fixing ". The trials and tribulations of an amateur watchmaker5 points

-

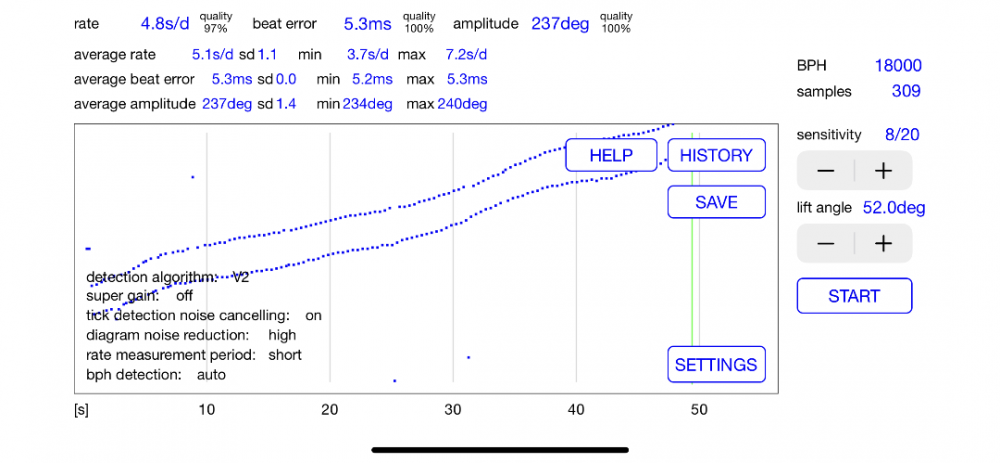

Just back from the Ayr Antiques fair. Spent my January spends. £40. Two watches. Both running. Roamer Sport. Back marked 49 and numbered 9253. Winder. Cracked glass +4s 212 deg 0.8ms 52 deg 18000 Seiko 7S26 0480 F, view thorough back. Time set for AM. Day still changing. +27s 177 deg 1.7ms 52 deg 21600. Will service the Seiko. Happy bunny.4 points

-

You are disappointed that the non-running watch you purchased on Ebay is running out of the box.3 points

