Leaderboard

Popular Content

Showing content with the highest reputation on 01/28/24 in all areas

-

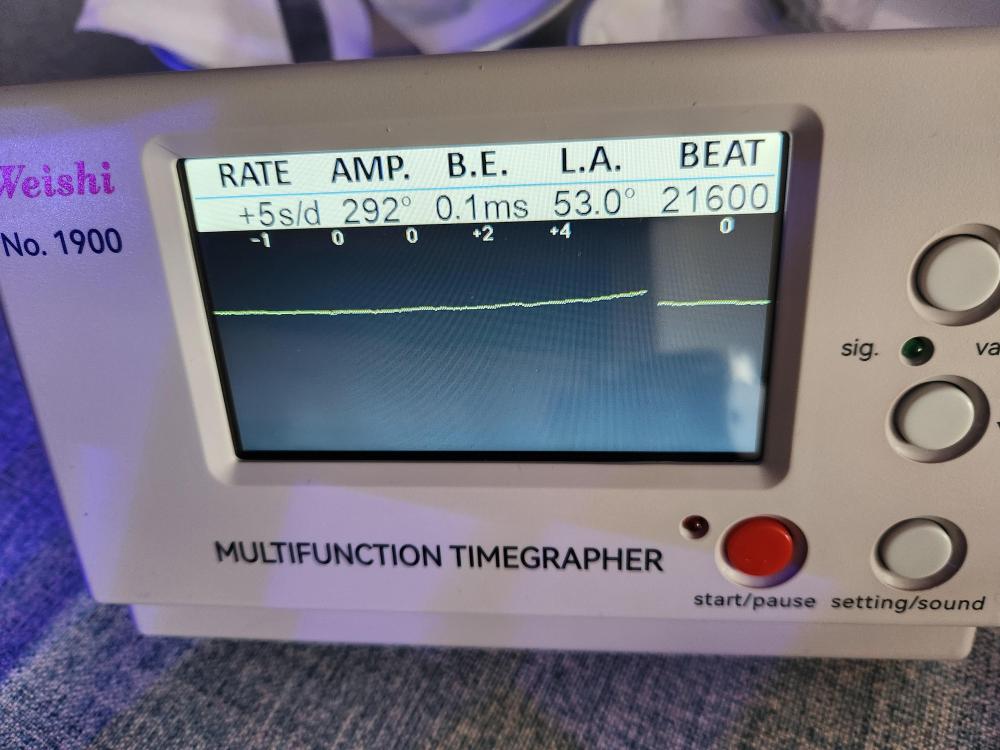

Hi all, I've had family issues which have settled slightly enabling me to get back to this. As per excellent instructions offered by people here, I've purchased some working movements (mostly 2824 chinese clones) but first I got to grips with my Weishi timegrapher. I aqcuired recently a Seiko 6105 copy (as worn by Captain Willard in Apocalypse Now) and it uses a NH35A movement. As it was recently purchased, I didn't feel the need to service it, but do some regulation It started out as 2.5 beat error and was presently surprised when I accidentally got the results shown in photo. This watch is sold by Steeldive and I don't try to pass it off as original in any shape or form, just enjoy wearing it. It's unusually comfortable to wear, I think because the case is chamfered to a rounded form on the edges. I really didn't expect to get the BE down to 0.1. Maybe it'll stray, but not bad for a start! My son is about to go to California on a post-doc appointment in UC Davis near Sacramento and I'd been promising him to regulate his watch pictured with its 7S36 movement. Whilst I didn't get the results on my Steeldive, I did manage to get the BE down to about 0.4 which will be good enough for him. This was his first mechanical watch, so hoping he moves on in the same vein if he ever comes back to UK.4 points

-

actually I already did do the experiment. Which is why was pointing out that missing the lubrication from one pivot would really make much different at all.. Then currently I've just finished the HP 1300 on the entire geartrain experiment. Now I need to scour my bench for another 6497 because I want to do two separate watches at the same time and different lubrication's on them just because. Then someday maybe I'll start a discussion on lubrication experiments has this isn't really the discussion for it right now.4 points

