Leaderboard

Popular Content

Showing content with the highest reputation on 01/30/24 in all areas

-

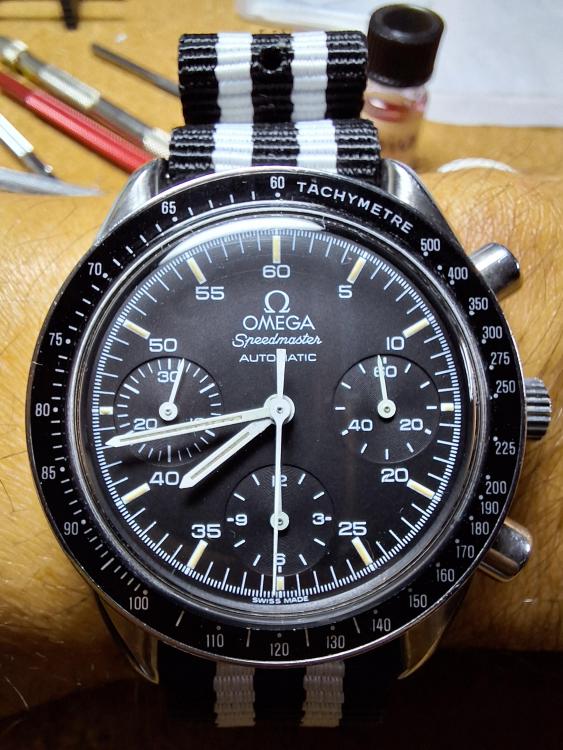

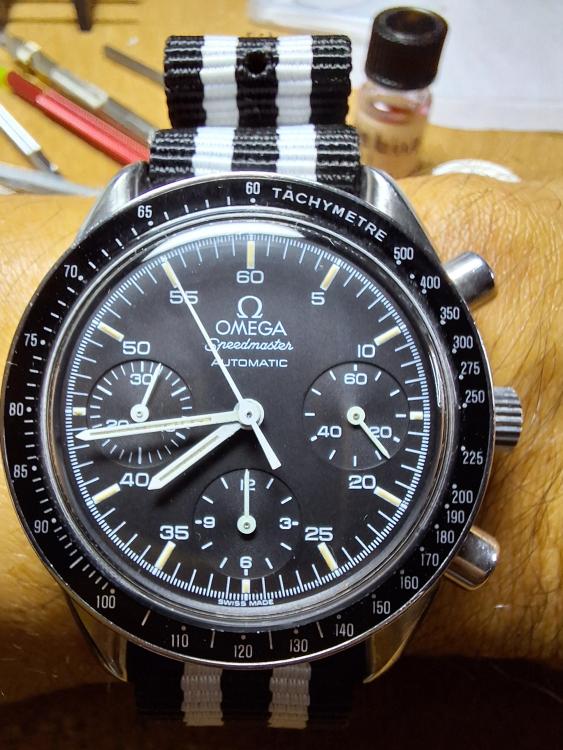

UPDATE! I took the DD 2020 apart and this time I got a small stainless basket and put all the parts in very warm water with a drop of dawn dish detergent. I rinsed everything off with water, pegged all the jewel holes in the module, and did a final rinse with 99% Isopropyl alcohol. Reassembled using the ETA 2892 A2 video by @Mark and took extra care with the Chronograph driving wheel friction spring-. I painstakingly adjusted the tension on my home-made second pinion friction spring using the specification sheet that @JohnR725sent me as a guide. I also checked the hour/minute heart cam wheels--thanks for the tip @eccentric59to my surprise I noticed a slight rust on the edges, nothing crazy, but wasn't expecting that. I cleaned and oiled them, and reassembled everything. The chronograph engages, goes around continuously, and resets fine. The watch is keeping good time (always did) and is back on my wrist! Thank you WRT! J6 points

-

Been there. Worn that Tshirt when I first started, so I know what you are going through. On advice from the members, I removed the pallet fork and check the pivots. Being new, I had added pressure to the bridge and broken the pivots of the fork. Did quite few in the first few month. All types of movements. Learned how to be gentle only by practice. Not damaged a pivot for over 18 month now. If they are broken, they are broken. I can't fix them. But a least it is not by my heavy hands any more. Don't worry. It gets better, and believe it or not, more and more interesting.3 points

-

I have had a handful in and out of my collection. If you are looking around ebay, the Kohinoor line seems to be the most consistently genuine, and also consistently in the best condition. When looking at the lower end (low end as in $18 instead of high end $35), you will find some of the Pilot line with an applied logo and applied numerals on the dial. Those are the ones to watch for. Any of the painted dials as described: Steer clear. They will likely be generic dial blanks with a terrible paint job which have just been stuck onto the movement with dial dots. They often have no dial feet, or feet not matched to the HMT0231 movement. Though I will say some of their more creative dial designs are fun and clever. But WORD OF CAUTION if you service one! Both the crown wheel and ratchet wheel screws are left hand thread, while neither will indicate as much. And the metal is very soft, thus it is super easy to shear the head off the ratchet wheel screw when attempting to loosen it to the left.2 points