-

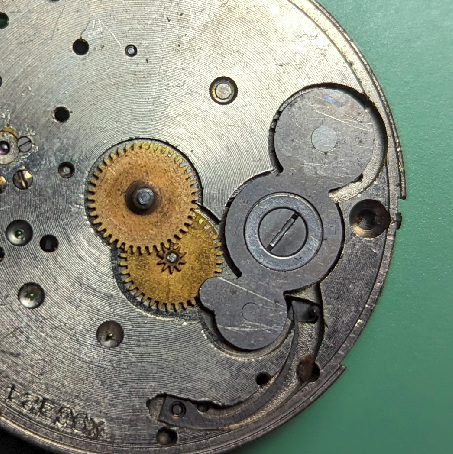

I'm not sure I have any question left here, but want to relate my Captain Ahab story getting this junk Elgin grade 206 7j watch to run. It came to me in a bag of broken watches a relative's acquaintance handed over. The "before" picture hides the fact that all 3 brass wheels were seized together with green corrosion. The case was black, but this I learned right away was just a badly tarnished coin silver. It cleaned up really nicely. It's a type of case I have not encountered before, extending a 6 size movement to more like the a 16 size case with a broad spacer ring. When disassembling the case, I broke the stem sleeve. It was rusted and brittle. I figured this was unimportant and I would eventually replace it. Though I was surprised to find how much those parts sell for. I expected them to be available by the sackful, but instead sellers want $15-$20 for a single one. I kicked this down the road so I could get the movement to run. The movement cleaned up okay, and I was able to remove corrosion enough to reuse all but the 4th wheel. It had 5 or 6 teeth that were eaten away not enough to stop the watch, but to send its timekeeping haywire every 45 seconds. I worked on this over several months, replaced some wheels with spares, tuned the escapement to my current skillset. The movement ran, eventually acceptably well. The balance is out of poise I think, based on a 40sec positional delta. I can deal with that when I have a poising tool. But with the dial and hands installed, it would never keep accurate time. Sometimes it would be good for a day then suddenly lose ten minutes or lose 6 hours. It felt like a cannon pinion problem. I got the tools to tighten the cannon pinion. This didn't help at all. I replaced the center wheel because its arbor was kind of worn. That did not help either. I replaced the cannon pinion entirely with a donor's. It had a positive snap on install and good feel to handsetting but still no change in behavior. I thought maybe the hour wheel was riding up out of mesh with the minute wheel so I tried manipulating and eventually stacking dial washers, no change. I learned how to close the holes in the hands for a firmer fit on the hour wheel & cannon pinion. I was going to give up on this one when I found someone selling a bag full of stem sleeves for a reasonable amount. I bought them and installed one that fit, planning to sell this watch on and note its fault for someone else to figure out. But after installing that stem sleeve and recasing it, the watch is now keeping time all week without any issues in the motion works. Why? Because the keyless works on this type of watch are inverted. The stem must be pushed in and secured by its detent with a stem sleeve to engage the winding mode. Otherwise, its default position under spring tension is to engage the hand setting wheels (in the photo above, that spring is not engaged but that's not the problem). All the while I was trying to get the hands to keep time, it was running uncased and the cannon pinion was therefore driving all the handsetting wheels. It can't do that without slipping occasionally and that was its issue all along. It still isn't perfect, I need to troubleshoot a problem with the spring tension in the keyless works while it actually is engaged in winding mode. But now it's all together, and will make a nice little desk clock or something once I clean up the dial a bit to hide those cracks. And the next time I work on an American stem wind/stem set watch I will make sure it is cased when I test it out with dial & hands.2 points