-

Hi There, I'm totally new to the world of watch making. I've been a builder / fixer my whole life. I grew up with a grandfather that owned an auto shop, one uncle was a plumber the other was an electrician and my best friends dad ran a construction company. I worked summers and holidays with them all and have enjoyed anything mechanical ever since. Professionally I am in the Software industry so I'm always looking for ways to work with my hands off hours. Like most people I utilize YouTube a lot when needing to fix something new. I ended up stumbling onto Marshall's Wristwatch Revival channel and was instantly hooked. I have purchased an ST36 movement and some basic tools to start messing around. Would love to get to the point where I felt comfortable servicing my own watch. I have a Rolex 16610 Submariner Date which I love. I've been into watches forever. Always fascinated by the mechanics and complications. I never imagined that I could be able to service one on my own but thats my current goal. I've had my ST36 apart fully and reassembled a few times (minus the main spring barrel as I dont have a winder yet) and I already have some questions. I'll be sure to find the right forum and post them soon. Thanks!3 points

-

3 points

-

3 points

-

in addition to the photos the tool photo of the crystal your trying to work with would be also helpful3 points

-

I have cheap ebay tweezers from my first set. I do two things often. Demagnetise and keep them 'dressed', sharpened. The demagnetiser cost me £10. A honing stone cost me £3. that's it. Press the red button on the magnetiser, Demagnetise the tweezers by lifting them off the base ad going up. Release the red button. Repeat twice. Dressing. Using my magnifying glasses to confirm what I think I see. Shape and form the points. Dress all four edges and then gently removes burs. Job done. I use a pair of curved brass tweezers when working on an expensive watch that might show scratches. These were a massive £3 also. And, I do keep them dressed. Would I like high end tools. Of course, but to what end would it make my work better and this stage of my learning curve I ask myself? My standards are getting better by practice, not by high end tools. This is a great hobby3 points