-

I have what I thought were a set of ‘mid-range’ winders - Chinese made, about 20, mix of left and right handed movement specific with steel arbors. I’ve had some success with them but generally find the arbors too small to catch the spring I’m trying to rewind. This has resulted in me trying to hand wind, and yesterday I damaged a barrel as it flew across the room into a wall. I don’t really want to spend over £1000 on a full Bergeon set. Are there any alternatives? Should I just get a few Bergeon ones, if so which?1 point

-

Up to now I've just been 'monkey see, monkey do' and oiling the escape jewel, never been on my list of things to think about.... until now. Will be interested to see what the others say.1 point

-

1 point

-

@lexacat reshaping hairsprings is more of an art than a science, sometimes you take a spring and make a minor tweak and everything miraculously falls into place (those are the good days), other times you can be 99% done and make a final micro adjustment and it ends up worse than you started. But practice and experience will get you there in the end, you can go from this: To this: Only general advice I can give is to look for the problem area (eg where the coils are touching) and then look 90 degrees away for the cause and make your adjustment, when making an adjustment hold the coil with a fine set of tweezers (No 5) and then stroke the spring on whichever side of the held section works with another set of closed No 5's or thin tool (eg oiler) to make the adjustment - repeat as necessary, if you try make an actual bend you will inevitably overdo it and start the downward spiral of fixing the fix, then having to fix that fix......take regular breaks to avoid frustration and re-fucus your concentration.1 point

-

Yes, reshaping of the end curve is definitelly needed. This can be done without taking out hte stud from the holder at all. The spring is not clamped in the stud, it is glued with heat melting glue and it is not protrding from the other side like in old watches that have 'reserve'. So it is as it should be there.1 point

-

Well, actually the Russian springs with T briddle are same as the swiss ones. The way is to wind the spring in the winder barrel not to the end, but 2-3 cm of the end to protrude from the barrel. Then put the winder barrel in the watch barrel and rotate the winder to get the T end coincide with the notch, then drive the 'ear' of the T end in the barrel notch and hold i with something pressed there, push the spring out of the winder and that's it. In case of SLAVA alarm clock spring - yes, it is to big for normal winder1 point

-

There are two most probable reasons for wahat You describe: 1: Something wrong with pivots/stones 2: Hairspring. To understand what is the problem, I will advice to take off the hairspring and to put on the pate the balance with it's cock. The lever must be out. Turn the balance and observe how it rotates free. When everything is OK, in horizontal positions it will rotate for long time and will slow gradually, and will turn with lo speed for a long time. Observe how it behaves in both horizontal positions and if there is difference between both position. If there is significant difference, search for the reason: Does the pivot head look normal (rounded, not flat and even riveted)? Is the pivot not bent? The pivot head must rest on the cap jevel in a manner that if the cap lewel was not there, the pivot would get in the hole stone at least 0.05mm deeper. If or when the balance slow free rotation is/gets to normal, then the hairspring comes to turn. Of course You know that it musd be centered, level and not to touch anywhere, but one has to know where to look. In DD position, it may rubb in the balance arms. Thow in rest position it may not touch them, when balance is rotated, the things may change. In DU position, the spring may touch the studd bottom and the regulator pins, and the overcoil - the cock.1 point

-

I have 6 different sets and counting. There will always be some deviant mainspring that won't fit any winder you have. So learning to hand wind is an essential skill. I just hand wound the mainspring of a Russian alarm clock last week. Must be one of my most painful hand winds to date. My finger joints still hurt! I have been wanting to ask @nevenbekriev, what is the proper way to wind a Russian mainspring with a "T" endpiece?1 point

-

Friendship is only the beginning in this forum. The members take care of us as we take part. Believe it or not, it just gets better.1 point

-

Is the ST 96 basically the same as an FHF 96 but produced by another company? Yeah this community is superb, did not know such nice places existed on the internet these days1 point

-

Thank you for the comprehensive technical info @JohnR725. I did not know about the new copper beryllium cannon pinion for the 1140. There's much info here to improve my level of precision. More to come! Excellent point @eccentric59. I did check the the engagement action of the yokes and levers (as well as all pivots of course)before securing the cover plate on, but it is definitely worth looking specifically at the teeth of the heart cams. Will also make sure the return hammer isn't hanging somewhere. Thank you.1 point

-

1 point

-

As long as the chips are at the end, you can still use the tool. I ended up buying 2 tools, the first had a big chip which I knew about, but I could work around. However this was not the only chip and the entire length was peppered with tiny micro-chips which made it unusable. I then bought a second tool, this time I got lucky and the jaws were in mint condition. So its a matter of getting lucky, but an expensive game of chance!1 point

-

it would help to have the old sleeve to compare, you also need the stem and crown not showing in picture, 6 size cases and movements are plentiful on Ebay, I can't tell if you have an open-face or hunting movement, because that will determIne the correct style of case, I say that because of the chip in the dial around where a setting lever could be for a hunting model and the case shown is open-face....Waltham used a 6/0 movement with a larger spacer in 6 size cases, so it has been done...1 point

-

1 point

-

It does adjust the beat error however they are co-dependant. If you move the orientation of the stud then the regulator will be in a different position. The converse can happen too if there is friction between the stud mechanism and the regulator mechanism, I have done a few where I have had to figure out a way to keep the stud mechanism in the same place to adjust the regulator. Tom1 point

-

Was doing a big backup - all back to normal now.1 point