-

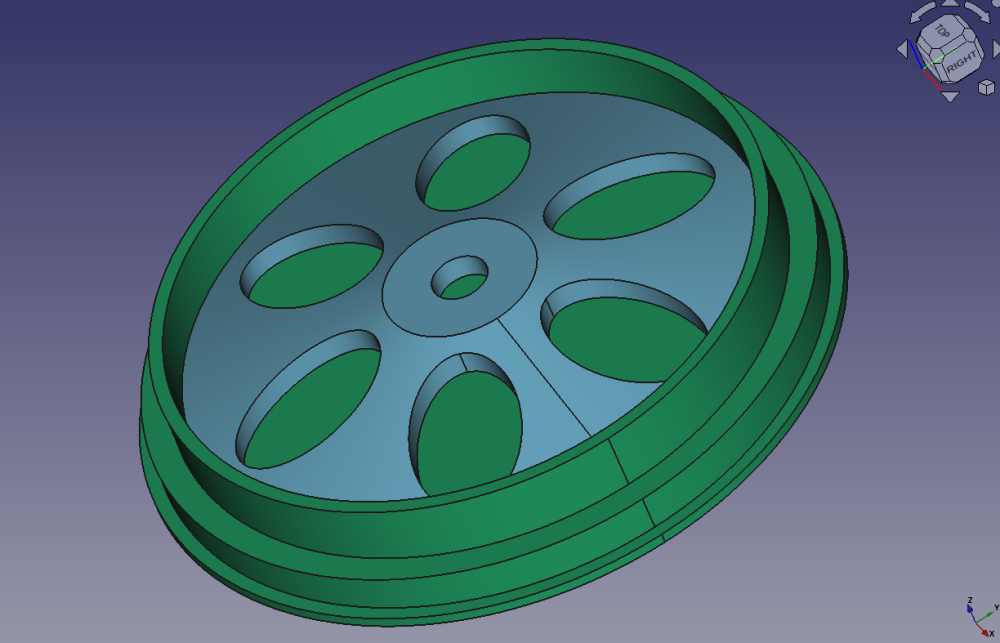

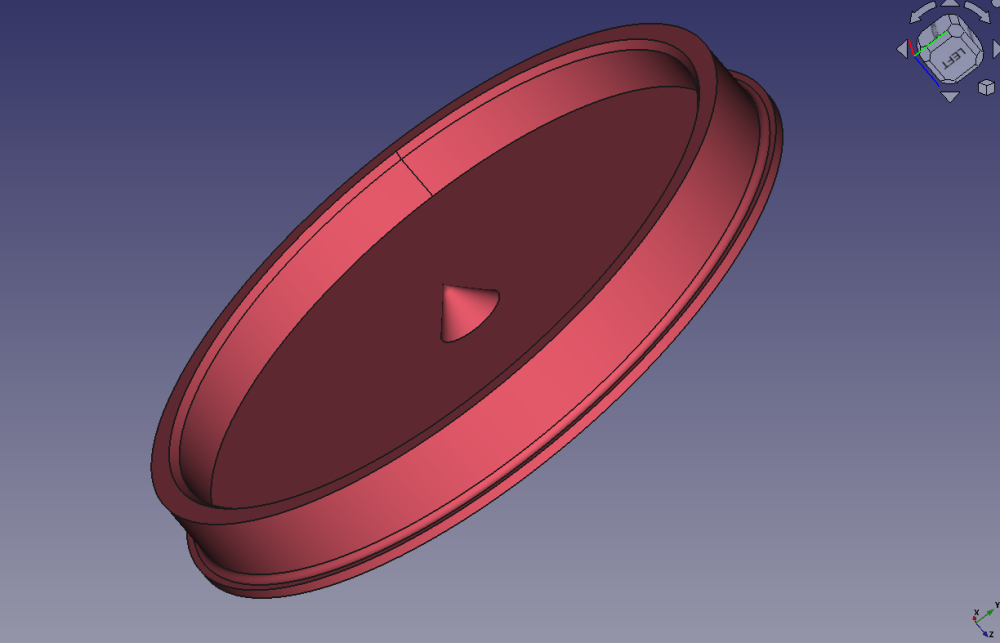

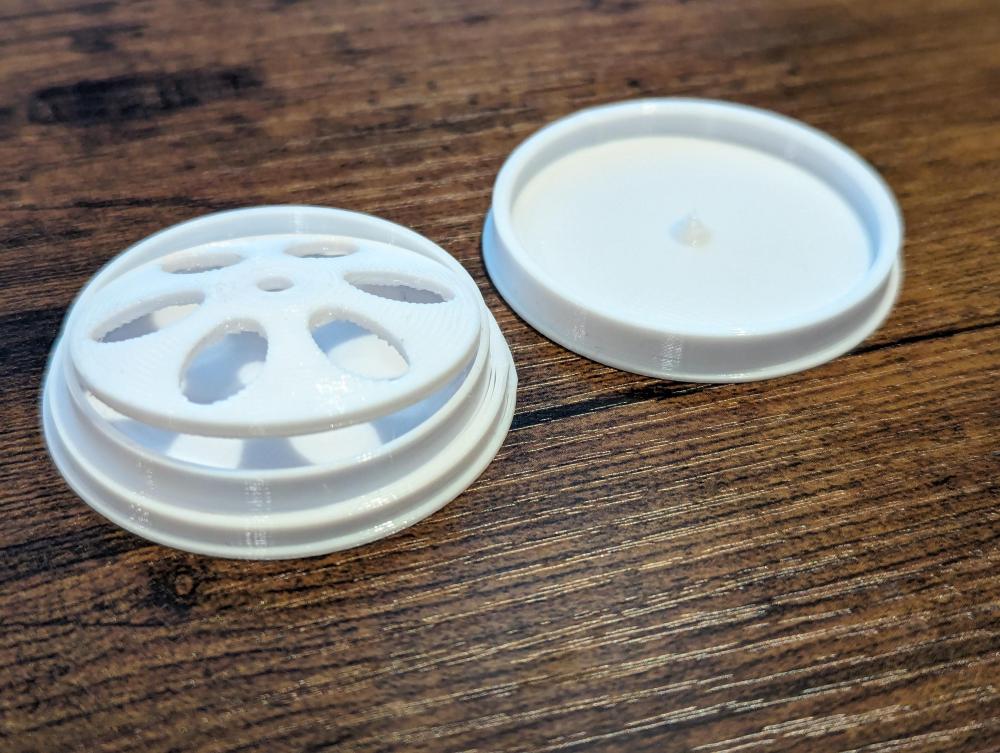

Hi there, been working on a few projects today, and the below is one of them. I have modelled the watch crystal protector trays and printed a prototype (see below picture in white). I printed all 3 parts in white PETG just to check fit and form. My plan is to print the base in white PETG (same as the prototype) but the lid in clear PETG. The clear PETG will not be crystal clear, but should let me get a good idea of what's inside without having to open the lid. For the 'spring' (blue mesh thing in picture below) I plan to use TPU which should give some springyness.. Once I have the real ones printed, I'll post pictured and the CAD files. Base and 'spring' Lid: Prototype:2 points

