Leaderboard

Popular Content

Showing content with the highest reputation on 02/13/24 in all areas

-

I never had proper storage boxes for watch dials, so I decided to buy some 45mm in diameter by CousinsUK. https://www.cousinsuk.com/product/watch-dial-box?code=B57672 Swiss made, so they should be good ! The internal "propeller" is made of silicone and the lid has a dial centering, making sure that the dial sits nice and snug. All nice an dandy, apart from the fact, once the lid is pressed on, that you have to open these boxes with a crowbar !! Not desirable with a sensitive dial inside, potentially flying through the room when the lid finally pops off. I spend close to 1/2 hr, with a file reducing the diameter of the bottom-edge. Now the lids go on & off as one would expect from "Swiss made". They should have cost no more than £1 GBP each max, but mind you, these are "Swiss-made" After the modification, I'm happy that I have them BTW, talking about "Swiss-made"; Considering the time I spent modifying these boxes, are they now "Danish-made" ?5 points

-

To all, I'm a career mechanical design engineer, recently retired. I own a seat of SolidWorks 3D CAD software. I've been a SolidWorks user since '95. If anyone needs a solid model created, I'd be more than happy to give it a wail. I'm a budding watch repairman and would like to give back to this community that has helped me immeasurably thus far. cheers4 points

-

Great advice. I found an old scrap balance to practice on, and re-dressed my cheapo burnisher, I too was making the mistake of trying to work looking through the microscope. Following your advice - once set up, sit back and feel and listen to what's going on. You can feel and hear what's happening. I found shaping the end quite easy - as the pivot is sat in a hole in the disc, there's no chance of the balance escaping and getting damaged. I was so pleased with the pivot end shape and finish I'm not going to bother getting the Bergeon tool.3 points

-

Have you every spent money outside Geoffrey Boycott country. I know very well you are all as tight as a ducks ass up there. Here you go.2 points

-

I tried really hard to like Fusion360. Early days it was interesting. Very basic, but showed promise. That was when Doug Bass was still CEO of AutoDesk. And then creeping featuritis took over. Lot's of new capability added, but existing bugs remained. Lot's of chatter in the forums about bugs. The MAJOR issue with F360 is it didn't support configurations and allow for easy insertion of "catalog" parts. I'm a design engineer and I lived and died by catalog parts that I just drop in models. Don't ever build something you can buy is my motto. And then Bass was shown the curb and the "suits" took over. After that there were lot's of acquisitions by the F360 team, and the maker/enthusiast versions started being reduced in capability. In all this it was a fair tool as it would import models that few (no) apps could (namely SketchUp) and provide useful output. It was even better that they had a browser only version so I could log in, convert a file and then go about my business. Then they restricted access to the browser version to just students and paid users and I was out. Done.2 points