-

I thought it might be useful to share this reference of watchmaking threads. It includes the modern threads you would get from Bergeon/Wiru/Horotec sets as well as from the old mysterious thread plates labeled Martin Fils/Perrelet/Latard/Bourgeaux All values in mm. 0.30x0.075 no.1 Bergeon tap, drill 0.24mm 0.35x0.075 no.2 Bergeon tap, drill 0.28mm 0.40x0.100 no.3 Bergeon tap, drill 0.32mm; 0.45x0.100 no.4 Bergeon tap, drill 0.37mm; 0.50x0.125 no.5 Bergeon tap, drill 0.40mm; 0.55x0.125 no.6 Bergeon tap, drill 0.45mm; 0.60x0.150 no.7 Bergeon tap, drill 0.48mm; 0.65x0.150 no.8 Bergeon tap, drill 0.53mm; 0.70x0.175 no.9 Bergeon tap, drill 0.56mm; 0.75x0.175 no.10 Bergeon tap, drill 0.61mm; 0.80x0.200 no.11 Bergeon tap, drill 0.64mm; 0.85x0.200 no.12 Bergeon tap, drill 0.69mm; 0.90x0.225 no.13 Bergeon tap, drill 0.72mm; 0.95x0.225 no.14 Bergeon tap, drill 0.77mm; 1.00x0.250 no.15 Bergeon tap, drill 0.80mm; 1.05x0.250 no.16 Bergeon tap, drill 0.85mm; 1.10x0.250 no.17 Bergeon tap, drill 0.90mm; 1.20x0.250 no.18 Bergeon tap, drill 1.00mm; 1.30x0.300 no.19 Bergeon tap, drill 1.06mm; 1.40x0.300 no.20 Bergeon tap, drill 1.16mm; 1.50x0.350 no.21 Bergeon tap, drill 1.26mm 1.60x0.350 no.22 Bergeon tap, drill 1.32mm; 1.70x0.350 no.23 Bergeon tap, drill 1.42mm; 1.80x0.350 no.24 Bergeon tap, drill 1.52mm; 2.00x0.400 no.25 Bergeon tap, drill 1.68mm; 2.2x0.45 2.3x0.40 in Wiru No.1 tap/die set, 2.6x0.45 in Wiru No.1 tap/die set, 3.0x0.50 in Wiru No.1 tap/die set, 0.213x0.086 Bourgeaux thread no.24, on Martin Fils/Perrelet et Martin 'B' 0.267x0.088 Bourgeaux thread no.23, on Martin Fils/Perrelet et Martin 'B' 0.291x0.091 Bourgeaux thread no.22, on Martin Fils/Perrelet et Martin 'B' 0.312x0.093 Bourgeaux thread no.21, on Martin Fils/Perrelet et Martin 'B' 0.344x0.094 Bourgeaux thread no.20, on Martin Fils/Perrelet et Martin 'B' 0.376x0.096 Bourgeaux thread no.19, on Martin Fils/Perrelet et Martin 'B' 0.414x0.101 Bourgeaux thread no.18, on Martin Fils/Perrelet et Martin 'B' 0.452x0.111 Bourgeaux thread no.17, on Martin Fils/Perrelet et Martin 'B' 0.496x0.120 Bourgeaux thread no.16, on Martin Fils/Perrelet et Martin 'B' 0.563x0.133 Bourgeaux thread no.15, on Martin Fils/Perrelet et Martin 'B' 0.640x0.150 Bourgeaux thread no.14, on Martin Fils/Perrelet et Martin 'B' 0.713x0.159 Bourgeaux thread no.13, on Martin Fils/Perrelet et Martin 'B' 0.782x0.167 Bourgeaux thread no.12, on Martin Fils/Perrelet et Martin 'B' 0.858x0.181 Bourgeaux thread no.11, on Martin Fils/Perrelet et Martin 'B' 0.936x0.200 Bourgeaux thread no.10, on Martin Fils/Perrelet et Martin 'B' 1.008x0.219 Bourgeaux thread no.9, on Martin Fils/Perrelet et Martin 'B' 1.097x0.239 Bourgeaux thread no.8, on Martin Fils/Perrelet et Martin 'B' 1.203x0.261 Bourgeaux thread no.7, on Martin Fils/Perrelet et Martin 'B' 1.299x0.271 Bourgeaux thread no.6, on Martin Fils/Perrelet et Martin 'B' 1.404x0.274 Bourgeaux thread no.5, on Martin Fils/Perrelet et Martin 'B' 1.523x0.289 Bourgeaux thread no.4, on Martin Fils/Perrelet et Martin 'B' 1.641x0.298 Bourgeaux thread no.3, on Martin Fils/Perrelet et Martin 'B' 1.797x0.320 Bourgeaux thread no.2, on Martin Fils/Perrelet et Martin 'B' 1.984x0.359 Bourgeaux thread no.1, on Martin Fils/Perrelet et Martin 'B' 2.169x0.388 Bourgeaux thread no.0, on Martin Fils/Perrelet et Martin 'B' 2.363x0.420 Bourgeaux thread no.00, on Martin Fils/Perrelet et Martin 'B' 0.367x0.087 Latard thread no.20, on Martin Fils/Perrelet et Martin 'L' 0.395x0.094 Latard thread no.19, on Martin Fils/Perrelet et Martin 'L' 0.432x0.102 Latard thread no.18, on Martin Fils/Perrelet et Martin 'L' 0.479x0.109 Latard thread no.17, on Martin Fils/Perrelet et Martin 'L' 0.529x0.115 Latard thread no.16, on Martin Fils/Perrelet et Martin 'L' 0.591x0.126 Latard thread no.15, on Martin Fils/Perrelet et Martin 'L' 0.665x0.138 Latard thread no.14, on Martin Fils/Perrelet et Martin 'L' 0.736x0.149 Latard thread no.13, on Martin Fils/Perrelet et Martin 'L' 0.798x0.164 Latard thread no.12, on Martin Fils/Perrelet et Martin 'L' 0.870x0.180 Latard thread no.11, on Martin Fils/Perrelet et Martin 'L' 0.956x0.196 Latard thread no.10, on Martin Fils/Perrelet et Martin 'L' 1.036x0.209 Latard thread no.9, on Martin Fils/Perrelet et Martin 'L' 1.106x0.219 Latard thread no.8, on Martin Fils/Perrelet et Martin 'L' 1.181x0.233 Latard thread no.7, on Martin Fils/Perrelet et Martin 'L' 1.269x0.246 Latard thread no.6, on Martin Fils/Perrelet et Martin 'L' 1.363x0.262 Latard thread no.5, on Martin Fils/Perrelet et Martin 'L' 1.464x0.284 Latard thread no.4, on Martin Fils/Perrelet et Martin 'L' 1.568x0.304 Latard thread no.3, on Martin Fils/Perrelet et Martin 'L' 1.703x0.325 Latard thread no.2, on Martin Fils/Perrelet et Martin 'L' 1.869x0.342 Latard thread no.1, on Martin Fils/Perrelet et Martin 'L' 2.029x0.352 Latard thread no.0, on Martin Fils/Perrelet et Martin 'L' I extracted these from https://www.improwis.com/tables/threads2.webt2 points