-

I had a 1960's EB8800 skindiver showing up in the mail with a caseback I expected would need the flat tips to open. It's a dive watch; obviously a screw down caseback right? With it in hand, seeing these soft bevels on the flat sides raised some concerns. There is absolutely no way to grip them, and I can get no purchase from a rubber ball. And there's no slot for a case knife. Why would there be? This is a dive watch with a screw down caseback. So I superglued a 16mm socket onto it and secured it in a vise. The glue held but it took a lot of rotational force to get it to turn. 4 full turns and it did not unthread and the gap against the case only widened a hair. On the 5th it popped off because this is indeed a pressed on caseback that just looks like it should be screwed down. Another lesson learned. But as soon as it opened, the movement sprang alive and ran on time so it should be an easy & rewarding restoration as soon as I buy some acetone to dissolve that glue.2 points

-

2 points

-

Hi John, I am late to this topic but hope your journey is going well. I have the same 8mm Boley lathe as you and refurbished it. In 2021 I took Marks courses and found them very worthwhile and perfect for my learning plan. I had read Henry Fried's book, and seeing Mark demonstrate the proper steps with clearly articulated instructions gave me a better understanding. In 2022 I enrolled in the BHI Distance Learning Course (DLC). About a year later I added the tutor option which motivated me to complete the work faster, and finished the level 3 material. It was worthwhile in the feedback received on both the theory and practical pieces I submitted for evaluation to help find where I was weak on knowledge or technique and need to circle back. Previously posts mentioned concerns about a lack of information about mechanical watches in the DLC, but that was not my experience (perhaps I recieved a newer course format). Sections 11 and 12 were very focused on the details of servicing mechanical watches. The clock and quartz material was extensive and very useful even though I too was more interested in mechanical watch movements. The intermediate BHI Level 4 DLC material covers topics like Calendar complications along with Automatic and Chronograph watch movements. I don't have a local mentor and can't take time to attend a two year full-time watchmaking course, which is why the BHI DLC appealed to me. I am also taking classes at AWCI a few weeks each year. The combination of information from BHI, AWCI, Books, help from people on forums like this, and online videos have shown me a variety of things to consider and approaches for repairs. BHI may present information on a particular topic differently from AWCI which helps, since one format or the other makes more sense to me at different times. Having the accreditation from BHI and AWCI may or may not open doors for me professionally, but I feel I am working with a broader perspective and striving for higher standards than I may have otherwise. And I totally agree with others that spending bench time learning to be a practitioner by turning knowledge into wisdom is the path we must all go if we want to improve. Good luck with your training. Terry2 points

-

Always best to use a piece of brass wire to fit into the cannon pinion to stop it from being crushed. Put the wire on a hardwood block with a groove scored into it with the edge of a file and file the brass wire with a slight taper until it fits snuggly into the cannon pinion. The same wood block can be used to polish arbors with a lolly stick and some Autosol then Brasso like in the pic2 points

-

Hey Joe, sorry I forgot all about this, I've been reading a lot of books just lately I'll try find it tomorrow when i get home.1 point

-

1 point

-

Hi all, Just got an old Favre Leuba and the caseback was well and truly stuck. Usually in this situation I would bring it to my mates shop and use his bench opener but as this Favre-Leuba has flats they usually don't work as well. Anyway, another solution is to glue a nut on the caseback and use a wrench on that. Well the superglue is pretty much a necessity for me and there are usually a few tubes in the freezer ...result! After 10minutes for the glue to set, a big adjustable wrench between the lugs and a 14mm spanner in the nut/caseback and it spun right off!. I must say the caseback did a good job keeping the movement clean! This trick has helped me out a few times. If you plan to do this just make sure you keep the superglue away from the caseback/case joint. If any superglue wicks into the joint then things get difficult! Anilv1 point