-

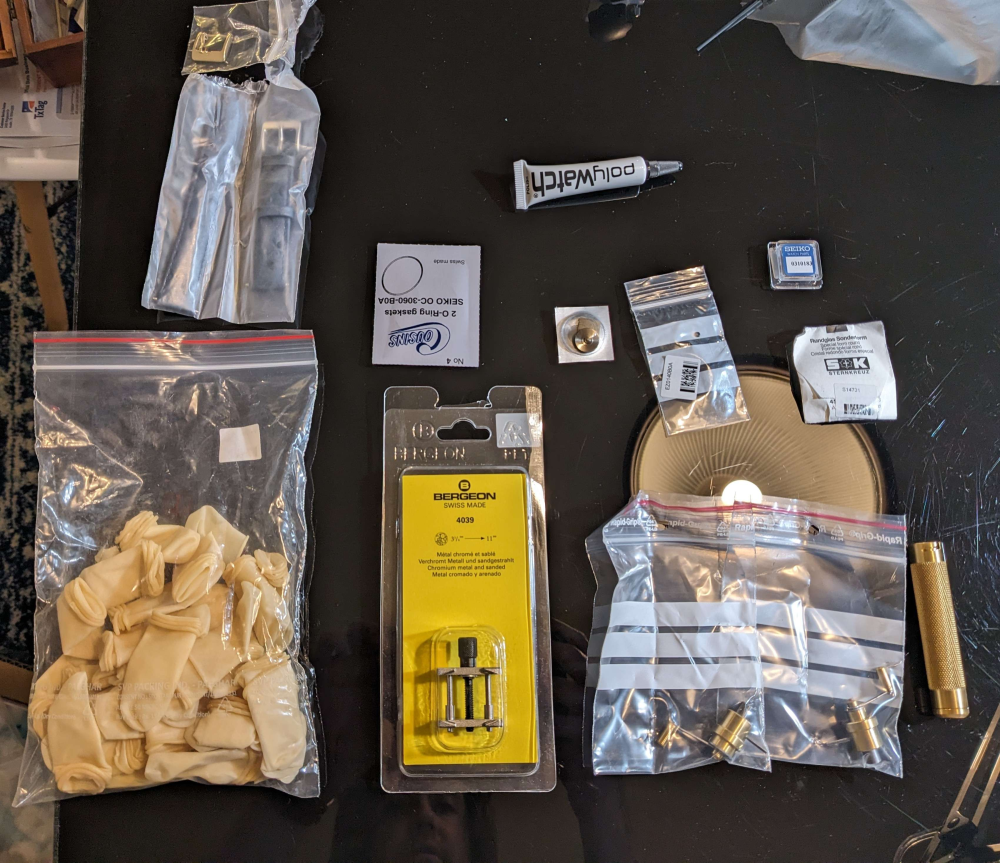

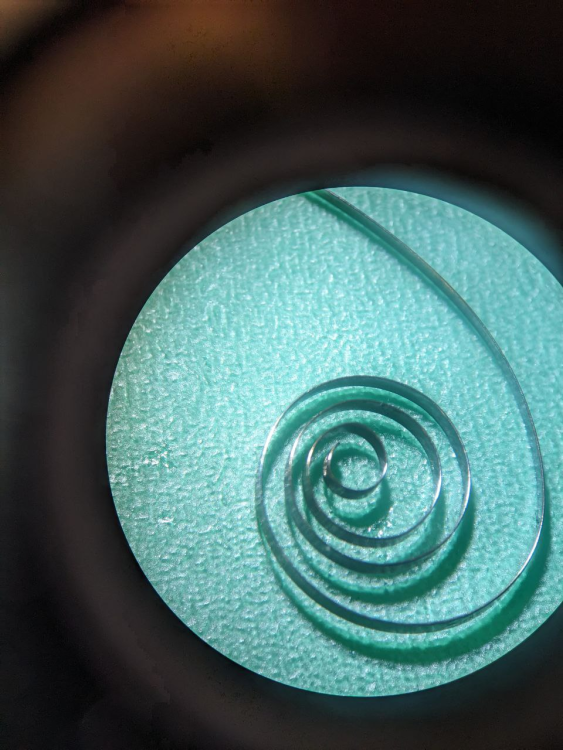

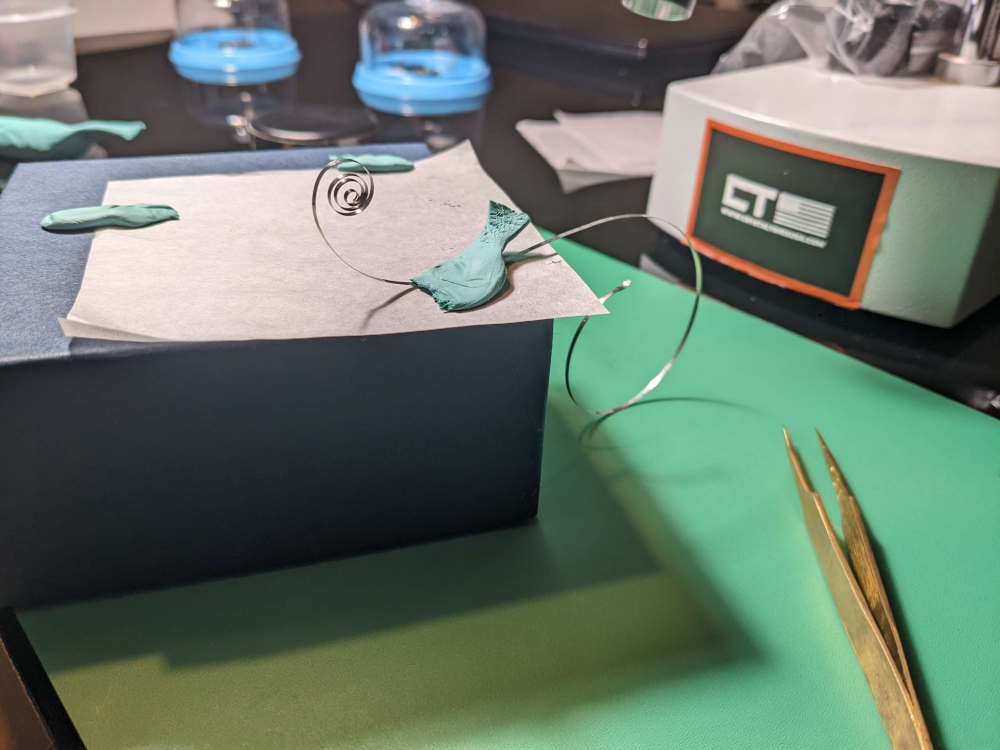

Ok so my cousins package came, the missing alarm ring clip came AND the jewel came but the only thing i'm missing is my mainspring grease which comes later today. Always love when a new cousins package arrives. Since i can't service the barrels on the 3 watches on my "bench" i decided to jump in the deep end of fixing the alarm spring who's inner coil is out of shape and can't clutch the arbor. Saw a tutorial from my favorite watchmaking youtuber on how to anneal the mainspring to make it pliable without breaking it and it worked, i think this will be adequate. While it doesn't make a full loop, i don't think i could have done that without breaking it the inner coil is considerably tighter than it was and i think once the arbor is in, if i can get it in it will hug it with a good bit of tension. Hopefully. I've heard from 3 people generics do not fit this particular weird arbor and NOS mainspring will be about 50 bucks which i'd like to avoid. Next up, i wanted to make it flat as it was quite warped in the inner coils as you can see. I've never tried to flatten a mainspring with most of the twists in the inner coil and it was driving me nuts. Having it flat on my matt there were so many twists it was almost impossible to tell where they were and what wasn't making it flat and everytime i twisted something because it laid on the mat it was adding a twist somewhere else so i decided to try something smarter and made this little setup so i could see it's natural shape without it's own weight throwing anything off. After wheel spinning for 2 hours the other way without much progress this worked REAL well! That's a pretty flat boy. If all goes as planned i hope to have her on my wrist by the end of the weekend!2 points

-