-

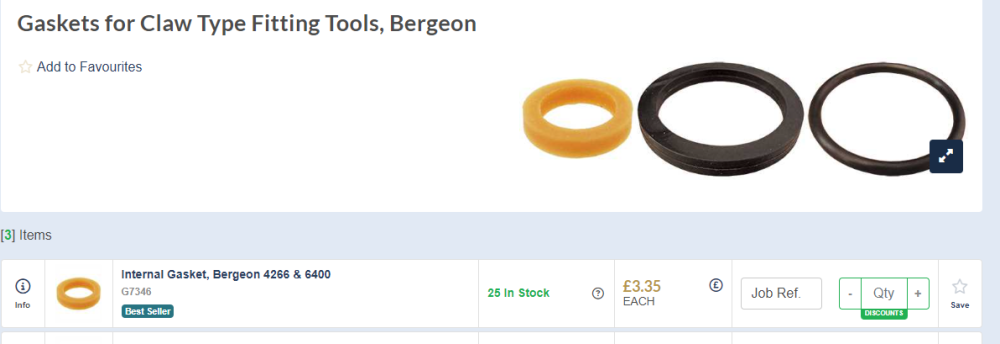

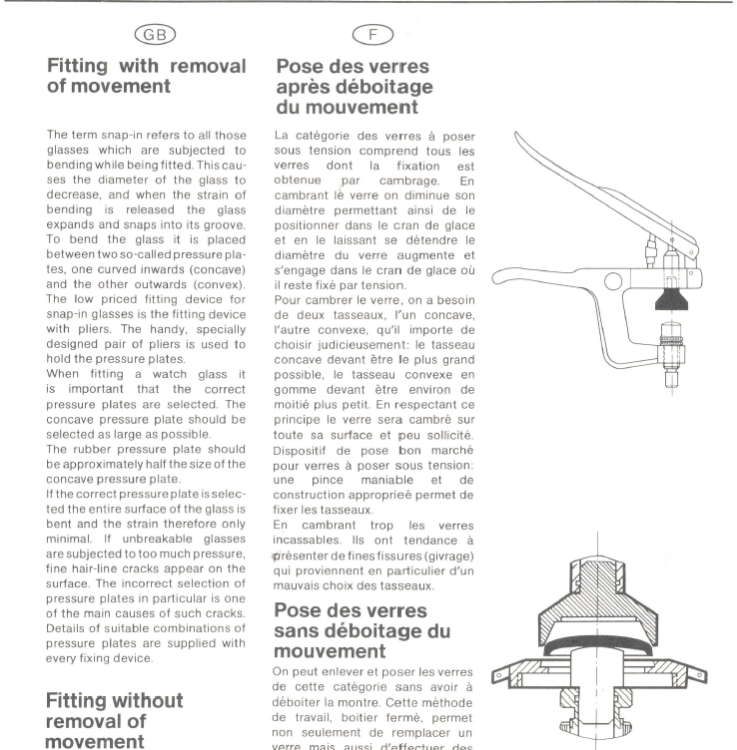

I use the crystal lift to fit all my acrylic glasses. You need to use the base to make sure you grip the acrylic in the right place, to avoid damage. I would try fitting with a press tool as shown in the Sternkreuz catalogue. I could use my cheap caseback press for the top plate, but I don't see anywhere to buy the lower convex rubbers pressure plates. It says it should be about half the size of the upper plate, but Cousins only show convex sizes of 38mm +.2 points

-

Birbdad I know you said you have looked. I had the same problem with one of my 4006. Jewel. Yes it's there. No it's not. Bummer. Took me 3 minutes to find it. I had spent £3.75 on a little UV torch. Inserted the batteries. Switched it on. Turned off the room lights. There it was, lying on the table, next to the bottom of the computer. How did it get there. Who cares? Found it. Jewels shine and glow in UV. One of the good bits of advice from members. Saved me a lot of time and money. Hope this helps.2 points

-

Are you certain you are using the tool in the right circumstances? Many (most?) crystals are not shaped appropriately and should just be pushed out manually for removal and inserted using a press tool rather than a lift. Front-loading movements that specifically require a lift will use crystals that have sufficient flat surface on the side of the dome to accomodate the lift. Another point is that if you are using a lift for insertion, the lift must engage part way up the side of the crystal rather than flush with the base. The lifts are initially sold with shims or jigs in order to accomplish this, but those may not be included when you purchase a used lift.2 points

-

2 points

-

Hello. Welcome to the great forum. All you will get from the members is guidance and information. "Would love to get to the point where I felt comfortable servicing my own watch. I have a Rolex 16610 Submariner Date which I love". If you love it, don't touch it. Set yourself a date to learn enough to do a service. I have been learning for 2 years now. Could I do your Submariner. Yes? That is my skillset at present. However, I set myself 2 years for my own Breitling. It has flown by. Can I do it now? Probably. Will I do it now? No. It's a chronograph and I'm still learning. This hobby is flipping brilliant. I feel that I have some way to go. Take your time. Enjoy yourself.2 points