-

I've been a lurker in these forums for a few years but for whatever reason never got around to introducing myself, so hello! First, I want to thank @Mark, @clockboy, and @oldhippy for making this place such an incredible resource for those of us interested in watchmaking. This community has saved me countless hours, dollars, and frustration during my self-education in this great craft. Like many newbies, I dove in too deep, too fast, and had it not been for the life-preserving wisdom tossed out in these forums, I probably would have given up a long time ago. In the not-too-distant past, work and family absorbed enough time that watchmaking only happened intermittently, but with the kids grown up and my work life on a glide path toward retirement, I'm looking forward to spending more time absorbing as much as I can and getting my skills to whatever point possible before Father Time arrives with the inevitable. Thanks to all of you who have no idea how helpful you've been to a fellow watch enthusiast in New England.1 point

-

See, understanding is needed, not blind following what they do in videos. If the cannon pinion is loose, the watch will not stop, but the hands will. The seconds hannd will run, but the minute and hour hand will stop. Is it the case? If the spring is weak, then the amplitude will be to lo and timekeeping bad. The spring is not likely to be that weak, but it is possible that it is not wound enough by the autowinding or the outer end slips and thus the spring unwinds. In such case, the power reserve will be to small. Is it the case? The problem can be in calendare itself. To check the watch without calendare, take out the day wheel and if the watch will start to work correctly (without calendare function), this is the case...1 point

-

Your day revolves around # wondering what the lads on WRT are discussing # When your first thought of the day as you wake up is # where the bloody hell did that spring go ? #1 point

-

why would you think lubricating the wheels of the watch would increase amplitude? lubrication has all sorts of interesting properties some of them good some of them bad. we will also note that I'm not a science major so I'm not use proper technical terms necessarily. Simplistically lubrication can have a dampening effect. So if you have something like a pallet fork it has to move really really fast and not necessarily in a circle just a small angle what would happen if you dampened that? The Swiss consider it a component that's never going to wear out because it does not revolve around in circles. The loading on the pivot is interesting and it does have to move superfast. So if you put lubrication on your pivot the dampening effect will cause a loss of amplitude. This is why the Swiss recommend never ever doing it. then we have Seiko who doesn't publish amplitudes except in the 4006 document and basically it suggests as long as the watch has the balance moving that's good enough for them in other words amplitude can suck and that's great. In the later documents they do have some concern about timekeeping but no mention of amplitude is ever mentioned ever again. Then there lubricating the pivots which upsets anyone that's a Swiss trained watchmaker because that goes against everything you ever taught and they are Seiko is doing it. Maybe they're just doing it to annoy the watchmakers? it depends upon the viscosity of the oil and especially the days of organic oils that would get sticky with time then non-synthetic oils would be even bigger problem which is why they like nice clean pivots. if we skip over the pallet fork aspect of this isn't this an odd statement? a watch is a rather interesting mechanical item. typically a mechanical devices were trying to reduce the speed of something and increase the torque to run our machinery. But I'll watch is trying to speed up the gear train and they're not really concerned about torque at all certain degree they want speed. Then on this gear train that you're trying to speed up you going to put lubrication that has a dampening effect. Now long term not lubricating things especially metal on metal things will have dire consequences. But I'm not looking at long-term things I'm looking at the amusements of horological lubrication and it doesn't always do what you think it does. I never oil the pivots of anything bigger small. But clock people may lubricate stuff especially of its metal on metal bearings. I've even heard suggestions that they will oil the roller jewel which often times is a brass pin as if they don't the metal on metal friction is too great.1 point

-

Once you have done a few you become much quicker. But you really need an accurate bench micrometer, digital calipers are a bit fiddly and not super accurate, they can vary from the tips of the caliper to the head of them. Some stems are also very close, staffs even more so, there can be differences of 10 - 20 microns between a particular dimension. But its certainly doable with the right tools. Not sure on the scope of different stems, i think about 3000 ronda upto 1965 the reference numbers go higher but there missing numbers that are not used. Staffs i would guess at double that. Plus all the old ones that aren't even listed.1 point