Omega case numbers are interesting because they referred to more of a style of the case then the material it's made out of. Then numbers have also been revised so that your number is actually 166.0020. Then at the link below you can find the casing information I snipped out an image the first one is 18 karat gold with the indication of a ring. The second case that are not snipping out apparently is pink gold and once again it's a ring and the letters are different indicating that the internal ring color would be different.Then I just picked the last one look at stainless steel and once again the letters are different indicating stainless steel ring so your Crystal has a ring which is why you can't easily push it out by hand. https://www.cousinsuk.com/document/search?SearchString=166.0022 points

-

You should be able to see if it has a tension ring if you look at it from the inside. If it doesn't have a tension ring you should be able to push it out with your thumbs, but as you can't do that I would say it has a tension ring. So, you will need a crystal press to get it out and back in. This could be a good option if you don't have one and are on a budget. I don't have it myself but I'm considering getting one as I'd like a bit more control than I have with my Bergeon 5500 which I demonstrate in this video.2 points

-

Figured it out. The lower jewel was set too low, so i needed to raise both by 0.2 mm. With that the watch runs without stopping and the amplitude is now around 300.2 points

-

1 point

-

All Yorkshiremen are born with short arms. The trouser pockets are deep, I was born a Scot’s man brought up in your shire and learnt the ways of gos own.1 point

-

This is all new well before my time when I was slogging away at the bench.1 point

-

Hi. Welcome to the forum. A look at the mikrolisk web site will give you some details..a full history can be obtained through Google1 point