-

Thank you I was confused a bit as it as this dust cover over the movement and I couldn't see how to take it off so I thought it had to come off dial side.. I now have taken the cover of with a bit of persuasion and it's all good. Thank you Richard and others much appreciated William2 points

-

https://www.spareparts-watches.com/product/2302839/cattin-66-mortima-66 ...they claim to have one...Jules Borel website claims to have one, too. Lucky dog...oh, you want one cheap/free?2 points

-

Wow I didn't realize it's aligned wrong. It's obvious now that you mentioned.1 point

-

I would top up the oil each time you use it, turn or run the headstock so the oil is pulled into the bearings. Dont use 3 in 1 oil , bike chain yes , precision bearings no.1 point

-

I agree with Malocchio, also the open part at the 12 o'clock should probably be at the 3 o'clock, you have a marker laying on the date window...1 point

-

Thanks, guys. We ended up replacing the balance staff. Pocket watch is now running perfectly.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Why buy a drill press if contemplating the purchase of a mill , I have Warco’s smallest mill WM12 and I have added DRO to it and I am happy with it and it’s cast iron not cast aluminium, I even use it for bushing and depthing for that matter but I only do clocks but I can make tools as well, recently made a T rest base for my Pultra & made the upright on the Myford. Dell1 point

-

Yeah I did, removed it again to make sure this was in place properly. I noticed that one side had a little material taken away (I don't know how you call this in English) so the screw sits flat so I am also quite sure that I got it right. Thanks, I'll take a look this evening. Don't know if I'll be able to see it clearly (max. magnification I have is 5x) but I'll do my best1 point

-

Depends what you are looking for. Obviously the dial shouldn't look like it was painted by someone under the influence of fungal intoxicants, and the case shouldn't look polished to death. These two from my collection are most probably "after-market" dials, but the movements were perfectly serviceable. They may end up as donors if I find something interesting that needs parts. They are pretty easy to service, and as I mentioned before, finding donor movements and parts is pretty easy, since they were produced in large numbers for many years. Most genuine 17 jewel manual dials say something like "India 0213", and a lot of the "Mumbai Specials" have "India Made", but this distinction doesn't guarantee anything, as it is presumably easy for the "reconditioners" to print whatever they like on the dial. Something you may not be aware of, HMT seems to have gone back into limited production of mechanical watches. These new models have different names from the older versions, but look to be very similar otherwise. Take a look on their web site, and as well as the not so inspiring quartz watches they have been showing for a couple of years, there are now a fair number of manual and automatic models. I'll need to look in to where these are being produced, as presumably at least one of the former production facilities has been brought out of mothballs. My suspicion is that production has been restarted at the Banaglore site. (Auxiliary Business Division, Jalahalli, Bengaluru), but if you really want to know what is going on, fire them an email. All of the contact details are on the website. https://www.hmtwatches.in/product_details?id=eyJpdiI6IlRxZ3dwL2tqTHpTZ29qZktUSDdjN1E9PSIsInZhbHVlIjoiK3pnSGFmZWpoOTBtU2xvTFo2ZlU5UT09IiwibWFjIjoiNDFlOWIxYTZhOTVhOTNlOWYxZDExYzI0MDE1M2I3MmQ0NDgzZjBmMTU5ZGNkYzZhNmNkNjc4MjE0NWI2ODE0MyIsInRhZyI6IiJ91 point

-

https://www.spareparts-watches.com/product/871431/enicar-167-ar-167 Does winding crown turn ? but wont wind . Hands and dial plate ought to be removed to get to date complication.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Just back from the Ayr Antiques fair. Spent my January spends. £40. Two watches. Both running. Roamer Sport. Back marked 49 and numbered 9253. Winder. Cracked glass +4s 212 deg 0.8ms 52 deg 18000 Seiko 7S26 0480 F, view thorough back. Time set for AM. Day still changing. +27s 177 deg 1.7ms 52 deg 21600. Will service the Seiko. Happy bunny.1 point

-

I’ve got a Seagull 3620 coming to practice with and for Marks course so I won’t be touching the Soviet watches till I’m confident I won’t mess it up to much.1 point

-

The black dial HMT Pilot was (is?) a nice one. I bought many of those on my travels to India. Frank1 point