-

I've been the lectures where people talk about what goes into servicing a Rolex for instance. Your procedure is similar to that where they'll look at it on the timing machine although Rolex gets a little more obsessed with this. in other words Rolex is looking for fully wound up and of course as a reminder fully wound up is not fully wound up you have to wait a little bit like up to an hour 15 minutes after you fully wind up it has to settle for a little bit. Then 24 hours later they compare the numbers. Then it typically goes on auto winder for several days where it records the time and they do an average over the several days. Then comes off the winder and they let it run until it stops just a verified actually run the correct number of hours. Often times people at auto winders think everything is wonderful but the problem is when it's kept fully wound up that's different than if somebody takes it off like overnight where maybe it stops could it won't run overnight for instance. Oh other things to do looking at the watch. For instance I can't remember the light source but with a very very bright light much brighter than you normally use look at the dial look at the crystal look at the hands you're looking for specks of dust. I can't quite remember how many specks of dust per cubic inch I'm joking about that part but there was a criteria of how much was acceptable and what was not acceptable and because you using a really bright light source makes it easier to see problems where you may casually not see the fingerprint or speck of dust or something oh to add your knowledge of things cousins is interesting what happens if we search for the word working for instance? https://www.cousinsuk.com/document/search?SearchString=working acquired it in the days when Swatch group let cousins have an account and they got a few of them there are way more than this by the way. You may find the very last one of interest doesn't cover everything but gives you a few clues about stuff oh and one of things express if you doing other people's watches it be really nice to keep a journal a logbook or something and keep your timing results. Like if you hand the customer receipt of I done all of this keep a copy for yourself. I don't do that I'm lazy at work we do keep notes in the computer but we don't keep timing results etc. so I get a damn watch came back but the timing issue and fingerprints where they shouldn't be because it's a pocket watch were somebody could unscrew the back for instance. These are the times where I keep thinking it be nice when I run a timing cycle at the end is to paste it into the record book or something where when it left here it was doing this I don't understand why it's now looking like crap plus a good picture the movement would've been nice. Oh and if your incoming customer watches always nice to get pictures of whatever comes in just in case somewhere along the line you discover something damaged or broken you can look at the picture to see if you did it or if it came in that way just didn't notice. Also just nice for data fine watches of the end up with lots of them the software we use they photograph everything sword out sometime somebody just photographs the pocket watch case and I don't get the see the movement or somebody writes up a description of the case but not the movement and I'm not sure which watches which was really good the document everything you have to avoid unpleasant confusions that will eventually pop up and be quite annoying. Also if you have an annoying customer make a note of that because they'll be back in the future to bother you again. Especially if it's a pocket watch a take the back off and play with it and it has some of the customers really do like to play with their watches.1 point

-

Thank you neven, I agree with ALL you said. A problem with putting the end stone upside down is that lubricants migrate from top of the dome easier, but lets be happy and hopeful that epilame treatment helps keep the lubricant where put. Another problem is the top of the dome might come in full contact with jewel hole leaving zero chance for pivot's axial play thus pivots jump out of the hole in the event of a shock, so I stopped ( long ago) recommending this approach to members as a permanant solution . I am pretty sure that OP ( Original Poster ) mzinski, will come back with news of success. but is it really a success? I think not. By thicker stone I was thinking deeper sink of the end stone's flat side, into the setting , not higher dome. This being a high end watch, I go with the best repair or not go at all. Rgds1 point

-

I recently did one and the comments are on watch of today: I think the secret is to glue the feet on the back where they poke through the dial, not the marker to the front of the dial. If the feet are already loose I would gently push the marker back in place and then flip over the dial and add a spot of glue to the feet to stop them pulling out again. I found using super glue gel for this much better than regular superglue (see details in the thread in the link above), but the 2 part epoxy would also work. IMPORTANT: There was a discussion further down on the same thread about using super glue and I advise you read that also, but I think the bottom line is that if you leave it to fully cure (>24 hours) before re-installing you are OK.1 point

-

See, the thicker endstone will lead to bigger force in the shock device spring, as it will be more bent than normally. The thinner - vice versa - will lead to smaller force, and even in some cases to no force at all and free play, which is not acceptable. But, if the spring apyes some force and the setting is pressed to the bottom of the shock device, then the thickness of the end stone will make no difference on the axial free play of the balance. Well, this is true if the diameter of the stone is correct - it must be not bigger than the 'nest' in the setting so it will go in, and it must be not to small so not to sink and touch the hole stone. I guess the problem really is replaced setting with one that is similar, but higher. Putting the enstone upside down will make free play smaller, as the rounded surface of the stone will go closer to the hole stone. May be Topic starter will be able to solve His problem this way. This is not so good probably in terms of oil retention, but yet will be some decision if it will ensure normal axial free play and amplitude.1 point