-

I am in the FreeCAD camp since 2017. I realize that professional programs are more polished and with perhaps more features, but FreeCAD has done well for me. Most of my designs are not too complex. When I need to do something complex, I find someone has done something similar and I learn from them. FreeCAD also supports OpenSCAD internally. The Part Design toolbox supports a spreadsheet feature to parameterize designs.1 point

-

I started off learning fusion 360 and almost immediately after they put a lot of features behind a license paywall. I don’t think Autodesk like me . So settled towards freecad as there seems to be almost as many YouTube channels teaching the basics. Can’t be as bad as autocad from the late ‘90s which is the last time I used any CAD software. Tom1 point

-

The top one's are burrs, used to smooth or enlarge holes. The bottom is a micrometer used to measure staff/ pivot lengths. https://youtu.be/JSuCh1lKo3Q1 point

-

Sorry but @Neverenoughwatchesand I are Yorkshire men, cheaper than the rest of you put together. Hehe.1 point

-

1 point

-

I had a feeling that could be the case I hadn’t worked with one before and tbh the inside of the case needs a good clean so I couldn’t really tell if it had a tension ring, good thing I have the press so I will give that a go later today thank you1 point

-

There is quite a big discussion on this very subject on this forum about halfway through the topic below, but the short version is that it appears to be a combination of reverse bridal and shallow barrel design which makes Seiko mainsprings more difficult to wind, even for the experts, many of whom choose to hand wind instead of using mainspring winders.1 point

-

1 point

-

Nah, if you can hold them all in one hand you are fine! But if you need eight display cases it’s a different story…1 point

-

The story I heard on the thicker top cap jewel (cock jewel) was after lots of practical study, they found that that jewel saw the most impact, so it made sense for it to be thicker. But in reality, I have never ever found a cracked cap jewel on a shock setting, so it seems to have been overkill. But you can't replace it with a thinner one, the spring won't hold correctly- or vice-versa, the spring won't go over the jewel without damaging it. On Jacot too use- This is a tool I use frequently enough I keep one set up in a vice all the time. I also see young watchmakers who supposedly learned to use it in school come to the shop and are useless on it. Aside from typically using far too short of strokes on both burnisher and bow, they always want to have their face right in the tool with a loupe while using it (possibly why the super short strokes). As I was taught, and continue to do, I get the pivot in place and runner adjusted, checking with a 10x loupe. Then, I get my burnisher in place, and from there it's almost like John said "eyes closed in the dark", that is, I'm not peering at what's going on, just focusing on keeping the burnisher in contact with the pivot (i.e. level and to the left), and listening to and feeling what's going on. I'm sitting in a normal position, looking at the tool, but not up close. Usually pinky and ring finger are resting on the right of the tool, burnisher held the same as one would hold a pen. Pressure is between 250g-1kg, depending on the pivot. It does take some practice to develop a bit of feel, but I have shown folks in 10 minutes how to use it and they are successful.1 point

-

This coil has been failing since basically the beginning of time. Basically it's not a new phenomenon the prevailing theory way back when was that because jewelry stores and other people change batteries that's why that coil is the first to go out. So basically they were all gone a very long time ago way before any other component in the watch. Somewhere but I don't remember where that I don't remember exactly why but there was a reference to the protective coating would cause a failure I'm guessing where the wire is soldered to whatever it's soldered to. So I suppose conceivably if the protective coating should change its size like shrink it could pull away and because the wire to break probably just about anywhere unfortunately.1 point

-

Hi all, Just got an old Favre Leuba and the caseback was well and truly stuck. Usually in this situation I would bring it to my mates shop and use his bench opener but as this Favre-Leuba has flats they usually don't work as well. Anyway, another solution is to glue a nut on the caseback and use a wrench on that. Well the superglue is pretty much a necessity for me and there are usually a few tubes in the freezer ...result! After 10minutes for the glue to set, a big adjustable wrench between the lugs and a 14mm spanner in the nut/caseback and it spun right off!. I must say the caseback did a good job keeping the movement clean! This trick has helped me out a few times. If you plan to do this just make sure you keep the superglue away from the caseback/case joint. If any superglue wicks into the joint then things get difficult! Anilv1 point

.thumb.jpg.e56d4273e2c5552bedb1964f2f003a53.jpg)

.thumb.jpg.710d886d7f8928d18ac339c827deab58.jpg)