-

1 point

-

Put the movement dial up on a watch cushion, place the case over the movement and then turn the cushion over.1 point

-

You might have to close up the shaped metal of the clasp ends to hold it properly. Seiko bracelets have never been great, even on GS or Credor. This is just the way I have found that works for me (so far ) Tom1 point

-

We are all learning, I even see @oldhippy constantly commenting that he just learned something. Have you tried Marks courses here on this web site, I did all 3 and got something out of each course. What have you done to learn so far so we can best advise? PS Don't mean to sound patronising, just want to help you in your journey PPS I know there is an additional course I haven't done yet (chronographs). Saving my pennies to sign up!1 point

-

one of the problems with watches that haven't been worn for long time is an indication that they might actually need to be serviced. then there's the other problem when you change the capacitor/battery of complicated watches they usually lose track of all their settings. this usually requires a reset procedure and setting everything by very exact procedure the watch knows where everything is again. I'm not sure it's actually in the users manual it took a quick look if it's not there it would be in the service manual which is normally one document but due to the fact that this is a rather complicated watch there is actually four separate PDFs. So somewhere in there should be the setting instructions if you change the capacitor/battery. 7D46A,7D48A_1.pdf 7D46A,7D48A_2.pdf 7D46A,7D48A_3.pdf 7D46A,7D48A_4.pdf Seiko setting instructions 7D48.pdf1 point

-

Looks like you are dealing with rubbed-in jewels or rubbed-into bushes and pressed in. Someone like JohnR725 or old hippy could answer your question. To be honest if you are looking for that buzz of a movement coming to life, you are choosing the wrong kind of watches. Too old , too broken and lack of replacements. These are difficult to work with murks, they are guys here with 5+ years experience that wouldn't attempt this kind of repair. I applaud your bravery indeed, i tried something equally as difficult last week. I wasn't expecting a good outcome and it wasn't but i wanted to test myelf and i did learn from the experience, so i do get where you are coming from if thats your reasoning to try this repair.1 point

-

as you're just starting out sometimes baby steps are nice. Like don't worry about the balance jewels just practice taking the watch apart and putting it back together. You really need practice on disassembling and reassembling it and still having all the pivots stay in place and not fall off for unknown reasons. Then yes definitely good to examine everything in particular everything located around the balance wheel. In other words what does the balance look like as it's oscillating back and forth, what does the hairspring look like and of course what is the escapement look like. It's really nice to have a good feel for what a running watch looks like versus a watch that's having a problem where if you to take the time to study at you might not actually know what a running watches supposed to look like. Like for instance looking at the hairspring that makes triplex flat for reasons they sometimes aren't flat they get bent typically would balance wheels get removed they just magically bend themselves I'm sure they have nothing to do with how the person remove their balance wheel. And then when you have a bent hairspring it's rubbing on the balance arms of the watch doesn't work. Or it loses a heck of a lot amplitude. So yes take things slow study everything.1 point

-

My jeweler gave me the same advice. He said he'd just do the same thing I could do at home. So I put some tape on my smooth-jaw pliers and gently started bending. I got them just open enough for an 18mm strap. After some careful reshaping of the hour hand, some crystal struggles, and a little more lug tweaking, it sure looks nice on my wrist.1 point

-

According to the Seiko casing guide you do just push down on the crystal from the top. I believe that someone else had the same issue fairly recently so a search may come up with something.1 point

-

Amazing what a fresh pair of eyes can see! Completely missed this, looks like I'm now in the market for a completely new case! Serves me right, only fools jump in where angels dare to tread!1 point

-

Found it! It’s a Marvin 362. The JW sponsors mark is for James Wier of Glasgow. Thank you for the replies!1 point

-

I apologize for not making it clear that this is a picture from another Seamaster. Not mine. I am trying to show what I am missing(: Thank you for your reply(:1 point

-

I had to re CAD most of this in SW 2017, but here is my version of matabog's mic holder. I'm using a single transistor on the mic input and with all the info I gathered off this thread it is working very nice. Working with Watch-O-Scope, TG (timegrapher) and PCTM. The EqualizerAPO64-1.3 with Peace makes a big difference. The Virtual audio cable as stated earlier ads a voice to announce it is a demo. The work around to this is to use the Virtual Audio Cable Lite. All the best and thank you to the software authors and those that contributed to this thread.1 point

-

HMT I believe stands for Hindi Machine Tool which is an Indian company, possibly government sponsored, set up in the early 1960's. They use Citizen designed movements made under license in India and produce some fairly good budget watches.1 point