-

From your analysis, it sounds like you are on the right track, looking to replace the thicker of the two jewel settings. That will reduce your overall endshake and prevent the pivot taper entering the hole. I suspect that will solve your problem, and you are unlikely to need to dismantle the balance. If you do need to remove the hairspring, the collet levers off like a conventional one: https://www.watchrepairtalk.com/topic/18380-does-hairspring-on-eta-2789-just-lever-off/ What movement is it?1 point

-

1 point

-

Sorry for the late reply I've been unwell ect but on the way to full fitness. Thank you for your kind words it's much appreciated I will take your advice and go through your post's. I've been slowly building up my tools and watching plenty of YouTube video's. I dare say I will be asking for help during this journey and like you said this is definitely the place to ask regarding guidance and support. Kind regards William1 point

-

William. Hello and Welcome. Been where you are. Novice extraordinaire. If it can help. Have a look at my posts which I did at 6 month, 12 month 18 month and 2 years. I have enjoyed every moment of learning. Even the 'pings'. I'll let you research that . This is the place to be for learning and guidance. Best wishes. Ross1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

1 point

-

1 point

-

Not a question, but something I've learned that may be useful to others. After cleaning an Omega 1012 the amplitude was low and all over the place - fluctuating between 220 and 240 deg. I couldn't get it any higher. The jewels, gear train, balance all look good. It took me a long time to identify the problem - I wasn't checking the gear train with the sweep seconds pinion fitted. As soon as I fitted that, the problem was clear - too much tension on the friction spring (the spring pushes down on the pinion). I knew the wrong pressure from the spring would make a difference, but I didn't realise how much. Now the amplitude is 280-290 deg. Another lesson learnt1 point

-

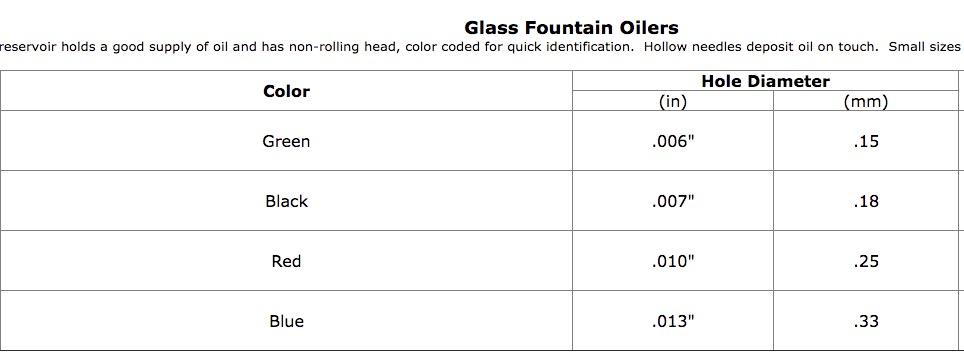

Thank you for that helpful information that lead me to the NWCC Forum where I found this: "To fill these oilers you need a small rubber hose that fits over the class tube. Place the hose on the end where the needle is,then place the other end in your oil bottle and suck on the hose. This will draw the oil into the glass tube. Don't fill the tube completely full. A small amount will last a long time. You can store the oiler laying flat in a dark place like a drawer of your watch bench." Not sure how you "place the hose where the needle is...then place the other end in the oil bottle then suck on the hose" I take this to mean suck on the glass tube to draw the oil into the tube? Agree? Edit: Found this on WUS: "In the past you could get glass "fountain" oilers. These are a blown glass tube with a very fine steel capillary in the end. They are about three inches long, and are filled by putting the tip down in an oil bottle and sucking on the open end of the tube. I have used these type oilers, but much prefer the control offered by a set of good dip oilers. "1 point

.thumb.jpg.29126d93c71a2b5ffd0c4ff93a8a13d5.jpg)